In crisis conditions, many people are put in a rather tough position, from ordinary citizens to representatives of big business. The automobile market turned out to be the most susceptible to various problems, and difficulties began to appear on it at the end of 2014, because it was from that time that experts noted an increase in the service life of various cars. Every person today tries to delay as much as possible the moment when his old, proven car needs to be replaced with a new car, using a wide variety of means, one of which is “Lavr” decarbonization. Reviews about this product can be found mostly positive, but in order to finally decide on a purchase, you need to understand the principle of action and the benefits of this product.

Today, a car service is a place where drivers prefer not so much to fix various malfunctions, but rather to prevent problems related to the age and mileage of the car. An intermediate means of such prevention is specialized auto chemical products.

How did she appear?

Immediately after various cars began to actively spread in the USSR, every owner knew that it was necessary to periodically clean the piston rings from various contaminants. At the same time, fuel in those days burned much worse compared to today, and sludge formed on the surface of parts quite quickly. Today, everyone can do decoking with “Lavr” to get rid of such faults, but back then they had to come up with something else.

The oil was also of much lower quality, so it oxidized quite quickly on the cylinder walls, forming a film and getting into the piston grooves. Among other things, during the combustion of fuel, soot gradually formed, mixing with this film, thus forming extremely persistent solid deposits that block the operation of the pistons.

Motorists tried to combat such pollution by any available means, for example, leaving kerosene in the engine overnight, and over time they began to use special solvents more often. Desperate car owners did not stop at the risk of being left without any means of transportation. In addition, the effectiveness of such compositions was practically absent, and even today many car enthusiasts are not afraid to experiment to their own detriment. Some have completely forgotten that such a procedure needs to be carried out, relying entirely on additives that are added to modern oils, as well as relatively high fuel standards.

Since those times, automotive chemistry has advanced significantly, and today many people use Laurel decarbonizing liquid for these purposes, but it is also not omnipotent, as many may think.

How and why does the so-called “coke” deposition occur?

Important: The main “supplier” of the problem is engine oil.

Let's immediately dispel some misconceptions. For some reason, it is generally accepted that slag deposits are possible only on old cars, and they are inherited.

Indeed, modern diesel fuel is cleaner (we reject unscrupulous gas stations, since this is not a systemic problem).

And synthetic oil does not contain a hydrocarbon base, which tends to separate from the composition and stick to the walls of mechanisms. However, the problem of hard deposits is equally inherent in modern power plants.

Causes of coke formation

- technology has become more precise: there are microscopic gaps between the parts of modern mechanisms that are easily clogged;

- engine operation (even diesel) is associated with high temperatures: an ideal environment for precipitation to stick;

Oil deposits on the shaft journals and housing

- the intensity of work has increased: the lubricant is susceptible to separation, individual fractions easily become slag.

In diesel engines, the situation is aggravated by the presence of soot. This is a unique substance: it can be as small as desired, but the dry component does not dissolve in liquid.

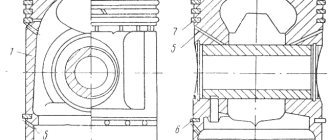

When the piston system operates, soot particles enter the ring gaps and are retained in the cavities. Then heated oil gets there, which evaporates on the hot surface of the piston (we note right away that this is possible if the oil scraper rings lose their tightness).

A mixture of hot grease with solid soot particles is the strongest cement. It instantly deposits on the metal and forms a layer of real varnish.

Carbon deposits on the piston and rings

Of course, in this state the rings do not work. Compression and traction disappear, fuel consumption increases. And the saddest thing is that the problem of coking is growing exponentially. Loaded oil scraper rings allow more and more oil into the hot zone, and the slag layer increases.

The same picture is observed in the timing system. Valves (especially exhaust valves) also operate under intense temperature conditions. If there is motor oil in the cylinders (and we know that it gets there when the rings become coked), then again, together with the soot of the exhaust gases, a dense mass is formed, which over time turns into stone.

Coked engine valves

Another problem that requires diesel decarbonization is incomplete combustion of fuel. During operation, light fractions evaporate and burn, and heavy sediment concentrates in the cavities. Mixing with soot and oil, these compounds again form a layer of slag, which becomes more and more monolithic over time.

Consequences of soot

- Violation of the tightness of the piston rings, valve mechanism;

- The so-called “bedding” of moving elements;

- Reducing the volume of the combustion chamber: hence the loss of power;

- Carbon deposits on the upper arch of the cylinder can lead to untimely ignition of the fuel;

- The biggest problem is the malfunction of the lubrication system.

We recommend: How to heat diesel fuel in severe frost: 4 methods

More about this:

The flow area of the oil channels is reduced: the consequences require no comment. Vibrations may cause small pieces of slag to fall off the walls. These elements can clog the same oil lines and damage various sensors.

How does LAVR help delay major repairs?

It is quite natural that engine overhaul is the most terrible event for most car enthusiasts, since this is a colossal expense, and the need for such a procedure indicates that the car is currently completely unsuitable for use. That is why, in order to avoid such situations, a special decarbonization “Lavrom” is used. Reviews say that the savings with the help of such a product are quite noticeable, because today the cost of overhauling most middle and budget class cars fluctuates around 50,000 rubles, while the drug costs only 400. But this remedy is not a panacea that gets rid of the need for repairs, but only prevention, so it will be useful to understand whether serious savings are actually being achieved.

Table: Laurel characteristics

| Characteristics | Description |

| Decarbonization methods | Rough |

| Application options | Without opening the engine, decarbonizing specific elements |

| Application area | Upper part of the piston device and rings |

Contents of delivery

The “Lavr” product is supplied in the following configuration:

- additive for cleaning the piston group (volume 185 ml);

- syringe for pumping the product from the container;

- a plastic or rubber hose with which liquid is poured into the engine cylinders;

- instructions for use, allowing you to perform an independent procedure for cleaning a group of pistons;

- sticker on the inside of the engine compartment lid.

Table: comparison of Lavr liquids

| Means | Compound | Articles | Decarbonization time | Additional procedures |

| ML202 |

Results of use

Auto chemicals manufacturer Lavr guarantees car enthusiasts the following results after using decarbonizing liquid:

- Lavr Anti Coks components provide gentle cleaning of the piston, piston rings and valve group.

- The decoking agent “Lavr” allows you to normalize and equalize the level of compression in the cylinders of the power unit. This makes it possible to avoid unscheduled repairs.

- By removing deposits, fuel and oil consumption is significantly reduced. In addition, the power properties and characteristics of the internal combustion engine are restored.

- By regularly cleaning the engine from deposits, the life of the internal combustion engine increases, therefore, there is no need to carry out major repairs.

New trend of car services

It is worth noting the fact that today even many car services have gradually begun to include in their price list such a service as Lavr decarbonization. Feedback from experts on this matter suggests that this is quite a profitable activity, since not all car enthusiasts can carry out this procedure on their own, despite the fact that they have this opportunity. For professionals, this is not a labor-intensive procedure, and it can easily be carried out on the street, since it does not involve the need to place the car in a service center. Thus, many companies ensure genuine gratitude from customers and a more active flow of them, and, consequently, profit. All this is ensured by Lavr decarbonization. Reviews from experts indicate that the flow of cars for this procedure is almost continuous. The reason is that it needs to be carried out every year or every 30,000 km, which means that a person who has already carried it out is guaranteed to become a regular customer of this service.

What are the advantages?

“Lavr” liquid for engine decarbonization is absolutely safe for various equipment, so its use completely eliminates the possibility of any conflict situations or complaints from customers.

The procedure is extremely easy to use, so the owner of such a business does not have to allocate additional funds to train specialists - just read the instructions for the drug and follow it correctly. If the “Lavr” liquid for engine decarbonization is dosed correctly, the consumption of the drug in a car service can even be recorded.

It is worth noting that this procedure was carried out by Soviet car enthusiasts, but LAVR is the first company to release the drug to the mass market, and at the moment there are no products that would surpass ML 202 in their technical characteristics. A separate advantage of this product is that that the car service does not need to allocate additional costs for equipment, since all the tools necessary for the procedure are included in the packaging of the drug itself, which is another significant advantage.

How to decarbonize an engine with your own hands?

According to the manufacturer’s recommendations, 45 ml of “Lavr” product will be enough to decarbonize one cylinder of an internal combustion engine. Thus, a standard volume motor will require about 185 ml of concentrate. In some cases, for example, if the engine has a non-standard shape or a recess on the piston, at least 330 ml of liquid will be required for the procedure.

In order to properly decarbonize the engine, it is necessary to calculate the fluid per cylinder, which is carried out according to the formula:

- D is the piston diameter in cm;

- pi = 3.14;

- h is the height of the liquid above the piston level (usually 1 cm).

Nuances regarding engine safety and preparation:

- Since the composition is highly toxic, all actions should be performed in special clothing. To avoid thermal burns, it is recommended to wear gloves and goggles before starting the procedure.

- An oil filter must be installed on the engine.

- There must be enough motor fluid in the internal combustion engine.

Modern engines do not require decoking

Of course, over the past few years the situation with oil and fuel has improved significantly, because in Soviet times, few could even start without using a blowtorch, but despite this, the problem of coking not only did not disappear, but also seriously worsened. Technologies have become more advanced, the gaps between the grooves and piston rings have decreased, but this ultimately led to greater vulnerability of modern systems. Also, a small layer of deposits ultimately leads to engine malfunctions; over time, deposits accumulate more and more, and the problems only become more serious - compression drops, detonation occurs, wear accelerates, and then serious breakdowns appear. If you are not going to spend money on major repairs, then proper decarbonization with “Lavr” can help.

Better decoking of piston rings

The best decoking of piston rings - is it possible, how to do it, the subtleties and nuances of the process.

Everything I write in this article will be based on my eight years of experience working with auto chemicals and lubricants, and on the experience of my clients. At the very beginning, it is necessary to clearly understand that decarbonization is a procedure, an action, a process, but not the name of any drug for carrying out the procedure.

Decoking is a procedure for removing coke (carbon deposits) from any surfaces that are susceptible to coking

In the case of an engine, it removes coke from the combustion chamber and from the area of the piston rings.

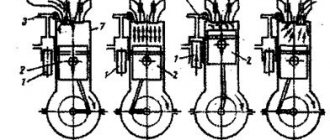

During engine operation, carbon deposits inevitably form in the combustion chamber. This can be caused by several reasons: – fuel of poor quality, containing harmful impurities; – operating the engine in unfavorable conditions (frequent trips over short distances, long-term idling, warming up when the engine runs on a rich air-fuel mixture); – oil burning in the combustion chamber (several reasons); – long engine operating hours (more than 100 - 150 thousand km or high operating hours. The engine runs, but the mileage does not increase). During long-term operation, the formation of carbon deposits in the combustion chamber is inevitable.

Carbon deposits in the combustion chamber

Carbon deposits in the combustion chamber (coke) reduce heat removal from its elements (piston, cylinder wall, cylinder head), which leads to an increase in the operating temperature of the parts. A frequent consequence of coking of the combustion chamber is premature ignition of the air-fuel mixture (glow ignition, detonation).

Carbon deposits in the grooves of the compression rings interfere with the normal movement of the rings, which interferes with their normal operation. As a result, compression and traction/power characteristics of the motor are reduced.

Coked piston rings

Carbon deposits in the grooves of the oil scraper rings also interfere with the normal movement of the rings while the engine is running, and, as a result, the rings do not fully cope with their main function - removing oil from the cylinder walls while the engine is running. This oil then reaches the compression rings, where the temperature is much higher and burns there, leaving behind carbon deposits. If the oil scraper rings are stuck, the compression rings will also be subject to further jamming. Due to the increased penetration of oil into the combustion chamber, carbon deposits will also form at an accelerated rate in the combustion chamber.

Despite the coked rings, the oil drainage groove is still open. Modern pistons have very small oil drain holes.

For a normal functioning engine, the occurrence of oil scraper rings threatens, at a minimum, with increased oil consumption and the owner’s expenses for “topping up”, and at maximum with the destruction of piston elements due to detonation. It all depends on the specific conditions.

Modern engines often use very thin oil scraper rings, which are more susceptible to coking than others. To be fair, I will say that a huge number of engines are destroyed by the owners themselves or the services that service them. The choice of oil for such engines and its replacement interval must be approached carefully. An oil that would work perfectly in an engine developed in the early 2000s can simply “kill” a modern engine. This is a separate topic, and a very long one, but that’s not what we’re talking about here...

To combat carbon deposits, various companies have long been producing a variety of drugs, most of which, unfortunately, are ineffective and do not give the desired result. Largely because of this, many car enthusiasts and professionals have a stronger opinion that auto chemical products are powerless in such cases.

Oil consumption should not always be attributed solely to coked oil scraper rings.

The reasons for increased oil consumption may be: – wear of the CPG (cylinder-piston group); – wear of valve stem seals; – oil of inappropriate quality.

Should I decarbonize the engine or repair it straight away?

The second option is an almost 100% guarantee of success with qualified repairs, but not every one of us is ready to pay a hefty sum for repairs.

Decarbonizing the engine will probably not make sense if there is an oil burn in the following cases: – the engine has been consuming a lot of oil for a long time. (If the oil consumption is from 500 ml/1000 km and this has already been for several tens of thousands of kilometers. In this case, often the stuck rings have already knocked out an ellipse in the cylinder); – the engine consumes oil after serious overheating. (Often, when overheated, the piston rings also overheat, and, as a result, simply lose the necessary elasticity. They can be as clean as you like. In almost all other cases, it’s worth trying. In this case, you need to use the most effective means for today decoking of the engine).

The best decarbonizers today

Flushing the oil system with a decoking effect BG-109 is today, without exaggeration, the best flushing of the oil system with the effect of decoking oil scraper rings. It also does not affect the paint of the pan and the rubber rubber of the motor. Produced in the USA by a reputable company in the field of auto chemicals - BG-Products.

Flushing BG-109 is added to the engine oil and, once mixed with it, affects the coke on the oil scraper rings. Does not affect the paintwork of engine parts. Neutral to seals and gaskets.

Cleaning the combustion chamber and decoking the compression rings

To decarbonize the combustion chamber and compression rings, it is recommended to use foam cleaners: – Pro Tec Carbon X – Mitsubishi Shumma Engine Conditioner – Gzox Injection Carb Cleaner. You need to choose based on the specific case in which it would be advisable to use one or another remedy.

Pro Tec Carbon X is a professional product for cleaning the combustion chamber and the compression ring area from carbon deposits. Produced in Germany. Today, it is the most effective and fastest preparation for decoking the combustion chamber and compression rings. It has a stable foam form, which makes it indispensable for use in boxer and displacement V-shaped engines. One minus is the price. When treating several motors, this disadvantage is offset by the volume of Carbon K1 active cleaning foam.

Mitsubishi Shumma Engine Conditioner - the name speaks for itself. Manufactured by the MItsubishi Corporation specifically for servicing engines with the GDI direct injection system. Excellent for decoking the combustion chamber of any engine.

Gzox Injection Carb Cleaner is a product from Japanese. Initially, based on the name, it is a carburetor cleaner. Car owners have noticed a very good ability to remove carbon deposits from the combustion chamber and the area of compression rings. The most budget option, at the same time, has sufficient efficiency, which made it the most popular among “decarbonizers”.

Effective ring decarbonization – comprehensive

The best preparations for cleaning the combustion chamber from carbon deposits, such as Pro Tec Carbon X, Mitsubishi Shumma Engine Conditioner, Gzox Injection Carb Cleaner, cannot fully affect the cause of all troubles - coked oil scraper rings. This is due to the design of the engine itself, where the oil scraper ring is practically isolated from the combustion chamber by two upper compression rings. Because of this, it is recommended to do decarbonization in a complex manner. Clean the combustion chamber and decarbonize the compression rings using the preparations indicated slightly above, and use BG-109 to decarbonize the oil scraper rings and flush the oil system. The procedure performed in combination (through the combustion chamber and through the oil) will have a much greater effect.

The procedure must always be performed using the means and method that will give the greatest effect in a particular case. If any questions remain, it is better to ask them to those who can give an answer on the matter, and who are based on personal experience and the experience of others. I have already accumulated some statistics from clients, if necessary I am ready to share it, ask questions, I will be happy to answer.

For those who decide to decoke the engine using BG-109 and Gzox-Shumma, there are instructions with general recommendations.

4.2 6 votes

Article rating

Additives and flushing liquids

Many believe that these procedures save you from any problems, so decarbonization is not at all necessary. In fact, the most effective way to remove various deposits is through “immersion,” when the decarbonizing composition is poured directly into the cylinders. At the same time, getting to the technological holes is not so easy, and you have to use special tools, as well as create comfortable conditions for yourself (it is better not to carry out such work outside in bad weather). That is why it is recommended to decoke the engine during a scheduled replacement of spark plugs or oil.

The liquid must perfectly clean the surface

“Lavr” is a preparation that cleans medium and high degrees of coking, but it often happens that in old engines the deposits have already become so “bored” to the parts that they hold on to them like cement mortar, and even cleaning such systems is white Not recommended. It is also worth noting the fact that solutions that are too caustic can cause engine damage.

But in any case, LAVR is considered a more effective product compared to analogues and standard solvents.

How is this procedure carried out?

Now let's talk about how Laurel liquid is used. Decarbonization (instructions below) does not take much time if you follow the instructions for this product correctly and choose the right dosage. The procedure itself is done as follows:

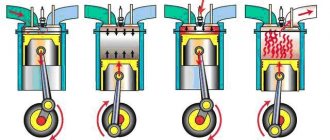

- The engine warms up to operating temperature, which should be more than 70 ⁰C.

- The ignition system is turned off. To do this, you can remove the connector from the ignition coil or Hall sensor. Thanks to this, you can get rid of possible ignition of the vapors of this drug, as well as damage to various elements of the system.

- The spark plugs are removed. If the procedure is carried out in a diesel engine, the glow plugs or injectors are removed.

- The pistons are set to a position close to the middle one, while the crankshaft must be rotated by the pulley nut or using the drive wheel when the gears are engaged. To determine the position of the piston, you can use a long feeler gauge inserted through the process hole.

- Using a syringe, pour an equal volume of Laurel decarbonizing liquid into each cylinder. After this, close the technological holes so that a “steam bath” is formed in the combustion chamber.

- Now we have to wait. For an express procedure, you need to wait at least one hour, but in case of serious coking, the exposure time of the drug should increase up to 12 hours. In order for the liquid to more efficiently seep into the lower part of the cylinders, the pistons can be periodically moved in different directions.

- Clear technological holes. The remaining liquid is removed with a syringe, after which the cylinders are purged with compressed air. Now you will need to fully depress the accelerator pedal, and then turn the engine shaft using the starter two or three times for five seconds. In this case, it is recommended to cover the technological holes with some thick cloth so that the decarbonizing agent for Laurel rings does not splash out.

- Install dismantled parts and assemblies. Be sure to additionally check for correct assembly.

- Start the engine and let it idle for 5-10 minutes to reach operating temperature. It’s worth noting right away that short-term smoke may appear, since the liquid for decarbonizing the “Lavr” rings remaining inside will burn out, and this smoke is not dangerous for the catalysts.

- Clean the engine with a product designed for flushing the lubrication system, or with a special product LAVR.

- To completely get rid of carbon deposits, it is recommended to drive the first few kilometers at slightly higher speeds.

This is the proposed decarbonization. The instructions are extremely simple, and the work can be carried out by experienced motorists in a garage, so if you are confident in your abilities, you do not necessarily need to turn to the services of car services.

Decarbonization instructions

When warming up the power unit before cleaning, it is worth pouring a flushing compound into the crankcase - “five minutes” in order to remove dirt from the oil channels as much as possible. You should also measure the compression on a hot engine in advance, this will help you see the result before and after decarbonization.

Perform further actions in this order:

- Carefully read the instructions on the cleaning product packaging and find out how much liquid needs to be poured into each cylinder of your engine.

- Remove the spark plugs and clean them thoroughly with a metal brush, rinse with gasoline and blow out.

- While turning the drive wheel by hand with 5th gear engaged, set all pistons to the middle position, measuring the depth with a long screwdriver.

- Lowering the tube one by one into the spark plug holes, fill the cylinders with aerosol from a spray can. Decarbonization of the engine “Lavrom” is carried out using a syringe (included with the drug).

- Screw the spark plugs back in without tightening them all the way.

- Leave for 8–15 hours, periodically moving the crankshaft by turning the wheel. The goal is to help fluid penetrate between the piston rings.

After the time specified in the instructions has passed, unscrew the spark plugs again and try to pump out the dissolved dirt from the cylinders with a syringe, and then blow it thoroughly with a compressor. The better you can clean out the remaining coke, the faster the engine will start.

Install the old spark plugs and start the engine without increasing the speed above 1500 rpm. Let it warm up and “spit out” pieces of carbon deposits through the exhaust tract. After 10–15 minutes of engine operation, when the smoke from the exhaust decreases, return the lambda probes to their place and begin replacing the engine lubricant.

Screw in new spark plugs last, after cleaning the power unit and changing the oil. Before installing spark plugs, re-measure the compression and make sure that the measure has a positive effect. If the result is negative, begin preparations for disassembling and overhauling the motor.

Decarbonization of a diesel engine differs in the method of filling the cylinders with a chemical. Since there are no spark plugs, the fluid is poured through the injector holes. The latter will have to be dismantled after first releasing the fuel pressure in the system and turning off the pump.

What do they say in the reviews?

Most people quite liked the product - the decarbonizer, and they note the positive effect of its use. Among the advantages of using this liquid are the following:

- Significant reduction in oil consumption during active pedaling (about 10-20%).

- After the Lavr diesel engine was decarbonized, many people's engines began to run quieter. In gasoline units the same effect occurs, and vibrations also disappear.

- The equipment has become more obedient at high speeds and accelerations, and also has a more pleasant sound.

Some people who used the Lavra composition for decoking say that they did not see any noticeable effect, and such products do not particularly help with problems that arise, and the rings are easier to replace than to carry out the indicated manipulations.