Checking with a tester

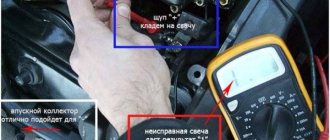

To check you need a multimeter. If a car enthusiast doesn’t already have one, then the device is definitely worth buying - it will be useful not only for diagnosing faults in the car’s electrical components, but will be useful in everyday life. A standard Chinese multimeter is quite inexpensive, and a separate article can be written about its usefulness. To check the glow plug relay with a conventional multimeter, you need to do the following:

- Set the measuring device to voltmeter mode;

- Connect the multimeter probes, or better yet alligator clips, with the plus to the glow plug bus, and the minus to the engine ground;

- Turn the car's ignition key to its first position;

- Listen and check the multimeter readings. The relay operates with a characteristic click, which is clearly audible in the absence of extraneous noise (it is best to work in a garage). The display should show readings: from 8 to 12 Volts. On engines with a two-stage heating system, 4-5 seconds after the first click, a second click will be heard, and the voltage shown by the measuring device will decrease by almost half.

If everything is in order, then the problem does not necessarily lie in the glow plugs. You can begin further checks. And this is what they provide:

- Checking the integrity of the wires. It would be more correct to say that all wiring needs to be ringed. We are interested in the wires leading to the relay;

- Checking the terminals. Often they are covered with a layer of oxide - they need to be cleaned;

- Checking the fuse. Firstly, if the fuse is blown, there will be no voltage supplied to the spark plugs. Secondly, a light will light up on the dashboard.

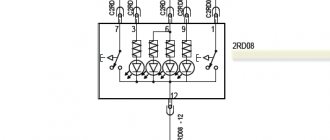

And now we come to the main thing. If the glow plugs, all the wiring with terminals, and the fuse are in order, it is logical to assume that problems with the diesel heating system are related to the spark plug relay. Finding a relay is not difficult: it is always larger than other relays and has more power. The sequence of actions when checking relays from different manufacturers may also be different, but here are general recommendations:

- As soon as 12 Volts are applied to the coil contacts, the control contacts close;

- If you connect a light bulb to the control contacts, then when voltage is applied to the coil contacts, this light bulb should light up;

- If the relay does not operate (no click is heard), it is faulty. The coil in a faulty relay burns out - repairmen do not undertake to change just one coil, so all relays will have to be replaced with a working one;

- The coil windings must have resistance, which will be shown by checking with an ohmmeter. If the device shows a break, then the relay coil has burned out;

- In two-stage glow systems, the relay has more than 4 contacts, so before starting the test it is worth studying the car manual. However, there is a general rule: always check the circuits for breaks.

In general, there is no particular difficulty in checking. A full check will take a lot of time, since it is advisable to check not only the relay, but also all the elements that are located between it and the glow plugs. It’s worth starting with the glow plugs - they fail more often than any other element of the heating system.

Sometimes the solution to the problem is unexpected: try removing the relay, pulling it out of the case, sending it back, and then putting the entire device back in place. As owners of Volkswagen diesel cars say, dismantling and subsequent installation of the relay helped solve the problem with “sticking” - sometimes the contact remains in one position and the relay cannot close the circuit, but with a slight mechanical impact everything returns to normal.

What is it for

It's no secret that today the most common internal combustion engines run either gasoline or diesel. Gas-cylinder installations are gradually gaining popularity, but since they are not the topic of our discussion, we will leave them for later. So, the main executive component of the car ignition system is presented today:

- Glow plug in diesel engines;

- The spark plug, respectively, in gasoline engines.

The principle of operation of a spark plug can only be described as “the formation of a spark at a strictly defined point in time.” The spark plugs of diesel engines are not so strictly tied to time - the fuel, when compressed, begins to ignite spontaneously. However, another problem arises: spontaneous combustion does not always occur when it is needed. This is where glow plugs are needed. They heat the fuel mixture to the optimal temperature for engine operation and make its further combustion process stable and predictable. However, another problem appeared!

As a diesel engine operates, its individual components become very hot. Increasing temperatures also have a detrimental effect on the fuel. There are often cases when it begins to burn even before it gets into the cylinder, where the heat of combustion will be used to perform work. The weak link is the glow plugs - if they heat up too much, they destabilize the operation of the entire engine. To solve this problem, engineers introduced special relays.

A relay is an electrical device that can close or open a circuit in the event of a change in some controlled quantity . With the glow plug relay, everything is very simple: when the glow plug needs to work, it allows the action of current, but when the spark plug needs to “cool down,” the relay opens the circuit. This chain will be looped until the driver turns off the engine.

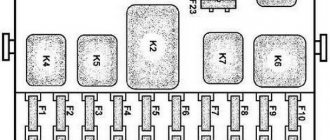

Glow plug relay on Volkswagen

The device on Volkswagen cars is located behind the fuse box, which, in turn, is located in the vehicle interior under the dashboard on the driver’s side. In order to dismantle the glow relay, this mechanism must be removed. These actions are carried out in the following sequence:

- The safety block is removed from the mountings.

- Rotates counterclockwise.

- In the depths of the structure there are fuses and filament relays.

The above actions apply not only to Volkswagen cars. When replacing a glow relay, it is necessary to take into account the country and company that produced the replacement part. Chinese fakes will not last long, and their use can lead to more serious damage.

Changing the filling of the glow plug relay

Replacing a relay is a fairly simple process and can be done by absolutely anyone, even those who have looked under the hood of a car for the first time. It is necessary to disconnect the relay, as was done in the test description, that is, disconnect all the terminals and carefully remove the relay out. Then it is advisable to clean the place where it was installed, as well as the part itself, which you have already successfully removed. After you have finished wiping, slowly unscrew the spark plugs from the relay. It is best if you work with special gloves.

Then, with a rag, we remove excess dust from the holes where the glow elements were installed, and begin to smoothly screw in the new spark plugs already purchased for your car.

It is necessary to pay attention to this fact: for each car different types and models are used

You should consult your dealer when purchasing these parts. After you have screwed in the spark plugs, install the relay in place and try to start the engine. If your car does not want to start, check that you have connected all the terminals. If your car does not start even after checking, then most likely the problem was not with the spark plugs.

Home → Device → Electrical system → Devices →

Replacing an element

When the test shows that the device is not functioning, it needs to be replaced. Even a less experienced car enthusiast can do this. To do this, you will have to disconnect all the terminals from the part and take it out. Then it is important to clean the place where the device was removed. Then you need to carefully unscrew all the spark plugs. Next, carry out the entire process in reverse order, only with a new block: screw the glow parts into the new block, install it in a previously cleaned place.

The location of the candles is shown by red arrows

After this, you should try to start the engine. If this does not work, then you need to check whether all terminals are connected. If everything is installed correctly, but the engine still does not start, then the problem was probably not in the glow elements.

It is important to note that different vehicles may require different types and models of glow elements.

Owners of cars running on diesel fuel should prepare in advance for the cold season and check the functionality of the relay. It is also worth keeping control over the candles themselves. It is especially important to check the performance before a long journey. Otherwise, the trip may be disrupted and postponed until the problem is resolved.

Why is it sometimes necessary to check glow plugs and their relays?

Glow plugs are located in the combustion chamber. The main purpose of this element is to heat the fuel for clearer and smoother ignition and interaction with the engine. All of them are divided into two types: with an open and closed heating element. At their core, they are part of some engine pre-start device. These elements are especially important in winter; it depends on them whether your car can start or not.

The candles themselves are made from a variety of materials. Their control circuit takes into account both the temperature of the air and fuel, and changes in their resistance. It is very easy to determine if this element is faulty: your car will most likely simply not start. Experienced car enthusiasts, first of all, when they cannot start, look at the condition of the spark plugs. There are plenty of reasons why they become unusable.

The very first and main factor that goes against these details is time. Every little thing has its own expiration date, and this also applies to glow plugs. They last approximately 3 years. Everything, of course, depends on the car, driving experience and weather conditions. Yes, it is weather conditions that can negatively affect the service life of these incandescent elements. And in our harsh weather conditions, not only candles, but also the cars themselves very quickly become unusable.

Air heating in the intake manifold

Heating the intake air improves the starting conditions of diesel engines with an undivided combustion chamber. An example of a device that provides an increase in the compression end temperature by heating the intake air is the CH-150 glow plug. A spark plug with a power of 400 W is installed on the inlet pipeline of tractor diesel engines with a working volume of up to 4-5 liters. Given its low power, two or more spark plugs are installed to increase the temperature of the intake air. But when using more than one spark plug, energy consumption increases and the aerodynamic resistance of the intake pipe increases.

The spark plug spiral is made of high ohmic resistance wire with a diameter of 2 mm. The spark plug is installed in a special socket on the inlet pipeline and secured with a union nut. The installation location of the spark plug is selected experimentally, based on its closest possible proximity to the intake windows, taking into account the number and layout of the engine cylinders. The rated voltage of the spark plug is 8.5 V, the rated current is 45-47 A, the heating time to operating temperature (900-1000 C) is 40-60 s. In series with the spark plug, an additional resistor is included in the electrical circuit, which is short-circuited during startup, a control element, a spiral enclosed in a casing or a control light. The time required to heat the candle coil is controlled by the degree of heating of the control element coil or by the glow of the light bulb.

When using intake air heating plugs in combination with low-viscosity oils and increased cyclic fuel supply, the maximum temperature for reliable starting of a cold diesel engine is reduced by approximately 5 C.

Rice. Intake air glow plug CH-150: 1 — glow plug; 2 - rod; 3 - body; 4 - contact nut

Rice. Flange spark plug: 1—body; 2 - spiral; 3 - contacts

To increase efficiency and reduce start-up temperatures, flanged spark plugs are used. For flanged spark plugs, by lengthening the spiral, the heat transfer surface increases, but its power does not change. In addition, heat loss is reduced as a result of their installation directly near the inlet windows. However, such spark plugs are not widely used due to the impossibility of unifying their designs for use on various types of diesel engines.

How to replace glow plugs?

These parts are located in the upper parts of the cylinder head. To replace, you need to disconnect the wires that are located under the head cover. Remove the wires connected directly to the spark plugs.

Then use a wrench to unscrew all the parts. You need to work carefully. After this, thoroughly clean the contacts, battery terminals, and spark plug wires. The holes into which the candles were screwed also need to be cleaned. You can use a scan for this.

After replacement, you should tighten the spark plugs, but not too much. If the tightening is tighter than necessary, the part may break during the next replacement. And this is already an expensive repair. But you shouldn’t tighten the part too loosely, as there is a risk that it will simply unscrew while moving. Now all that remains is to connect all the wires back. That's it, the replacement of diesel glow plugs has been successfully completed.

Classification according to electrode material

Copper/Nickel

The main characteristics of spark plugs are quality and budget. Of course, in terms of performance parameters, the products are far from those discussed below, but for their price segment they have decent performance. On average, a copper-electrode spark plug lasts for 20 - 30 thousand kilometers, after which replacement is required.

Platinum (sometimes made from other precious metals)

The electrodes of the products are coated with platinum, which increases their service life and improves their quality. This spark plug is designed for a mileage of 50 thousand km.

Iridium

The service life is up to 100 thousand km, and the quality indicators are many times better than those of previous options. But the price of the product is appropriate.

How does it all work?

Ignition of the fuel-air mixture in the cylinders of a diesel engine occurs at temperatures of 800–850 °C. When the engine is warmed up, such indicators, at the moment of the compression stroke, are achieved instantly and the diesel engine starts without failure.

But when the car is not warmed up, it is difficult to achieve such a temperature only by compressing the mixture, especially in cold weather - starting the engine is problematic.

To solve this problem, glow plugs were installed in diesel engines, the task of which is to very quickly warm up the air in the cylinders to 75 degrees and thereby ensure the desired temperature at the moment of the compression stroke.

Inside the products, two spirals are structurally provided - heating and regulating.

The first one has a heating function. The second, due to floating electrical resistance, protects the glow plug from overheating.

The spark plugs will work until the coolant temperature goes above 60°C, this is about 3 minutes. Then the motor will be able to work without them.

Before starting the car, you must turn on the ignition and pay attention to the instrument panel. The glowing spiral indicator indicates that the glow plugs are heating up

As soon as the light goes out, you can start the car.

In modern cars, the spiral lamp may not light up. This will happen if the engine is already warmed up, which means there is no need for glow plugs. All this is achieved thanks to modern electronics that monitor the temperature indicators of the motor.

There are also glow plugs that maintain the temperature for a long time after warming up, and therefore turn off immediately after the starter is turned off and heat the air in the diesel cylinders due to residual heat.

The devices are very energy-consuming; heating one glow plug to 850-1350°C in half a minute can take an average of 8-16A (96-192 W), sometimes 40A. The amount of voltage and the time it is supplied are controlled by an electronic unit and a thermal relay (switch).

The latter, if necessary, only closes and opens the circuit, thereby setting the desired air temperature in the cylinders. And the ECU regulates the entire heating process by sending signals to the relay. It takes the necessary information from the crankshaft and coolant sensors.

The first sign indicating that one of the glow plugs has failed will be the re-ignition of the indicator in the form of a spiral after starting the engine and its prolonged burning (about 50 seconds).

If after the specified time, after warming up the car, the indicator does not go off, then the time relay (thermal switch) has failed.

It is important to replace the device immediately, otherwise the glow plugs will fail due to burnout of their heat pin

If it is still relatively warm outside (above +5°C), then you are unlikely to notice the output of one or two products; the car will still start.

Otherwise, when the thermometer scale approaches zero and below, even with one faulty spark plug, starting the car when cold is problematic. This can only be done if it is heated to 60°C or more.

Reasons for failure

There are two main reasons for glow plug failure:

- Failure of fuel equipment components, for example, a faulty thermal relay;

- Maximum service life of the spiral.

Approximately, every 75-100 thousand (often after 50-75) km, you need to diagnose the spark plugs and, if necessary, change them. As a rule, not only the faulty product is replaced, but all products at once.

The service life of glow plugs can be reduced by:

- Dirty or faulty injectors - a fuel jet directed at the heating element destroys its body, and subsequently the coil itself.

- Incorrect installation of products;

- Glow plugs sticking to the cylinder head - in this situation, they often break during dismantling.

- A faulty thermal relay will lead to overheating of the heating elements, their spirals will burn out, and the housings will become deformed;

- Faulty ECU.

This is interesting: What kind of oil should I put in a viburnum box?

How to check glow plugs without unscrewing them (on an engine)

Checking glow plugs should begin by finding out whether voltage is supplied to them at all, since sometimes the contact of the supply wire simply oxidizes or weakens. Therefore, there is no way to check without a tester (with ohmmeter and voltmeter modes) or, in extreme cases, a 12-volt light bulb.

On an engine, glow plugs can only be checked for their general performance, since the intensity and speed of heating of the heating element cannot be seen (only on some engines you can unscrew the injectors and look through their wells). Therefore, the most reliable diagnostic option would be to unscrew the spark plugs, check the battery and measure the indicators with a multimeter, but for a quick check, at least something will do.

Test methods (diagnostics)

Many diesel car owners will say that the weak link in their car is the glow plugs. And this is not far from the truth.

These products really often fail, and the breakdown could have occurred in the summer, but it would appear in the winter, when the car stopped starting in cold weather.

Before diagnosing a malfunction, it is important to understand the principle by which diesel heating works in your car. At the moment there are two of them:

At the moment there are two of them:

- Turning on the glow plugs every time you start the engine is typical for older diesel engines.

- Periodic activation of heating elements depending on the temperature of the engine and the air supplied to the system.

It is also important to understand what types of glow plugs are installed, rod or ceramic. If your car meets environmental standards up to Euro 4, then most likely the diesel engine has rod heating elements

If Euro 5, 6 - ceramic

If your car meets environmental standards up to Euro 4, then most likely the diesel engine has rod heating elements. If Euro 5, 6 - ceramic.

The latter have many additional features, the main ones:

- Intermediate glow function, with which the DPF particulate filter is regenerated.

- Pre- and post-start heating – ensures that the fuel burns out in a cold engine.

To check glow plugs, for example, on Renault Megane 2 station wagon 1.5 86 hp, Ford Mondeo 2 1.8 90 hp, Ford Transit 2.2, Renault Laguna 3 or other cars with diesel engines, you can use several methods. Moreover, the approach to checking will be the same regardless of whether they are removed from the engine or standing still.

Verification methods:

- BY VISUAL INSPECTION. The integrity and condition of the relay and wiring are checked, and after removal, the product itself is checked;

- USING A TESTER (MULTIMETER). The winding resistance or its breakage is checked.

- SPARKING. It is not used on new diesel engines with an ECU, since the latter may fail.

- USING A 12V BULB. A simple way to check for a broken spiral.

For quick diagnostics, provided you have access to the glow plugs and a multimeter, you can measure their resistance. You need to check it when it is cold. The advantage is the presence of a non-contact ammeter (induction type). Indicators should vary from 0.6 to 4.0 Ohms. A new spark plug may have 0.7-1.8 ohms.

If your tester does not show such a low resistance, then you can check for a break in the spiral - readings to infinity (1) will indicate this.

Also, many multimeters support the sound signal function when the wiring is ringing - there is a sound, which means the spiral is intact.

Despite the results obtained, an external inspection of the spark plugs is recommended, especially if the car’s mileage has exceeded 50 thousand km. The presence of tip deformation, melting, and soot deposits are unacceptable.

If the results of preliminary diagnostics are disastrous for all glow plugs at once, then most likely, a complete diagnostic of the electrical equipment included in the heating system will be required, since the simultaneous failure of all products indicates a global malfunction.

To check glow plugs on a diesel engine, in addition to visual inspection, you must use all the methods described below.

Each of them will require the presence of certain instruments and knowledge in electrics, but if you repair electrical wiring yourself at home at a household level, you will figure it out here too.

see also

Comments 25

did you take the glow plug relay from an Audi of the 80s? It has 7 contacts, if you want the diagram I’ll send it to you in PM

I don’t understand why the candle is a torch. Are we talking about those glow plugs that are installed in each cylinder?

No, there’s one spark plug here, in front of the turbine.

Then I don't know. My Toyota diesel did not have a turbine))

I had an Estima diesel car with a 3speed engine. So that’s where the candles are glowing. The operating principle is as follows. When starting, the spark plugs burn for about 5 seconds. Then they go out. And when cranking the start, they light up again and stay on for 5 to a minute. It depends on how many are overboard. And they don't burn. I see I’ve already figured out the connection. Pay attention to the voltage at the spark plugs. Maybe it’s below 12. Then that’s why it burned. And if it’s not a secret, then why do you need it?

So I have a candle on Ivek, so I’m dealing with it.

Maybe the relay is stuck. I don't know the circuit diagram on your model. So it burned out

Sorry, the question is not clear, if this is a torch plug, then where is the fuel control valve, the torch heating turns on after -20 or even -25, or is it a glow plug just heating

Is this a question from a physics test at school?

By circuits, and knowledge of the contact numbers on the relay. Well, you can also make non-crossing wires in the diagram. Not any auto electrician will undertake such work. Although maybe a guy somewhere is trying to break the captcha. BGGGGGGGGgggggggggggggggggggg.

Like any other load, probably.

There are different types of candles! at 10 volts at 11 or 11.5 maybe there are other voltages. As I understand it in a diesel engine, it works through a special relay that gives heat for a certain time before starting to warm up the combustion chamber. They burn out because it must work for at least 20 seconds. and a maximum of 40 seconds. before starting the engine. Place the lamp directly parallel to the spark plug, but you will have to look for the relay! At a minimum, the way out is to simply power up the button via the relay and press it for 30 seconds before starting. I repeat - spark plugs are only needed for starting! Then they turn off! since they consume a lot of current, first the spark plugs turn on, then they turn off, and only then turn on the starter!

A lamp in the form of a spiral, or a regular 12V control?

and which one is better to put?

I just don’t know where it is, and what kind of spark plugs it is, on tractors, for example, the lamp was a spiral, and was switched on in series with the spark plugs, which provided both heating control and resistance for the spiral

and which one is better to put?

Yes, you can put an LED on it to indicate that there is power to the candle. Place it parallel to the candle and that’s it. Good luck!

look in the bulletin board, I installed an additional relay on the starter there, I think you can do the same)

Checking the glow plugs without unscrewing them from the engine

Many people try to check the glow plugs directly on the engine. But in this way it will not be possible to conduct a high-quality diagnosis. But you can find out whether voltage is supplied to them, whether the supply wire is working properly. The ringing mode in the tester and a voltmeter, as well as regular testing, will help with this.

It is also important to check whether the contacts are oxidized and how securely they are connected. In some diesel engines, you can visually check how the spark plug works, the speed and power of its glow

This can be done through the wells of unscrewed injectors

In some diesel engines, you can visually check how the spark plug works, the speed and power of its glow. This can be done through the wells of unscrewed injectors.

But this method is rarely used, since preference is given to the above verification options, since they are more informative.

Checking with a multimeter (tester)

The tester for checking diesel glow plugs is used in three modes:

- Measurement of resistance readings;

- Dialing method (if supported);

- Measurement of current consumption readings.

All methods can be applied without removing the product from the engine. But in this way we will only answer the question - “is the spark plug working or not.” It will not be possible to find out what condition it is in and the reasons for its breakdown.

Chain ringing

To check using the dialing method you need to:

- Disconnect the supply wire from the glow plug;

- Set the regulator on the tester to the desired position;

- Press the negative probe to the engine block, the positive probe to the electrode.

- The presence of sound indicates that the spiral is intact.

If you are using an analog tester, then you need to follow the arrow; its deviation indicates the integrity of the circuit.

This can also be done on a removed spark plug, only instead of a block, the probe must be attached to the body of the product.

The first and third methods are more informative, but they have their own characteristics that are important to know

Resistance measurement

Here it is important to understand the principle of the relationship between the ECU unit and the resistance of the spiral, which in a new glow plug should be in the range of 0.7-1.8 Ohms. The ECU is guided by the current consumed by the heating elements (A), which changes depending on their warming up

The amount of current is inversely proportional to the amount of resistance

The ECU focuses on the current consumed by the heating elements (A), which changes depending on their warming up. The amount of current is inversely proportional to the amount of resistance.

Those. Glow plugs are turned off when their resistance increases as a result of heating, and the current passing through the coil decreases. When a certain current value is reached, the ECU receives a signal that the spark plugs are warm and need to be turned off.

If the resistance, as a result of a malfunction of the heating elements, is too high (more than rated), then the current strength decreases earlier than necessary.

At this moment, the ECU receives a signal (premature in our case) that the glow plugs are warmed up and need to be turned off, which is what happens. At the same time, the air temperature in the cylinders remains insufficient for reliable engine starting.

Current consumption measurement

The most informative method, which involves starting a still cold engine. Those. There is no need to remove the glow plugs.

By measuring current consumption, you can quickly identify a faulty heating element. In this case, the reliability of the result obtained will approach 100%.

But here it is important to understand what types of glow plugs are installed in the engine and what their standard current consumption is. For example, if we take rod products, they can be single-pole and double-pole

For example, if we take rod products, they can be single-pole or double-pole.

The first ones are connected according to the classical scheme - ground on the body, one terminal coming off. Consume from 5 to 18 A.

The latter are determined by the presence of two terminals and can consume up to 50A.

To measure the current consumption, it is necessary to connect the tester in series in the “ammeter” mode into the electrical circuit that supplies the glow plug.

For this:

- Disconnect the power cable from the product;

- We switch the multimeter to ammeter mode;

- We connect one probe to the power wire, the second to the central terminal of the glow plug.

- An assistant will be needed. We start the car (the engine must be cold) and take readings from the device.

In the first seconds, the resistance on the electrode will be minimal, since the engine is still cold, and accordingly the tester will show the maximum current.

As the spark plug warms up, its resistance will increase and the current will drop. This will be displayed on the device. The reduction should take place without sudden changes, gradually. And then, at some stage, the current must stabilize.

It is better to write down the results of checking each spark plug so that they can be compared later. They should be as identical as possible.

If the behavior of a certain glow plug differs from others, then most likely only its middle or tip warms up. The absence of current will indicate an open circuit.

Here you will have to unscrew the product and recheck it, but visually observing the heating process. Typically this is already done using a directly connected battery (see below).

Signs of faulty glow plugs

Indirect signs of the presence of a malfunction:

- When starting, white-gray smoke comes out of the exhaust. This indicates that fuel is flowing but is not igniting.

- Rough operation of a cold engine at idle. The noisy and harsh operation of the engine can be noticed by the shaking plastic parts of the interior due to the fact that the mixture in one cylinder ignites late due to the lack of heating.

- . You have to do several repetitions of spinning the engine with the starter.

Clear signs of a bad glow plug will be:

- Partial destruction of the tip.

- A thick layer of carbon deposits on the tip near the body.

- Swelling of the glow tube (occurs due to excess voltage).

How can you check the glow plugs of a diesel engine?

How to check?

Depending on the model and age of the car, there are different principles of operation of the diesel engine heating system:

- In older cars, glow plugs usually turn on almost every time the engine is started.

- Modern cars can start successfully even without glow plugs at above-zero temperatures.

Therefore, before starting to diagnose the diesel preheating system, you need to find out at what temperature conditions the combustion chamber is heated. And also, what type of candle, since they are divided into two groups: rod (the heating element is made of a refractory metal spiral) and ceramic (the heater is ceramic powder).

To check the spark plugs of a Ford, Volkswagen, Mercedes or other car diesel engine, you can use several methods, and depending on whether they are unscrewed or on the engine, the principle will be the same. Functionality testing can be done using:

3 ways to check glow plugs - video

- Battery. On the speed and quality of incandescence;

- Tester. By checking the break of the heating winding or its resistance;

- Light bulbs (12V). The simplest test for breakage of the heating element;

- Sparking (can only be used in old diesel engines, since new ones are dangerous due to ECU failure);

- Visual inspection.

The simplest diagnosis of glow plugs is to check their electrical conductivity. The spiral must conduct current, its resistance in a cold state is in the range of 0.6–4.0 Ohms. If you have access to the candles, you can “ring” them yourself: not every household tester is able to measure such a low resistance, but any device will show the presence of a heater break (the resistance is infinity).

If you have a non-contact (induction) ammeter, you can do without removing the spark plug from the engine. But it is often necessary to inspect the working part, on which signs of overheating may be noticeable - melting, deformation of the tip, up to its destruction.

In some cases, in particular if all spark plugs fail at once, it may be necessary to check the vehicle's electrical equipment. Namely, the spark plug control relay and its circuits.

We will describe all the ways to check diesel glow plugs. The choice of each of them depends on skills, availability of equipment, tools and free time. But ideally, you need to apply everything together, plus a visual inspection.

We set up heating of a diesel fuel filter at home with our own hands: diagrams

Modern technologies

There are not so many current methods for creating an autonomous thermal field. You can build a diesel engine fuel filter heater with your own hands or make a flow-through design that will heat the fuel at the inlet of the filter element.

As an alternative or additional solution to the problem, heating the fuel lines will do just fine. There are also fuel intakes with thermal radiation elements on sale.

Heating methods

What makes you turn to independent methods, since there are a lot of branded separator structures with a built-in heater on sale? The answer on the surface is a high price. For example, Separ-2000 for KAMAZ will cost almost 40,000 rubles. The amount does not include installation operations. The fuel system of a diesel car has two filters: a coarse filter (separator) and a fine filter. Each of them has its own methodology. There are several designs of heaters:

- Belt flexible (for fine cleaning structures).

- Rod (installed in the separator).

- Bandage (mounted on a fine filter).

- Heated nozzles (for separators).

Experts advise dissipating heat in the housing of both the separator and the fine filter. In a critical financial situation, you should first of all pay attention to the filter element of the second design - the slightest waxing of the liquid is unacceptable for it.