13.12.2012

Additional generator weight

As a rule, over time, all “mass” connections on the car body are subject to corrosion and oxidation. As a result, voltage drops occur, which can lead to various consequences: from a non-working headlight - by the way, a sore subject for all SAMARs with oxidized wires (why don’t the headlights light up?) to unhealthy engine performance.

Also, especially in winter, with a large number of electrical consumers (stove, headlights, radio, heating), voltage drops can drop to such an extent that the devices refuse to work. Also, a poor ground connection can affect power leakage. For example, a bad generator mass slowly eats up the battery charge (battery charge leakage).

There are two options for solving voltage sags:

- Find and eliminate the source of the “bad” mass. To find out where the ground is attached, use the following article: Where is the engine ground mounted? Why is the engine unstable?

- Carry out additional mass. Additional grounding should only be done if the source of the poor ground connection cannot be eliminated. But it’s worth remembering that if you “hang” your car with additional grounding connections, interference may occur that will affect the operation of electrical appliances.

What is engine demining?

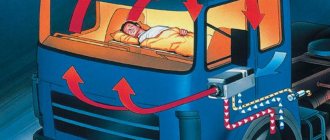

Structurally, the car has a developed electrical system, in which the serviceability and accuracy of the controllers, various sensors and many other electrical devices depend on the mass. The electrical ground (minus) is connected from the battery to the car body. The body is conventionally a return wire, forming a closed electrical circuit.

The movement of electrons along the circuit is initiated by the battery, and the body acts as a conductor of negative charge for return via the negative terminal. For this reason, the metal body of a car is called car body. In this case, engine demining should be understood as a number of improvements that involve additional connection of the most powerful consumers of electricity in the car to ground.

Additional weight on the VAZ-2114 (generator, battery, engine)

Additional weight per battery

Additional weight per engine

Additional weight on the generator

Additional weight per engine

Additional weight on the generator

According to the observations of our fellow club members, additional mass can help in solving a number of problems. If you experience voltage drops or surges, you can try this method.

Why do they do the de-mining?

During the operation of the car, you may encounter the fact that the electrical on-board network literally “sags,” especially at times of peak loads (simultaneous activation of the dimensions, low and high beam headlights, various heated mirrors and windows in parallel with the use of the air conditioning system, electric windows, powerful acoustics and other devices).

Also, voltage dips can occur for no apparent reason, affecting the stability of the internal combustion engine, its ignition system, ECU, sensors, servos and other electrical devices. This can happen if oxidation has occurred in the place where the negative terminal is normally attached to the body, the contact has broken down, or corrosion has appeared. The automobile electrical network naturally begins to operate unstably.

In the first case, additional demining of the engine is often necessary due to the fact that the car body is old, the standard place for attaching the mass has become unusable, etc. Regarding improvements and tuning, there is an opinion that additional de-mining allows a more even distribution of electricity in the vehicle’s on-board network compared to using the standard negative terminal.

Additional Weight: Benefits

Engine demining for the purpose of improvement has both supporters and opponents of this method. Skeptics consider this solution a waste of time and money, citing the fact that standard solutions in the car are quite sufficient, the cross-section of the factory wires is sufficient, each sensor has its own separate negative ground (sensor ground), etc.

The main argument among those who have already implemented the procedure is the stability of spark formation and operation of the entire ignition system as a result of the most efficient and reliable mass in the car. It is also claimed that the mass becomes even for all devices that consume electricity. Such uniform distribution cannot be achieved with standard mass, even if the terminals are cleaned regularly. The list of main advantages of power engine demining includes:

- fuel savings at a minimum level of 5-7% or more are achieved due to the fact that the generator is unloaded and the resistance is reduced;

- the starter rotates the crankshaft more actively at low temperatures at the time of start-up;

- the engine runs more smoothly and smoothly after de-mining;

- the power plant responds better to the gas pedal;

- the motor produces more power;

- the battery lasts longer and is recharged more efficiently from the generator;

- engine vibrations disappear when powerful consumers are turned on (air conditioning, increasing the music volume when using external amplifiers, etc.);

This modification makes it easier to start the car and increases the stability of speed in idle mode (the speed does not fluctuate). It was also noted that after the diesel or gasoline engine has been de-energized, headlights begin to shine brighter, increasing the comfort and safety of movement at night. Additionally, it is worth noting that after de-mining, interference and interference are minimized or completely eliminated, and music from the media and radio in the car’s speaker system begins to play clearer. Another advantage is increased safety for electrical equipment in the event that the standard ground wire breaks or its attachment to the body is destroyed.

Problems with bulk wires

How do problems with ground contacts manifest themselves?

Engine

If the ground wire from the ECM is oxidized or disconnected, this manifests itself in a spontaneous change in operating modes or the car suddenly stalls. Poor contact from the torpedo causes unstable engine operation at idle.

If the contact is broken, the battery charge deteriorates, the starter speed decreases during startup, problems arise in the ECM, because the second ground wire from the battery goes there. To correct the violation, first check the tension of the nuts securing the thick wire to the engine.

To do this, the outer nut is loosened, the inner nut is checked and, if necessary, tightened. The outer nut is then screwed back on. The thin wire is the main conductor of the negative charge. In case of malfunctions, check its condition and the tightness of the nut on the housing, as well as the bolt on the battery terminal.

If you find a point with poor contact, completely disassemble the assembly, find all burnt and oxidized areas, clean and level all surfaces before reassembling. Crimp and solder all terminals.

Problems may arise due to the lack of a castle washer under the bar and a loose nut connecting the stud and wire in the factory configuration. Over time, due to the resulting backlash between the pin and the wire, voltage surges appear in the channels of several sensors. The result is an uncontrolled increase in engine speed when the fan is turned on.

Models with 1.5 engine. If the first ground connection from the computer (on the power steering shaft) is in poor contact, when turning on the headlights, direction indicators, sound signal, windshield washer and other consumers, deviations in the temperature and fuel level readings are possible.

Quick check. If you suspect that the problem lies in the ground point of the ECU, take alligator clips and attach one to the engine and the other to the ground in the passenger compartment. Start the car. If the problems disappear, repair the faulty contacts.

Models with 1.6 engine. If the first ground connection from the computer (inside the dashboard) is poorly connected, when the headlights or power windows are turned on, the windshield wiper and washer may start working or the door locking system may work.

How to de-minus the engine yourself

The procedure involves running additional wires to ground from the main sources of current consumption. For most cars, the minus is carried out from 4-6 sources:

- minus generator;

- mass from starter;

- negative wire from the engine (preferably at least 2 points);

- weight of the gearbox (if automatic transmission is available);

- minus the body in the engine compartment (remote part from the battery);

- Wires must be flexible, made of high quality pure copper with a minimum content of impurities. The use of wiring based on copper alloys is not recommended.

- Also, the wire must have a large cross-section. This is necessary to ensure the best conductivity of electrical current.

- Additionally, you will need to pay attention to the insulation of the wires. It must be durable, resistant to mechanical wear and have the ability to withstand significant temperature fluctuations (large heating in the engine compartment followed by cooling).

It is worth adding that you can purchase both ready-made solutions for sale and do the demining of the engine yourself. For manufacturing you will need a copper cable, heat shrink tubing and terminals. The length of the cable and the number of terminals will depend on how many devices are planned to be grounded to the body (connected to ground). After cutting the cable, you need to crimp the terminals and apply heat shrink in those places where the cable is exposed to connect to the terminal. The final stage will be the installation of the manufactured wires in the engine compartment of the car.

How does the engine start button work? Available options and solutions for installing the starter button yourself. How to install the engine start button yourself.

Signs of malfunction or breakdown of the high-voltage spark plug wire of the ignition system. How to check car armored wires with your own hands.

The starter clicks and/or buzzes, but the engine does not turn over. The main causes of starter failures, diagnosing and troubleshooting them yourself.

How to quickly start the engine with a discharged battery. Features and advantages of using an autonomous battery charger. Tips for choosing a booster.

Conditions for proper storage of a car battery. Removing, inspecting and preparing the battery. How to preserve your battery without regular recharging.

Basic methods for repairing a cracked engine block. Crack detection, repair by welding, riveting or applying an epoxy layer.

Source

Replacing windings and brushes - we do it ourselves!

If there are no sounds, but the car still does not start, then you need to check the relay winding - it may be burnt out. In this case, in addition to replacing the winding itself, it is necessary to find out the reason for the burnout of the previous one and eliminate it so that the breakdown does not recur. Any experienced electrician can help with this.

Don’t also forget about the brushes in the starter relay, which wear out due to prolonged use and constant load. As a result, the brushes may not adhere tightly to the torque commutator, causing poor contact and the starter not being able to complete the required number of revolutions to start the car's engine. In the VAZ 2114, the starter relay brushes can be replaced by yourself; they do not require additional soldering. You can buy them at any auto store. It is worth noting that the brushes for this starter model are also suitable for other VAZ vehicles.

Engine demining and signs of poor grounding

An electrical circuit needs a good ground to function properly. Many people ask - why is engine demining necessary? The answer is - poor electrical grounding can affect one or more electrical systems, because it forces the current to look for other simpler paths. This can cause all sorts of problems with lights, sensors, modules and other electrical and electronic components, all of the above is also true to answer the common question - what is the purpose of mass in a car.

Causes and symptoms of poor engine grounding

Engine malfunction may be caused by:

- Loose, rusty, or damaged ground terminals or wires

- Weak, damaged or corroded battery ground terminal

- Poorly installed or repaired components

Symptoms of a poor motor ground may include:

- Dim lights

- Flickering lights

- Electrical devices operate erratically

- Faulty fuel pump

- A slipping or burnt A/C compressor clutch

- Intermittent sensor failure

- Throttle or transmission cables are damaged

- Hard start

- Low battery

Electrical ground diagnostics

The following sections are divided between tests. This will make it easier to test the starter and accessory ground paths to identify common electrical system problems.

Here are some important points to keep in mind when troubleshooting your car:

- When testing, make sure the terminals are attached to an unpainted surface. You have to connect to bare metal. Paint, corrosion, greasy surfaces, frayed or broken wires, and loose connections are the main causes of poor automotive finishes.

- Some vehicles use a separate chassis ground wire in addition to the main one (black battery cable) that runs from the negative battery terminal to the chassis. This is for headlights, accessories and other electronic equipment.

You can use the remote starter switch to crank the engine while testing your vehicle. Connect the switch to the battery and the "s" terminal on the starter solenoid or remote starter relay.

Where is the mass located?

When operating a car, it is important to know all the places where the mass of the VAZ 2114 engine is located. If a malfunction occurs in this direction, you can quickly detect the source of the problem and eliminate it accordingly. So, where is the mass of the ECU for the VAZ 2114? Let's try to understand this issue.

Where is the mass located on the VAZ 2114:

Battery weight of VAZ 2114

The negative battery branch consists of branches of wires of two types - thin and thick wire. The battery negative is directed to the motor housing using a thick wire. As a result of poor contact fastening, the charge will be supplied in a small volume, as a result, the starter will not be able to develop sufficient power, and the ECM will therefore fail, because it receives the required mass from the engine.

In order to check the negative charge connections between the battery and the engine, it is necessary to check the reliability of the two nuts, so you first need to loosen the nut from the outside and tighten the nut from the inside, and then screw the nut back on from the outside.

A thin negative wire is connected to the car body next to the battery. It plays the role of an energy source necessary for all consumers equipped in the car. To check, you also need to make sure the degree of tension of the nut both with the body and with the battery terminal.

Weight of engines VAZ 2114

Samar engines with a volume of 1.5 liters take weight from the engine body, from the mounting plugs, which are located to the right of the cylinder head.

Samar engines with a volume of 1.6 liters, or 1.5 liters equipped with a new type of ECM, take weight from a welded stud. The pin is attached directly to the metal body of the instrument panel near the floor tunnel in the area under the ashtray. When assembled at the manufacturer's factory, the stud is usually poorly secured and painted, as a result, during operation of the machine it can become completely loose, as a result, when the ventilation device is turned on, the electrical voltage of the system will drop, and the following devices will react accordingly: mass air flow sensor, air metering sensor, air pressure sensor.

Weight of the VAZ 2114 dashboard

In this version, there is a connection between the torpedo harness, the circuit from the mounting relay and fuse block, and the rear harness. This connection is located under the steering shaft mount. If the connection of this mount is not of good quality, problems may arise in the operation of the dashboard readings when the main energy consumers are turned on, for example: turn signals, headlights, etc.

- Electric motor heater weight

This ground connection is located under the instrument panel on the left side of the heater housing.

Why is mass needed in a car?

Grounding the engine provides an electrical return path for the starter. Poor engine grounding is a common problem resulting in hard starting and no starting.

The following test takes a voltage drop reading to determine any unwanted resistance in the motor ground circuit.

- Disconnect the ignition or fuel system to prevent engine starting during testing.

If the ignition system has a distributor, you can disconnect the high voltage cable from the distributor cap and ground it to the engine (bolt or bracket) using a jumper wire. On other systems, you may be able to remove the fuel pump fuse. Consult your vehicle's owner's manual or vehicle repair manual to locate the fuse. You can also use a remote starter switch. Connect the switch to the starter relay or solenoid (selector relay) control circuit terminals.

- Set the DMM to a constant voltage and select a range as close as possible but greater than the battery voltage. For example, 20 volts. Or select the auto-ranging feature, depending on your multimeter's features.

- Connect the red meter lead to a clean surface of the engine and the black meter lead to the negative (-) terminal of the battery.

- Have a helper run the engine for about five seconds, this is enough to get a good current reading.

You should get a reading of 0.2 volts or less. If necessary, refer to your manufacturer's specifications in your vehicle's repair manual. Did you get a higher reading? There is unwanted resistance in the ground circuit. To find the problem, proceed to the following steps.

- Move the red lead of your meter to the main ground terminal on the engine side.

- Have a helper crank the engine while you take a voltage drop reading.

Where is the ignition relay located on a Niva Chevrolet?

The ignition relay is located in the passenger compartment fuse box; it can be found on the driver's side of the instrument panel, opposite the seat. On the diagram it is usually designated K6 and in the technical description it is sometimes called an addition relay.

Also interesting: Niva-Chevrolet with an Opel engine: brief description, technical characteristics, owner reviews

It is responsible for turning on the fuel pump and supplying voltage to other elements. Triggered when the ignition key is turned. At this moment, you can hear a click behind the instrument panel. This electric coil built into the relay receives voltage and closes the contacts of a certain circuit. If there is no characteristic sound when turning the key, this may indicate its failure.

Checking grounding in a car

Electronic modules and many electrical components in the engine, transmission and passenger compartment use the body as an electrical ground. This test checks for unwanted resistance at these points, including the secondary ground between the battery and chassis used by some older models. If necessary, consult your vehicle's repair manual.

- Connect the black lead of your meter to the battery (-) terminal and the red lead of your meter to where the wire connects to the body.

- Have a helper crank the engine for a few seconds.

You should get a voltage drop of 0.2V or less. If the voltage drop is higher, proceed to the next steps.

- Move the red lead of your meter to the terminal on the end of the secondary ground wire. Take voltage drop readings.

If you get a reading higher than 0.2 volts, proceed to the next step.

- Move your meter's red test lead to the next terminal and ground point. Take voltage drop readings at each point.

When you get a reading around 0.2V or lower, the unwanted resistance is between this and the previous test point. Check for corrosion, broken or loose wires.

Also, check the voltage drop on the ground circuits that connect the engine to the chassis.

Search, check and replace transfer grounds if necessary.

Checking weight in a car

Transmissions on some vehicle models are equipped with a chassis or protective shield for modules, sensors, and solenoids (relays). You can also test these grounds using your digital multimeter.

- Check the voltage drop between the transmission and the negative terminal of the battery. The voltage drop should be 0.2V or lower.

- Check individual chassis grounding by checking the voltage drop across each ground terminal on the transmission. The voltage drop should be 0.2V or lower.

Clean, repair or replace the transmission ground as necessary. Remove grease, rust and paint from ground terminals or replace damaged ground straps.

General Voltage Drop Values

Choke cables and other equipment can be damaged when high electrical current cannot find the correct path back to ground.