Brake band malfunction

With frequent surges in oil pressure (which can be caused by a broken sensor), the brake band breaks. Many motorists come to the conclusion that it is cheaper to order a spare part “at disassembly”. However, most AL4 transmissions that are “disassembled” are far from in ideal condition. Almost all of them have exhausted their resources. We also note that this box has been constantly modified. The type of pressure regulator and software changed. By the way, the software on the first models of this box was of poor quality, which is why it often generated an error.

The solution is to re-upload the software and replace it with a newer one. But there is one thing. After 2004, the box was significantly modified, and when reprogramming you need to take into account the year of manufacture of your car.

Heat exchanger

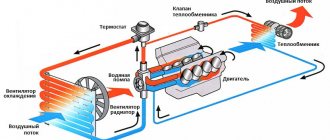

Transmission fluid heat exchanger design may vary depending on the specific automatic transmission model. On most models, the automatic transmission heat exchanger is located in the engine radiator housing. This design of the transmission cooling system can significantly simplify and increase the efficiency of transmission cooling. Some models use larger heat exchangers, which are necessary to service automatic transmissions with an increased number of gears. Such gearboxes are intended primarily for powerful diesel vehicles with increased torque.

Automatic transmission heat exchanger

The car owner must closely monitor the technical condition of the transmission cooling system. A dirty heat exchanger can lead to a significant deterioration in the cooling efficiency of the working fluid, and the presence of contaminants inside the heat exchanger housing will lead to a drop in pressure inside the cooling system. That is why it is recommended not only to regularly replace the hydraulic lubricating fluid in the gearbox, but also to perform mechanical cleaning of the radiator with the heat exchanger of the cooling system. The latter quite often becomes clogged with dirt and fluff. As a result, cooling efficiency is significantly reduced.

Checking the cooling system pipes

When carrying out service work, it is a good idea to check the condition of the transmission cooling system pipes. During vehicle operation, such pipes may lose their elasticity and become covered with a layer of deposits. It is recommended to replace the cooling system pipes of automatic transmissions after 100 - 150 thousand kilometers. This way, you can protect yourself from leaks of transmission coolant that can occur when the seal of the cooling system line is broken.

Heat exchanger clogged

If the heat exchanger is clogged, other problems with the operation of the torque converter may appear. This appears in problems with gear shifting. There is a partial or complete blocking of the torque converter. In this case, when changing the operating modes of the gearbox, the automatic control system will turn off the engine. During operation of the automatic transmission, wear products accumulate in the coolant, which in turn can lead to jamming of the coolant line valve. In this case, the risk of automatic transmission failure due to overheating increases. That is why it is necessary to monitor the condition of the valve and the quality of the coolant.

How to clean the heat exchanger?

Cleaning the heat exchanger and replacing the coolant is not difficult. With proper work experience and special equipment, you can easily clean the heat exchanger yourself. You need to disconnect the line from the automatic transmission cooling system. The automatic transmission cooling pipe can only be disconnected when the car is not running. Hoses from cleaning equipment are connected to the radiator pipes. An active liquid is passed through the heat exchanger using a special apparatus under high pressure, which allows wear products, slag deposits, and clots of old oil to be washed out of the heat exchanger. After this, you need to turn off the cleaning device and connect an air compressor to the heat exchanger pipes. The heat exchanger is dried under high pressure, after which it can be connected to the automatic transmission cooling system.

How to extend the life of an automatic transmission?

Why is overheating harmful and how to deal with it?

There are several reasons why you should be careful about temperature fluctuations inside the automatic transmission. Temporary or regular increase in it threatens:

- Oil inside the gearbox. Upon reaching a temperature of 120-130 Celsius, the liquid becomes unusable and loses its physical properties, which affects the operation of the box itself.

- Friction discs made of not too hard alloys are also deformed by temperature changes.

- Solenoids and valve body as a whole. In a number of modern models, to reduce the cost, they are made from very ductile metals or even plastic. In the end, constant overheating can further “kill” the automatic transmission by disrupting the distribution of oil inside.

- Wiring.

- In rare cases - even planetary gears.

Quite often, some car models use an additional automatic transmission radiator, which is located exactly next to the base one. This eliminates overheating and associated troubles, prolonging the life of the gearbox. This is especially clearly seen in a number of older models, where an additional automatic transmission cooling radiator was installed by default - some examples lasted several hundred thousand kilometers.

Vehicle behavior

Any driver has sooner or later encountered strange behavior of an automatic transmission while the car is moving. The smoothness of gear shifting is lost, and this often manifests itself after a long period of sitting in a traffic jam. This may already be a reason to install an additional automatic transmission cooling radiator.

Also, jolts and kicks often appear at the moment when the speed switches from low to high.

This behavior is typical for a car that is operated in difficult conditions:

- frequent gear changes;

- tug of a loaded trailer;

- long engine operation at high speeds.

Under such a load, it is impossible to avoid strong heating of both the automatic transmission itself and the transmission oil that is poured into it. Often this indicates overheating of the gearbox oil, which can be verified by readings. On many modern models, you can monitor the temperature of the transmission oil.

Methods and technologies

There is a strong opinion that in most cars the ATF cooling system of the automatic transmission is insufficient.

Especially when the car is operated in difficult conditions, under heavy loads or in hot weather, installing an additional cooling radiator is simply necessary and significantly extends the life of the automatic transmission. I would like to dispel this myth right away! Let's start with the fact that the optimal operating temperature range of an automatic transmission is between 80 C and 120 C, which is approximately 20% higher than that of the engine. To maintain a stable operating temperature, the automatic transmission cooling system is organized in such a way that the ATF is cooled in special blocks combined with the engine cooling system, and occurs by washing the thin-walled radiator with antifreeze with a stable temperature of 90-95 C, through which the ATF is driven, which allows it not to overcool at low ambient temperatures. Note that this factor in this case is maintaining the proper oil fluidity parameter.

In case of hypothermia, ATF thickening occurs and two problems occur at once:

- Thick oil does not lubricate bushings and seals on calipers well because it has difficulty penetrating thin gaps

- Thick oil forms a thin film on the fractional elements, preventing its rapid squeezing out when the clutch pack is compressed and, as a result, increased sliding and slipping, and at temperatures below -30 C it generally loses its properties.

All of the above causes severe wear and tear of the automatic transmission ultimately. In addition, I would like to say that the standard automatic transmission cooling system is designed with a triple reserve for removing excess heat, and in a fully corrected automatic transmission it simply should not form so much. So what happens... does an additional radiator harm the operation of the automatic transmission? Of course not, but only if the additional radiator is installed correctly.

Additional automatic transmission radiator

Most automatic transmission malfunctions occur as a result of overheating. Today there are many different automatic transmissions with different operating temperatures, but the range for many automatic transmissions is between 65 and 95 degrees Celsius.

If the temperature rises above permissible limits, the transmission fluid will overheat and lose its properties. An increase in temperature and, accordingly, overheating of the fluid can occur for various reasons (the car is parked in a traffic jam, aggressive driving is practiced, etc.). In any case, in order to prevent overheating and premature repair of the automatic transmission, an additional radiator is installed.

An automatic transmission radiator can be purchased at any specialized store. When installing the radiator yourself, you must purchase a complete kit, which will include hoses, clamps and adapters.

When replacing a radiator at a service station, experienced specialists will not only install it with high quality, but also select the best option for a particular car. If the installation of an automatic transmission radiator is carried out independently, then you need to take into account certain nuances.

As a rule, an additional radiator on an automatic transmission is placed in a break in the existing circuit, between the main radiator and the automatic transmission itself. Install it in front on the “standard” (main) radiator.

Installation sequence of the automatic transmission add-on radiator:

- secure the additional radiator to the “standard” one with special ties;

- Screw the hoses to the additional radiator using clamps;

- install adapters into the main line of the automatic transmission lubricant;

- top up to the level or completely replace the transmission fluid;

- install a thermostat (with a thermostat, the additional automatic transmission radiator will only be used when the transmission fluid is heated to a certain temperature).

The advantage of installing an additional radiator:

- overheating of the automatic transmission is eliminated, the service life is increased;

- the cooling of the transmission fluid is improved, the service life of the ATF is extended;

- the service life of solenoids and valve body is extended;

It should be noted that some manufacturers of additional radiators have recently installed special spiral plates in them to create a turbulent flow of lubricating fluid.

The advantage is greater heat transfer, but the disadvantage of this solution is the occurrence of resistance to the flow of liquid if there are metal shavings in it.

Installation of an additional automatic transmission radiator in the professional version

An additional radiator is installed parallel to the standard cooling system; a thermostat is also installed, which, when the temperature is exceeded, will transfer the ATF flow through a more efficient additional radiator (similar to an engine cooling system with a large and small circuit and a thermostat). Unfortunately, there are no standard oil thermostats for passenger cars, so you will either have to design one yourself, which is extremely difficult, or use a system from heavy trucks and tractors. But there it is designed for a large volume of oil, and under these conditions it does not work properly. As an option, you can make a system based on a temperature sensor, an illegible block and two solenoid valves, one of which opens and the other closes at a certain temperature value. The danger here is that if both sensors hang inaudibly in the closed position, the automatic transmission will instantly fail due to lack of lubrication and overheating.

The conclusion from all of the above is that it makes sense to install an additional radiator only if the car is operated in critically unusual conditions (at races, in constant heat, with excessive load).

Is the standard cooling system sufficient?

First of all, it is worth paying attention to the fact that there are two types of cooling radiators:

Separate. Such systems, as a rule, were installed on older automatic transmission models. In this case, cooling is carried out by blowing air or a fan. Thanks to this, it is possible to maintain the oil temperature within acceptable limits.

Important! When using a separate radiator, you need to change the oil in a timely manner (it is advisable to do this every 50,000 km). Although manufacturers claim that the fluid will work after 160,000 km, it is better not to check this in practice if a separate gearbox radiator is installed in the car

Built-in. More modern automatic transmissions do not have a separate radiator for the gearbox. In this case, a pipe is connected to the main radiator of the engine cooling system, which controls the automatic transmission fluid. In fact, under one housing there are two radiators - one cools the engine oil, and the other cools the transmission oil.

It would seem that this is the solution to the problem - we install a built-in cooling system and kill two birds with one stone. But it's not that simple. The fact is that the internal combustion engine (especially if it is highly accelerated) and the automatic transmission operate at different temperatures. Thus, the engine can function normally at 100-110 degrees (and if we are talking about cars like the Chevrolet Aveo or Cruze, the temperatures reach 115 degrees), and for some automatic transmission components such indicators become critical.

In addition, the area of the pipe connected to the main radiator is too small, so the cooling process will be less efficient. Therefore, the risk of overheating remains.

We recommend: Single injection and everything you need to know about it

At first, the built-in cooling system can work without any problems. However, gradually the radiator pipes and the transmission itself will become clogged with dirt. In this case, changing the oil will not help improve cooling.

Thus, if the car does not have a separate radiator, the integrated model will not be enough. In addition, flushing an integrated system is much more difficult than a separate unit. That's why many people buy additional radiators. They are installed on the main radiator in the place where there is an open circuit between the “standard” cooling system and the “machine” itself.

How the cooling system works

There are different types of radiators that are responsible for cooling the working fluid inside the automatic transmission.

But the system's operation scheme looks approximately the same. It includes several main elements:

- Pump. A special device that creates pressure inside the system. Helps pump oil from the moving elements of the automatic transmission to the hopper.

- Oil receiver. It's a bunker. It includes a rectangular body with pipes on both sides. The hopper can be located inside the engine cooling radiator or at the bottom of the sump. The location allows for efficient cooling.

- Filter. Usually presented in the form of a metal mesh. But synthetic materials can also be used. The filter is needed to clean the oil from various particles and impurities that appear as a result of wear and friction of surfaces.

The operation of the automatic transmission cooling system largely depends on what type is used in a particular car.

Cooling system on old and new automatic transmissions

It is already clear that the radiator is responsible for cooling. But there are two types. These are separate and built-in.

The first type is used mainly on old automatic transmissions. Built-in ones appeared on modern machines.

Separate radiators are a privilege for older cars. For automatic transmissions, there is a separate radiator from the engine cooling radiator specifically for the gearbox. Blowing is carried out by counter air flows or forced by a fan. This allows you to maintain the temperature within a specified range.

Schematic illustration of the cooling system

Built-in. This is an option for modern automatic transmissions that do not have a separate radiator for the gearbox. Here the pipe responsible for supplying oil to the machine is connected to the main radiator. That is, structurally, there is a pair of radiators in one unit. One cools the engine lubricant, and the second cools the oil in the box.

Switching to integrated radiators seemed like a revolutionary way to solve two cooling problems at once. In practice, everything looks different. Many engines have a higher operating temperature compared to the temperature of the automatic transmission lubricant. And if the motor can operate at 100-110 degrees, then these parameters will be disastrous for the machine.

Also, small pipes are often used to cool transmission fluid, which negatively affects cooling efficiency. Therefore, the oil may overheat under heavy load.

To solve the problem of insufficient cooling, they began to use an additional radiator, which is installed to help the main cooling unit. Such elements are mounted in the gap between the main radiator and the box.

Correspondence of signs and causes

Here is a table of common automatic transmission breakdowns.

| Signs | Causes |

| Reverse gear does not work. Only speeds 1 and 2 function, but speeds 4 and 3 do not work. | The friction discs are worn out, the piston cuffs are broken, the sealing rings are destroyed. |

| The car does not move forward, it slips, reverse gear works. | Worn discs, front clutches, broken cuffs, worn clutch rings, stuck valve body. |

| The car does not move back and forth. Strong shocks when switching. | The torque converter is faulty; oil needs to be added and the filter needs to be replaced. |

| You can only drive in third gear. | Wear of friction discs, front clutches, breakage and wear of piston cups, wear of clutch rings, valve sticking. The electronic unit has switched the box into emergency mode; diagnostics and repairs are required. |

| Shifts on a cold box are made with jerks. | Dirty solenoids or hydraulic plates. Consumables need to be replaced and the valve body needs to be cleaned. |

| No reverse. | Worn brake band, broken cuffs, brake band, broken piston rod. |

| The car is unable to move in any direction. Switching is carried out without jolts. | Malfunction of the torque converter, pump drive gear, no gear engagement with the torque converter. It is necessary to add oil and clean the filter. Wear of the brake band, clutch and disc, as well as piston seals. Wear and breakage of O-rings. The valve body solenoid or valve is faulty. |

| The increasing rumble of the box, vibration when driving, intensify with increasing engine speed. | Bearing wear. |

| There is reverse gear, forward gears - only first and second. When the box warms up the problem goes away. | A dirty solenoid or valve body is stuck. |

| The car drives in neutral. | Incorrect adjustment of the gearbox lever or cable. Clutch piston jamming. Welding friction clutches. |

| Speeds are included at high speeds | Incorrect throttle cable adjustment, clogged filter, faulty throttle valve. |

| The car drives normally, but on an ascent the automatic transmission slips and switches to a reduced speed. | Low oil level, wear of friction discs, brake band. The oil pump and valve body solenoids are faulty. |

| A sudden press on the gas does not switch to a lower speed, and the kickdown does not work. | The button or sensor under the pedal is faulty, the switch valve is stuck, the damper cable is faulty, there is no power to the sensor. |

| When starting from a stop, it slips, but when the speed increases, it drives normally and the gearbox shifts properly. | Worn turbine wheel splines, broken cuffs. |

| When switching, slippage occurs. | The oil pump is faulty, the filter is clogged. |

| No forward or reverse. | The splines on the turbine wheel hub were cut off. |

| Significant shocks occur when changing speed. | Wear of the brake band, friction discs, clogged solenoids or valve body channels. |

| The car slips when driving and jerks when shifting. | Clutch failure. |

| No movement in both directions, no oil pressure. | Oil pump splines cut off. |

| The car moves normally until the oil warms up. Then slipping occurs and the car stops. | Faulty friction discs. When the oil is cold, its pressure and viscosity are higher compared to hot oil; worn discs are pressed better and form traction. Friction wear, oil contamination, filter mesh. |

| Noise in the form of metal beating at idle. | Severe wear on drum discs. |

| The transmission does not switch to a lower speed when the pedal is depressed, there is no kickdown. | Engine malfunction. |

| The transmission does not switch to a lower speed when the pedal is pressed all the way. The car moves normally until the oil warms up. Then the car slips and does not move. The car accelerates slowly. No reverse. | Violation of the tightness of the fan blades of the turbine and pump. Broken blades. |

| There are large metal shavings in the tray. | Severe wear on the planetary gear. |

| The oil in the box foams and slippage occurs. | Water penetration into automatic transmission. |

| Low oil pressure. | Dirty solenoids or valve body. It is necessary to check the oil level and the relief valve in the pump. |

| When the gear is engaged, the car stumbles and stalls. As the rpm increases it moves normally. | The speed clutch valve needs to be checked. The torque converter is faulty. |

| Aluminum shavings in a tray. | Wear of the plain bearing and planetary gear. |

| The tray contains plastic elements. | Broken plastic part. |

| Metal scraping. | Wear of differential bearing, gears. |

| Magnetized rollers were found in the automatic transmission tray. | Broken roller thrust bearing. |

Automatic transmission radiator

An automatic transmission cooling radiator is installed in order to solve problems with cooling the automatic transmission. Removing excess heat from the transmission fluid can significantly increase the service life of the automatic transmission. Also, automatic transmission radiator equipment is recommended when the following conditions are present during vehicle operation:

- Using a car at high air temperatures;

- Frequent vehicle downtime in city traffic jams;

- Off-road driving;

- Aggressive driving style.

If the car has an antifreeze heat exchanger, the radiator is installed as a continuation of the cooling circuit, which is located in the lower part of the front bumper. Connecting it is not difficult; in fact, it is installing a pipeline to the radiator. Its size depends on the amount of oil and the behavior of the gearbox in the summer.

You can purchase a cooling radiator at any store that specializes in cars. If you contact a car repair shop to install it, qualified specialists will be able to choose the best option for a particular car. If you decide to install the radiator yourself, then you need to purchase hoses, clamps and adapters.

Installation of additional automatic transmission cooling

Automatic transmission cooling is an important element when operating a vehicle. Installing additional equipment for this procedure will reduce wear on the box and increase its service life by 30-40%, and also reduce the operating temperature of the oil by 15-40 °C, depending on the model of the additional radiator.

Installing an additional automatic transmission cooling radiator has several advantages. Among its advantages are:

- softer and smoother operation of the automatic transmission;

- increasing the service life of the automatic transmission, including the hydraulic control unit;

- Extending the service life of seals and seals.

In some cases, with the help of cooling, it is possible to get rid of bumps when changing gears.

Note that the original cooling system works on the principle of heat exchange between engine coolant and automatic transmission oil, that is, in the main engine radiator there is a tube washed with antifreeze. While the car is new, the system copes well with the task. However, its effectiveness is decreasing every year. Depending on the manufacturer, the operating temperature of the box begins to vary from 85 to 100 °C, although it should not exceed 80-85 °C.

For more efficient automatic transmission cooling, we recommend flushing the standard cooling system and removing the radiators once a year!

Installing automatic transmission cooling will save you from possible vehicle malfunctions and increase the service life of the automatic transmission. In addition, by installing an additional cooling radiator, you will eliminate the need to repair the automatic transmission valve body.

Our company officially represents HAYDEN and LONG COOLERS. The former's job is to remove excess heat from the transmission fluid while maintaining its operating temperature, as well as preventing excessive cooling during the colder months.

(the price is for the radiator and its installation on the car)

| Model | Radiator dimensions, mm | Price |

| OC-1401 | 318x127x19 | 6500 rub. |

| OC-1402 | 403x127x19 | 6700 rub. |

| OC-1403 | 318x190x19 | 6800 rub. |

| OC-1404 | 403x190x19 | 7100 rub. |

| OC-1405 | 403x254x19 | RUB 7,800 |

Radiators LONG COOLERS

The advantage of LONG COOLERS radiators is that they are made of brass, while HAYDEN are made of aluminum. Adapter plates are available for installing additional cooling on automatic transmissions 09G, 09K (TF-60SN), 096 (01M, 01P,01N), DP0 (AL4).

Installation of an additional automatic transmission cooling radiator is recommended for cars with a mileage of more than 100 thousand kilometers. This can be explained by the fact that the cooling system in them is ineffective due to dust trapped in the radiator, as well as oil oxidation products and wear of the automatic transmission and the subsequent decrease in heat transfer.

Additional automatic transmission cooling radiators are installed on any type of car, with any type of transmission. The only limitation is the availability of free space to install an additional radiator. Our specialists are ready to provide more information on this issue. To contact them, call the phone number listed in the header of the site.

Installing a cooling system will have a positive effect on the automatic transmission and will make this unit last longer. It is important to understand that installing a device is not so much about cooling, but about maintaining the optimal operating temperature in both summer and winter.

Share on social media networks

RќСЂР°РІРёС‚СЃСЏ

Kinds

According to the method of transmitting the signal to the thermal element, it can come from the coolant, indoor air. The valve of different types can be almost identical. They will differ in the thermal head. Today, all existing varieties can be divided into 2 types: mechanical and electronic. Devices have their own characteristics, which affect their performance characteristics.

The devices differ not only in the type of material, but also in the installation method. They can be of angular or straight (pass-through) type, depending on the type of connection. For example, if the main is connected to the side, a direct type valve is installed. The corner method is used when connecting from below. The valve option is chosen to be the one that fits best into the system.

The choice between them depends on the preferences of the buyer and his financial capabilities. Products can be designed for a specific type of thermoelement. To understand the differences between thermostats, you need to briefly note their main nuances.

Mechanical

Mechanical thermostats are easy to use, precise and consistent in use. They do not need a network connection. Manual products are different from their electronic counterparts. They work on the principle of a regular faucet: the regulator is turned in the desired direction, allowing the required amount of coolant to flow through. The devices are cheap, but not the most convenient, since to change the heat transfer you need to manually turn the valve each time.

If you install them instead of ball valves, you can use any of them to adjust. The devices are technologically advanced and do not require preventive maintenance. However, often there are no markings at the inlet and outlet of radiators of this design to adjust the heating temperature. Almost always you have to set it experimentally.

Before installing such structures, it is necessary to adjust them, as well as install hydraulic resistance. Smooth adjustment is carried out due to the throttle mechanism, which is located inside the device. This can be done on one of the valves (inlet or return). The operation of a mechanical thermostat depends on the hot and cold points inside the room, as well as the direction of air movement in the room. Another disadvantage is the fact that they react to the operation of household appliances with their own thermal circuits (for example, refrigerators, electric heaters, and hot water pipes).

Electronic

Such modifications are more complex in design compared to manual analogues. With their help you can make your heating system flexible. They not only allow for temperature control of an individual radiator, but also provide control of the main components of the system, including the pump and mixers. Depending on the model, programmable devices are equipped with different types of sensors.

The electronic mechanism can measure the ambient temperature of a specific space (the place where it is installed). Using the software, the received data is analyzed and a decision is made to reduce or increase the temperature. Such a mechanism can be analog or digital. The digital version has 2 modifications: its logic can be open or closed.

The difference between the categories is that products with closed logic are not able to change the functioning algorithm. They remember the level of the initially set temperature and maintain it. Analogs of open logic are able to independently select the desired control program. However, they are rarely used in domestic conditions, since it will be difficult for the average buyer to initially program them, selecting the desired options from the many built-in functions.

The harmful effects of overheating

Now I want to talk about the harmful consequences of fluid overheating, using the example of an automatic transmission.

First of all, the oil itself suffers; its threshold is approximately 120 - 130 degrees Celsius. Often, in traffic jams (especially in summer) or during intense (sharp driving modes), the automatic transmission can heat up to critical temperatures. And this is 120 - 130 degrees! The oil begins to lose its properties, literally burns, and accordingly its properties are lost, which has a detrimental effect on many automatic transmission components.

Valve block and solenoids

The valve body is a kind of oil distributor in the box, and the solenoids close and open the channels inside (I won’t focus on the work now). So, if earlier solenoids were often made only of metal, now they are often made of plastic or using plastic parts

High temperatures are simply destructive for them. There are also cases when the valve body itself overheats, and “specifically” it even reaches the point where the metal turns blue

Wiring. There is wiring inside the machine; it can also simply melt due to high temperature.

Actually, these are only the initial reasons, but there may be much more of them, including the destruction of planetary gears, due to the fact that the oil has lost its properties. That is, there is no normal lubrication. As you can see, a cooling radiator is simply necessary, but often NOW not all manufacturers configure cooling well.

Installation of an additional radiator

Empirically, it turned out that the situation is saved by installing a dedicated additional radiator. It should be installed in the gap in the existing circuit, between the gearbox housing and the standard cooling element. Also note: the best location for it would be in front of the engine radiator.

What are the advantages of such a solution? The tube is better ventilated, heat exchange with the medium increases, and the output results in very stable indicators: no higher than 80 degrees in any weather. As a bonus, owners received increased service life of the valve body and reduced oil wear.

The installation process is as follows:

- A radiator, thermostat, and fluid hoses that can withstand high temperatures are purchased. You also need to buy adapters, clamps and oil (if not for replacement, then for adding to the required level).

- The radiator is secured with ties in front of the main one (in most cases included in the kit), and hoses are attached to it with clamps.

- The tees for the main line and the additional cooling element are cut.

- The tubes are attached to the tees with clamps, and the oil is added to the automatic transmission to the required level.

- A thermostat is installed in the system to prevent unwanted heat loss in winter.

Error P0730

She's talking about clutch slipping. It can occur both on a warm box and on a cold one.

Symptoms: gearbox knocks and transition to emergency mode. Sometimes when driving the engine speed fluctuates (the accelerator pedal is in the same state). This is the effect of the towing clutch. In this case, the automatic transmission solenoid valve AL4 fails. It is also possible that the hydraulic unit itself may fail. Further driving in such a vehicle is prohibited, as there is a risk of breaking the donut band brake. This malfunction usually occurs on older cars and is solved by replacing the valve and pulling the valve body. As in previous cases, upon completion of the repair, new oil is poured into the transmission and the AL4 automatic transmission sensors are checked for variations in oil pressure.

How to connect an additional automatic transmission cooling radiator

Often, when deciding to purchase an additional automatic transmission radiator, car owners are faced with the question “how to connect?” There is a lot of completely different advice on this matter on the Internet. There are a lot of opinions. How to determine the option for yourself.

In this article we will look at the installation methods offered on the Internet and try to discuss the pros and cons.

Method 1. Consistently without a thermostat.

With this scheme, the oil leaves the automatic transmission, enters the main radiator, then goes to the additional one and then back to the automatic transmission

This is perhaps the simplest scheme of all, which uses an additional radiator

Method 2. In series with the thermostat

With this scheme, the connection is carried out in the same way as in the previous one, but in addition a thermostat is included in the circuit.

In this case, the thermostat acts as an automatic connection for an additional radiator.

Method 3. Bypassing the main one without a thermostat.

With this scheme, an additional radiator is placed separately from the main one and performs its function

This circuit makes the cooling of the box independent of the heating of the main radiator.

Method 4. Bypassing the main one with a thermostat

With this scheme, the connection is carried out in the same way as in the previous one, but in addition a thermostat is included in the circuit.

.

In this case, the thermostat acts as an automatic connection for an additional radiator.

Which scheme is the most optimal for a car? Is a thermostat needed and what is its function? And is it even worth bothering with this topic?

1. Sequentially or separately?

Probably the most optimal and common connection method is serial. On many forums they write that this is how it should be and no other way. Weighing all the pros and cons, we can accept it, but let’s consider the connection and the same thing separately.

Pros of serial connection:

- does not require any special modifications, the additional radiator simply fits into the circuit immediately after exiting the main one

- an additional radiator cools the automatic transmission oil, further reducing its temperature

Cons of serial connection:

- modern engines operate at very high temperatures, so in the radiator the coolant heats up to 100-110 degrees, and the oil temperature in the box should be around 80-90 degrees, so the hot oil will go from the box to the main radiator, where it will heat up and flow cool down extra

- at least this is 6 connections

Pros of a separate installation:

- The radiator cools only the automatic transmission and is not connected to other components

- the minimum number of connections is 4

- Simplicity of design

The disadvantages of a separate installation are difficult to determine. They write a lot on the forums that in winter, due to the main radiator, the oil is heated up at the first start and the oil in the box is already warm when starting off. Maybe so. This is in gasoline engines, where the engine heats up quite quickly and the coolant thermostat quickly switches to a large circle, but what about diesel engines? As you know, a diesel engine heats up very poorly when running without load, and accordingly, the radiator heats up for the same long time. What about the gearbox in a diesel engine?? No way. It goes and that's it.

2. Do I need a thermostat?

There is a lot of debate on the Internet about whether an oil thermostat is needed or whether it is an unnecessary part. The function of the thermostat when installed to cool the automatic transmission is that when a certain temperature is reached, for example, when the main radiator fails, the thermostat will connect an additional one, and also in winter, prevent the automatic transmission oil from cooling too much. But when installing a thermostat, at least 4 additional connections appear in the line. We also discussed in the previous paragraph that the box can easily start and move on cold oil.

3. Is it worth worrying about whether or not to connect an additional radiator?

Our opinion is that it's worth it. In some models of modern cars, additional automatic transmission cooling radiators come as standard, and in most cars, cooling goes through the main radiator. When delving deeper into this issue, you can see that in cars with a mileage of 15 years or more, automatic transmission radiators, additional or main ones, are installed on almost every car and the cars still run smoothly on their original gearboxes. Now during production they are trying to reduce the cost of the car and run cooling through the main radiator.

What breaks most often in torque converters?

Locking clutch

Malfunctions in the torque converter most often occur due to slipping or friction of the lock-up clutch. The friction disc wears out, material detachments and glue get into the oil. As a result, the automatic transmission fluid becomes contaminated and overheats. Increased wear of bushings and bearings.

Inhomogeneous abrasion of the clutch in the automatic transmission gas turbine engine causes vibrations when the clutch is blocked. Seals, bearings, bushings break, which leads to accelerated wear of the donut. The oil pump also suffers, which leads to oil starvation of the entire box.

Seals

Another “weak point” of the torque converter is the oil seals and seals. The parts are made of Teflon or plastic. They are capable of traveling 200,000 km. But due to aggressive driving or poor automatic transmission design, the seals begin to leak and age faster. When the oil seals become thin, large fragments break off and clog the oil.

Overrunning clutch

In rare cases, the overrunning clutch may be faulty. The rollers wear out and begin to slip or jam. As a result, the clutch cannot block the reactor. The gas turbine engine will not switch to fluid coupling mode. Due to excessive load, the clutch race may rotate, and metal wear debris will enter the oil.

How does it affect automatic transmission?

“Diseases” of the torque converter affect other gearbox components and disable them. The “donut” is the main “pollutant” and “heater” of the automatic transmission. Oil spreads friction and metal dirt throughout the box. It clogs valve body channels, solenoids, valves, and sensors with slag. As a result, gear shifting occurs with a delay, fuel consumption increases, and machine parts wear out. Therefore, if extraneous sounds or vibrations appear in the automatic transmission, you need to immediately check the condition of the torque converter in the automatic transmission. This will help save it with minimal costs.

Robots

Robots can be divided into two groups. A robot with one clutch is a regular “mechanics”, in which the clutch and gear shifting are controlled not by the driver, but by automation. In theory, the reliability of such a unit should be the highest among automatic transmissions. But practice does not confirm this. For example, the editorial Vesta with the robot already had three clutches with a mileage of less than 45 thousand km. The Easytronic box, which was installed on Opel, tormented its owners with electronic failures. In terms of speed and shifting comfort, a single-clutch robot is the worst automatic transmission. Its main advantage is its low price. Therefore, it is installed mainly on small and inexpensive cars.

Cooling of transmission oil in automatic transmission

So, taking into account the peculiarities of operation, the oil in an automatic transmission requires effective cooling. To solve this problem, an automatic transmission cooling system is integrated into the design. The specified cooling system for the automatic transmission is necessary in order to avoid an increase in the temperature of the transmission oil and overheating of the automatic transmission. Moreover, since modern engines and gearboxes are characterized by high efficiency, they are intended to be used in severe conditions.

In such conditions, the cooling system allows not only to effectively cool the box, but also to maintain the necessary properties of the ATF working fluid. The fact is that the service life and quality of operation of the automatic transmission directly depend on the condition, level and properties of the hydraulic transmission fluid.

In simple words, the transmission oil in the automatic transmission must reach operating temperature as quickly as possible, while loss of properties due to strong heating is also unacceptable. It is for this reason that a separate group of special transmission oils has been developed for automatic transmissions, and it is also prohibited to use motor oils and lubricants for manual transmissions.

As for the automatic transmission cooling system, such a forced automatic transmission cooling system includes:

- An oil pump that pumps oil under pressure and pumps transmission fluid from the moving elements and parts of the box into the oil receiver;

- The oil receiver is located in the automatic transmission pan or in the car radiator (depending on the implementation diagram);

- The heat exchanger for transmission oil (automatic transmission oil cooler, also known as automatic transmission oil cooler) may differ on different car models. On most cars with an automatic transmission, the automatic transmission cooler is located in the radiator housing of the engine cooling system. The solution simplifies the design and improves transmission cooling. On some cars, the automatic transmission oil cooler can be installed separately; there may also be enlarged heat exchangers for powerful internal combustion engines that produce high torque.

- An automatic transmission filter is also additionally installed in the system, which is a coarse filter (metal mesh or synthetic mesh). This filter, like automatic transmission oil along with fine filters, needs to be changed every 40-60 thousand km. mileage If operating conditions are severe, it is better to reduce replacement intervals by 15-20%.

It is not difficult to guess that the automatic transmission heat exchanger is one of the main elements of the transmission cooling system. The fact is that contamination of the automatic transmission oil cooler from the outside leads to a deterioration in the cooling efficiency of the ATF fluid.

Deposits and dirt inside the heat exchanger mean reduced capacity and pressure drop in the cooling system. For this reason, as part of automatic transmission maintenance, it is necessary not only to change the oil and filters, but also to perform mechanical cleaning of the radiator of the transmission cooling system.

ZF center › Blog › Automatic transmission cooling system. Device. Part 1 “What men talk about” (c)

Good afternoon, dear readers of our blog! This article continues a series of materials based on popular topics and questions that are often discussed on forums on the Internet, and are also asked by phone to our specialists.

We plan to answer the most frequently asked questions from users regarding the design, operation and maintenance of automatic transmissions in an accessible and understandable form.

So, what do male owners of cars with automatic transmissions often talk/ask about?

The question of the day is: automatic transmission cooling / does the automatic transmission have cooling? / They advise me to have an additional radiator for the box - is this necessary? /breakdowns due to overheating... what is this about?/ the manufacturer has provided for everything - don’t interfere with the machine’s operation... etc. etc.

Questions about the design of the automatic transmission cooling system, overheating, additional radiators, etc. — we put it together and decided in several parts to introduce the readers of our Blog to the design of the automatic transmission cooling system, to highlight the issues of overheating and additional cooling. There is too much information in one article. Let's prepare several materials to make it easier to “learn the material” :).

So, in the first part, we will show a diagram of the automatic transmission cooling system, the main design features of the automatic transmission cooling system

Most hydromechanical transmissions (we will talk specifically about the most common type of automatic transmission) have a similar internal hydraulic circuit. Look at the diagram. The diagram is simplified as much as possible for general understanding).

The oil in the automatic transmission housing is located in the sump. When the box is operating, the oil is sucked in by the pump through the filter and enters the hydraulic distributor (“hydraulic block”). The valve body distributes oil to the operating mechanisms of the automatic transmission and to the torque converter.

The oil in the GT gets quite hot and requires additional cooling. Hot oil from the valve body - through a separate line - enters the external cooler (more about cooler designs below). Their external cooler - cooled oil - returns to the box and goes to lubricate the shafts inside the box. And then it drains into the pan. This is roughly what the general pattern of oil movement inside the automatic transmission looks like.

What is important to pay attention to. In any box there is an external cooler, the task of which is to reduce the temperature of the oil in the automatic transmission. Oil temperature is one of the critical parameters

The main problem is that with significant overheating, the life of the oil is noticeably reduced and the oil degrades. Please note that the oil for lubricating the shaft bearings comes after the cooler, as cool as possible

Oil temperature is one of the critical parameters. The main problem is that with significant overheating, the life of the oil is noticeably reduced and the oil degrades. Please note that the oil for lubricating the shaft bearings comes after the cooler, as cool as possible.

Next, we’ll show you for understanding how the external cooler works and what shaft bearings are.

There are several basic external cooler designs.

Option 1 - Heat exchanger built into the main cooling radiator.

In one of the engine cooling radiator tanks there is a small radiator built in through which automatic transmission oil passes. Oil K and FROM the radiator is supplied through pipes. As the oil passes through its radiator, it transfers the temperature to the engine coolant. This design of the heat exchanger complicates and increases the cost of the design of the main radiator; long additional tubes appear from the automatic transmission to the radiator. In some models - if the fitting leaks - it can lead to mixing of automatic transmission oil and antifreeze!

Option 2. Separate remote heat exchanger

. Two pipes are from the automatic transmission, and two pipes are from the engine cooling system. Liquids do not touch inside the heat exchanger

Small feature

The installation procedure described above works well in the summer, and the oil temperature is guaranteed not to rise above 80-85 degrees. But what about in winter? This is where the other side of the coin lies - the automatic transmission oil cools and thickens, which is also not good for it.

Why not install an additional radiator now?! Of course, there shouldn’t be any doubts – it’s worth asking how, but correctly! Additionally, a thermostat must be built into the system, which must be set to operate at a temperature of 75-80 °C. Thanks to this, the additional radiator will be used as needed. That is, when there is a threat of overheating.

Features of cooling radiators

When talking about installing an additional radiator, one cannot fail to note the solutions that are used in the latest models of major European, American and Japanese brands. We are talking about a layout in which an additional cooling element is installed inside the main radiator.

This separation is quite effective - ideally, the automatic transmission itself and the oil should be cooled separately. But there are a couple of nuances. Firstly, there is no way to make the dimensions of the tube (and this is exactly how the radiator exists on some cars) always small - for some cars and temperature conditions it will simply not be enough. It is also worth considering that for a number of engines 100-110 degrees is the normal operating temperature, but for an automatic transmission and the fluid inside it it will always be too high. Consequently, even for such machines, installing additional. The automatic transmission radiator is a forward-thinking solution.

Also, do not forget about the chronic problem of dual radiators: over time, dirt will begin to accumulate on the walls of the pipes, which will worsen the circulation of liquid inside and significantly increase the temperature. When the mark rises above 100 degrees, wear and tear on the fluid and automatic transmission will increase greatly.

And here you can consider another type - installing a dedicated radiator. For the first time they began to be installed en masse on Chevrolet cars. They just used a “high-temperature” engine, for which 115 degrees was an absolutely normal indicator.

In practice, it turned out that the owners felt the first symptoms of a failing gearbox after 50 thousand kilometers, even with very careful operation. Shocks and extraneous sounds appeared in almost everyone who bought them - this was a consequence of overheating of the automatic transmission.