Until the early 1980s, the use of a scheme with four driving wheels not on SUVs, where it was impossible otherwise, but on ordinary passenger cars was considered an event from a number of technical oddities. After all, an all-wheel drive transmission requires the introduction of new components into the design, which makes the car heavier, noisier and vibration-laden.

Increasing design complexity increases production costs, which affects the cost of an all-wheel drive vehicle. In turn, maintenance and repair of such a machine will require large expenses. Cars with all drive wheels consume more fuel than their counterparts with a single axle drive - this is due to an increase in the total weight of the car and mechanical losses in additional transmission units.

But the automotive industry does not stand still. Modern cars have a large reserve of power, and at the start, when you sharply press the gas pedal, the adhesion forces of one pair of wheels with the road surface may not be enough. The drive wheels slip, slip, and excess traction goes away along with the smoke of burnt rubber. And the distribution of traction force not over two, but over four wheels and the ability to use the entire weight of the car as traction reduces the likelihood of slipping by half and guarantees impressive starting acceleration. In addition, all-wheel drive provides better handling and directional stability of the car in motion, especially on slippery roads, allowing the driver to corner more confidently and quickly.

Audi gave impetus to the development of road all-wheel drive cars with its Quattro model. Its popularity required adequate steps from other car manufacturers, and the model ranges of even family cars began to rapidly fill up with 4x4 versions - and they all found their admirers. Subaru even made all-wheel drive, and over time, all cars produced by this Japanese company became all-wheel drive.

The merit of Audi engineers is that they were able to develop a lightweight and compact design in which, based on a front-wheel drive layout, torque was selected to the rear drive wheels directly from the center differential built into the gearbox. True, this differential required a lock, but the introduction of self-locking viscous couplings and friction differentials (like the Thorsen design, which uses the self-braking ability of helical gears) eliminated this problem. 4x4 passenger cars were freed both from additional mechanical locking levers, which did not at all decorate their interiors, and from the jerks that accompanied differential locking if it was carried out mechanically.

Viscous couplings, by the way, not only freed cars from unnecessary levers and jerks, but also made it possible to smoothly redistribute torque between the axles depending on the specific situation in which any car wheel finds itself at any given moment in time. However, viscous couplings were not without their quirks. With the advent of ABS, viscous couplings began to “conflict” with these systems, interfering with their operation and only correcting it for the worse.

Mercedes-Benz was the first to introduce ABS, and it was the first that had to rack its brains on how to “calm down” the viscous coupling. Fortunately, by this time the Ferguson center differential with automatic locking, controlled by electronics, had already been created. Inside this differential there was a multi-plate clutch, which was engaged when the difference in wheel speeds reached a certain value. The blocking command came from a microprocessor, which in its work used signals from three wheel speed sensors - the same ones used in the ABS system.

The automatically locked differential made it easier to start the car, especially on slippery roads, to improve handling at high speeds when cornering, and at the same time did not at all affect the effectiveness of ABS, because it turned off whenever the brake pedal was pressed.

The basis of the Volkswagen 4-Motion all-wheel drive system is the Haldex clutch, which is an electronically controlled multi-plate clutch. In favor of the coupling, Haldex abandons the viscous coupling and Volvo.

BMW has developed its own xDrive all-wheel drive system, which does not have any locks. BMW all-wheel drive is controlled by electronics, more precisely by the ABS, ASC+T, DSC and ADB–X systems. The important thing is that the first three systems are used on rear-wheel drive versions of BMW, that is, they are standard. By and large, it was only necessary to expand the software of these systems to accommodate all-wheel drive.

The role of the first violins in the system “quartet” is played by DSC - Dynamic Stability Control, and ADB-X - Automatic Differential Brake (judging by the second technical term, there is still a differential in the BMW 4x4 system, but in fact we are just talking about its imitation using the brakes). All commands to the brakes come from DSC, ADB-X recognizes when the wheel begins to slip and brakes it, thereby providing the same effect as a differential lock.

The driver knows that the system has reached a certain critical operating condition (in other words, that the wheels are beginning to lose traction) and ADB-X has come into action using a flashing indicator on the dashboard. By entrusting the functions of all-wheel drive control to electronics, BMW managed to achieve not only a reduction in weight and a simplified transmission circuit, but also optimized the operation of the braking system, where now each wheel receives strictly dosed braking force and does not interfere with the braking of its “neighbors”, as happens in full drive with conventional interlocks.

Mercedes engineers did not follow the beaten path and invented their own transmission with automatically connected all-wheel drive, which they called 4 Matic. The principle of its operation is as follows: on a dry surface, the rear wheels are driving, and when they slip, the central computer engages the multi-plate clutch through a hydraulic drive and redistributes torque to the front wheels. The material from which the friction linings of the discs are made is not afraid of slipping, and it is precisely thanks to slipping that the multi-plate clutch used in such schemes can operate. The electronic system, through a hydraulic drive, changes the degree of pressing of the disks against each other, gradually transferring torque to the axle whose wheels have better traction. This unit is called a hydromechanical coupling.

What is all-wheel drive, what is it for?

All-wheel drive, or in other words 4WD (4x4), is the structural type of transmission with which the car is equipped. This system allows the torque to be distributed equally to the wheels. Until the 80s of the last century, cars equipped with a 4x4 drive were associated with all-terrain vehicles or off-road vehicles.

However, now, a lot has changed; not only all-terrain vehicles, SUVs and crossovers, but also sedans and station wagons are equipped with all-wheel drive. Not only cars from leading foreign manufacturers can have all-wheel drive. Domestic cars can also be equipped with 4x4 drive. Let's figure out what is hidden behind the mysterious abbreviation 4WD.

The design of the transmission of a car with a 4WD drive (Four-wheel drive) is made in such a way that it is possible to transmit torque to all wheels at once. Torque can be called a kind of collector of the forces of the horses that are collected under the hood - i.e. in a car engine. The more torque, the faster the car works and accelerates. Torque depends entirely on the engine size.

A car with front-wheel drive is where the driving wheels are at the front (front axle). In such a car, engine thrust is transmitted to the front wheels. In a rear-wheel drive car, the rear wheels (rear axle) are driving.

Types and features of all-wheel drive systems

Permanent all-wheel drive. In such a transmission, torque from the engine is transmitted to all wheels. True, during the process of its creation, one problem arose that did not allow engineers to borrow technical solutions from conventional all-terrain vehicles. The fact is that in real “jeeps” the connection between the front and rear drive axles is rigid, i.e. without differential.

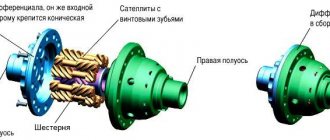

If you drive a car with such a transmission on paved roads, its handling will be very poor, since the front and rear wheels travel a different path, and therefore the less loaded ones tend to slip. In addition to the front and rear cross-axle differentials, it was necessary to install a third one - an interaxle or, as it is also called, a central differential.

Depending on its characteristics, the torque was distributed between the wheels of the front and rear axles in the required proportion. However, in this form, the all-wheel drive transmission turned out to be suitable only for roads with a uniform road surface. On a slippery road, a situation may arise when all the engine torque is transferred to the wheel that has lost traction, and the car will not be able to move. Moreover, the chances of getting into such a situation are two times greater for an all-wheel drive car than for a front- or rear-wheel drive one. This problem was solved by installing a limited-slip center differential or an automatic locking mechanism.

Automatically connected all-wheel drive. Under normal road conditions, this transmission operates as either front- or rear-wheel drive. This allows cars to retain the “family” features characteristic of a particular type of drive. And in extreme situations, when one or two drive wheels lose traction and begin to slip, the torque is redistributed to the wheels of the other axle.

Structurally, this is done in this way. The shaft, which transmits torque to the drive axle, is connected to the wheels of the other axle through a special coupling. The clutch is usually installed instead of the center differential or in close proximity to the rear axle. Under normal driving conditions, the clutch is unlocked, but in extreme situations, it locks and transmits torque to the wheels of the auxiliary axle. In cars with automatically engaged all-wheel drive, several types of clutches are used: the already mentioned viscous coupling, electronically controlled friction clutches, hydraulic friction clutch locking systems, etc.

Systems with manual all-wheel drive . Unlike “charged” versions of passenger cars with a sporty character, all-wheel drive in SUVs should fulfill its original function - to help move on roads with poor surfaces, where you don’t really want to drive. Such transmissions, as a rule, do not have a center differential, which “passenger cars” with permanent all-wheel drive cannot do without.

When four-wheel drive is engaged, the front and rear axles in this configuration have a rigid connection, and torque is transmitted in a 50:50 ratio. But in this case, driving on the highway with all-wheel drive engaged is strictly prohibited. Firstly, there is a danger of wheel slippage, especially when cornering, and secondly, transmission parts (drive shafts, wheel differential gears, etc.) experience large overloads and if the all-wheel drive is not turned off in time, breakdowns cannot be avoided. But still, drivers sometimes forget to do this. Therefore, some circuits have warning lights or devices that automatically turn off all-wheel drive when driving at higher speeds.

All-wheel drive device

All-wheel drive device

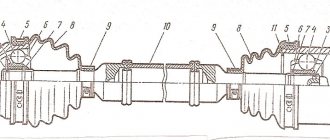

A typical all-wheel drive transmission of a car consists of the following elements that perform their functions:

- Gearbox (manual or automatic);

- Multi-plate clutch or transfer case;

- Center differential;

- Cardan shaft;

- Differentials (rear or front);

- Controls.

The most famous all-wheel drive systems are:

- 4Matic from Mercedes;

- All wheel control from Mitsubishi;

- 4motion from Volkswagen

- Quattro from Audi;

- ATTESA from Nissan;

- xDrive from BMW;

- VTM-4 from Honda.

Types of all-wheel drive

Permanent all-wheel drive

Permanent 4x4 all-wheel drive is a type of drive in which torque is distributed from the engine simultaneously to all wheels. Such a drive can be used on different classes of cars with a longitudinal or transverse engine layout. For optimal distribution of torque, modern all-wheel drive systems are equipped with limited-slip differentials with the ability to distribute power across the axles in different ratios.

Elements of permanent all-wheel drive Quattro system

Electronics coordinate the operation of the system, receiving signals from wheel speed sensors, and instantly changes the power ratio depending on road conditions and driving patterns. This type of all-wheel drive is the most advanced system, providing better active safety and driving dynamics.

Disadvantages: increased fuel consumption and constant load on transmission elements.

Branded permanent all-wheel drive is used in their cars by manufacturers such as Audi (Quattro), BMW (xDrive), Mercedes (4Matic) and others.

Forced Connection

For off-road vehicles, the optimal way to implement all-wheel drive is forced. It is designed according to a standard design, only the central differential is missing. The driving axle is the rear, the connected axle is the front. Torque is transmitted to the front axle through a transfer case, which is controlled manually.

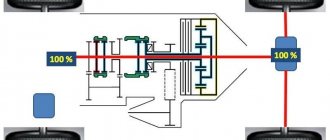

Diagram and elements of connected all-wheel drive

The driver independently turns on the drive of all wheels using levers or control buttons before overcoming a difficult section or, for example, off-road. The inclusion of the transfer case ensures a rigid connection between the axles and an equal distribution of torque. The all-wheel drive indicator lights up on the instrument panel. Often the design additionally provides for the possibility of rigidly locking cross-axle differentials, as well as the use of high and low gears.

When all-wheel drive is engaged, the transmission elements experience heavy loads, and the vehicle's handling deteriorates significantly. Under normal driving conditions, the transfer case is disengaged and the four-wheel drive indicator goes off and driving continues with the rear driven axle. The transmission is freed up, which extends its life and reduces fuel consumption. Forced all-wheel drive is used mainly on SUVs. For example, on Toyota Land Cruiser and Land Rover Defender.

Automatically connected

Scheme of automatically connected all-wheel drive

The scheme of automatically connected all-wheel drive is designed taking into account the possibility of instantly connecting the second axle to the drive one. The main drive is rear or front. When the difference in wheel rotation is detected, the friction clutch of the center differential closes at the command of the electronics, and power begins to be transmitted to all wheels. A number of models provide a switchable 4x4 mode, and the car becomes single-wheel drive. The automatically connected 4Motion all-wheel drive system is used on Volkswagen models.

Advantages and disadvantages

Having all-wheel drive has its advantages and, of course, disadvantages. The main advantages of such a car are:

- high safety and increased stability of the machine on different surfaces;

- increased cross-country ability;

- improved driving dynamics, use of the power plant more efficiently;

- agility and quick start without delay or slipping are common for cars with the 4x4 formula.

The disadvantages include the following:

- complex design;

- increased fuel consumption;

- high metal consumption of the transmission itself;

- In addition, an all-wheel drive car is more expensive in price compared to a single-wheel drive car. Accordingly, car repairs are more expensive due to the complex design.

Benefits of all-wheel drive

The advantages of a car equipped with an all-wheel drive transmission are easy to understand based on the disadvantages of a single-wheel drive car, in which the drive is carried out on only one axle (front or rear), i.e., the driving wheels are either front or rear.

All-wheel drive off-road vehicle

The use of free differentials on the bulk of budget cars in difficult road conditions actually makes one wheel driving, which has the worst grip on the road surface. This is a feature of the differential. And even if both wheels have enough traction, too much power will often cause them to spin, lose control, or cause the vehicle to get stuck. These are the disadvantages of a mono-drive, which are especially visible on slippery road surfaces and off-road conditions. In order to eliminate these shortcomings, manufacturers use self-locking cross-axle differentials.

However, the optimal solution is to make all wheels driven by improving and supplementing the transmission design with the necessary components. All-wheel drive provides the vehicle with the following advantages:

- increased cross-country ability;

- improved traction when starting on slippery surfaces;

- directional stability and predictable behavior on slippery roads.

All-wheel drive transmission

So, the design of the transmission of an all-wheel drive vehicle allows for effective transmission of torque to all wheels, that is, to both the front and rear axles. In practice, such schemes make it possible to transfer maximum power from the internal combustion engine to the wheels, increase cross-country ability and stability on the road, improve handling, and achieve improvements in terms of active vehicle safety.

All-wheel drive transmission is usually designated as 4x4, 4WD or AWD. The main advantages of all-wheel drive are clearly visible in a variety of conditions, from off-road driving to high-speed driving on the autobahn.

An all-wheel drive car, that is, equipped with an all-wheel drive transmission, does not have many of the disadvantages of single-wheel drive cars (when only the front or rear wheels are driven, that is, with drive to the front or rear axle).

In the design of various types of transmissions with drive only to the front or rear wheels, many vehicles actively use free differentials. In the event of slipping and slipping, these elements actually leave only one wheel driving, which has worse traction with the surface. This is the peculiarity of the differential operation.

Moreover, in the case when both wheels have acceptable grip on the road surface, active power supply causes them to slip, controllability deteriorates, and the car may get stuck.

Usually, the disadvantages of single-wheel drive cars immediately appear on snow or ice, in mud, off-road, etc. To improve the situation, automakers often use self-locking cross-axle differentials to partially solve the problem. However, it is still not possible to completely get rid of shortcomings.

The only way out is to implement all-wheel drive for the car. To do this, the transmission needs to be modified and the overall design needs to be supplemented, which leads to a noticeable increase in cost and complexity of the latter (the use of a large number of additional parts, the general design of the device).

Article on the topic: Tires for a crossover - the subtleties of choosing summer and winter tires

However, only all-wheel drive is capable of providing better cross-country ability and traction with the road surface during acceleration and in motion, directional stability is maintained and increased, the car behaves more predictably on ice, etc.

As for the all-wheel drive transmission design, the general scheme assumes the presence of:

- Manual transmission or automatic transmission (manual or automatic transmission)

- transfer case (transfer case) or use of a multi-plate clutch;

- center differential;

- driveshaft, rear differential, front differential;