In our country, cars are often used for more than fifteen years, sometimes after major repairs for more than twenty or even longer. VAZ kopecks produced in the early seventies of the last century can be found very often on our roads. One of the biggest malfunctions can be called stuck piston rings - signs and solutions that we will describe in this article.

With proper care and timely service, a car of any brand can last for many years, and this does not require the knowledge of a top-class mechanic.

What are piston rings?

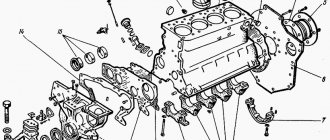

Piston rings are open rings located in grooves in the surfaces of power plant pistons.

Piston system

When designing a motor, designers constantly have to solve the same problem - the diameter of the bottom of the piston and cylinder must be different sizes. And at the same time, the lubricant should in no way end up in the chamber where fuel combustion occurs. The use of a heavy piston may cause it to jam in the cylinder, even though its diameter will be slightly smaller. But the use of a narrow flexible ring, which has a movable lock, will allow it to move freely. This option is still considered the best.

Rings are divided into two types - compression and oil scraper. The main purpose of the former is to create pressure in the chamber.

Two types of piston rings

The engine design has a small gap between the cylinders and pistons, which makes it impossible to create the required pressure in the chamber. When expanding, the gases would certainly penetrate into the crankcase of the power plant. This problem was solved only by installing additional compression rings, which are thin rings with a cut. The cut is a lock that allows the tight ring to compress and expand within specified limits, while not allowing it to jump off the piston. To allow the rings to compress freely, there are grooves on the outer surface of the cylinder body.

The rings are made of a special grade of steel and are a kind of spring, which is in a slightly compressed state, which allows it to fit tightly to the walls of the cylinder. During operation, they gradually wear off, but the tightness of their fit remains the same until their wear reaches a critical level.

A design feature of modern pistons is 3 rings. Compression - a pair, oil scraper - one.

The use of compression rings does not completely solve the problem of gas breakthrough. It can be solved in a variety of ways, for example, during the installation of the rings, they are positioned in such a way that the locks are not located on top of each other. Their best location is 180 degrees, so that they are in opposite directions. You should definitely pay attention to this during engine overhaul.

Why do the rings lie?

To understand the reasons for the occurrence, you should remember how they work. The piston rings are located in the grooves of the piston. The grooves themselves are wide enough to allow the rings to move fairly freely. The rings placed on the piston do not fit closely to it, but, on the contrary, are pushed apart. Thus, the expanding force forces them to fit tightly against the cylinder walls, providing high pressure inside the combustion chamber at the end of the compression stroke.

The occurrence is caused by deposits of combustion products that clog the piston grooves, preventing the free movement of the rings. The latter, in turn, get stuck in the grooves and no longer adhere to the cylinder walls, as a result of which the required pressure is not created in the combustion chamber.

This entails all the symptoms indicated at the beginning of the article: difficulty starting the engine, especially in cold weather and a drop in power due to the presence of compression rings, as well as increased oil and fuel consumption and thick blue smoke from the exhaust pipe, for which the oil scraper rings are to blame.

There are several reasons for the appearance of deposits in grooves:

- the car is not used for a very long time, as a result of which the engine oil loses its properties, thickens and begins to play the role of glue;

- The car often takes short trips, during which the engine does not have time to fully warm up. In this case, a large amount of carbon deposits forms in the cylinders, which does not have time to completely burn out due to the engine operating time being too short;

- low-quality motor oil, which burns out much more intensely than high-quality lubricant.

Reasons for occurrence

Most car owners do not even imagine why the problem occurs and how to eliminate this problem at an early stage. In reality, everything is much simpler than it might seem at first glance. The main culprit for the occurrence of rings is the carbon deposits that form in the power plant. Motor lubricant partially burns out in the engine, and the ring grooves become clogged.

Carbon deposits from oil combustion

The result is deterioration of the seal between the pistons and cylinders of the vehicle engine. As a result, carbon deposits form, which leads to sticking of the rings.

Signs and symptoms of rings:

- Reducing engine compression. This can be determined not only by diagnostics, but also by a decrease in engine power. A stuck piston cannot guarantee the required level of mixture compression. This is especially noticeable when starting in the cold season.

- If lubricant consumption has increased.

- There is a burning smell. Blueish smoke comes out of the exhaust pipe.

The occurrence of rings is caused by operating the car without first fully warming up the engine. Short trips of up to five to seven kilometers have a negative effect on the engine. This time is clearly not enough for the engine to warm up to the required operating temperature.

The use of low-quality oil that burns out at high temperatures directly in the engine.

Signs of buried rings

Previously, we found out that when the rings are stuck in the engine, the tightness of the piston to the cylinder is broken. It follows from this that gases from the combustion chamber partially “fly” into the resulting gap, without performing useful work, they enter the crankcase.

Symptoms of stuck rings are mainly caused by a drop in compression in the combustion chamber due to gaps between the piston cup and the liner wall. Problems begin with a deterioration in the dynamic characteristics of the car. The engine does not respond well to the gas pedal. This is the main sign.

If the oil scraper rings are stuck, a film of lubricant remains on the inner surface of the cylinder (by the way, compression rings get stuck much less often). During the power stroke of the piston, when fuel vapors ignite, the lubricating fluid burns out. The oil is wasted, and bluish smoke comes out of the exhaust pipe. This is the second sign.

Difficulty starting the engine in any weather is another sign of stuck rings. The crankshaft with counterweights has a large mass and requires significant force to turn it. In addition, the oil flows into the oil pan; at the first revolutions, the friction force also impedes the movement of the piston. If one or more cylinders are not firing, starting is difficult.

Increased fuel consumption may also be a sign that there are rings in the engine. Due to the gap between the piston and the cylinder, the energy of the fuel is not fully used: compression is insufficient. Therefore, the on-board computer overestimates the enrichment of the air-fuel mixture to compensate for the lack of thrust. This leads to excessive consumption of fuel.

Remedies

Having discovered the first symptoms with the occurrence of rings, all car enthusiasts deal with them in different ways, but there are three main ways.

- The most common method is to use a mixture of kerosene and acetone (in equal proportions). The spark plugs must be unscrewed and the mixture must be poured into all combustion chambers. Next, the motor needs to be left for 8-12 hours, acidification should occur in the chambers. Then the candles are put back. The engine starts and you need to drive along a flat road at maximum speed for about fifteen kilometers. Typically, this method allows you to solve the problem of rings sticking and without resorting to expensive repairs. Next you need to change the filters and oil.

- The next method is almost identical to the previous one, with the only difference being that regular kerosene is poured. Other conditions, driving on a flat road and changing the lubricant mixture and filter must be met.

Do-it-yourself additives or soft decarbonization

Decarbonization of piston rings can be carried out in a gentle way, accessible to any car enthusiast. It involves simply adding special substances to the fuel, offered in car dealerships.

They must be poured according to the instructions. Soft decarbonization is carried out without dismantling spark plugs or injectors; it does not require adding new engine oil.

But there are also disadvantages: not a single fuel additive can cope with severe coking. Also, such substances cannot decarbonize the combustion chamber and valves.

Therefore, if the problem is pronounced, then it is better to pay attention to a harsh method of cleaning the engine.

Video “Coking rings”

This video shows what to do if the piston rings are stuck. What are the best products to use and how to use them correctly.

Engine malfunctions are some of the most annoying and costly. If, for example, a rusty or rotten body does not affect the speed in any way, then a malfunction in the engine will somehow affect the dynamics and overall operation of the power unit.

One of the most important engine groups is the cylinder-piston group (CPG). This group is directly involved in the combustion of the air-fuel mixture (FA). Working in harsh conditions, the CPG is subjected to serious loads, which in one way or another affect the service life of the working parts.

One of the main failures of the CPG is the occurrence of the piston rings, which are responsible for a lot of processes during the power stroke of the piston. The occurrence is mainly due to the appearance of deposits, which over time turn into hard carbon deposits. Carbon deposits block the mobility of the rings and also clog technological holes in the compression and oil scraper rings. As a result of this phenomenon, compression in the engine decreases, and the supply of lubricant to the cylinders also deteriorates. Working under such conditions, the piston is subjected to even greater stress. since there is no proper lubrication, friction occurs almost “dry”, and due to a drop in compression, power decreases and fuel consumption increases.

Selecting additives for oil scraper rings

- Liqui Moly logo

Liqui Moly

How can you navigate the choice of additive for restoring oil scraper rings for engine operation that can be considered normal? A good example would be those variants of multifunctional additives that were the first to be used in motor oil for BelAZ loading equipment. Indeed, soon after a series of successful experiments it turned out that these additives are perfectly suitable for other lubricants. One of these additives at that time was the most successful invention of the Liqui Moly company - OL-VERLUST-STOP. Today, thanks to its well-established production, this miracle can be found in any stores and shops specializing in the sale of auto chemicals in sufficient quantities. OL-VERLUST-STOP is a universal tool for stopping engine oil leaks. It can cure minor ailments of rubber gaskets and seals, eliminating the possibility of oil getting into the environment, and reduces oil consumption. But most importantly, this product protects oil scraper rings from grease waste products, restoring them to their former mobility. This occurs due to the stabilization of the oil viscosity at fairly high temperatures.

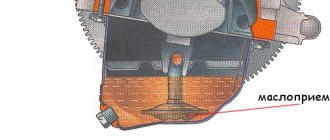

But the company decided not to stop there either. L-Shclamm-Splung is an excellent additive for combating black sludge in the engine. It is extremely important to avoid its accumulation, since it settles not only on the oil scrapers, but also clogs the oil receiver mesh, oil channels and filters. The liquid completely cleans the internal combustion system, ensuring the absence of “lubricant starvation”.

- XADO and Edial

Another good option is detergent and anti-wear additives in the oil. Among these, it is worth highlighting revitalizants under the XADO brand, of which there are more than enough on the Russian car market, as well as the friction modifier Edial. The latter is a multifunctional additive used to restore worn rubbing metal surfaces. It increases the service life of engine mechanisms and restores their structure as well as if it was done manually. The same applies to their beneficial effect on oil scraper rings. With its polygamous compatibility with all known oils for diesel and gasoline engines, Edial “Internal Combustion Engine” is one of the best means of cleaning oil scraper rings from carbon deposits.

- Additives from the American manufacturer

Hi-gear

Even a novice motorist is familiar with the phrase “Hi-gear”. This American company develops and produces all the auto chemicals you can think of. So they also invented something for oil scraper rings. Oil Treatment HG2243 and HG2246 are two high-tech additives that can do a lot: they will prevent oil oxidation and its dilution, restore their former strength to exhausted additives in the lubricant mixture and increase compression. As practice shows, all rings present in the engine behave as well as possible when interacting with these substances, and the overall dynamics of the vehicle improves. These additives will cure even moderate ring damage, something that many others cannot boast of. Experts recommend adding them to the oil of cars with high and medium mileage.

Americans constantly delight the four-wheeled (and not only) world with new arrivals. To some extent, the company can even be called an auto pharmacy. Among the latest special products, we should mention such as HG2219 (contains SMT2) for washing six- and eight-cylinder “stomachs” of vehicles. HG2214 is practically the same, but with a milder principle of action, conditioning of the insides of the engine and a small content of “Friction Winner” as an auxiliary active ingredient. And don't forget about rinsing with HG2217. Return to content

Signs of stuck piston rings

- Traction disappears, power drops. The car accelerates poorly and loses power at the slightest load (driving downhill, with a load, etc.).

- Compression in the cylinders decreases. This parameter, as a rule, manifests itself with signs characteristic of the previous paragraph, however, it is possible to accurately establish that the compression has decreased only by taking appropriate measurements. You can check the compression like this!

- The engine does not start well. As a rule, stuck piston rings affect starting, especially in cold weather, when the temperature drops below -5 C°.

- The engine takes oil. Due to improper lubrication and removal of oil, it burns and naturally its consumption increases and the level drops. The derivatives of this phenomenon are blue smoke from the exhaust and a characteristic smell of burning and oil.

Signs of ring wear and their diagnosis

You can find out when oil scraper rings need repair or replacement by using some factors:

- engine oil consumption has become much higher;

- at the beginning of movement or after a short stop - the appearance of bluish smoke;

- leakage and evaporation of oil in caps, sealing gaskets, etc.;

- The color of the leaking liquid also matters: if it is dark, then the seals need to be replaced;

- The next step is to check the spark plugs; if they are dirty, then you need to contact a car service or carry out repairs yourself.

If any signs of wear are detected, the first thing you need to pay attention to is the oil scraper rings. Checking the caps is quite easy. You need to remove the ventilation hose; if the pressure in the crankcase is high, then the caps are out of order.

Causes of stuck piston rings

Poor warming up of a cold engine. Although most modern engine manufacturers claim that there is no need to warm up the power unit, practice shows the opposite. Regular driving on a cold engine, especially when the engine receives heavy loads immediately after starting, leads to engine malfunction. A cold motor that has received a load wears out without proper lubrication and with gaps in parts that disappear only after warming up.

Low quality motor oil. Those who like to save on oil for their engine risk completely ruining the engine. Low-quality oil does not have the proper tolerances, detergent components, and also does not have the necessary fluidity, therefore, it cannot create a dense oil film.

Decarbonization of piston rings

If there are piston rings stuck in the engine, you will one way or another have to find out what piston ring decarbonization is. This procedure can be carried out in different ways, the most popular of which I will describe below.

- Method one . A composition of kerosene and acetone in equal proportions is poured into the combustion chambers through spark plug wells. Next, the motor is given time to oxidize, usually a day or a day, depending on the degree of contamination. After this, the spark plugs are screwed into place, and the engine, after normal warming up, is given a normal load while driving. This could be a highway and good acceleration, during which the engine can “cough up” all the dirt and carbon deposits contained in the cylinders. After completing this procedure, it is necessary to replace the engine oil, oil and fuel filters.

- Method two . In the same way, a special wash is poured into the chambers, which can dissolve carbon deposits and unblock the engine piston rings. There are a lot of different products on the market designed to do this job, so there is no point in naming specific brands. The method of application is approximately the same, but it is still better to follow the instructions for using a particular chemical.

How to determine wear of valve stem seals

All symptoms of wear of valve stem seals, the causes leading to this and diagnostic methods are collected for convenience in the table below.

| Symptom | Reasons for appearance | Consequences | Diagnostic methods |

| Blue smoke comes out of the exhaust | The oil flowing from the cylinder head into the combustion chamber along the valve necks burns together with gasoline and its combustion products color the exhaust bluish. | Oil combustion products form carbon deposits, the rings “stick”, the valves no longer fit tightly and can burn out. If the lubricant level drops below the minimum, the internal combustion engine may fail due to oil starvation. | Start the engine after sitting for 2-3 hours or sharply press the gas pedal to the floor for 2-3 seconds at idle speed with a warm engine. Assess the presence and color of smoke. |

| Carbon deposits on spark plug electrodes, oily threads | Excess oil from the combustion chamber is squeezed out along the threads of the spark plugs, but the O-ring prevents it from coming out. | Spark formation worsens, causing the air-fuel mixture to burn worse, and the engine begins to operate unstably. On injection engines, the ECU sees misfires and tries to eliminate them by changing the size of the injected fuel portion and the ignition timing. Because of this, gasoline consumption increases and traction is lost. | Unscrew the spark plugs and inspect their electrodes, as well as the threads for oiling and carbon deposits. |

| Increased oil consumption | Oil freely penetrates into the combustion chamber through damaged valve seals, where it burns along with the fuel. | Engine performance deteriorates, carbon deposits form in the cylinders, and a critical drop in the lubrication level can be fatal for the internal combustion engine. | Check the lubricant level regularly after reaching a certain mileage mark. Oil consumption when valve stem seals wear reaches 1 l/1000 km and even more. |

| Difficulty starting a cold engine | The oil flowing from the cylinder head accumulates on the valves and pistons and “throws” the spark plugs. Since its ignition temperature is much higher than that of gasoline or gas, and an oiled spark plug produces a spark worse, it becomes difficult to ignite a mixture enriched with lubricant. | The load on the battery increases and its service life is reduced. Candles in oil also work worse, as they quickly become covered with soot. Remains of unburned oil contaminate the catalyst and lambda probes, reducing their service life. | During a cold start, the number of starter revolutions increases until the engine starts. |

| Blue smoke comes out of the oil filler neck | When the valve opens, exhaust gases enter the cylinder head through a worn oil seal and exit through the neck. | The oil becomes saturated with combustion products, which is why it quickly changes its color and loses its original lubricating and protective properties. | Open the oil filler cap with the engine running. |

On a car with a working catalytic converter, there may be no blue smoke from the exhaust, as it burns the combustion products of the oil. If a neutralizer is present, pay special attention to other symptoms!

How can you tell if the valve stem seals are worn out or a problem with the rings?

Diagnosis of wear of valve stem seals is not limited to visual methods. These same symptoms may also indicate other problems, such as stuck or worn piston rings or a malfunctioning crankcase ventilation system. To distinguish signs of worn valve seals from other problems, you need to:

How to determine wear of valve seals with an endoscope: video

- Check compression cold and hot . When the MSC wears out, the pressure in the cylinders is usually normal due to the abundant lubrication of the CPG parts. If the cold compression is normal (10–15 atm for gasoline, 15–20 or more atm for diesel, depending on the compression ratio of the engine), but after a short period of operation (before warming up) it decreases, problems with the caps are possible. If it is low both when cold and after warming up, but increases after injecting 10–20 ml of oil into the cylinders, the problem is in the rings or cylinder wear.

- Remove the breather pipe with the engine running . If blue smoke comes from the oil filler neck, you need to remove the crankcase ventilation pipe leading from the crankcase to the cylinder head (its hole on the head must be covered to prevent air leaks). If the valve seals wear out, smoke will still come out of the neck. If the problem is in the rings or cylinders, smoke will come from the breather.

Blue smoke from the exhaust pipe at startup indicates the presence of oil in the combustion chamber

- Determine at what moments the exhaust smokes . When the valve seals wear out, blue smoke escapes from the exhaust at the time of startup (because oil has accumulated in the combustion chamber) and during re-gas after warming up (because when the throttle is open, oil is sucked into the cylinders). After a few gas passes, the smoke may disappear. If the piston oil scraper rings are faulty, it smokes constantly, and the higher the speed, the stronger the smoke.

- Inspect the valve plates with an endoscope . The engine must be allowed to cool, then unscrew the spark plugs and inspect the valves with an endoscope through the spark plug wells. If the valve seals do not hold oil, it will gradually flow down their journals, forming oil stains on the valve plates and seats. If there is a severe leak of the valve stem seals, droplets of oil may even get onto the piston. If the valves are dry, then the problem is in the rings.

How can I prevent this from happening in the future? Prevention is better than cure!

A number of simple rules should be followed to avoid a similar phenomenon in the future.

- First of all, you should warm up the engine for at least a few minutes, and after starting to move, try to move at minimum speed until the engine reaches the desired temperature.

- Do not skimp and fill only high-quality oil into the engine. Good oil is the key to the success of any mechanism. Using good oil, you can avoid engine problems, as well as avoid the appearance of soot, deposits and other troubles.

- Carry out intermediate inspections. If possible, do preventive examinations from specialists, measure compression in the cylinders, check the condition of the spark plugs, monitor the cleanliness of the exhaust, and also conduct comprehensive computer diagnostics of the power unit and all its systems.

Only this approach will allow you to protect yourself and avoid possible problems with piston rings and CPG. However, even if you had to deal with the problem of stuck piston rings, you shouldn’t be too upset, any breakdown can be repaired, and a car is, first of all, hardware that breaks down regardless of brands and prices. The main thing is to have health and the desire to fix it all. Stay safe and thank you for reading to the end.

That’s all I have, I would be grateful if you share this article on social networks using the special buttons located under the article. Bye everyone, good luck!

Decent care contributes to a significant increase in the trouble-free operation of the vehicle. It is also guaranteed by regular maintenance, vigilant monitoring of the condition of consumables and timely replacement of worn or deformed parts that threaten impending failure.

Regardless of the time the power unit is used, mileage of more than 150 thousand km usually affects its performance, causing significant problems. Among them, we can note the unpleasant situation with the occurrence of piston rings.

Timely detection and immediate elimination of such a malfunction can protect the car owner’s wallet from significant costs for unplanned engine overhauls.

Purpose of piston rings

Among the main key elements that make up the design of power units, pistons are by no means the least important. To maintain their working condition for a long time, it is necessary to maintain high-quality lubrication of the parts. In this case, the combustion chamber must be constantly protected from oil penetration.

The entry of lubricant into the system leads to the formation of carbon deposits, negatively affecting the functionality of the motors. Gases entering the crankcase from the combustion chamber also have a negative impact on the performance of the engine.

Open rings placed on the piston have two types: compression and oil scraper. Their difference lies in the functions they perform:

- The main purpose of compression rings is to protect the crankcase of the power plant from the penetration of gases from the combustion chamber. By compressing and expanding within the limits provided by the designers, they maintain the required pressure in the system. Engine compression rings are usually used in pairs. In this case, the breaks of open elements are positioned relative to each other at 180 0. This placement method promotes better compaction;

- In the design of modern engines there is one more ring, an oil scraper ring. Its function is to protect the combustion chamber from oil penetration.

Separately, we note that special grooves are provided on the pistons for installing rings. Such a device is included by the manufacturers in the design of the unit, providing fairly reliable fixation of the parts.

What to do if the rings wear out?

In order to choose a way to solve a problem, you need to find out why it arose. The occurrence of the above symptoms may be caused by wear or breakage of the compression and oil rings, or if they are coked and stuck.

In the first case, it will be necessary to disassemble the engine and install new parts instead of damaged ones. In this case, you should carefully inspect all mating parts, since if the rings break, scoring may occur, which can only be eliminated by carrying out a major overhaul.

If there is an assumption that the piston and oil scraper rings are stuck, then you can add a special additive to the oil. But this method is used, as a rule, for preventive purposes.

Malfunctions related to piston rings arise in practice quite often. Therefore, in order to prevent serious consequences and, as a result, high repair costs, it is necessary to recognize their first symptoms in time and take appropriate measures.

FEATURES OF OIL RING INSTALLATION

I would like to draw your attention to the installation of oil scraper rings. There should be no problems with compression if you follow simple rules, install them with the inscriptions facing up (inscriptions, dot) and use a special tool.

When installing oil scraper valves, difficulties may arise if there are no inscriptions, or if the expander lock is installed correctly. Let's look at this in more detail. If there are no inscriptions, then it does not matter which side you put the ring on and which one will be on top and which one will be on the bottom (inlaid).

Often errors occur when installing the piston into the cylinder, even if a special clamp is used to tighten the rings on the piston. The peculiarity is as follows. When assembling the oil scraper ring, you should pay attention to the expander lock and the correctness of its docking. For clarity, see the image below.

During compression of the rings on the piston, the lock of the oil scraper ring expander can jump out of the correct position and overlap, gathering in a spiral, so the plates fall through the expander and this will lead to scuffing of the cylinder walls and piston grooves. To avoid this, the tightening clamp should be positioned as shown in the image.

Prerequisites for the occurrence of rings

During long-term operation of the engine, a large layer of soot forms on its elements. This is considered to be the main reason causing the occurrence of rings. And the main prerequisites for the formation of excessive amounts of soot are:

- short driving on an insufficiently warmed up engine. Short distances of 5-10 km are considered especially dangerous;

- various damage to valve stem seals, up to complete failure;

- lubricants of insufficient quality poured into the power unit. It should be noted that oil with the proper level of properties does not burn out in the engine, maintaining the specified initial characteristics;

- The last cause of excessive carbon formation is untimely replacement of lubricant. The manufacturer's recommendations should be carefully followed, limiting the period of use of the petroleum product. Also, do not forget to change the oil filter regularly and on time.

Symptoms of stuck piston rings

First of all, it should be noted that most often the priority occurrence of oil scraper rings is noted, while compression rings are able to maintain mobility much longer without succumbing to coking. The main signs indicating the onset of an undesirable process are:

- unreasonable increase in engine oil consumption by the power plant. The increase in consumption is explained by partial penetration of the lubricant into the combustion chamber, where it is used for waste;

- engine operation is accompanied by the release of blue smoke from the engine compartment. The rationale for this process is the combustion of oil trapped in the chamber. It has been noticed that puffs of bluish smoke become especially noticeable when the crankshaft speed increases under a certain load or after the engine warms up;

- difficulties when starting the power unit when cold;

- the appearance of a noticeable decrease in compression in the cylinders;

- reduction in engine output. The engine is unable to achieve the required power.

Note that the explanation for the last three symptoms is a decrease in the compression ratio of the fuel-air mixture in the cylinders due to insufficient sealing caused by the presence of piston rings. In particularly advanced cases, a burning smell can be clearly felt in the cabin. In such difficult situations, it is impossible to do without replacing the elements in question.

The appearance of any of these signs requires immediate intervention. It is urgent to take measures to decarbonize the rings in order to prevent the occurrence of more significant problems in the power unit.

White or black smoke appears from the exhaust pipe

Let's start with the main types of smoke to better understand the problem. So, white smoke from the exhaust pipe is quite normal for warming up a cold engine. Moreover, it is a mistake to believe that it is smoke. It's actually steam. Water in vapor form is a natural product of the engine.

In an unheated exhaust system, this vapor partially condenses and becomes visible, and water usually appears at the end of the exhaust pipe. As the engine and exhaust system warm up, condensation decreases.

The colder the environment, the denser the vapor produced. At temperatures below 10 ° C, steam is formed even on a well-warmed engine, and in frosty temperatures of minus 20 - 25 degrees it acquires a thick white color with a bluish tint. Air humidity also affects the color and saturation of steam. The larger it is, the thicker the steam.

Note that if steam is visible in the warm season, it is quite possible that this is due to coolant getting into the cylinders. Its shade depends on the composition of the coolant, weather, lighting, and also on the amount of coolant in the combustion chamber. Sometimes it can take on a bluish tint, resembling “oily” smoke. But, unlike oil smoke, which leaves a bluish mist in the air for a long time, steam quickly dissipates.

It is quite difficult for an inexperienced motorist to determine by appearance what is the source of the smoke. In this case, you can use a proven verification method. To do this, on a well-heated engine, it is necessary to briefly cover the cut of the exhaust pipe with a sheet of white paper, while the condensed steam in the form of drops of water, when it hits the paper, will gradually evaporate and will not leave obvious greasy marks.

If this simple test confirms that it is steam rather than oil smoke coming out of the exhaust system, action must be taken to correct the problem that is allowing coolant to enter the cylinders.

Most often, liquid can enter the cylinders through the head gasket due to insufficient traction (in winter, coolant leakage is often observed at the junction of the block and head), burnout, and less often as a result of the formation of microcracks in the head or cylinder block. By opening the radiator cap or expansion tank, it is easy to detect the smell of exhaust gases and a film of oil on the surface of the coolant.

All problems associated with white smoke from the exhaust pipe require elimination of not only the direct causes, but also a mandatory check of systems that can affect their occurrence: thermostat, switch sensor, clutch or fan itself, condition of the radiator, its plugs, hoses or connections. If white smoke and accompanying defects are noticed, then the car cannot be operated, as the defects progress quickly.

- Let's move on. Black smoke from the exhaust pipe indicates an over-enrichment of the fuel-air mixture or a deterioration in fuel combustion conditions. Therefore, we are talking about malfunctions of the fuel supply system. Such smoke is usually clearly visible against a light background and represents soot particles - products of incomplete combustion of fuel.

Black smoke is accompanied by high fuel consumption, often poor starting, unstable engine operation, high toxicity of exhaust gases, and often loss of power due to a non-optimal composition of the air-fuel mixture.

By the way, in carburetor engines, black smoke usually occurs due to overflow in the float chamber due to a defective needle valve or due to coking of the air jets. In gasoline engines with electronic fuel injection, over-enrichment of the mixture usually occurs due to malfunction and failure of sensors (oxygen, air flow, etc.), as well as leakage of injectors. In diesel engines, black smoke appears when there is a malfunction in the high-pressure pump, injectors, or when the injection timing is not optimal.

To carry out accelerated diagnostics, it is also necessary to examine the condition of the spark plugs. Black deposits indicate that there is a need to replace the spark plugs with new ones, and diagnostics and adjustment of the power unit systems may also be required.

Please note that it is the bluish smoke (gray) that is associated with the combustion of motor oil in the engine cylinders. There can be many reasons for this:

- Damage to valve stem seals;

- The occurrence of rings designed to remove residual oil from the cylinder walls;

- Turbocharger malfunction;

- The oil used is of poor quality, etc.;

Now let's take a closer look at the problem of damage to caps and rings. Let us note that smoking and the most common causes of oil consumption are caps and rings.

The purpose of the caps is to retain oil while the valves are operating. Poor quality and malfunction of these elements lead to loss of tightness; lubricant constantly leaks and accumulates in the cylinders.

As soon as the driver starts a cold engine after the vehicle has been idle for a long time, the accumulated oil will burn along with the fuel in the chamber. As a result, blue or blue smoke comes out of the car's exhaust pipe in a cloud.

Wear and sticking of oil scraper rings leads to excess lubricant entering the engine cylinders and subsequent combustion of the lubricant. The use of the ring decarbonization method temporarily solves the problem, but in this case the rings lose their elasticity, and the occurrence may resume. To avoid serious damage to the power unit, it is necessary to constantly monitor the color of the exhaust gases.

With little wear of engine elements, a short-term appearance of blue smoke is observed during cold operation. As the motor heats up, the parts expand, and as a result of an increase in their temperature, the gaps between the mating surfaces of the elements decrease. The entry of oil into the combustion chamber stops, and the smoking disappears.

Decarbonization of rings

So, having recognized the above symptoms, you have discovered that there are compression or oil rings stuck in the engine and you are wondering what should be done first. How can the situation be resolved with the least damage to the affected unit? Let's try to figure it out together!

If the rings are stuck, it is not at all necessary to rush to the nearest workshop or urgently call a specialist, whose services will not be cheap. The problem can easily be fixed on your own.

To do this, it will be necessary to carry out the so-called decoking of the rings, based on the removal of various deposits, such as coke and soot, from the internal space of the combustion chamber. It is the formation of these substances that causes the piston seals to stick, limiting the necessary mobility.

Let's consider the most accessible way to decarbonize the rings yourself, without removing the engine. It involves cleaning the combustion chamber with special compounds. So that you don’t have to rack your brains about how to replace the piston rings later, we recommend using this method.

There is a fairly wide range of such products available on the automotive market. Among the variety of products offered to caring owners of personal vehicles by the chemical industry, a composition called Lavr is in high demand.

However, domestic car enthusiasts are not accustomed to using ready-made products, preferring, in order to save money, to do everything with their own hands from scrap materials.

Let's sum it up

For cars of recent vintage, the cleaning procedure will help get rid of problems with compression, loss of engine power and dark smoke exhaust from the car muffler, or in especially severe cases it will show that a major overhaul is indispensable.

In any case, we advise you, before going to a car service center for major repairs, to try to decoke the oil scraper rings in the engine on your own, using any of the methods described above. This way you can save your money and time.

Also, many motorists have noticed the fact that after cleaning the power unit from carbon deposits, the consumption of gasoline and oil is significantly reduced. In any case, preventative cleaning of the cylinders before changing the oil never hurts. We hope that after reading our article you will no longer have the question of what to do if the rings are stuck in the engine. We wish you good luck and success on the road!

Recommendations for eliminating problems with stuck piston rings yourself

Enterprising Russian owners of personal vehicles have come up with their own cleaning product to remove deposits from the internal space of the cylinders. The following provides step-by-step instructions for cleaning the combustion chamber with a mixture of acetone and kerosene:

- before freeing the rings from plaque and deposits, without disassembling the entire power unit, you must first disconnect all the wires and remove the spark plugs;

- It should be taken into account that proper cleaning of the chamber is only possible if there is a complete absence of oil in the system. Therefore, before starting decoking of the piston rings, the lubricating oil product is drained from the engine;

- then, simultaneously, the working space of all cylinders is filled with a mixture of kerosene and acetone prepared in advance;

- after this, the candles are screwed into place and the cleaning agent is allowed to perform its intended functions. Usually the process lasts for 10-12 hours. It is recommended to diversify the waiting period by regularly cranking the crankshaft a few degrees;

- then the spark plugs are removed again and the cleaning liquid is drained. In order to completely free the engine from the mixture, the engine is cranked with a starter;

- return the drained lubricant to its place. This is necessary to carry out a preliminary check of the quality of cleaning the engine from deposits in the combustion chamber. If after some time of operation of the power unit the symptoms of the occurrence do not appear, the goal is considered achieved;

- At the final stage, all that remains is to change the oil. At the same time, you should not ignore the manufacturer’s recommendations and fill in lubricant that does not correspond to this engine model. The seasonality of the petroleum product should also be taken into account. When updating the lubricant, be sure to install replaced oil filters.

It should be noted that instead of the mixture mentioned above, kerosene is quite suitable as a cleaner. Is that the time of its influence on deposits in the chamber is somewhat extended.