Radiator related problems

The main problems with the radiator can be divided into two groups:

- Antifreeze leaks;

- The radiator becomes clogged with various debris and does not work one hundred percent.

It is quite simple to understand that there are problems with the cooling system; if the engine begins to overheat and the temperature begins to rise above 95 degrees, then the system cannot cope with the load. It is possible that the pipe has ruptured, or the radiator may have leaked. Often, an aluminum radiator is damaged as a result of accidents, stones, or careless repairs, because its honeycombs are quite soft, and plastic elements can crack upon impact. Any coolant (coolant) leak must be repaired if you want to avoid costly repairs to an overheated engine.

Danger of constant coolant leakage

The biggest nuisance is engine overheating due to the inability of antifreeze to effectively remove heat. If the cooling radiator leaks, the cylinder head may change its configuration: in this case, the gasket will inevitably fail. In the worst case, the motor will simply jam, which will result in a major overhaul. A lack of coolant in the radiator is also dangerous for the person himself. If the driver opens the hood while antifreeze is boiling, a breakdown of some CO element is possible, resulting in the formation of a real geyser of liquid heated to a high temperature. If it gets on the skin, a burn cannot be avoided.

Share with friends on social networks:

Telegram

What can happen if there is a lack of coolant?

If the radiator leaks or the pipe ruptures, the following may happen:

- The engine will overheat;

- The cylinder head gasket is deformed;

- When attempting to examine the problem, pressurized liquid may splash into the face, causing burns;

- The engine will seize.

All these troubles can lead to expensive repairs, and damage to health can be irreparable.

What's the result?

As you can see, there are several main reasons why the heater in a car does not heat. If we talk specifically about the tenth VAZ model, the radiator of the VAZ 2110 stove is one of the most serious problems. It’s not even a matter of the cost of the radiator, which is quite affordable, but the need to carry out a whole series of work to remove individual elements to gain access to the radiator.

The main thing is to completely remove all air pockets from the cooling system when replacing antifreeze, and also when removing the VUT to gain access to the heater radiator, to prevent airing of the brake system. If problems with the brakes are noticeable, they must be pumped.

How to fix a radiator leak

One of the reasons that your car radiator is constantly leaking may be a broken radiator cap. Due to old age, the radiator cap may not hold pressure, as a result of which the antifreeze in the system will constantly evaporate. This problem is often invisible to the eye and although the entire system is in order, the antifreeze disappears somewhere. You should replace the cap with a new one and check the antifreeze level after some time. If the level is normal, then the problem is solved.

Radiator fluid often disappears due to wear and tear on the rubber hoses. This is easy to notice by the traces of smudges on the hoses. Such pipes are recommended for replacement, since their repair is not advisable.

The most problematic option is when there is a leak in the radiator itself. Often in such cases, repairs do not help. If there is a large crack in the radiator, it is immediately noticeable by steam and coolant splashes. A large hole can only be repaired in a garage or auto repair shop. Copper or brass can be soldered, aluminum can only be welded with argon. You should know that such repairs are unreliable and even a service station will not give you a guarantee for more than a month.

Causes of leaks

There are not many of them and they are all conditionally divided into several groups, which are worth considering in more detail:

- Natural wear and tear. First of all, this refers to corrosion processes that, over time, destroy thin radiator tubes and form leaks. But sometimes the cause of failure of the structural elements of the radiator can be small scratches, dents, chips, which turn into corrosion spots.

- Mechanical damage. They usually occur after a head-on collision. Even a small defect in the bumper or decorative grille can be enough to cause the radiator to leak. The second point is sloppy installation work, during which the honeycombs of the product and its tubes were carelessly damaged.

- Loosening of fastenings. It can happen over time due to vibrations or during repairs, when an inexperienced car enthusiast simply forgets to properly tighten one or another clamp on the pipe.

- Wear or defect of the expansion tank (radiator) cap. In this case, the pressure created in the CO will push the antifreeze through the bad cap. This can be determined by the traces of coolant around the filler neck.

All of the above reasons lead to the formation of a coolant leak. Moreover, in some cases (for example, with corrosion), it is quite difficult to detect it right away. In such a situation, you need to drain the antifreeze and remove the radiator. Further:

- Close all its openings with suitable plugs.

- Place the product in a large container of water: escaping air bubbles will indicate the location of the leak.

Article on the topic: Instructions: How to flush the engine cooling system with your own hands

There is another method for locating the leak if the method described above did not help. To do this, you will need a special kit that includes an introductory gun, an ultraviolet lamp and a fluorescent additive. Add it to the cooling system and check all CO elements, including the radiator, with a lamp: leaks will glow. But all this can be checked under stationary conditions, but what to do if the radiator leaks while on the road?

How to fix a car radiator leak using cold welding

Cold welding is often used to seal small cracks. It should be applied to a cleaned surface from which all contaminants must be removed. When the weld hardens, the crack will be sealed. Such repairs are not very reliable, since under the influence of high temperatures, cold welding loses its properties and becomes colored.

Some car owners, when their radiator is leaking, use “folk” methods to fix the problem. For example, they add dry mustard, which swells due to temperature and covers the cracks with its particles. Such repairs may result in large repair costs in the future. The channels, every thin tube, and even the coolant drain valve will become clogged. A faucet is essential when replacing a radiator, especially if you plan to do it yourself. A clogged tap will prevent you from draining the coolant and there will be problems with replacement. It’s better not to take risks and not use mustard, but to get to the repair site by constantly adding antifreeze.

If the radiator is leaking. What to do

If the radiator leaks on the road, and it’s still a long journey to the workshop, remove the safety valve from the radiator cap, which will reduce the pressure in the radiator to atmospheric pressure, as a result the leak will at least decrease, and may disappear completely if the crack was small.

With a small leak, special sealants may well help, fortunately there are a lot of them on sale now and it is better for the car owner to have some in the trunk.

Sealants are divided into two types: liquid and solid plastic . In composition, they are epoxy resin with various fillers and additives, which can glue various surfaces, of course not like traditional welding, but if the surfaces are well prepared for the gluing process, the result is very good.

Liquid sealant consists of epoxy resin and hardener, which are mixed when used. The use of liquid sealants is not difficult; just pour the contents from the container into the radiator or coolant reservoir and this composition will reliably eliminate leaks in the cooling system in general or the radiator in particular. The sealant is not subject to evaporation, is able to prevent refrigerant leakage in the future, since it remains in the cooling system, and is inert to all materials with which it can interact, steel and rubber, plastic, cast iron and non-ferrous metals and their alloys. It does not interact with all coolants currently in use.

Sealants harden only in areas of leakage and do not clog radiator pipes. They are effective for small holes; manufacturers' recommendations indicate sizes up to two square millimeters.

The principle of their operation is to interact with atmospheric air, transition from the liquid phase in which they are in antifreeze, to the solid phase, hardening and the formation of a solid film around the crack, sealing it.

After applying sealants, the system must be flushed to avoid clogging of the cooling system passages.

Repairing a cooling radiator using sealant

Leaking car cooling radiator - elimination

You can hear many stories about how car owners ruined their car engine due to the use of sealant. Often these stories are not fiction. So what should you do, use sealant or not? In fact, high-quality sealants cannot damage the engine; many people simply buy cheap analogues or fakes. It is also extremely important to choose the type of sealant that will help in your case. A properly selected composition will restore the tightness of the cooling system.

Types of sealants

There are three types of sealants:

- Powder;

- Liquid;

- Specialized.

Each of these types can cope with routine radiator repairs, but you need to choose them taking into account the size of the crack or hole.

Powder sealant is the cheapest. Often, instead of a specialized powder, car enthusiasts use mustard, which is not recommended. The powder is simply added to the antifreeze if your radiator is leaking. The main disadvantage of using powder is that it severely clogs the radiator channels and tubes.

Liquid sealant is made with the addition of polymers. These sealants can most often be purchased at car dealerships and gas stations. Metal particles are added to it. Liquid sealant clogs the cooling system much less, the main thing is to choose a quality product and not run into counterfeit products.

In addition to polymers, a specialized sealant also contains fibers, due to which it copes with larger damage. Of course, this is the best option among sealants, the only problem is its high price.

It is necessary to understand that the use of sealant is not a solution to the issue of radiator repair, but will only help to get to the place of global repair if the elements of the cooling system are leaking.

How to use sealant

Brief step-by-step instructions:

- Wait until the antifreeze cools down;

- Open the radiator cap;

- Pour sealant into antifreeze;

- Start the engine for a few minutes;

- Shut down and visually check the system for leaks.

If the damage was minor, the seal should be restored. When using low-quality sealants, you can clog the radiator with particles, damage the pump, disrupt the operation of the thermostat, and cause many more problems with the car. To avoid them, carefully study the information on the packages, look at the protection system and all kinds of holograms. When using, carefully follow the instructions included with the sealant. The main thing to remember is that the system with sealant must be restored in the near future.

To avoid major repairs, you should regularly check the cooling system for the slightest malfunctions and leaks, change hoses and pipes in a timely manner, and monitor the temperature of the antifreeze during operation. Also, do not forget to change the antifreeze, as over time it loses its properties, which can lead to problems with the entire system.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

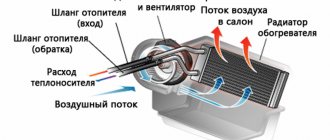

Design and operation of the radiator

This product performs the function of a heat exchanger. The cooling process is carried out due to the circulation in the system of a special non-freezing liquid - antifreeze using a pumping device - a pump (water pump). Connecting pipes with a relatively small diameter are also actively used. And, as you know, it is much easier to cool a small volume of liquid. In order for air flows to more actively influence the heated radiator, a fan is installed in front of it, which turns on at a certain temperature. The design of the radiator is simple:

- upper tank: serves to receive hot antifreeze entering it, has a neck with a plug (sometimes there is none and antifreeze is poured through the expansion tank), equipped with an air and steam valve, a steam outlet tube and a temperature sensor;

- core: made of flat tubes “wrapped” with thin (almost like foil) plates of copper or aluminum that conducts heat well, less often steel;

- lower tank: necessary for receiving cooled antifreeze, connected to the outlet pipe, sometimes equipped with a drain valve.

Types of cooling radiators

The differences between these products mainly lie in the design of the tubes, tanks and material of manufacture. In the latter case, copper or aluminum is used. The second option is the most common due to the light weight of the products and the better rigidity of the metal compared to Cu. This allows the production of single-row radiators and wider tubes: they can be with a round or oval cross-section. The former are used less and less, because they have an aerodynamic “shadow”: a zone behind the tube where cold air does not penetrate. The most common radiators installed on cars include:

- tubular-tape aluminum (brazed);

- copper-brass tubular: used in trucks and special equipment;

- aluminum, consisting of plates and tubes;

- copper-steel (outdated design): here the tubes are strung on lamellas.

How to diagnose a heating system in Kalina?

Before performing a diagnostic procedure, you will need to carefully study the diagram. You should only try to check while the engine is running.

- The temperature regulator, located on the control unit in the cabin, is installed in the extreme left position. We activate the fan and observe hot air entering the cabin through the deflectors. Gradually moving the handle to the right until it stops, we reach the exit of the cold air stream.

- Checking the speed should begin by setting the appropriate knob to the minimum speed position. If the fan and its control module are working properly, then the force of the air stream should increase as the handle is moved to subsequent positions (and so on until the 4th speed mode, corresponding to the maximum number of revolutions).

- We check the dampers. Here we move the temperature level regulator to the maximum to the left position. We move the fan speed switch to the position corresponding to the 4th speed. The check itself boils down to smoothly moving the damper regulator between the extreme positions. This should be done in order to feel the adjustment in the direction of flow. By moving the temperature regulator to different positions, we observe a change in the degree of heating of the incoming air.

Solving broader problems

Radiator or pipe leaks cannot always be eliminated using simple, accessible methods. In some cases, this will require the use of specialized cold welding.

This is a special substance that, in fact, works like a very reliable glue. Metallic substances are additionally introduced into its composition, which are an excellent binding material.

Today on the market you can find both cold welding, produced in the form of powders, and a ready-made version. Of course, on the road it is better to have an option ready so that you can immediately use it for its intended purpose.