Installation of ignition ZMZ 417 by marks

Hi all . In general, the problem is this: they removed the distributor along with the drive and rotated the elbow a couple of times, but they did not put any marks on where the distributor was located and where the slider was directed.

I tried to set it according to the book, but either I’m doing something wrong or there’s some other problem, that is, it won’t start.

The distributor was set as follows: = placed the mark on the crankshaft pulley opposite the protrusion (pin) on the engine crankcase. OPTION 1: the piston of the first cylinder is at the top (the first cylinder is the one that is closest to the engine cooling radiator). There is a GAP on both valves of the first cylinder

. I set the distributor so that the slider looks at the first cylinder (look from the radiator). The slider is obtained between the two contacts of the distributor cover. I tried installing the spark plug wire for the first cylinder both before the runner and after the runner. The spark plug wires are connected to the distributor cap as cylinders 1-2-4-3 (count from the radiator)

OPTION 2: I turned the crankshaft another 1 revolution to match the marks on the engine crankcase and on the crankshaft pulley and tried the same thing again:

The piston of the first cylinder is at the top (the first cylinder is from the engine cooling radiator). There is NO CLEARANCE on both valves of the first cylinder

. I set the distributor so that the slider looks at the first cylinder (from the radiator). The slider is obtained between the two contacts of the distributor cover. I tried installing the spark plug wire for the first cylinder both before the runner and after the runner. The spark plug wires are connected to the distributor cap as cylinders 1-2-4-3 (count from the radiator)

Result: the engine does not start.

I read that the distributor slider should look specifically at the first cylinder.

If the slider is placed specifically on the first cylinder, then the contact of the slider in both the FIRST and SECOND variants is between the two contacts of the distributor cover, and if the slider is placed a little forward clockwise, then it is between the first and second cylinders.

In general, there are 4 settings: 1. the piston of the first cylinder is at the top. There is a gap on both valves of the first cylinder. The slider is for 1 cylinder.

2.piston of the first cylinder is at the top. There is a gap on both valves of the first cylinder. The slider is located between the first and second cylinders.

3. piston of the first cylinder is at the top. There is NO CLEARANCE on both valves of the first cylinder. The slider is for 1 cylinder.

4. piston of the first cylinder is at the top. There is NO CLEARANCE on both valves of the first cylinder. The slider is located between the first and second cylinders.

[B] IN THREE OF THE FOUR SETTINGS THERE WERE CHANGES: in one setting the engine seemed to jam sometimes when I turned the starter, as if the engine was recoil in the opposite direction, and in the other setting there were shots in the muffler. in the third setting the engine started but did not develop power, it smoked thick white smoke and as soon as you let off the gas it immediately stalls, and in the fourth setting the starter turns it stupidly and no changes occur. /B]

I don’t remember what setting I used and how the slider was set; I spent the whole day fiddling around and didn’t do anything, I just tried different options and didn’t remember where and how it worked.

When the engine was previously assembled after capitalization, there were also some problems with setting up the distributor, but not for so long. The engine was overhauled 2 years ago and I no longer remember how I did it.

Friends, tell me what I’m doing wrong and how to correctly place the slider on the first cylinder when there is a gap on the valves or when there is none (the mark on the crankshaft pulley was placed opposite the protrusion on the crankcase)?

source

UAZ 3303 Camel › Logbook › Engine repair, Installation of camshaft drive.

The camshaft, crankshaft and connecting rods are installed. We bring the connecting rod of the first cylinder to the top dead center TDC. If the pulley is not installed, then look at the camshaft. The lobes on the camshaft should be visible. If the cams are not visible, then this is a working stroke.

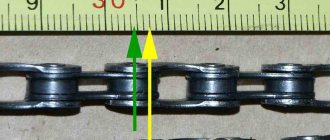

It’s easier on the pulley: with the piston positioned at the top, the second mark along the pulley’s direction must match. The first, as in the photo, is the ignition installation.

Next, install the gasket and distributor drive according to the instructions.

We install the oil pump, washed from grease. Remove the mesh and fill the oil pump full of oil through the intake hole. We install the grid.

We straighten the dented pallet.

We install cork seals. cut off with a small margin of 2-3 mm.

We install the pallet. The bottom of the engine is assembled.

From the collection of “best practices”...

When installing the rear cover of the pushers, I encountered a problem: between the pin and the distributor drive, the cover did not fit. “Praise to the designers! Smart guys." Well, the idea came to remove the distributor drive. Installing the distributor drive was a complete dead end. During installation, the drive did not enter the oil pump. There was no oil pressure, and even when cranking the starter, a metallic clicking sound was heard (the drive was touching the block).

Next, it was necessary to drain the oil and remove the pan. Then, install the drive, pan and fill the oil again.

The reason was found: play in the drive (it “swings”, deviates from the longitudinal axis, not falling into the groove of the oil pump).

To secure it, I inserted wooden wedges. Later, they fall off on their own and are removed when the oil is changed. I turned the groove of the oil pump into the desired position using a cleaning rod. The distributor drive was easily inserted.

More “advanced users”, in this case, simply unscrew the pin, install the cover, and then the pin. But, without beer, I didn’t realize. “And experience, the son of difficult mistakes...”

Drivers, sometimes who have just received their license, enter the army. Little driving experience. In repair and maintenance, even less. The drives were “pushed” as best they could: both 180 degrees and 90. The position of the gears was incorrectly set. And, since there were also lazy people who didn’t want to rearrange... They went to the “grandfather”, and he set the TDC and threw the wires of cylinder 1 to the one where it fell. Further, in a circle. So the whole unit drove without problems, some with 3, some with 4...

source

Review of SZ on famous UAZs

What is the connection diagram for electronic or contactless ignition on a UAZ 417, how to convert contact ignition to contactless? Why does the coil heat up and how to adjust and adjust the advance angle? First, let’s look at the main points regarding the action and types of SZ.

Operating principle of SZ

Contact system diagram

The ignition system, or rather its correct setting, plays a big role in the operation and starting of a car engine. With correct adjustment, the combustible mixture will burn correctly in the power unit as a result of the supply of charge through the spark plugs. A spark plug is placed on each cylinder of the UAZ engine, each of which is turned on in a certain order, in turn, delivering a discharge to the cylinder after a certain time. It must be taken into account that any SZ makes it possible not only to deliver the required discharge, but also determines its strength.

Due to its technical characteristics, the car’s battery cannot produce the voltage and current required to ignite the mixture. This is due to the fact that the battery can only produce a current of a certain strength. And thanks to the correct operation of the system, the current value increases significantly, which allows you to successfully ignite the air-fuel mixture.

The operating principle of the system consists of several stages:

- First, the driver inserts the key into the ignition and turns it, electrical energy is stored in a coil.

- Then the coil converts the low-voltage voltage in the on-board network of 12 volts into high-voltage. As a result, the voltage value increases to 30 thousand V.

- After this, the discharge is distributed and supplied to one or another spark plug.

- The candle itself produces a spark that ignites the mixture.

Diagram of the UAZ contactless system

What types of SZ are there?

Domestic UAZ vehicles can use one of three ignition systems; let’s look at each of them in detail:

- Contact view. This type of SZ is outdated, however, it is used on most machines. In such a system, the principle of operation is to issue a certain impulse that is formed in a distributor - a distribution device. The contact system is considered one of the simplest in terms of design, which is an advantage, since if a malfunction occurs, the car owner will be able to independently check and repair the system. In addition, prices for structural parts of the contact system are usually affordable, which is good news. The contact SZ includes a coil, a switchgear, a breaker, a capacitor and spark plugs.

- Non-contact type, also called transistor type. Compared to the contact system, the contactless system has more advantages. The resulting spark has a higher power, which is achieved due to the formation of high voltage in the secondary winding of the coil. Also, contactless systems are equipped with an electromagnetic device, which makes it possible to achieve more stable operation of the engine. Ultimately, if the UAZ power unit is configured correctly, then by using a contactless system you can not only increase its power, but also achieve fuel savings, albeit insignificant. Also, such systems are easier to maintain. One of the main nuances in terms of maintenance is the need to periodically lubricate the distributor drive - at least every 10 thousand kilometers. One of the main disadvantages is the difficulty of repair. In practice, repairing a contactless SZ will be problematic, since diagnosing the system will require equipment that is usually available at a service station.

- The ignition system can also be electronic. This option is currently considered one of the most progressive and expensive; it is installed mainly on new cars. Compared with contact and non-contact systems, the electronic system has a more complex structure. The main advantage of this system is that, if necessary, the process of adjusting the ignition angle will be much easier. In addition, there are no contacts in the electronic system that are susceptible to oxidation. It should also be noted that in practice, the combustible mixture in the cylinders of a power unit with an electronic system almost always burns completely. But despite all the advantages, electronic repair systems also have their disadvantages, which relate to device repair. It is almost impossible to repair such an SZ with your own hands, since to perform this task, again, you will need equipment (video published by Nail Poroshin).

Engine Modifications

Trying to eliminate the shortcomings, the designers constantly refined and corrected the unit. As a consequence, fixation of changes led to the appearance of modifications of the model, the performance characteristics of which differed.

The base engine “4218.10”, which became the basis for the rest of the modifications, had a defect due to which coolant penetrated into the oil through aluminum pores. It was not possible to eliminate the defect by replacing seals and gaskets. The designers used the technology of impregnating the frame with resin, after which the defects disappeared, and the modification received the marking “421.10”.

In order to increase the impulse at lower speeds and the power of the unit, an improved resonator was supplied to the product and the compression ratio in the combustion chamber was increased. Modification “421.10-30” after modification is installed on the Gazelle car. The same engine with a modernized power supply and exhaust gas removal mechanism is marked as “4215.10-30”.

In order to reduce fuel costs, UAZ engines used for buses and trucks began to be converted to fuel with a lower octane number “A-76” (“4215.10-10”).

The appearance of the UAZ 421 engine injector, which was intended for installation on vehicles with all-wheel drive, led to the creation of a new modification “4213.10”. A special feature of the engine is the use of a cast iron camshaft, which made the modification stand out in comparison with a carburetor product. The same motor with a modified fan drive was installed on the Gazelle, product identifier “4216.10”.

Types of UAZ with carburetor (421...):

Frequency of motor monitoring and adjustments

When calculating the power plant, the designers determined the operating life of the unit at the level of 250,000 km. To achieve the specified period, the following is configured and adjusted:

Replacing the oil filter:

The same deadlines for the work are observed after the overhaul, regardless of how many manipulations are performed. For engines running on gas and gasoline, seals are replaced more often. You can also read about the UAZ Patriot Razdatka.

General concept

The contact ignition circuit itself is not bad, because humanity has been using it since the advent of the first car. But, of course, it is far from the capabilities of contactless ignition. Therefore, many UAZ owners, in an effort to improve the performance of the power unit, reconfigure it.

General ignition circuit for older UAZ models

And not only UAZs, but also other domestic cars, for example, the wiring of the Moskvich 2141 and a number of other brands and models are subject to alterations.

Effect of modernization

What is important is that the engine compartment and interior electrical wiring of the UAZ 31514 remains virtually unchanged, and the alteration itself is characterized by the installation of new elements under the hood.

As a result:

- The engine begins to operate stably in all modes;

- Improves cold starting;

- Fuel consumption is normalized;

- The engine power will reach the passport data.

Differences between ignition systems

The main difference between the two systems is the moment of sparking:

- In classic ignition, a slider under the distributor cover is responsible for this when it comes into contact with the output contact on the spark plug wire. In this case, the supply of a high-voltage pulse occurs with an increase. It seems to be lubricated, reducing the spark power at the spark plug electrodes.

- In contactless ignition, the switch generates a charge and releases it almost instantly upon receiving a signal from the Hall sensor. As a result, the candle produces a more powerful spark. Among domestic off-road vehicles, the Niva has a similar contactless ignition system - see the VAZ 21213 wiring diagram.

The electronic switch is often mounted in UAZ vehicles on the partition on the left side

Note! More powerful sparking promotes self-cleaning of the spark plug, because The fuel burns intensively, leaving no deposits.

Read more: Cost of servicing Opel Astra

Expert recommendations on how to configure correctly

So, how to set the advance angle yourself in order to achieve proper operation of the UAZ engine:

- First of all, you must lock your car in one place by pulling the parking brake lever. Rotate the crankshaft so that the piston of cylinder 1 reaches TDC (top point). In this case, you need to ensure that the hole on the crankshaft pulley coincides with the mark marked on the timing gear cover.

- After this, remove the cover from the distribution mechanism. After dismantling, you will be able to see the slider, which is located inside the cover itself, opposite the contact. If there is no slider, you should turn the crankshaft 180 degrees again, and then set the octane corrector to 0. Using a wrench, you will need to screw the pointer to the distribution mechanism housing so that it aligns with the middle mark. When these steps are completed, the fastening bolt with which the plates are attached to the distributor body must be loosened slightly.

- Then, holding the slider in one place with a finger to prevent it from rotating, you need to carefully rotate the housing itself, this will allow you to remove possible backlash in the drive. The housing must be rotated until you achieve alignment of the sharp end of the stator mechanism petal with the red mark located on the rotor device. After this, the plate itself must be secured to the body using the appropriate bolt.

- Once you have completed these steps, you need to replace the controller cover and check the high voltage cables. You need to make sure that these wires are installed in the correct sequence, taking into account the firing order of the cylinders. When you manage to correctly adjust the lead angle, you need to make sure that the entire procedure was performed correctly.

- To diagnose the correctness of the actions performed, you need to start the engine of your UAZ and wait about 5-10 minutes until the power unit warms up. The operating temperature of the engine is about 90 degrees; you can wait until the internal combustion engine warms up to 80 degrees. Then you need to drive onto a flat road and accelerate the car to 40 km/h, after which you should sharply press the gas. At this moment, the car will accelerate and if, when the speed increases to 60 km/h, a short-term detonation (metallic knock) is heard from under the hood, then this indicates that all actions were performed correctly. If the detonation is too long, the system will need to be adjusted. To do this, the housing of the distribution mechanism will need to be turned one notch or half, and it must be turned counterclockwise. If the diagnostics showed that there is no knocking of the “fingers” at all, then the advance angle should be increased. To do this, the mechanism should be turned in the opposite direction.

Photo gallery “How to adjust correctly”

Engine Description

The UAZ-421 engine has been produced at the plant in Ulyanovsk since 1993. The motor is used for installation on UAZ cars: “469”, “Bukhanka”, “Bars”, “31519”, “Hunter”, etc. The designers decided to replace the outdated “417” unit with a motor, introducing new trends into it.

Thus, an original design of an aluminum frame was used, in which dry liners with thin, cast-iron walls are filled. This made it possible to increase the cross-section of the chambers to 100mm, and leave the same size between the cylinders, 116mm. The solution had a positive effect on the service life of the unit, since rigidity increased and the tendency of the cylinders to become “oval” during operation decreased.

The changes affected the piston; the distance between the bottom of the displacer and the pin axis was reduced by 7.5 mm, which reduced the weight of the product. In addition, the length of the connecting rod has increased by 7 mm, reducing the force on the side surface.

Since the distance between the axes of the chambers remained unchanged, most of the components of the “417” and “421” power plants remained mutually interchangeable. The unification affected the cylinder heads, part of the chamber volume was transferred to the piston bottom, in the form of a cone. This increased the volume of the combustion chamber by 12 cm3.

The engine uses a disposable oil filter element, borrowed from the VAZ-2101. The rear crankshaft oil seal is made as a full rubber seal, rather than stuffed with cord.

The negative aspects of the UAZ-421 engine are insufficient quality of components, and increased fuel consumption. Fitting causes frequent leaks of liquids, and surface treatment affects the resource and potential of the unit.

A guide to replacing a distributor with an oil pump drive

Before installing a new distributor with a drive, you need to weigh your strengths, since it is not recommended to make mistakes when performing work.

So, how to replace and install the distributor:

- Turn off the ignition and remove the distributor cover; the tips and high-voltage cables are connected to it.

- Then you need to disconnect the wire connected to the switch from the distribution mechanism. You also need to disconnect the pipe connected to the vacuum regulator.

- Taking a 13mm wrench, unscrew the two nuts securing the device and remove the mechanism along with the oil pump drive from the power unit.

- After completing these steps, you will be able to see the gasket located under the drive. If as a result of these actions the position of the crankshaft has not changed, then simply install a new mechanism, making sure that the slider is located opposite the mark. All actions are performed in reverse order. When the installation is completed, the advance angle is adjusted.

- If, as a result, the location of the shaft has changed, then before installation it is necessary to move the piston of cylinder 1 to top dead center. You need to ensure that the marks on the pulley align with the pointer on the motor itself.

Finding the ignition moment in the ignition

On engine 402, ignition adjustment occurs according to the following algorithm and order:

- The crankshaft occupies a spatial position corresponding to 5 degrees of advance in ignition of the fuel mixture;

- This position can be easily achieved by aligning the mark on the pulley with the recess on the motor block;

- The coincidence means that the power plant has marked the end of a full piston stroke.

With the distribution sensor removed, adjustments are made as follows:

- I remove the spark plug from the head of the combustion chamber of the cylinder, which is listed as No. 1 in the order of fuel ignition;

- I cover it with a sheet of paper and turn the engine crankshaft;

- The air pushed out by the piston blows off the sheet, which indicates that it has reached the vertical maximum, from which the stroke begins;

- Then, using the keys, I set the octane corrector scale to 0.

Blog about UAZ

After checking and adjusting the elements of the ignition system, check that the ignition timing (sparking) is set correctly. This is very important, since the fuel efficiency of the UAZ engine largely depends on it.

Checking and setting the ignition timing on a UAZ engine using a test lamp or strobe light, what to do if the engine stalls after turning off the starter.

With an early ignition timing, the working mixture will burn before the piston reaches top dead center and the resulting gases will inhibit further upward movement of the piston. With late ignition, the working mixture will burn during the downward stroke of the piston, and the gas pressure on the piston will quickly drop.

In both cases, engine power decreases and fuel consumption increases. To prevent this from happening, periodically check the ignition timing. It is advisable to do this every time the vehicle is serviced. Checking and adjusting the ignition timing can be done in two ways: using a test lamp or using a strobe light.

Checking and setting the ignition timing on a UAZ engine using a test lamp.

When checking the ignition timing using a test lamp, do the following:

— Connect a test lamp in parallel with the capacitor. — Turn the crankshaft of the UAZ engine using the starting handle until the rotor spacer plate approaches the contact of the distributor cap connected to the spark plug of the first cylinder. — Turn on the ignition and slowly crank the engine until the warning light comes on.

In this case, the ignition timing marks on the pulley and the timing gear cover must match. If the warning lamp lights up before or after the marks coincide, it means that the ignition timing is set incorrectly.

Adjusting the ignition timing on the UAZ engine.

To adjust the ignition timing, do the following:

— Set the octane corrector nut to zero. — Rotate the engine crankshaft until the ignition timing marks coincide. The rotor spacer plate should be directed towards the contact of the first cylinder in the distributor cap. — Loosen the nut securing the distributor and turn it in one direction or the other until the lamp lights up. — Tighten the distributor fastening nut. — Check that the ignition timing is set correctly two or three times, aligning the ignition timing marks and noting that the control pump lights up. — Put on the distributor cap and check that the high-voltage wires are installed correctly in the distributor cap.

The terminal in the cover, against which the rotor spacer plate is located, must be connected with a high-voltage wire to the spark plug of the first cylinder. As a rule, this terminal has the number “1” on the distributor cap. The remaining wires must be connected to the spark plugs in accordance with the operating order of the engine cylinders, that is, 1-2-4-3, taking into account the direction of rotation of the rotor.

After each adjustment of the ignition timing, check that it is optimal when driving the car with a well-warmed-up engine. At a speed of 40-50 km/h, sharply press the carburetor throttle control pedal - the gas pedal. At this time, light detonation knocks should appear for a short time (1-3 seconds).

If knocking sounds are heard for a longer period of time, this indicates an early ignition timing. If knocking does not appear at all, then the ignition timing is set late. Correct this moment using an octane corrector. Where it is not there, make adjustments by changing the ignition timing setting by turning the distributor housing.

Adjusting the ignition timing using an octane corrector or turning the distributor housing.

If the ignition timing is early (strong detonation), turn the octane corrector nut clockwise (towards the “-”), and if the ignition timing is late (no detonation), turn it counterclockwise (towards the “+”). After adjustment, check the optimal ignition timing when the vehicle is moving.

Setting the ignition timing by turning the distributor housing.

Some drivers adjust the ignition timing not with the help of a control lamp, but by turning the distributor housing to achieve maximum engine idle speed. Of course, this ignition installation is very simple. However, it provides the correct ignition timing only for one engine operating mode - idle mode.

In other modes, engine performance deteriorates, which ultimately leads to increased fuel consumption. Therefore, do not be tempted by the simplicity of this method. It’s better to spend a little more time, but be sure of the normal operation of the UAZ engine ignition system.

Checking and setting the ignition timing on a UAZ engine using a strobe light.

The second way to set the ignition timing is using a strobe light. It allows you to do this more accurately, and at the same time check the operation of the vacuum and centrifugal machines. Checking the ignition timing and adjusting it using a strobe light is quite simple. Connect the device to the UAZ ignition system, start the engine and set the crankshaft speed within 800-900 rpm.

Direct the light of the strobe lamp at the engine crankshaft pulley so that it also illuminates the ignition setting marks. Since the flashes of light from the strobe lamp occur synchronously with the appearance of a spark between the electrodes of the spark plug of the first cylinder, the crankshaft pulley mark appears motionless and if the ignition timing is set correctly, the marks will coincide.

If the marks are offset relative to each other, then ensure they coincide by turning the distributor body. The ignition timing can be set and adjusted without stopping the UAZ engine, which significantly reduces the time for its regulation.

Checking the capacitor of the UAZ ignition system.

The serviceability of the capacitor can be checked using a regular 220 V alternating current network. Connect the capacitor being tested to the network in series with a 15-30 W lamp for a short time. The lamp will not light up, since the current in the circuit is small. After disconnecting the probes, bring the tip of the capacitor conductor to its body.

If a spark discharge occurs, then the capacitor is working. Check the capacitor 3-4 times. If the capacitor is broken, then there will be no spark, and if there is a short circuit in it, then when it is plugged into the network, the lamp will light up.

What to do if the additional ignition coil resistor is faulty and the engine stalls after the starter is turned off.

The reason the UAZ engine stops after turning off the starter is the failure or unreliability of the connections of the additional ignition coil resistor. In order for the engine to operate normally, short-circuit the terminals “BK” and “B” of the coil with an additional conductor. This is a good way out, but try to quickly find and replace the additional resistor with a new one, otherwise the ignition coil will fail after a while.

Setting the Ignition Timing on Your Harley

Check ignition timing:

At every 5,000 mile (8,000 km) service interval. Check the correct RPM and Ignition Timing is as follows:

1. See Figure 0. Thread the TIMING MARK VIEW PLUG (Part No. HD 96295-65D) into the timing check hole. Be sure to look at the plugin, it does not touch the flywheel.

1a. See Figure 1. Find the correct evaluation time for your engine. If a shop manual is not available, remove the spark plugs, crank the engine until the front piston is at TDC on compression, press and identify the TDC mark on the flywheel.

2. Connect the INDUCTIVE TIMER leads to the front spark plug cable, battery positive terminal, and ground.

3. Make sure the vacuum hose is properly installed on the carburetor and on the vacuum electric switch (V.O.E.S.).

4.Start the engine. Set the engine speed by turning the idle speed screw clockwise to increase speed or counterclockwise to decrease speed.

What to buy

In fact, you don’t need to buy much, and if you have a working distributor and reel, then the list of purchases will be minimal.

So, you need to buy:

- Hall Sensor;

- High-voltage wires (preferably silicone);

- Switch from VAZ 08.

Advice: If your UAZ is already many years old, then we recommend that in addition to the already indicated list, you buy a new distributor, a coil, and you will also need UAZ 31514 wiring with connectors for the switch.

For reconfiguration and operation, you will also need a new UAZ 31514 wiring diagram, which is shown in the photo below, and which you can print for convenience.

For a new ignition - a new circuit

You can also make your ignition system more powerful by upgrading it with two kits at once:

- Two switches;

- Two Hall sensors;

- Two ignition coils.

With this approach, each subsystem will be responsible for sparking 2 cylinders at once:

- First and third;

- Second and fourth.

Most often, UAZ cars that take part in competitions or are used by professional fishermen and hunters are subjected to such serious modifications. The video below shows how an engine works with such a system.

Advice: if you use your UAZ 31514 in everyday life, not related to extreme sports, then it is enough to limit yourself to alterations with one set - it’s easier to maintain it. After all, domestic all-terrain vehicles use a proven UAZ wiring diagram.