The power steering pump is designed to pump oil into the steering mechanism and ensure fluid circulation in the system. During rotation, the pump shaft and blades create a centrifugal force, as a result of which the working fluid enters the discharge cavity under high pressure and then into the power steering system. The power steering pump is mounted on the engine and driven by a belt drive.

As a rule, replacing the power steering pump is carried out in conjunction with changing the oil, clamps and hoses. In this article we will look at how to perform this procedure with your own hands using the example of a VAZ-2110 car.

Preparing to replace the power steering pump

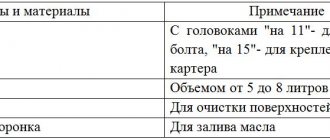

For work, you should prepare the following tools and materials:

- jack and wheel chocks;

- pliers and socket wrench 10;

- plastic container 1.5 l;

- rags and hose for draining liquid;

- bulb or syringe;

- new fluid, hoses, clamps, power steering pump;

If you decide not to replace the pump, but simply change the cuff and bearing, then these spare parts will be needed.

Disassembly and self-repair of power steering

For different brands of cars, manufacturers use hydraulic boosters that differ in design, so there are some features to restore the functionality of this unit. However, there are similar problems that can be eliminated using the same methods.

Removing wear and tear using a drill and sandpaper

At the same time, it is worth assessing the risks associated with the fact that when working independently, the chance of further breakdown of this product increases. It is worthwhile to reasonably assess your capabilities, because some work can be carried out by a more experienced specialist from an auto repair company.

For disassembly, you will need an open-end wrench and a sufficient container into which the remaining liquid can be drained. We release the fitting from the plugs and turn the block over so that the glass is removed from it. Next, remove the bipod shaft and unscrew the bolts mounted on special grease. It will take some effort to “rip” them out of place.

We get rid of the lock nut, push out the bipod and the shaft, which will give in to the force along with the cover. In the absence of obvious play, the bipod can remain in its place, and it is advisable to change the cuff in any case.

We unscrew the check valve plug and carefully remove the spring from under it. We unscrew the bolts from the cover and do not unscrew them from the ball nut. We insert a small screwdriver into the slot, pry up the cover and take it out with the piston. Now you can remove the ball nut.

Loosen the locknut and dismantle the bearing. We disassemble the bearing and nut from the piston, which is fixed by the edging. We unscrew the bolts and disassemble the ball line.

How to remove burrs that appear

- cleaning filters in the power steering and replacing them with new ones;

- replacement of oil seals and cuffs;

- replacing the safety valve;

- control of cleanliness, topping up to the level and replacing the working fluid;

- replacing hoses on the unit;

- removing air from the system;

- removal of burrs, dirt and roughness;

- replacing a worn bearing.

After cleaning, restoring and replacing individual elements, we reassemble in the reverse order of disassembly.

You need to know that it is important to monitor the level of working fluid in the system during operation. If it gets dirty, you need to replace it with the one recommended by the car manufacturer.

The power steering pump is designed to pump oil into the steering mechanism and ensure fluid circulation in the system. During rotation, the shaft and blades of the pump create a centrifugal force, as a result of which the working fluid enters the discharge cavity under high pressure and further into. The power steering pump is mounted on the engine and driven by a belt drive.

As a rule, replacing the power steering pump is carried out in conjunction with changing the oil, clamps and hoses. In this article we will look at how to perform this procedure with your own hands using the example of a VAZ-2110 car.

Draining oil from power steering

Using a jack, we raise the front part of the car, having previously installed stops for the rear wheels. Then open the hood and pump out the oil from the power steering reservoir. The easiest way to do this is with a bulb or syringe. For convenience, use an extension hose for the syringe. After the oil has been completely pumped out of the tank, you need to turn the steering wheel several times until it stops, alternately left and right, so that a new portion of liquid appears in the tank. We pump it out again. Again we repeat a similar procedure with rotating the steering wheel and pumping out the oil.

When the liquid is completely removed from the system, using pliers we loosen the hose clamp that goes from the passenger compartment to the tank. Remove the hose and insert it into a container to drain the liquid. Turn the steering wheel alternately left and right until it stops to drain out any remaining oil.

Conclusion

In the design of a car there are very important components, devices and parts, and there are less important ones. Especially important nodes need to be monitored frequently. If signs are detected, try to eliminate the cause as quickly as possible.

This video shows the design and operating principle of the Chevrolet Aveo power steering pump

How to repair a power steering pump yourself

We'll tell you about the main components of the power steering, how to properly replace the pump and bleed the system.

Anyone who has driven a domestic car without power steering and then switched to a foreign car will immediately say that the difference is significant and the driving sensations are completely different. There is no need to strain your hands, think about the turning trajectory, the hydraulic booster also helps maintain maneuverability, control the vehicle and softens shocks.

It is much more pleasant when such a hydraulic booster is installed on a car, but sooner or later there comes a time when it fails. Typical failures of the hydraulic booster are considered to be noise when turning the steering wheel, a decrease in fluid, turning the steering wheel with jerks or tight rotation of the steering wheel, various types of knocking when driving on uneven roads, or worst of all, a decrease in vehicle controllability.

Replacing power steering hoses

Simultaneously with replacing the pump or power steering fluid, it is recommended to thoroughly check the condition of the hoses and pipes. If necessary, replace them with new ones. Hoses must be changed only after the oil has been completely pumped out.

To replace hoses or pipes, first unscrew the clamps. Installing new hoses causes some inconvenience, since the location of the hydraulic booster is not entirely convenient for performing such operations. New hoses and pipes should be securely secured with clamps. However, you should not be too zealous so as not to damage them.

Dismantling the power steering

First you need to remove this mechanism from the car. But before doing this, it is highly recommended to clean the dirt from the mechanism so that when you disconnect the hose, it does not get inside the device itself, otherwise this could cause problems.

Next you will need to pump out as much liquid from the tank as possible. We climb under the car and use a hexagon to unscrew the bolts securing the steering shaft. When carrying out such an operation, you need to note in advance the position of the elastic coupling relative to the power steering shaft. This will be very important during installation.

Now it's time to remove the steering rods. They will need to be disconnected from the bipod with a special tool - a puller. Next, we jack up the car and unscrew the left wheel, and then remove it.

The video describes the operation of power steering:

We take a 15mm wrench, preferably a socket one, and from the side of the wheel arch we loosen the bolts that secure the power steering to the side member. Then remove two of the three bolts. We leave one in place.

When removing the hoses, be sure to place a container under them so that the remaining liquid can drain there. Then you will need to cover the hoses and fittings with pieces of rag.

Now you will need to disconnect the very bolt that secures the power steering. Do not forget to hold the hydraulic booster with your free hand so that it does not fall.

Let's remove the power steering pump

As a rule, ZF version power steering pumps are installed in VAZ-2110 series cars. These devices are also equipped with hydraulic boosters of some models of Volkswagen, Audi A6 and so on. Pumps usually cannot be repaired and, if necessary, are replaced with new ones. However, in some cases, you can try to restore their functionality with your own hands, for example, replacing a worn bearing or cuff. It all depends on the nature of the malfunction.

Removal sequence for power steering pump:

- Loosen the clamp and remove the return hose. When doing this, care must be taken not to spill the oil.

- We very carefully remove the sensor from the fitting bolt, which is designed to measure fluid pressure in the power steering system.

- Remove the fitting bolt and disconnect the discharge pipeline.

- Remove the power steering drive belt.

After this, we proceed to dismantling the direct pump.

- First, loosen one mounting bolt.

- Then unscrew the second bolt and remove the complete power steering pump assembly.

- We install the new pump in the reverse order.

8-915-240-67-73

Power steering rack pump

There are 2 types of pumps:

1. Driven by the engine crankshaft pulley;

2. Driven by electric motor.

The crankshaft driven pump is simple. These are two surfaces in which channels are cut out for the intake and supply of liquid, which cover the chamber where the rotor with blades rotates.

Due to the centrifugal force, the blades move out of their grooves during rotation, resulting in liquid intake. The rotor with blades rotates along the surface of the stator, where the blade moves inside the groove and pushes liquid under pressure into the system channel. The pressure in the pump is regulated by a valve.

Power steering pump

What do you get after repairing the power steering pump?

After repairing the pump, you will stare at it:

— oil seals (rubber seals); — additional bushings; — defective parts will be replaced; — the system will be washed from dirt; — New oil is poured into the hydraulic system.

Reasons for calling for repairs

— a hum in the steering, in the pump itself; — heavy steering wheel control; — increased steering play — leakage of working fluid.

Pour fluid into the power steering

After replacing the power steering pump, you need to fill the system with new fluid:

- First, pour oil into the tank until about.

- Then we sit in the cabin and turn the steering wheel several times all the way in both directions so that the fluid fills the system.

- After this, add oil to the barrel and turn the steering wheel again.

- Add fluid, start the engine and turn it off after a few seconds.

- Rotate the steering wheel several times until it stops in both directions.

- Add oil to the tank again.

- We turn the steering wheel at least 10 times all the way in each direction with the engine off to thoroughly bleed the system.

- We start the engine and again turn the steering wheel in both directions 10 times.

- We control the oil level in the tank and add fluid if necessary.

How does power steering work?

It is worth noting that each car model may have a different structure, however, there is still a common “basis” for all. For example, this is a pump that sets hydraulic fluid in motion and maintains optimal pressure within the system. Next comes the distributor, which, as the name suggests, distributes hydraulic fluid. A hydraulic cylinder, which acts as an intermediary between the steering wheel mechanism and the piston, which is responsible for turning the wheels. Don’t forget about the connecting hoses through which hydraulic fluid circulates.

After any malfunction or breakdown has been discovered, it is recommended to carry out repairs immediately, because in the future the situation can only get worse.

Even in domestic cars, for repair or replacement you need to remove the engine and some elements of the car's chassis. What can we say about foreign cars, the design of which is much more complex, so sometimes it is better to turn to specialists.

Typically, the minimum replacement cost is $30, but the price may vary depending on the vehicle model.

In the next paragraph of the article we will discuss in detail the replacement of the pump, since it is with it that problems often arise.

Changing the “blood vessels” of the power steering

Let us now consider another cause of power steering failure. It may consist of hoses - a kind of “blood vessels” of the entire device. The liquid necessary for normal operation flows through them. And if the hoses are worn out or excessively worn, they will require replacement. Repairing power steering hoses is a simple and quick process, although it does require some knowledge.

It is recommended to immediately purchase a new set of hoses and replace the old one. You need to join new hoses skillfully so that liquid does not leak out at the joints. This is the most difficult thing in replacing hoses: to ensure a reliable connection so that there are no open spaces, even the thinnest ones.

The video shows how to change the oil in the power steering system:

Signs and causes of malfunctions

For what reasons can a MSG or another brand system hum and whistle, and how can I check the unit? In general, plate systems represent a unit with a long service life. But if mistakes were made in using the unit, this can lead to buzzing and other damage.

The main malfunctions of the MSG pump or any other are as follows:

- an oil leak occurred, its level in the lines decreased;

- the oil has been changed quite a long time ago and has already lost all its features and characteristics;

- foreign objects or impurities have entered the lines or mechanisms of the system;

- the oil stops moving through the system, and the mechanism may overheat (the author of the video is the Do-It-Yourself channel).

To avoid having to repair your power steering, you should always monitor the level of consumables in the system. In addition, repair of the power steering pump can be avoided by regularly diagnosing the lines for integrity.

So, we figured out why the system is humming, now let’s look at the main signs of a malfunction:

- When driving at low speeds, you have to put more effort into turning the steering wheel. When the speed increases, this need disappears.

- When turning the steering wheel, extraneous sounds appear.

- Under the bottom of the car and on the elements of the power unit, leaks from hydraulic oil may appear.

- While driving, the bearing device may whistle.

Before repairing, you need to check the pump. If external diagnostics show a faulty unit, it needs to be replaced or repaired.

Sorry, there are no surveys available at this time.

Preventive measures against power steering failure

Preventive measures and the correct approach to the hydraulic booster often make it possible to significantly extend the life of the device.

The hydraulic booster is a fairly durable and also undemanding spare part, and with proper operation and care it can last approximately 100-200 thousand kilometers. But in order to continue the life of the power steering, you should be guided by simple laws, including:

- Monitor the fluid level. This condition directly has a great influence on the good performance of the power steering.

- Change oil according to schedule. You will find clear information on replacing the fluid in the vehicle manual.

- Always use the correct oil.

- Operate the power steering correctly.

- Monitor the position and condition of the rack boots.

- When parked, the vehicle must have balanced wheels. This requirement makes it possible not to create an excessive load on the power steering.

- In cold weather, after starting the engine, do not immediately turn the steering wheel. Instead, it's better to wait and let the system warm up well.

- Under no circumstances should you drive with a faulty power steering. Your life is more important than saving.

- Periodic vehicle diagnostics. In the salon or at home with your own hands. The main thing is to fix problems in time. This will reduce wear on parts and also save your money.

How to repair power steering

Power steering is an important part that helps you easily drive your car in the most emergency situations. Its use allows you not only to get more pleasure from driving, but also significantly increases overall safety on the roads. This is all due to the fact that with the help of power steering it is much easier for the driver to manage complex maneuvers.

However, over time this part becomes unusable. Particularly high wear is observed with dangerous driving styles. Sharp turns significantly reduce the service life of the power steering, and it requires repair.

Service

You can avoid most problems simply by taking proper care of your car. If you want your power steering to last as long as possible, then follow a number of recommendations:

- periodically change the fluid in the entire system;

- monitor the condition of the belt, it should fit tightly;

- all clamps must be well tightened;

- do not hold the steering wheel in extreme positions for more than 5 seconds;

- change filters on time.

Now what should be replaced if there is a problem with the power steering.

- Complete replacement of the fluid and preferably the reservoir itself.

- Replacement of all worn pipes, especially high pressure ones.

- Inside the pump we replace the bearing, oil seal, and seals.

- We clean off all sharpened parts with sandpaper and check how the blades move.

By following these simple rules, you will extend the service life of the power steering and will not soon be able to repair your power steering.

Source

Repair of power steering steering gear (do-it-yourself)

The steering gear is the main part of the car. Together with other parts of the steering, it guarantees smooth and comfortable driving.

Its purpose is to help the driver turn the steering wheel with effort, that is, it facilitates this process.

How to repair a power steering gearbox

Gearbox repair is a very complex process. Repairing it requires fine work and patience. If you do not have enough knowledge, then leave this work to specialists, and if you have experience, then you should:

Adjust the steering gear if there is play or strange sounds. For this task you will need an assistant and a set of tools.

Next, you need to loosen the locknut and tighten the adjusting screw.

If adjusting the gearbox did not help you or you notice a leak of technical fluid, then this section must be disassembled. For this:

Remove the shaft plug, lock nut and ring.

Knock out the shaft and remove the lower oil seal.

Remove the locking pin and ring, then pull out the upper oil seal.

Clean all components and replace sealing parts, bushings and bearings.

We assemble the power steering gearbox in reverse order.

Shaft defects and gearing can be determined using special equipment, which is available only to specialists in car services. So when doing a DIY repair, you will have to determine the condition of the components “by eye.”