Vehicle suspension is an important part of any vehicle: cars, trucks, buses, etc. It is the one that absorbs the entire load that is transmitted from the road - vibrations, resistance forces, including other influences. Since the structure can withstand increased loads, car suspension repair is considered one of the most common and sought-after types of restoration procedures. Some to a lesser extent, others to a greater extent.

In addition, car suspension maintenance, as well as a number of necessary operations, cannot be avoided. Otherwise, road safety is reduced, which has a negative impact on other road users. The regularity and scale of work are determined by the operating conditions of the machine, including mileage. It also does not hurt to take into account the owner’s attitude towards his own private movable property.

And any transport will not tolerate negligence towards it. It’s not without reason that they say: you need to treat a car like a woman - that is, love, care, service, troubleshoot problems in a timely manner and treat them with due respect. Then she will repay you a hundredfold!

What is a pendant?

What is meant by this definition? This is the connection of nodes into a single complex, thanks to which the load-bearing part of the car rests on the surface of the roadway. In this case, the main role is given to wheels and axles. An important task that is assigned to the responsible part of the transmission is to soften the impact force that occurs when vehicles move over uneven roads. Based on the geometry, two groups of this node can be distinguished:

- dependent;

- independent.

The first group applies to classic vehicle models. But manufacturers equip modern vehicles with an independent mechanism.

Need for maintenance and repair

Malfunctions of suspension components can lead to vibration, poor vehicle control, increased noise while driving, and even a serious accident. Timely diagnosis of the condition and repair of the suspension is the key to safe operation of the machine. At the same time, it should be noted that many parts of this system cannot be repaired. They need to be replaced with new ones.

The suspension is one of the actively working systems and therefore requires repairs more often than others. Even the best parts from well-known manufacturers are not able to work for a long time in the conditions of our roads and periodically fail. The front suspension most often needs to be repaired, due to the fact that it is the one that first receives all the impacts coming from the road.

Most cars today are equipped with a MacPherson system, since it is convenient in that in its design the shock absorber and spring work as a single unit, forming a strut. This reinforced stand absorbs all impacts transmitted from the wheels and allows us to move comfortably. But such hard work leads to rapid wear of this unit.

In addition, when performing repair work, it is almost always necessary to disassemble and replace silent blocks along with levers, ball joints or CV joints. Wear on the support can lead to a serious situation during the ride when it is pulled out of the saddle. In this case, the wheel may stand completely across the direction of movement.

Diagnostics

Before repairing a particular component, the vehicle suspension is diagnosed to assess the technical condition of the elements. At the same time, the procedure is performed not only in the presence of a malfunction, but at least once a year for preventive purposes. This will allow you to avoid serious troubles in the future, as well as detect the problem in time.

As for checking the front and rear axles, the procedure is practically no different, based on the make and model of the car, with rare exceptions. At the same time, there are much more parts in front of the car than in its rear.

Few people guess, but there are several types of diagnostics:

- computer;

- bench;

- manual.

Each of these operations has its own characteristics. When performing diagnostics, you should pay close attention to the nodes that most often lose their functionality.

Computer help

Such diagnostics involve the use of electronics. The procedure only applies to cars with an ECU. Consequently, it is not possible to assess the technical condition of the complex of old models. But in the latter case, you can use one of the other methods.

Specialized technological diagnostics

Before repairing the suspension of Mercedes, BMW, Audi and other brands, you can use the services of specialized car services. Here it is possible to carry out diagnostics at a high technological level using special equipment - a vibration stand.

This procedure simply does not have any restrictions, as mentioned above - the procedure is relevant for all vehicles, regardless of the year of manufacture. The operation is carried out on a special stand, which is capable of simulating difficult road conditions. With the vibration stand used, any malfunction can be identified. For this reason, this is the most common diagnosis of all those considered.

Diagnostics allows you to get an idea of all the elements, as well as find out what is damaged and requires urgent replacement. The information content of this method is quite high, since the data obtained at the stand is compared with factory characteristics.

The cost of such a procedure may seem high for some car owners. True, you can count on an accurate assessment of the condition of a particularly important unit.

Master's Specialization

For such diagnostics, you will have to find a qualified car service center, where a master works who has been repairing important vehicle components for many years. As a result, his skills and abilities are developed so much that he is able to identify a malfunction by driving the car enough. And then fix the existing problem at a professional level.

At the same time, the technician can assess the technical condition of all components of a passenger car’s suspension, not only visually, but also by ear. Unfortunately, you rarely find such workers anywhere, unless you are lucky. In addition, few people use such diagnostics anymore.

Car suspension repair yourself

As mentioned above, no matter what kind of car you have, Lada Granta or Audi A7, BMW M5, Hyundai Genesis, Mercedes S600, etc., sooner or later you still need to diagnose and replace suspension parts.

If the car is economy class and it is driven on bad roads, then it is easier to learn how to repair the suspension yourself than to have it repaired at a service station every year.

If knocking or squeaking noises occur, for example when turning or on small bumps, this is a reason to inspect the car’s suspension.

Front node

Despite all the manufacturers' assurances regarding the reliability of the responsible bond, it is still a fragile system. In constant unfavorable operating conditions of the vehicle, it ends with wear of working elements, including consumables. The resource in this case will largely depend on the intensity of the harmful effects.

Any passenger car (not only modern ones, but also old cars) has two wheel axles (axles). They include a system of levers and shock-absorbing units, which ultimately provides vehicles with a smooth and soft ride. Of the two bridges, one is always leading. It transmits torque from the engine to the wheels. Although there are options where both axles are driven - such variations are called all-wheel drive.

And it is the front axle that experiences the greatest loads, since it is the first to encounter all the obstacles that can be encountered on the road. Therefore, repairs to this part are performed more often. It is worth noting that the technological process of repair in 80% of cases refers to the replacement of parts or mechanisms. Restoring them is extremely difficult, and also more expensive - sometimes repairing something is more expensive than simply replacing it.

Accordingly, restoration of damage is an irrational and unfavorable activity. But what exactly does the front axle include that requires close attention?

Design features of the entire front structure

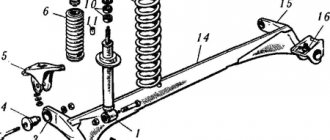

Today, many manufacturers are inclined to choose an independent unit, which contains its own set of necessary components:

- shock absorbers;

- levers;

- CV joints;

- ball joints;

- support bearings;

- springs;

- anti-roll bar;

- stabilizer's pole;

- stabilizer bushings;

- hubs with bearings;

- brake mechanisms.

Moreover, each component is equipped with gaskets and seals of a certain number. All these parts require responsible care, and if necessary, appropriate procedures must be carried out - repairs and maintenance.

Shock absorbers

The first step is to check these elements, since they are subject to enormous and constant load while the car is moving, especially when hitting bumps. It is important to assess the condition of the shock absorber itself, including the support cups and springs. You also need to inspect the surface of the part for leaks of working fluid. And if they are present, and even more abundantly, the part must be replaced.

It is worth noting that replacing shock absorbers on front-wheel drive cars requires a lot of effort. First you need to “break the connection” between the strut with the steering knuckle by unscrewing the fasteners. Then remove the spring, which is most often simply replaced with a new shock absorber.

It is also important to determine the resistance of the shock absorber - if, after pressing the rod, it rises back slowly or there is no reaction at all, this also indicates a malfunction. In this case, the condition of the springs should be assessed: damage to the structure of the first turn is already a reason to be wary. There is only one conclusion - replacing the elastic element.

When the operation of the shock absorber is accompanied by the appearance of extraneous sounds, it means that the rubber seals need to be changed. And if the fasteners are not tightened enough, knocks and creaks are inevitable.

It is worth noting that according to technology, replacing shock absorbers is carried out in pairs, and not individually. Otherwise, the parts will begin to wear out unevenly, which will ultimately lead to repeated repairs, and ahead of schedule.

CV joints, ball joints, steering ends

These parts are checked after unloading the suspension. That is, the car needs to be driven into a pit, a lift, and in garage conditions it is enough to put it on a jack. Next, all that remains is to check the parts for play using available means. In addition, inspect the elements and identify the presence of mechanical damage.

The detected play indicates the need for suspension repair and, in particular, replacement of parts. It is also worth paying attention to consumables and, if necessary, replacing them too. If the CV joint or ball joints are damaged, operating the vehicle is strictly prohibited!

Levers

Unlike shock absorbers, these elements have a much longer service life and are not changed as often. But this does not mean that they can be neglected during diagnostics or suspension maintenance. Replacing levers is indicated if their integrity is damaged, which carries certain risks. It is also worth mentioning one more difference from shock absorbers, including brake discs - these parts can be changed one at a time.

Bearings

If the ball joint is damaged, characteristic knocking noises can be heard; damage to the integrity of the hub bearing leads to a hum. Moreover, it intensifies during acceleration. You can identify the problem yourself by putting the car on a jack. Next, all that remains is to spin the wheel - if you hear a slightly creaking sound, there is a problem!

If the malfunction is not corrected, in the future the bearing will begin to crunch and click, and after some time it may jam. In this case, the car loses control, which usually ends in creating a dangerous emergency situation. The service life of wheel bearings is different for each vehicle, but on average they can serve properly for 50-100,000 km.

However, if there is a lack of lubrication, the bearing will have to be replaced sooner. Accordingly, its presence and quantity should be checked during diagnosis.

Brakes

This system deserves utmost attention, since the level of road safety depends on it. Moreover, each machine has purely individual design features. In this regard, if you have the desire and opportunity to replace damaged elements yourself, you should first look at the instruction manual for your iron horse. To avoid serious trouble, it is important to follow the manufacturers' instructions.

Hinges, seals

Often the appearance of knocking is caused by wear of rubber elements. In this regard, even if any components are changed, the condition of the sealing elements should be inspected at the same time. And if severe damage to the bushings is detected, they must be replaced immediately.

Why does the rear torsion beam need repair?

By and large, it is IMPOSSIBLE to call it unreliable! Another thing is that the engineers focused on the European climate and the lack of salts and reagents. In addition, owners of commercial vehicles often exceed the maximum load capacity of 600-800 kg by 1.5-2 times.

The needle bearings of the rear beam are subject to the greatest wear . According to the manufacturer's recommendations, their replacement or maintenance should be carried out at least once every 60 thousand kilometers . But most owners neglected these instructions, which leads to the destruction of the elements of the rear torsion beam.

Rear mechanism

In addition to the front axle, there is also a rear axle. Only in this case, during diagnostics, as a rule, a smaller number of parts are inspected. The rear structure of modern vehicles contains mainly shock-absorbing devices, which will significantly reduce the time of the procedure, including repair of the rear suspension of the car.

Characteristic signs of malfunctions of components and parts are common to the front and rear axles. The most common of them:

- Knocks and squeaks indicate wear on the rubber elements of the shock absorbers, which requires their replacement.

- When you release the steering wheel, the car begins to deviate from the set course. This calls into question the wheel alignment or the condition of the rear axle rods.

- Body settlement also indicates problems with shock absorbers.

At the same time, vehicle owners can repair light damage to the chassis themselves, using minimal resources. However, major repairs require the use of professional equipment, as well as the participation of an experienced craftsman who knows his business. First, you need to at least perform the diagnostics yourself, and then draw the appropriate conclusions.

Composition of the rear of the car

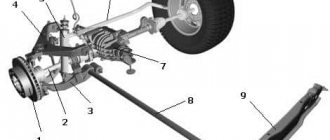

There are not many varieties of rear suspension:

- The rear axle is dependent.

- The beam is semi-independent.

- Multi-link - independent.

Moreover, regardless of the design, the design contains the following mandatory elements:

- shock absorbers;

- hubs with bearings;

- springs or leaf springs - to soften the impact of bumps;

- levers;

- jet thrust;

- stabilizer with bushings;

- brakes

During the operation of the car, parts consume their resources, especially rubber elements. As a result of wear, knocking noises of varying nature and intensity appear. In addition, with some malfunctions, operation of the vehicle is prohibited.

What is the structural meaning of the rear beam on a Peugeot/Citroen?

There are several reasons why the French chose a torsion bar rear beam:

- the compactness of the beam made it possible to increase the trunk volume for B-class hatchbacks and utility vehicles;

- light weight has a positive effect on handling;

- the ability to adjust the ground clearance of the rear of the car (rather an advantage for owners). MFC LFA masters have repeatedly increased the ground clearance of such cars as Peugeot Partner, Citroen Berlingo and Peugeot hatchbacks.

The rear beam itself is simple in design and consists of:

- beam (attached by bolts to the steel pipe body);

- shock absorbers;

- rear beam torsion bars (stretched between the levers) of different lengths and diameters at the front and rear;

- anti-roll bar;

- fingers (pressed into the beam on both sides);

- levers (attached directly to the fingers);

- needle bearings (act as a spacer between the fingers and levers).

Shock absorbers

These elements are designed to dampen vibrations from uneven roads. In the simplest design, the liquid inside the shock absorber passes through a system of holes during its operation, as a result, part of the vibration energy is dissipated in the form of heat.

The most common parts to wear out in shock absorbers are the piston O-rings and valves. Another popular scenario is liquid boiling over. This can occur when driving for a long time in the heat on an uneven road: the oil foams and begins to penetrate through the seals, and the effectiveness of shock absorption is greatly reduced. Visually, a “boiled” shock absorber can be recognized by a layer of dirt adhering to the oil-stained body.

Symptoms of malfunction:

- After passing the bump, the car continues to sway for some time.

- Roll increases when cornering.

- Knocks are heard when driving on uneven roads.