Operating principle of the carburetor solenoid valve

The carburetor solenoid valve is used to regulate the supply of the fuel mixture bypassing the throttle valve, which is controlled by the accelerator pedal. At idle, fuel enters the ICE inlet manifold through a separate channel. This is why the solenoid valve is also called the vehicle idle air control valve. The main purpose of the valve is to stop the fuel supply in inertial modes, which, for example, allows engine braking and coasting.

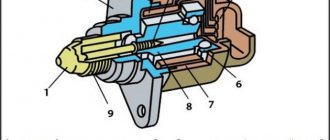

In gasoline carburetor engines, the valve is installed directly in the carburetor and is part of the car's forced idle economizer system. The valve is controlled by the system's electronic control unit; when a pulse is received, the valve needle retracts and closes the fuel supply, bypassing the valve. After the engine is started, power is supplied from the control unit and the valve begins its operation, which consists of two strokes:

- on the first stroke, the valve opens, as a result of which air enters the chamber and mixes with fuel;

- at the second stage, the air channel is closed and the fuel channel is opened, as a result of which the fuel-air mixture enters the engine.

The movement of the valve shut-off needle is carried out by incoming electrical impulses from the control unit. As soon as the gas pedal is pressed, the valve moves to the open position and the needle extends. At idle, the valve goes to the closed position at engine speeds above 2100 RPM. The transition to the open position occurs when the engine speed drops below 1900 RPM. Closing and opening the valve allows you to regulate the flow of the fuel-air mixture into the engine and, accordingly, save gasoline consumption by up to 5%. Also, the operating principle of the valve allows reducing wear of the piston group. The immediate consequence of the operation of the solenoid valve is a reduction in emissions of harmful substances (CO) into the atmosphere, which increases the environmental friendliness of the car.

Operating principle

To determine the cause of the problem and take action to troubleshoot the EPHH, you need to know about the principle of its operation.

- The economizer is equipped with output and input circuits.

- The input circuits are a limit switch and a wire that connects to the switch.

- The throttle (throttle) limit switch tells the economizer whether the gas pedal is depressed or not at that particular moment.

- If the pedal is not depressed, the limit switch closes to ground.

- As soon as the gas pedal is pressed by the driver, the contact is switched off.

- The wire that connects the switch and the economizer reports the number of pulses to the ignition coil. In fact, due to this, the economizer is able to find out about the actual current speed of the power unit.

- The EPHH has only one output circuit - the XX solenoid valve of the carburetor system (XX - idle speed). The economizer can turn this valve on and off.

- Fuel economy is ensured by closing the XX fuel jet at high engine speeds.

- If the gas pedal is not depressed, the throttle limit switch closes to ground, the speed is less than 2.1 thousand per minute, then the economizer opens the XX solenoid valve.

- When the gas pedal is depressed, the limit switch opens, leaving the valve open anyway. The valve closes only when the engine speed exceeds 2.1 thousand per minute.

- The valve is in the closed position until the speed drops below 1.9 thousand per minute.

Article on the topic: Which ball joints are better to choose for the VAZ 2110

If the car is coasting with the gear engaged and the accelerator pedal released, the EPHH will not turn on, even if the revolutions drop below 1900 per minute. The economizer monitors the closed position of the damper. If the engine speed at idle is too high, it is perceived as coasting.

Actually, this is all you need to know about the operation of such an element as EPHH.

Practice and research show that the use of an economizer allows you to save about 5 percent of engine consumption.

Signs of a malfunctioning carburetor solenoid valve

A malfunction of the carburetor solenoid valve can be determined by several characteristic signs:

- the engine regularly stalls at idle;

- the engine stalls when coasting;

- Fuel detonation occurs after the ignition is turned off.

The instability of the solenoid valve can also be determined by a drop in engine speed when an additional load is turned on (car radio, headlights, etc.). Thus, the main sign of a valve malfunction is unstable engine operation in idle mode.

Valve check

Checking the solenoid valve for correct operation can be done in three different modes:

- when the engine is idling;

- when braking the engine;

- after turning off the ignition.

The general serviceability of the valve can be checked after turning on the ignition. To do this, you need to increase the engine idle speed to 2100 RPM. After crossing this mark, a characteristic click should be heard, which means that the valve has closed. After this, you can lower the speed, as soon as its number reaches 1900 RPM, a click should be heard again, meaning that the valve has opened.

When braking with the engine while the gear remains engaged, the valve should not open, even if the engine speed has dropped below 1900 RPM. If a click is heard at this moment, the valve is not working properly.

If detonation and vibration occur after the engine ignition is turned off, this means that the valve does not close the idle jet and the fuel mixture enters the engine, which also indicates a malfunction of the solenoid valve.

You can also simply check the valve by disconnecting the power cable with the engine running. The motor should stop immediately after disconnecting.

You can check the valve by completely disconnecting the device from the carburetor. After dismantling the valve, you can connect it to the battery, after which you should hear a click and the valve needle should retract into the device. After turning off the power, you should hear a click again and the needle should move out.

The problem with the solenoid valve may lie not only in its malfunction, but also in the electronic control unit and in the wires. You can check the functionality of the wire using a multimeter (12 V ± 10%).

Checking the functionality of the control unit will require connecting the valve to the battery using an additional wire. A standard voltage control light is also required. First you need to disconnect the supply wire from the valve and connect it to the positive terminal of the battery. An additional wire is also connected to the battery positive. After this, you need to start the engine, at the cut-off of 900 RPM the warning lamp should light up, after reaching 2100 RPM it should go out. When it drops to 1900 RPM, it lights up again. If these indicators are met, but the engine stalls at idle, then the fault is probably in the valve control unit.

Price

Prices for auto choke kits are quite high: for a good kit you will have to pay about 4,500 rubles. For this money you will receive a gear motor, a control unit and a set of wires, as well as a cable and a program for setting up the system.

Everything would be fine if it were not for the injector, which is gradually replacing the old fuel supply mechanism. For example, a kit for installing a fully electronic fuel supply for a front-wheel drive VAZ will cost 6-7 thousand rubles. Naturally, this will be a used device, but there is practically nothing to break there. But you will get a fully automated injection system that does not require adjustments. Fuel consumption will decrease and power will increase. In any case, it's up to you to decide.

Installing the carburetor solenoid valve

When replacing a solenoid valve, it must be adjusted correctly so that the incoming fuel-air mixture meets the required parameters. The installation is carried out with the engine running, as this will allow you to accurately adjust the valve. In a carburetor, the valve is located under the air filter cover, so to remove a faulty solenoid valve, you must first remove the air filter cover.

First, you need to hand-screw the valve into the carburetor seat and put on the standard wire that connects the valve to the control unit. After this, you need to start the car’s engine, which will stall and possibly try to stall. If the engine still maintains speed, then further tightening of the valve into the carburetor is done using a wrench (13 or 14 depending on the type of valve). Further installation is carried out in the following way:

- the key is turned 1–2 cm clockwise, after which the wire is removed;

- if the car engine does not stall, then the wire is put on again and the procedure is repeated;

- As soon as the engine stalls after removing the wire, the valve is installed correctly in the carburetor.

Installation of the solenoid valve must be carried out carefully so as not to damage the fuel nozzle and seat in the carburetor. During the installation process, the size of the fuel mixture entering the engine is automatically adjusted, after which tripping and detonation stop. For precise adjustment, you can tighten the “quality” and “quantity” screws on the valve.

If, after tightening the valve several times and disconnecting the wire, the engine still does not stall, this means that fuel is entering the engine bypassing the solenoid valve and it is necessary to look for a malfunction in the fuel supply system.

Many owners of cars with carburetor engines, after the solenoid valve fails, simply block its operation or dismantle it, which solves the problem with the engine, which stops stalling at idle. However, such actions are only at first glance the right decision. Blocking the solenoid valve significantly increases fuel consumption (up to 5%), which will cost much more in the future operation of the vehicle.

Briefly about the main thing

The solenoid valve stops fuel supply when the accelerator pedal is released and the crankshaft speed is more than 2,100 rpm, and resumes fuel supply at a frequency of less than 1,900 rpm under the same conditions. A faulty switch will prevent the engine from starting or will deliberately stop it from running.

There are several ways to check the serviceability of the solenoid valve on the carburetor of a VAZ 2109 car:

- connect standard or bypass power to the element output - a click should sound;

- remove the standard wire from the device with the engine running - the engine will stall;

- dismantle the sensor, connect it to the standard circuit and lean it against the carburetor - the needle will retract with a characteristic click;

- Connect the dismantled sensor to the battery: the needle should retract freely when voltage is applied and extend when there is no voltage.

Application of two-way valves in automotive systems

Since numerous vehicle systems constantly require shutting off, redirecting and mixing various flows of liquids or gases, the use of various bypass devices, such as valves, is required. The principles of their operation are based on different drives: pneumatic,

Setting up the carburetor of a 4-stroke scooter

Tuning the carburetor of a 4-stroke scooter is, of course, not rolling back the injector using broadband lambda, but it also requires a competent approach and knowledge. For stable operation and efficiency, Chinese manufacturers have developed and implemented several design additions. Before you get started

Carburetor DAAZ-4178 - installation and main causes of malfunctions

The Dimitrovgrad Automotive Component Plant produces DAAZ-4178 carburetors for UAZ vehicles, which can be used instead of the standard K-151V. The manufacturer guarantees an increase in dynamics and a reduction in fuel consumption to the level of 11 liters per 100 km in mixed mode, which is comparable to the fuel consumption of a GAZ

Selection of jets on a Solex 21083 carburetor

The Solex 21083 carburetor model with jets that affect the properties of the fuel-air mixture can be modified to suit any engine size. To do this, it is enough to select jets, which is quite possible for an experienced car enthusiast. Solex 21083, subject to proper improvement, is quite

What’s easier: to rack your brains or figure out how the carburetor works in a Lada?

To an uninitiated user, it may seem that the VAZ 2109 carburetor is complicated, so not many people decide to adjust it themselves.

Why did the Solex break down?

A carburetor is the main element of a car's fuel system. It is designed to mix air with fuel in the required proportions and form a fuel mixture supplied to the combustion chambers of the engine.

Source