Let's start with the fact that today you can find a large number of auto chemical products on the market that promise to protect the engine from premature wear and improve the properties of the base motor oil. Also, the manufacturers of the compounds themselves emphasize that the use of certain additives in the engine even makes it possible to restore an internal combustion engine that has become worn out during operation, has received certain damage, has begun to smoke, consumes oil, has lost traction, etc.

As a rule, in practice, drivers do not often think about using additives in a working engine for prevention. Often, increased interest in such additives arises when it comes to the use of such compounds specifically for the purpose of engine restoration. This is not surprising, since when problems arise with the power plant, the owner is faced with an urgent need to disassemble and repair the power unit.

It is quite obvious that the desire to save money or delay costly repairs as much as possible forces car enthusiasts to look for budget-friendly ways to solve the problem as an alternative. Given the active advertising support, widespread distribution, and reasonable cost, additives may seem like a reasonable way out of the situation.

Let's find out if this is actually true. Next we will talk about the principle of operation of restoration additives, as well as what to expect after using the popular FENOM engine additive, ER additives, Hado, etc.

Different types of engine additives - what are the main differences?

Before moving on to what exactly the additive for the Phenom, ER or Hado engine is, it is necessary to understand the question of what compositions exist and what are their main differences.

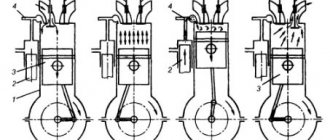

As is known, some additives reduce friction, others change the properties of motor oil (viscosity additives), others restore worn surfaces, and others are specifically aimed at reducing oil consumption and fuel economy (anti-smoke, anti-wear). Various solutions have unique lubricant compositions, containing so-called friction modifiers, metal conditioners, etc.

As you can see, such diversity may well confuse not only an inexperienced buyer, but also an experienced car owner who has not previously dealt with similar products. So, to make it clearer, all additives that are added to the engine can be divided into three large groups.

The first group includes compositions that are based on mineral powders. Such solutions include the well-known manufacturer Hado on the domestic market, as well as Suprotek. In a nutshell, the presence of powder makes it possible to grind friction surfaces, after which a metal-ceramic layer is formed on such a surface. This layer has a low coefficient of friction and is also resistant to loads and wear.

Various experiments have confirmed a certain effectiveness of such compositions, however, in case of significant damage, such additives are not able to “polish” scuffs, level out gaps that have appeared, etc. The disadvantages also include the need to strictly monitor the use of the composition and perform all actions according to the instructions, since exceeding the amount of the substance or its frequent use can harm the engine.

The second group includes additives that are based on metal-clad additives. These include the RiMET composition offered on the market and other similar solutions. This additive contains soft metals, which are contained in ionic form or in the form of fine powder.

After these components fall on the surfaces of the rubbing parts, they create a thin layer that fills small defects, partially levels the surfaces, improving the performance of crankshaft bearings and CPG elements.

The disadvantage of such drugs is the short-term restorative effect, since after the formation of a protective layer, then such a layer quickly wears out. The reason is that soft metals are not inherently highly resistant to wear.

The third group contains solutions that are known as so-called metal conditioners, revitalizants or simply restorative additives. These compositions are presented on the market by ER, Hairdryer, etc. In a nutshell, the drugs have a chemical effect on metal friction surfaces. The compositions also form a special protective layer, based on a chemical process (chemisorbation).

Simply put, the protection layer is formed from the wear products of the internal combustion engine themselves. This becomes possible due to the fact that the additive contains active chemical components (chlorinated paraffins, polyesters).

Once exposed to conditions of high heat and pressure in the friction zone, a chemical reaction begins. As a result of this reaction, the metal wear products of the motor turn into an ionic state and return back to the rubbing surfaces. This is exactly the principle on which the Phenom or ER additive works.

Using engine additives: disadvantages and possible consequences

After the main advantages and features of additives have been considered, certain disadvantages should also be highlighted. It's no secret that many drivers and auto mechanics are skeptical or even strongly negative about decisions of this kind. Let us note right away that there are good reasons for this.

First of all, after using additives based on mineral powders, cases of clogging of the oil channels of the lubrication system were noted. As a result, the pressure in the system decreased, particles clogged the oil filter, bypass valves, etc.

Also, impact in the form of grinding can damage the factory hone on the cylinder walls. As you know, honing is the application of a characteristic grid of small marks. This mesh allows you to retain oil, but metal cladding compounds compare the mesh. On the one hand, the effect of reducing friction is achieved, but after the protective layer is activated, the process of engine and CPG wear intensifies.

It was also experimentally established that comparing the condition of different engines (when one engine was operated with the additive and the other without) determines significant wear of both one and the other power unit. This suggests that even if the additive has a positive effect, its practical benefit is still minimal or completely absent. Moreover, in some cases, the wear of the engine in which additives were used was even greater in certain areas.

We also recommend reading the article about what molybdenum additive is in an engine. From this article you will learn how a molybdenum additive in motor oil works, as well as what are the pros and cons of a molybdenum additive.

Observations also show that the shortcomings of additives usually become obvious not immediately, but after their long-term use. In other words, it turns out that there is no particular benefit or harm for the new engine. However, if an engine that has traveled about 100 thousand km with additives is subsequently disassembled for troubleshooting and repair, the owner may be unpleasantly surprised.

As for engines with wear, into which they begin to pour the additive, at the initial stage you can quite count on some effect (reduced oil consumption, the engine starts to run softer, compression increases, exhaust smoke decreases, etc.)

At the same time, you need to understand that the effect will definitely be short-term, and the consequences for the engine in the future may outweigh the temporary benefits. In other words, the use of an additive can significantly affect the amount of internal combustion engine repairs, which will soon have to be performed anyway.

It is important to understand that any additive means the introduction of additional components into the base engine oil. It is well known that any modern lubricants (mineral, semi-synthetic, hydrocracking or pure synthetics) already contain a package of active additives.

For this reason, oil manufacturers themselves strongly do not recommend using third-party additives, since there is a high probability of various chemical reactions occurring, sedimentation cannot be ruled out, loss of properties of the motor oil, etc. In simple words, it is not known for certain how the additive will interact with engine oil. Considering that it is not even recommended to mix motor oils from major manufacturers with similar properties, the issue of third-party additives is even more pressing.

FENOM auto chemical products for car maintenance and repair

Official review of the Maxima-Grand car service center

9 main rules for choosing a DVR

AUTOSERVICE "MAXIMA-GRAND" Moscow, st. Lyublinskaya, 133-b

Technical information

Results of tests of preparations of the brands “FENOM” and “PROFIX” (manufactured by Avtokhimiyainvest LLC, Moscow) when eliminating the defect - knocking in the crankshaft bearings (c.v.) when starting the engine and cleaning the power supply and exhaust systems (catalytic converter) of the car " Renault 19".

Test object: Renault-19 car, state-owned. number E 350 SU 99, year of manufacture 1991, mileage 148 t.km.

Preparations for testing: Reconditioner for engines of cars with high mileage FENOM OLD CHAP (FN437), Liquid crystal additive for engine oil PROFIX OIL CRYSTAL (PF451), Injector cleaner FENOM INJECTOR CLEANER (FN116), Catalytic converter cleaner FENOM CATALYTIC CONVERTER RECTIFIER (FN468) .

Diagnostics. As a result of diagnostics of the Renault 19 engine before testing, the following was revealed:

The clearances in the k.v. bearings have been increased. engine; late build-up of pressure in the lubrication system and knocking in the k.v. bearings. when starting the engine; increased idle speed (~ 1500 rpm) and fuel consumption due to poor quality injectors (due to contamination of the fuel injection system). To eliminate these defects, the following were sequentially introduced into the engine lubrication system (into the oil): the drug FN437 and after a run of ~ 300 km, the drug PF451, and the drug FN116 was added to the gas tank (in the fuel) (according to the instructions for using the drugs).

Test results.

1. Adding FN437 to the engine lubrication system did not reduce the knocking noise in the AC bearings. at startup (due to increased clearances). No negative effect from the drug FN437 was detected. 2. The addition of the drug PF451 led to the complete elimination of knocking in the AC bearings when starting the engine after a run of ~ 50 km (after using PF451). The effect is associated with increased strength of the oil film and improved lubricating properties during cold engine starts. It is quite possible that the combined effect of the drugs FN437 and PF451 compensated for signs of wear in the engine friction pairs. 3. The addition of FN116 to the fuel led to the cleaning of engine injectors of contaminants, but to the deposition of some of these contaminants on the surface of the catalytic converter. O.G. after running ~ 600 km. After adding the FN468 neutralizer cleaner to the fuel and driving ~50 km, the normal operation of the injectors and idle speed were completely restored. engines decreased to normal (~ 900 rpm), fuel consumption in the urban cycle, according to the organoleptic assessment of the driver of a Renault 19 car, also decreased.

Director of the Maxima-Grand Auto Service V.A. Soloviev

Benefits of using engine oil additives

Numerous studies have shown that the use of additives makes it possible to:

- reduce the wear rate of the internal walls of the engine by up to 40%;

- significantly reduce the friction coefficient by 2-4%;

- facilitate engine starting in sub-zero temperatures;

- restore the compression level in the cylinders, which will make it possible to increase its power by 3-5%;

- increase oil pressure in the system;

- protect the internal working surfaces of the engine from negative effects;

- remove deposits from the internal walls of the engine;

- reduce oil loss from the system and optimize fuel consumption.

A car that has engine rebuilding additives added to its engine emits much less carbon monoxide into the atmosphere. The motor also starts to run much quieter and more stable.

It is important to remember that the effect of using these products begins to appear only after a certain mileage (500-700 km). But it will remain in effect until the next oil change (but not more than 10-15 thousand kilometers).

Variables

Clause 9.7 of the Traffic Rules of the Russian Federation

Variables can be displayed or used for functions, attributes, modifiers within complex expressions, etc. Variables in Fenom are represented by a dollar sign followed by the variable name. The variable name is case sensitive. A valid variable name must begin with a letter or underscore and contain any number of letters, numbers, and underscores.

Using Variables

The following example uses simple variables to generate a welcome message.

div class="user">Hello, a href="/users/{$user_id}">{$user_name}a>.div>

The example will output the following HTML code:

div class=”user”>Hello, a href=”/users/17″>Bzicka>.div>

Variables can be an array. In this case, the key is accessed through an operator or, as in PHP, through the operators and

div class="user">Hello, a href="/users/{$user.id}">{$user.name}a>.div>

and it's the same thing:

div class="user">Hello, a href="/users/{$user}">{$user}a>.div>

In the case of an object, access to its properties is carried out as in PHP - through the operator:

div class="user">Hello, a href="/users/{$user->id}">{$user->name}a>.div>

Methods, like properties, can be called through the operator by passing any arguments to the method:

div class="user">Hello, a href="/users/{$user->getId()}">{$user->getName()}a>.div>

Note Be careful, Fenom does not check for the presence of a method in a class before calling it. To avoid a fatal error, define a method on the object class. Calling methods in a template can be completely disabled in the settings.

Below are combined examples of working with variables:

{$foo.bar.baz} {$foo.$bar.$baz} {$foo.baz} {$foo.$baz} {$foo.bar.baz} {$foo} {$foo} {$foo .5} {$foo.bar} {$foo.'bar'} {$foo."bar"} {$foo} {$foo} {$foo.$bar} {$foo} {$foo->bar } {$foo->bar.buz} {$foo->bar.buz} {$foo->bar(5)->buz(5.5)}

System variable

An unnamed system variable begins with and provides access to global system variables and system information:

- - array .

- - array .

- - array .

- - array .

- - array .

- - array .

- - array .

- - array .

- - array .

- returns the current template name.

- returns the current template name without schema.

- returns the template schema.

- returns template parameters as an integer.

- returns an array of templates referenced by the current template.

- returns the timestamp of when the template was last modified

- returns the version of Fenom.

- accessing a PHP constant: accessing a constant . A namespace is supported that is separated by a dot: access to a PHP constant, if there is no such constant, the constant will be taken.

- calling a static method. call to method . The setting disables the ability to access . You can also limit and specify the list of classes and functions available for calling.

- checking for the existence of blocks that were defined before the accessor was contacted. For example, .

- You can also use your own or existing system variables and functions

How to properly blow dry your hair

Video fact: a cyclist violated several points of traffic rules at once

1. Remember, it is strictly forbidden to dry very wet hair. Dry your hair with a towel, then let it dry a little and only then can you start using a hairdryer. When you dry your hair with a towel, remember that wet hair is very fragile, so do not rub or twist it, just gently pat it dry;

2. Before drying your hair with a hairdryer, you need to apply a small amount of protective emulsion to your hair (thermal protection for hair). This emulsion will help relieve static tension and the hair will not become electrified;

3. Before styling, it is recommended to apply special styling products to your hair, preferably using a hair spray. The spray penetrates the hair structure most quickly, but you can also use gels or styling foams;

4. Divide your hair into even sections and dry each section separately. In this case, the hair will not get tangled, therefore it will not get out during combing;

5. When drying your hair, the hair dryer should be on top, and the air stream should be directed from top to bottom, this way you will cover the hair scales and the hairstyle will look neat;

6. Dry your hair with cool, or at least warm, air, as hot air will make your hair more brittle and dull;

7. If you want to give your hair a little volume, then take a round brush, twist your hair on it and dry it with a hairdryer;

8. In order to get perfectly straight hair, you need to twist your hair around the brush, then pull it back and dry it with a hairdryer (the air stream should be from above)

This procedure must be done along the entire length of the hair, with special attention being paid to the ends so that they do not curl;

9. One of the most important rules is that you cannot use a hair dryer every day; your hair should dry naturally at least once a week. Even if you dry your hair with cold air, you are still exposing it to friction as well as damage. Blow-drying should be done no more than 4 times a week, and styling should be done with cool air;

10. After finishing styling, spray your hair with hairspray to prevent the hairstyle from becoming disheveled. Thanks to modern styling products, the hair does not become weighed down, and the style lasts throughout the day;

11. Stylists recommend applying shine to your hair after styling so that your hair shimmers not only in the sun, but also in cloudy weather. But you need to use glitter with small particles, as large glitter will look vulgar.

Kira Voloskova Editor of Voloskova.ru, knows everything about hair growth

3 min

The best professional hair dryers

Professional hair dryers are more powerful and functional than ordinary ones. They are also quite large, have an elongated body shape, a rubberized handle and a long cord.

Diva Genesis Dryer Mak Technology – for all hair types

4.9

★★★★★ editorial assessment

89% of buyers recommend this product

This model has really rich functionality: there are 5 temperature modes alone, and the same number of fan speed levels.

Simply put, Diva Genesis can be customized to work with any hair type. And Infinity Field ionic technology with a high level of negatively charged particles will make even exhausted strands smooth and manageable.

The front grill of the hair dryer is made of high-strength ceramic and tourmaline. On top of it is applied a layer with keratin and caring argan and macadamia oils, which heal the hair. The power of the device is 2100 W, the maximum temperature reaches +110 °C.

Pros:

- As many as 25 operating modes;

- Cold air;

- Intensive ionization;

- Conditioning effect due to heated oils;

- Ergonomic shape;

- Hinged filter for easy cleaning.

Minuses:

There is only one nozzle included.

Although Diva Genesis Dryer Mak is positioned as a professional model, its price is quite prohibitive. So if you want to do hair styling at home no worse than in the salon, you can fork out for this miracle hairdryer.

Ga.Ma G-Evo 3800 – ultra-light hair dryer for pros

4.8

★★★★★ editorial assessment

88% of buyers recommend this product

Unexpectedly compact and lightweight for a professional device, this hair dryer at first glance is no different from “home” models.

The same 2 speeds and 3 thermal modes, supplemented by cold airflow. And the power is rather average - 2 kW. But there is a removable filter grille and an outer mesh made of titanium.

And yet, the Italians have created a truly unique styler with a halogen lamp instead of the usual spiral heater inside. Thanks to it, soft heat easily penetrates the scalp, improving blood circulation and, as a result, hair growth.

Ion Plus ionization technology also contributes to the health of hair, producing 80% more particles than amateur counterparts.

Pros:

- Compact size and weight only 465 grams;

- Gentle heating;

- Maximum ionization;

- Long 3-meter cord;

- The set includes two hubs of different widths.

Minuses:

Inconveniently located “cold” button.

The capabilities of a professional hair dryer in a compact body will be appreciated by girls who do hot styling at home every day. It will especially appeal to those of them whose hair has already suffered greatly from other stylers.

Kapous Turbo 3800 ST – big, light, powerful

4.7

★★★★★ editorial assessment

87% of buyers recommend this product

The extended body and increased power to 2.5 kW make this hair dryer easy to use and reduce drying time.

The Soft Touch coating prevents the device from slipping in the palm, and the handle has a special ergonomic shape and is equally suitable for right-handers and left-handers.

Despite its relatively light weight, you won’t be able to use this hairdryer yourself – it’s very bulky. But for salon workers, this design is ideal.

Except that the Turbo's set of settings is not rich - at the level of amateur models. But the kit comes with two hubs at once.

Pros:

- Ergonomic shape and light weight;

- High-quality case material;

- Good power (even at minimum the hair dryer produces 2300 W);

- Fixation of styling with cold air;

- Cord 3 m long.

Minuses:

- No ionization mode;

- It is inconvenient to use such a hairdryer on your own.

The Kapous Turbo is an affordable and well-designed hairdryer that every hairstylist in your salon will be happy with.

TOP 5 best hair dryers for home

There are a great variety of devices for drying hair on the shelves of specialized stores, so it’s easy to get confused by such an abundance. We have compiled a rating of the most popular hair dryers, which includes products that are especially popular among domestic women.

Bosch PHD9760/9769

This model is suitable for both ordinary customers and professional hairdressers.

Hair dryer Bosch PHD9760/9769

The device is distinguished by power, 6 speed modes, 3 temperature modes, and also has a cool air supply function.

Pros:

- a powerful motor that allows the device to work for a long time without a pause;

- ionization (it can be turned off);

- long cord (about three meters);

- additional attachments – concentrator and diffuser;

- quick drying;

- ease of use of the diffuser.

Minuses:

rather heavy model.

Hair dryer Bosch PHD9760/9769

Philips HP8280

A stylish hairdryer that lovely ladies like not only for its appearance, but also for its excellent characteristics.

Philips HP8280 hair dryer

The device has a special touch sensor that determines how hot the hair is and reduces the temperature when drying the hairstyle.

Pros:

- 6 speed modes;

- powerful device;

- ionization function;

- supply of cool air;

- stylish appearance;

- convenient diffuser;

- long wire;

- removable filter.

Minuses:

- high cost;

- Quite a heavy model.

Hairdryer Philips HP8280 DryCare Prestige

Panasonic EH-NE31

A compact and convenient model that allows you to quickly and easily dry your hair.

Hair dryer Panasonic EH-NE31

The convenience of a hair dryer lies in the fact that it releases separate air flows of different power levels, which, alternating and separating the strands, evenly dry even thick hair.

Pros:

- compactness;

- 6 speed modes;

- the ability to ionize hair;

- drying with separation flows;

- quiet work.

Minuses:

lack of attachments.

Panasonic hair dryer

Polaris PHD 2077i

In addition to its bright design (the device is made of purple plastic), the hair dryer is low cost, has good functionality and is of high quality.

Hair dryer Polaris PHD 2077i

In addition, the product is quite compact and weighs little, so your hand will not get tired when drying.

Pros:

- stylish appearance;

- light weight;

- reasonable price;

- overheat protection;

- 3 temperature settings;

- 2 stages of power switching;

- high speed hair drying.

Minuses:

- the cord does not rotate;

- The hair dryer makes noise when drying.

Hair dryer Polaris PHD 2077i

Rowenta CV5351D0

Quite a good model with high power and gentle treatment of hair.

Hair dryer Rowenta CV5351D0

Several modes, including gentle, will allow you to efficiently dry and style even the most unruly hair. Additional features will only enhance the positive effect.

Pros:

- ionization function;

- cold air mode;

- 3 temperature settings;

- gentle drying mode;

- stylish design;

- quick hair drying.

Minuses:

- the model is a bit heavy;

- The cold air supply button is tight and has to be pressed.

Rowenta hair dryer It is impossible to give the only correct answer to the question of which hair dryer is better. Owners of short hair should ask how to choose a good hair dryer brush. For quick drying of hair, a regular powerful hair dryer is suitable, and for short hair, a hair dryer with a concentrator attachment is suitable.

A professional device will help a master create an interesting image, but in the hands of an amateur it is dangerous. Choose the hair dryer that suits your technical specifications.

Maria IvanovaHousewife

Mother of two children. I have been housekeeping for more than 7 years - this is my main job. I like to experiment, I constantly try different means, methods, techniques that can make our life easier, more modern, more fulfilling. I love my family.

Partner news

Sections of the site

- News

- Family and children Children's health

- Development and education of children

- Goods for children

- For women

- We live in cleanliness and order

Handicrafts

- Signs and superstitions

Travel

Results

Brand FENOM

The brand name FENOM is derived from Fe (designation of iron in D.I. Mendeleev’s table) and Nom (part of the Latin word nomen - “name”). The FENOM line of products is designed to increase the efficiency of vehicle preventive maintenance and significantly extend its service life.

FENOM products, developed and produced in Russia, are today rightfully considered one of the most knowledge-intensive and functional auto chemical products. Thanks to the use of high technology, FENOM products allow us to achieve a truly phenomenal improvement in the performance characteristics of a car and extend its service life.

The first products under the FENOM brand appeared in 2000. Even then they differed from their analogues in their exceptional efficiency. FENOM products have won more than 50 international awards for innovation and efficiency.

Many FENOM products have become classics of auto chemical products and have gained recognition among motorists.

For example, the multifunctional metal conditioner FENOM, which simultaneously has anti-friction, anti-wear and extreme pressure properties.

How does FENOM air conditioner work? The carrier - that is, oil - delivers it to the lubricated friction pairs, where FENOM forms a thin, but at the same time very durable protective film on their surface, which isolates the rubbing surfaces from each other and thus protects them from wear. In case of damage, the protective film has the ability to self-heal. It is significant that the FENOM air conditioner reliably protects rubbing parts even in extreme conditions, for example, in the event of an emergency loss of oil in the engine. As a result of regular use of the FENOM multifunctional metal conditioner, not only friction and wear of parts, but also the consumption of fuel and lubricants are significantly reduced.

Experienced motorists are familiar with the FENOM piston ring decarbonizer firsthand. It is used if compression in the engine cylinders decreases, engine oil consumption increases, blue smoke appears from the exhaust pipe, or the car simply begins to pull worse. All these reasons are in most cases caused by the occurrence of piston rings due to the formation of carbon deposits. The FENOM decarbonizer allows you to free piston rings “from captivity” and thereby reduce the smoke and toxicity of exhaust gases, increase engine power, reduce fuel and oil consumption, and restore vehicle acceleration dynamics

It is important that thanks to the FENOM decarbonizer, there is no need to disassemble the engine to clean the piston rings! A special place in the FENOM assortment is occupied by the Old Chap line, which includes reconditioners for the engine, transmission and power steering. Today, these drugs are one of the best means for restoring the performance characteristics of high-mileage vehicles (more than 100,000 km)

FENOM chemists and technologists are constantly working to develop new drugs and improve the formulations of existing ones.

Recently, a new group of products has appeared in the FENOM assortment: car fragrances. We present three series of fragrances that differ from each other in the method of attachment and operating principle: membrane fragrances, fragrances for the air deflector and capillary pendant fragrances. Each line includes 12 scents for every taste: popular berry, fruit, floral scents, freshness, coffee, elegant perfume, etc. From such a variety, it is not difficult to choose the optimal solution for yourself and your favorite car.

Ask for new items in stores in your city!

Oil additives. "Phenom" according to "Forsan"

If you think of auto chemicals as quackery, you can skip this article. Our material is addressed to a large circle of car enthusiasts who are interested in everything and who want to get more from the car than the factory gives it. Especially if it doesn’t cost crazy money and doesn’t require long and risky torment in the garage over the “insides” of the engine: you just need to pour something from a beautiful bottle into the oil neck or fuel tank.

Alexander Shabanov

If you regard auto chemicals as quackery, you can skip this article. Our material is addressed to a large circle of car enthusiasts who are interested in everything and who want to get more from the car than the factory gives it. Especially if it doesn’t cost crazy money and doesn’t require long and risky torment in the garage over the “insides” of the engine: you just need to pour something from a beautiful bottle into the oil neck or fuel tank.

Rice. 1. Change in the torque of the ZMZ-402 engine when combined with RVS preparations and an ionic metal-clad composition. © Photo:

Many people have tried using various oil additives, or, as they should be correctly called, anti-friction restoring agents. For some, the effect appeared immediately, and they believed in the effectiveness of this method of engine treatment, while others were disappointed in the drug itself and in all auto chemicals in general. But those who have received the effect often wonder: what will happen if, in addition to, say, Phenom, after a while you add, for example, Forsan? Maybe then you won’t have to refuel at all, and the car (at least the engine) can be inherited by your great-grandchildren?

We have already written about the effect of these drugs many times before. But what will happen when the same engine is treated together with different oil additives is an absolutely obscure question. Representatives of companies answer this question differently. Those interested only in the volume of their sales say: “Pour our drug anywhere, it will still be good!” (it will be good for them, that's for sure!). Others, more cautious, note: “There is no need to mix any compositions; if you have already used something for processing, then under no circumstances should you change the compositions to others.” Which one is right? And, as before, only an engine test can answer this question.

But who would want to risk their engine for such experiments? Probably, such a thing would not occur to a normal car enthusiast. We -

Rice. 2b. The piston after sequential treatment with the RVS composition and an ionic metal-clad composition. © Photo:

another matter... During previous tests, some of which were described in previous issues of our magazine (“You Can’t Deceive the Motor,” Nos. 11–12, 2003), we accumulated a fair number of motors, each of which was treated with various additives. We know their “history” and parameters. Why not risk this “wealth” to obtain data on

Rice. 2a. Piston after treatment with RVS composition. © Photo:

do additives work together?

There are now more than two dozen drugs of this type on the Russian auto chemical market at the same time. If you work on the principle of “everyone with everyone,” then probably life will not be enough for such work. So let's do it simpler. Despite the assurances of any additive manufacturer that their drug is unique, one of a kind, a product of the military-industrial complex, or at least of space technology, which the Americans once smeared on something in the Shuttle, all these drugs are The principle of operation can be divided into several groups.

The first, most common group is preparations based on serpentinite mineral powders, or friction geomodifiers. These include such well-known drugs as “Forsan”, “Hado”, RVS, “Suprotek”, “Avtomineral”, etc. They produce micro-grinding of engine friction surfaces with the formation of a special protective metal-ceramic layer, characterized by low friction and wear coefficients. In general, this is a purely Russian invention; you will not find drugs of this class in other countries of the world, except perhaps in a few representative offices of some Russian companies.

The second, also numerous group of additives is metal-clad compositions: “Resurs”, RiMET, “Avtoplus”, “Metallize” and the like. They contain various soft metals either in the form of fine powders or in ionic form. When these compounds enter the friction zone, they form a thin covering (cladding) layer on the surface of the part, “healing” its microdefects and thereby helping to improve the performance of crankshaft bearings and cylinder-piston group parts.

The third group is drugs that carry out a certain chemical effect on the friction surface and form protective layers using chemisorption mechanisms. These are the notorious metal conditioners - ER, "Phenom", "Renom", preparations of the epilam group - "Universal Modifier", as well as compositions of the "Energy-3000" group, which form protective organometallic layers. All of these drugs, with the exception of epilamide, work according to the so-called Garkunov principle, according to which a cladding protective layer is formed through the use of wear products. These preparations contain active substances - chlorinated paraffins and polyesters for metal conditioners, special groups of organic substances for Energy-3000 preparations, which, under conditions of high temperatures and pressures in friction zones, supposedly convert metal wear products into an ionic state and return them to the zones friction. These compounds mainly came to Russia from abroad, although the principle of their operation bears the name of a Russian scientist. Apparently, they are carefully studying our achievements...

Fig.3. Change in torque of the VAZ-2108 engine during joint treatment with a metal-clad composition and a friction geomodifier. © Photo: 5 wheel

There are also all sorts of exotics - various “liquid diamonds”, “fullerenes”, Teflon-containing additives. What auto chemical specialists can’t think of! Either the torsion fields lift the shaft in the bearing, or the additives generate some kind of waves unknown to science, or they activate the hereditary memory of metals, forcing them to grow and compensate for wear... Let’s leave all this on the conscience of the manufacturers of these drugs.

In general, the three groups of additives described above account for more than 90% of the total auto chemical market in this drug sector. Therefore, it makes sense to focus on them. So, there are three principles of surface treatment - micro-grinding with the formation of a metal-ceramic layer, metal cladding and chemical surface treatment. So let's see how these principles are combined with one another, what can be expected from the consistent application of these methods in various combinations.

The first “martyr of science” was the ZMZ-402 engine with a fair history and a mileage of more than 160 thousand km. The initial state of the engine was characterized by reduced and uneven compression, and the presence of significant signs of wear on all friction surfaces. Moreover, the initial bulkhead revealed destruction of the inter-ring bridges of the pistons, making it impossible

Rice. 4a. The surface of the connecting rod bearing after sequential treatment of the engine with a metal-clad composition and friction geomodifier, magnification x32. © Photo:

further use of the engine is possible. To revive the engine, we replaced the pistons with new ones without touching other parts.

After initial diagnostics and running-in, necessary due to the replacement of pistons with new ones, the engine was treated with the RVS compound. This is a repair and restoration gel, built, according to its manufacturers, on the basis of a certain composition of fine serpentinite powders and catalysts. The gel was introduced into fresh oil, after which the engine worked on the stand for more than 50 hours. During the tests, we measured changes in power, fuel consumption and exhaust gas toxicity at certain intervals.

The result was quite optimistic: after treatment, compression increased, fuel consumption decreased significantly, and power increased (Fig. 1). The engine has clearly “perked up”. Its autopsy after testing showed a generally common picture for the use of drugs of this group: alignment of the surfaces of the cylinders and shaft journals, but at the same time a network of small scratches appeared on the surfaces of the piston trunks. The depth and number of scratches on the working surfaces of the bearing shells has decreased, but we have not received complete “healing” of these surfaces. The effect of engine treatment with the RVS composition is persistent and does not require repeated treatments. We were also convinced of this by running the engine for a long time on clean oil. The engine was pre-washed to remove particles of the drug from the oil. The change in the result obtained after processing was within the measurement error.

But the surfaces of the pistons and liners clearly asked for something more. The simplest option is to try to “treat” them with some kind of metal-clad composition, which is what we did. For re-processing of the engine, an ionic cladding composition similar to the Swiss drug “Metallize” was chosen. Soon after the composition was introduced, the engine parameters increased slightly (Fig. 1). After several dozen engine hours, the oil was changed, the engine was allowed to run some more, and then it was opened. The result was interesting.

Microphotographs of the surfaces of the cylinders and piston rings did not reveal any noticeable changes compared to what we saw after the engine was treated with RVS. Something was observed only in the lower parts of the cylinders, where the piston rings do not reach. This is understandable: soft layers of cladding metals cannot resist the hard chromium of piston rings. But the surfaces of the pistons (Fig. 2) and liners shone like new. Interestingly, the initially black surfaces of the piston trunks became shiny and white due to the technological running-in coating. The initial network of scratches was visually weakly distinguishable. Hence the effect of increasing power: first of all, the improvement in the performance of bearings affected. A reduction in friction between the pistons and cylinders also contributed.

Rice. 4b. The edge of the first piston ring after sequential engine treatment with a metal-clad composition and friction geomodifier, magnification x40. © Photo:

The conclusion is simple: preparations from the group of friction geomodifiers are quite compatible with metal-clad compositions when processed in the sequence “micro-grinding - surface cladding”. Moreover, such a combination when processing an engine makes serious sense. Geomodifiers work effectively in the area of friction units whose surfaces have high hardness (piston rings - cylinder, camshaft cams - rocker, etc.), but at the same time they can, especially with a large size of mineral particles, partially damage the working surfaces of “soft” ones. details. Ionic metal-clad compositions eliminate these defects, enhancing the processing effect.

But this does not apply to compositions into which soft metals are introduced in the form of fine powders, such as “Resurs” and RiMET. We have not tested these compounds, and it is not in our rules to assert something without appropriate justification.

What will happen if the processing sequence is changed - that is, first cladding with a layer of soft metals, and then processing with some kind of friction modifier containing mineral components? Logically, nothing good. But we need to check - what if we are wrong?

For this purpose, another “guinea pig” was taken - the VAZ-2108 engine, treated with the metal-clad composition “Autoplus-2025”. The results of these tests were described by us in the article “You Can’t Fool the Motor” at the end of 2003. In general, despite the fact that the engine underwent a complete overhaul before treatment (this was the condition of previous comparative tests), the effect was not very large, but quite noticeable (Fig. 3).

This seemed to us not enough, we reassembled the engine, installed it on a stand, rolled it, took off the basic characteristics so that we had something to compare with in the future, and then treated it with a drug of the first group - a friction modifier, in its pure form containing only powders of the mineral serpentinite. The technology for treating this composition does not provide for its long-term presence in the engine. It is introduced into the oil for 30–40 minutes, which the engine must run at idle. Then an oil change, filter replacement and engine flushing are required to remove the compound. In this case, the maximum effect is not achieved immediately, but only after a certain time - about 1500 km. This is explained by the fact that the residues of the composition introduced on the friction surface during processing continue to work.

The dynamics of changes in motor parameters after treatment showed a significant decrease in the rate of their growth compared to what we saw earlier, when the geomodifier was introduced into an engine that had not been treated with anything before. And the treatment effect itself was significantly less than expected, and in some modes it became even worse (Fig. 3). When opening the engine, we saw that there was practically nothing left of the metal-clad layer: the mineral powders “ripped it off” during processing, which, in general, is understandable... The surfaces of the liners were covered with deep scratches, and chipping of the edges of the piston rings was observed (Fig. 4).

Rice. 5. Change in torque of the ZMZ-402 engine during joint treatment with a metal-clad composition and the preparation “Energia-3000”. © Photo:

But something else was interesting: engine measurements after testing revealed a sharp change in the geometry of the cylinders. Moreover, which is generally paradoxical, in the unloaded plane of the cylinder (along the axis of the piston pin) great wear was observed, and in the loaded plane, on the contrary, a decrease in diameter! Whether this is an accident or a pattern is difficult to say based on the results of one test, but, in principle, it can be explained as follows:

Rice. 6a. Surface of the connecting rod bearing, initial state, magnification x40. © Photo:

way.

During geoprocessing with mineral powders, which are hard compared to the cladding layer, the metals of the layer on the surface of the cylinder experience an alternating load, which leads to their so-called embrittlement. Particles of the layer are torn off the surface of the cylinder and washed off with oil. In loaded areas of solid parts - cylinders, crankshaft, these particles, under the influence of high contact pressures and temperatures, transform into a plastic state and return from the oil - “smeared” onto the surface. In unloaded zones, there is not enough pressure to return the metal, and effects similar to abrasive wear operate. On the surfaces of the pistons and liners, covered with a layer of soft cladding metal, solid particles simply penetrate, turning them into a kind of “grater” that sharply accelerates the wear process. This is such a “selective” transfer! It is unlikely to be useful for the engine. And indeed, the compression in the cylinders after such geoprocessing dropped significantly: the deterioration of the fit of the rings to the cylinder mirror affected it.

Of course, this is only a version that explains the result obtained, but it is quite plausible if you understand how each composition works and what it does. However, further research should show whether we are right or wrong.

So far, the conclusion is obvious: geoprocessing after metal cladding does not give anything good. Well, we confirmed our initial assumptions, albeit at the cost of a damaged engine. But such is the fate of “guinea pigs” - to sacrifice themselves for the sake of others...

Rice. 6b. The surface of the connecting rod bearing after joint treatment with a metal-clad composition and the “Energia-3000” composition, magnification x40. © Photo:

What will happen if, after metal cladding, you use any of the drugs of the third group, the operating principle of which is based on chemical modification of the surface - something from metal conditioners or drugs like “Energy-3000”? We tried this too. The ZMZ-402 engine was taken as the next sufferer. The initial condition did not inspire much optimism; it was found in the garage of our university after many years of faulty service.

In motor oil d

Rice. 8. Change in torque of the VAZ-21083 engine when combined with a friction geomodifier and the Energy-3000 preparation. © Photo: 5 wheel

The drug "Autoplus-2025" was added, after which the engine worked for 30 hours on the stand. The oil, as required by the instructions for use, was not changed. We did not see anything new compared to the tests of this drug on the VAZ-2108 engine described above. The engine parameters rose somewhat, the compression leveled out, the dynamics of the “treatment” were rather sluggish, but continued throughout the test. As our experience in previous tests has shown, metal-clad compounds only work when they are in oil. When you change the oil and stop using the drug, the effect quickly disappears.

But before changing the oil, we introduced the oil preparation “Energy-3000” into the engine for about 10 operating hours. For some time, both the metal-clad composition and the drug, the operating principle of which is based on the formation of protective metal-organic layers on friction surfaces, ended up in the oil. At the same time, the growth dynamics of engine parameters noticeably increased. According to the instructions for the Energy-3000 drug, an oil change was required after 500–1000 km. The same 10 engine hours that the two drugs worked together provide an analogue of this mileage. The engine was washed, the oil was changed and we began to see what would happen next. We drove the engine for another 30 hours, measured its parameters, but both power and fuel consumption changed over time only within the measurement error. That is, the effect of the treatment was recorded despite the fact that there were no longer any compounds in the motor oil.

Rice. 7a. Surface of the piston ring, initial state, magnification x52. © Photo:

When opening the engine, we were pleased with the appearance of the friction surfaces (Fig. 6) - even without any microscopes, the processing effect was visible. The surfaces of the parts in the loaded areas had a characteristic “glassy” shine, which we noted earlier when testing the “Energia-3000” drug.

What happened? Obviously, we have combined the positive properties of both compositions. Metal cladding preparations provide a good, but unstable restorative effect - they contain a lot of “building material” for building up the surface in wear areas, but the lifetime of the formed layer is clearly not enough due to the use of soft metals. Preparations such as “Energy-3000” or metal conditioners work on the principle of forming stable chemisorbed layers - essentially, something like oxide films, but they just lack this “building material” for effective restoration. And together it turns out quite well... For the sake of interest, we tried to combine two drugs with similar mechanisms of action during processing. Representatives of the third group were taken - first “Phenom”, and then, after changing the oil, “Energia-3000”. We treated the engine, which also participated in the comparative tests described in the article “You can’t fool the engine.” Then we revealed a fairly high effect from using Phenom, but also noted its increased tendency to form deposits.

Rice. 7b. The surface of the piston ring after joint treatment with the metal conditioner “Fenom” and the drug “Energy-3000”, magnification x52. © Photo:

We repeated the experiment, again treating the engine with Phenom, and the effect compared to the initial state was similar, but, of course, significantly less: after all, this was not the first treatment. Then the engine was washed and allowed to run on clean oil. As before, the effect of the treatment began to slowly decrease. Energy-3000 was added to the oil. Positive dynamics of parameter growth appeared again, and at the end of the treatment, both power and fuel consumption became better than after the Phenom. And again the effect turned out to be more persistent: metalorganics recorded the “servovite” layers of the “Phenom” (Fig. 7).

Immediately after introducing Energia-3000 into the engine, a sharp increase in the yield of residual hydrocarbons in the exhaust gases was observed. This can only be explained by the cleaning effect of the drug, which removes organic deposits formed during the decomposition of chlorinated paraffins, which are the active components of metal conditioners. Over time, the toxicity returned to normal.

Rice. 9a. The surface of the crankshaft after joint treatment with a geomodifier and a metal conditioner, magnification x32. © Photo:

But we observed the most interesting thing when we tried to combine engine treatment using friction geomodifiers (preparations of the first group) with metal conditioners (third group). For this purpose, another VAZ engine was taken, pre-treated with Forsan. The dynamics and effect of the treatment were generally positive. Both engine power and efficiency have increased significantly, and the wear rate of friction joints has dropped sharply.

Rice. 9b. The surface of the connecting rod bearing after joint treatment with a geomodifier and metal conditioner, magnification x40. © Photo:

And then a metal conditioner group drug was added to the oil. At first, the engine parameters even seemed to increase, but then suddenly they began to get worse and worse (Fig. 9). The power began to drop and the oil pressure dropped. Without bringing the matter to the complete destruction of the engine, we stopped the experiment. The engine was disassembled, and then everything began to become clearer. The working surfaces of the crankshaft and cylinders were covered with “ulcers” that were visible even without a microscope. And on the liners there was a picture similar to what we could see if the first drops of rain fell on a dusty road (Fig. 9). This is pronounced chemical erosion of the metal. But where did it come from?

We have analyzed

Rice. 10b. Crankshaft surface, initial stage of geomodification, magnification x32. © Photo:

the state of friction surfaces after geoprocessing, before introducing a metal conditioner into the engine. And everything became clear. The microphotographs (Fig. 10b) clearly show foci of formation of the metal-ceramic layer - white spots on the dark surface of the part. Moreover, with an increase in treatment time, concentration of the drug and a change in its composition, the size and concentration of these spots expands, gradually occupying an increasingly larger area: the geomodification of the layer progresses (Fig. 10c). In these zones, mineral particles are introduced into the metal structure. But this process is associated with large local heating of the surface layers of the metal. It continues even after the composition is removed from the oil: the already embedded mineral particles continue to work. In addition, sections of the geomodified layer have thermal conductivity two orders of magnitude lower than the metal itself - that is, there is practically no heat removal from these parts of the surface, which further increases their temperatures.

The action of metal conditioners causes activation of surface chemical reactions generated by active compounds.

Rice. 10a. The crankshaft surface before treatment with a friction geomodifier, magnification x32. © Photo:

agents included in their composition (chlorine, halogens, organic compounds). And the rate of these reactions increases greatly with increasing temperature in the core. The concentrations of the components of metal conditioners were selected, naturally, based on normal temperatures in working areas, without taking into account the possibility of their anomalous increase caused, for example, by the use of friction geomodifiers. And the process of chemical modification of the surface turns into the development of local erosion of the surface layers of metals in the areas of mineral penetration.

Rice. 10th century Crankshaft surface, development of the geomodification process, x32 magnification. © Photo:

Therefore, such a combination of engine treatments is extremely contraindicated. There is no need to “smear” the engine, for example, with “Phenom” after “Forsan” - this is a sure way to ruin it.

Firstly, you can combine treatment with drugs from the same group. Thus, the use of RVS gels allows for repeated treatment, for example, with Forsan. The main thing is not to overdo it: we described the possible negative effects of such treatments in our magazine (see “Debate on Friction”, No. 5, 2002). Various metal cladding compounds or metal conditioners are also combined.

Secondly, treatments in the sequence “micro-grinding - metal plating” and “metal plating - chemisorption of the protective layer” are combined and even desirable, especially for worn-out engines, that is, the sequential use of drugs of the first and second, as well as the second and third groups.

And what absolutely cannot be done is to use micro-grinding with preparations of the first group after metal cladding with compounds of the second group (for example, Forsan after Resurs or RiMET) or treat the engine with preparations of the third group (metal conditioners) after they have been geotreated with preparations of the first group.

Unfortunately, how much

“PHENOM” BY “FORSAN” © Photo:

No manufacturer of motor oil additives has this information. It's a pity! After all, engine additives are like medicines for humans, and they should be checked for any compatibility and contraindications. The only way to ensure that the medicine does not turn into poison for the engine is the certification of these drugs, which has been discussed for quite some time. Of course, this is extra trouble for auto chemical manufacturers, but it guarantees the quality of the product for all its consumers.

And further. In order to understand how to use additives correctly, what can be expected from them and what they are combined with, it is necessary to have accurate information about their composition and mechanism of action. But it is not always possible to find out about this not only from the seller, but also from the manufacturer of the drug. And most often you can only dream about having this written on the packaging.

The conclusion is simple: if, instead of a specific answer to the question of what principle of surface protection is used in the preparation, they start telling you fairy tales about “fields of unknown nature”, “hereditary memory of metals”, “new physics”, “loosening and growth of the crystal lattice” and However, it is better to avoid these “specialists”.

News Media2

Discussion Cancel

I want to receive the most interesting articles

What's the result?

Taking into account the above, we can conclude that in addition to the declared positive effect, which in practice may not appear, may be short-lived or insignificant, there are always serious additional risks.

We should not forget that after pouring the additive into the engine, the lubrication system may become clogged, a layer will form on the internal combustion engine parts that can impair cooling in friction zones, etc. Also, some compositions have a chemical effect on metal surfaces, as a result of which, after the additive is activated, the process of even more accelerated wear begins.

For this reason, the best way to protect the engine is not an additive, but proper operation of the internal combustion engine, the use of high-quality motor oil and timely replacement of lubricant. As for the additives Xado, Suprotek, ER or Fenom, the engine additive of one or another manufacturer has not been tested for compatibility by the oil manufacturers themselves.

This means that even on worn-out engines it is necessary to carefully weigh the pros and cons so as not to further increase the cost and complexity of repairing the power unit.

Operational tests of the "Renom Engine" additive on the MTZ-82 wheeled tractor

In March-April 2013, specialists carried out operational tests of the repair and restoration additive Renom Engine on the MTZ-82 wheeled tractor when performing transport work.

Before replacing the engine oil on the diesel engine D-242 of the MTZ-82 tractor with a total operating time of 8951 engine hours, the compression of the engine cylinders was measured, and the average fuel consumption for transport work was estimated using the GLONASS navigation system. Before replacement motor oil, the repair and restoration additive Renom Engine was introduced into the oil and filled with it into the tractor engine. The MTZ-82 tractor was sent into operation for transport work at Moscow HorseGAZelle LLC for a year and a half, operated with and without the specified metal conditioners for 160 thousand kilometers.