Which are the best 4th generation HBO injectors? Full review

Car enthusiasts often wonder which are the best 4th generation LPG injectors. Gas equipment is becoming increasingly popular. This is due to the high efficiency and cost-effectiveness of gas equipment. But, when installing new equipment, it is important to choose the right components for it. Particular attention should be paid to the injectors. The effectiveness of the entire complex largely depends on the correctness of their operation. Therefore, it is a mistake to buy the first injectors you come across, without taking into account their features and technical characteristics. The cost of such a mistake is usually increased fuel consumption and low vehicle response.

Malfunctions in the gas injection system

The LPG gas injector, if there is a malfunction in the injection system, is completely repairable. But for this you need to have a repair kit of gas injectors on hand.

Since the correct and coordinated operation of the entire LPG system is determined by the injectors, you need to learn how to diagnose their malfunctions.

It could be:

- nozzle contamination;

- imbalance of the rack;

- open circuit;

- coil short circuit;

- electronic problems.

There can be many reasons, but if you ignore them and do not react in time, you can limit yourself to not just replacing parts of the injection mechanism, but say goodbye to the entire power unit. Therefore, if in doubt what exactly the fault is, it is better to take the car to an electronic stand, where mechanics will describe the breakdown in detail.

It might end up figuring out how to clean your gas injectors, or maybe you'll need an advanced repair. But, in any case, this is more profitable from an economic point of view than replacing the entire engine.

Although the new generation of gas equipment is already equipped with systems that themselves monitor and diagnose problems. But still, if the car is retrofitted with a gas installation, inspecting the system itself is absolutely not an unnecessary manipulation. It happens that during the investigation, minor little things come to light, which, however, can lead to serious damage.

Also, when purchasing injectors, you need to read reviews of the manufacturer and compare prices for such parts, since cheap parts can cause big problems. It is best if you have any questions regarding HBO, contact the station, where specialists can advise on the operation of the HBO system.

On our website there are articles about gas injectors from companies:

- Lovato;

- Valtek;

- AEB;

- Barracuda;

- OMVL.

General characteristics

Which are the best 4th generation HBO injectors? Before answering this question, it is necessary to understand the main technical features of these parts. The gas injector is the last link in the fuel system. Its task is to accurately dose the gas supplied to the cylinder. The injectors are controlled by the HBO control unit. Thus, it is possible to produce the most accurate distribution of gas among the cylinders and supply it at the right time. The use of such controlled nozzles was able to eliminate many problems associated with the use of gas that were common in earlier generations of gas equipment.

Essentially, an injector is an electromagnetic valve. The control unit sends a signal in the form of a pulse and the valve opens. The opening time directly depends on the pulse duration. Thus, the supply of the required amount of gas is achieved. Most of the injectors on the market are rod injectors. They are sometimes called "type 30".

Recommendations for selection

Having understood some of the features of injectors, you can move on to choosing a specific part. The first thing you need to decide is how much price you are willing to spend to purchase them. Sometimes people, trying to save money, buy the cheapest options. Such parts usually fail quickly. Having spent less money when purchasing, you will soon be forced to purchase and install new ones. As a result, you will not receive any benefit.

Many consider injectors in the mid-price category to be the best option. But there are limitations here. If the car is powerful and has a modern engine management system, budget injectors cannot cope with the load. This is reflected primarily in dynamics and power. For such cars, it is best to purchase good injectors recommended by the manufacturer.

Please note that the operation of the nozzles is affected by their position in space. This especially applies to modifications with lateral gas supply. Before purchasing, determine how the injectors are located in your car. Purchase only parts whose documentation indicates the operating position after installation. If you do not pay attention to this factor, problems with injector contamination will soon arise. The engine will begin to operate unstably, and other unpleasant features associated with clogging of the power system will begin to appear.

It should also be taken into account that all injectors are divided into repairable and non-repairable. The latter are usually a little cheaper, but they are disposable. After failure, you will have to replace them with new ones. Repairable injectors are more reliable in operation; some of their parts can be replaced with new ones. This option is usually more expensive.

There are quite a large number of different brands on the market that offer injectors of varying quality. Let's name the most reliable and popular of them:

- OMVL REG

. It is easy to install. Due to the structure of the ramp, it can be installed at any suitable angle; - Barracuda

. These nozzles appeared on sale relatively recently. The original technology made it possible to reduce the friction of the moving parts of the part. The service life of the injectors has increased significantly; - Valtek tape 30

. The main advantage is the low price. They are repairable. On average, the repair kit is changed every 30-40 thousand kilometers. There are known cases when such injectors served for 400,000 kilometers.

Conclusion

. Gas equipment on cars is becoming more common. Therefore, more and more drivers are interested in which 4th generation LPG injectors are better. In fact, although there are many options, the whole choice comes down to evaluating the main functions.

I’ll briefly go through the most popular options.

Valtek Type 30. Very popular among installers, and it's easy to explain

The injectors have a simple and understandable design, can be easily repaired and are unpretentious to the quality of “our” gas, which is important. In addition, the price of such injectors is quite reasonable, so there are quite a lot of people who want to install such “forces” for themselves.

The disadvantages include low accuracy, although to a large extent everything depends on the correct calibration and configuration of the entire gas equipment. Due to their popularity, these injectors are copied by all and sundry, so “clones” of Valtek Type 30 are also found in Alex, Mimgas and Rail.

Valtek Type 34. These injectors are no less popular compared to “Type 30”, but they have more disadvantages. The first and biggest drawback is that the injectors are not repairable. The second disadvantage is that they have a short resource, so be prepared to replace them after 50 thousand km.

OMVL

The injectors from this manufacturer have much better dosage accuracy than the “bestseller” Valtek Type 30, in addition, the plastic housing allows you not to take into account temperature and use these “forces” with electronics that do not take into account the temperature of the injectors

Premium class

Barracuda. These injectors have excellent accuracy and reliability, they are not “afraid” of low-quality fuel, are resistant to contamination and are close in their characteristics to the market leader in injectors - Keihin. Another plus is that Barracuda injectors do not require calibration and have a long service life.

Keihin. Keihin injectors are rightfully considered the most accurate and temperature-independent. In addition, they work on any fuel, even the worst. The only drawback of these devices is their price. But, as you understand, you have to pay for everything...

Hana. Hana injectors are also quite good and belong more to the “premium” segment than to the mass market. Hana are an almost exact copy of Keihin injectors and have the same advantages as Keihin. The only difference is the price, it is more affordable.

Cylinders are also usually selected according to two criteria: volume and type (toroidal or cylindrical). The most important thing when choosing a cylinder is to buy original products that have all the necessary certificates and have passed all tests.

Read more about how to choose a cylinder here. I also recommend: Inspection of HBO cylinders: what is it, why and how does it happen?

The choice of gas equipment is a very important step, which should be taken no less seriously than the issue of installing this equipment. Even the most expensive and high-quality gas equipment installed with violations can cause a lot of troubles and inconveniences; in the end, you will overpay in vain, get a lot of problems and, most likely, will forever refuse to use gas as an alternative fuel. Weigh all the pros and cons, study the issue as thoroughly as possible and make your choice. If you are not sure that the selection of components will be correct, I advise you to buy a ready-made LPG kit, the components of which fit together perfectly and will not cause problems during operation. Monitor the quality and demand all the necessary certificates; there are often scammers on the market.

I have everything, write what you think about this, what in your opinion is better to buy and what do you think is the right way to choose LPG for a car

Thank you for your attention and see you again at HBOshnik. I would be extremely grateful if you repost this article on social media.

networks, there are special buttons for this below. Thank you in advance, peace and goodness to everyone! Bye

Gas injectors

Today, car gas equipment systems are becoming quite popular due to the more economical cost of fuel. Starting from the fourth generation, the system includes electromagnetic gas injectors. We will conduct a comparative analysis of these LPG elements from individual manufacturers to understand which injectors are right for you.

General concepts

LPG or gas equipment (approved abbreviation - LPG) is additional equipment for a car, the purpose of which is to store and supply fuel in a gaseous state to the internal combustion engine.

This type of fuel includes methane and a mixture of butane and propane. There are six generations of gas equipment. Differences between HBO generations in gas supply and regulation systems (injector, carburetor). 4th generation HBO injectors are an equipment unit that is used in parallel or distributed sequential injection of a mixture into an engine. Its task is to dose the fuel.

About Lovato

The first Lovato workshops, named after Ottorino Lovato, appeared in Vincenza (Italy) in 1958. In 2007, Lovato workshops became known as Lovato Gas, and in 2008 Lovato Gas became part of the Group, a world leader in alternative automotive fuel systems for the Compressed Natural Gas (Methane) and Liquefied Petroleum Gas (Propane) markets. Landi Renzo Group is listed on the Borsa Italia stock exchange and has several branches around the world.

Lovato is one of the first European companies to enter the Russian market. The experience of Lovato engineers made it possible to translate the harsh operating conditions of gas equipment into the manufacturer’s products, and therefore make them more adapted to the Russian market.

Operating principle

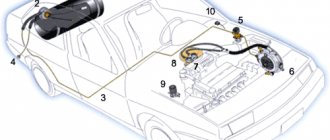

The gas unit is responsible for controlling the operation of gas injectors, which processes the signals from the gasoline electronic unit for gasoline injectors. The volume of gas for supply to the internal combustion engine (internal combustion engine) is calculated based on the temperatures of the gas and the reducer, the pressure of the gas mixture and other parameters.

Injection technology using an HBO gas injector intersects with the idea of gasoline injectors. An electromagnet (solenoid valve) is required that moves a part (rod) to open the flow of fuel from the reducer, which evaporates the mixture, to the intake manifold. The nature of the fuel affects the cross-section of the injector channels - for gas the cross-section is larger, because the volume of the gas mixture exceeds the same dose of gasoline (about 250 times) and greater throughput is required.

To ensure such tasks, the gas injector of the HBO has a reduced electrical resistance. Gasoline injectors have a resistance of 16 - 17 Ohms, while for gas it is 1 -3 Ohms.

What is an injector emulator

For 2nd generation gas internal combustion engines, an electronic device is installed to simulate gasoline injectors. This device is called an LPG injector emulator. For the 3rd and 4th generation it is integrated into the electronic gas control unit.

Emulators depend on the number of engine cylinders because it is necessary to read the signal to supply the appropriate fuel to each cylinder using a switch on the dashboard. This device allows you to set the interval for switching from gasoline to a gas mixture. You can set the delay in the range of 0-5 seconds.

The task of the emulator, when turning off the gasoline injectors, is to transmit signals to the control unit that simulate the operation of the injectors.

Rail (Italy)

Rail SPA injectors are a world-famous Italian company producing components, replacement and consumable parts for gas equipment, in particular gas valves that can operate on both a mixture of propane and butane and methane.

Rail IG1, without exaggeration, is the most common brand in Russia. The operating pressure ranges from 0.5 to 2 bar, the maximum is 3 bar. Until 2010, they were produced with a valve seat diameter of 4 mm; after modernization carried out in 2010, its diameter is 3 mm. The operating temperature range declared by the manufacturer is from -20 CO to +120 CO.

The Rail IG1 fire rate at idle is 3.3 milliseconds with an accuracy of +3%. Experts recommend setting such a gas pressure and selecting the diameter of the nozzle opening so that the response speed when lifting the armature 0.6 mm is within 4 - 4.5 ms.

The massive aluminum body ensures quiet operation of the valves; they are not demanding on the quality of the gas mixture. The average service life before repair or replacement is about 50,000 km.

Types by manufacturer

Which LPG gas injectors are better? The choice is up to the car owner. There are cheap options, and there are more expensive ones. Each model has its own pros and cons. Injectors from different manufacturers differ in their designs. Let's look at some of them.

Rod gas injectors

The most common and budget-friendly are rod gas injectors. Their representatives:

- Rail Type 30,

- Valtek Type 30,

- Rail IG1-IG5-IG9.

Advantages of this model:

- Price

- Work even with deviations in the stoichiometric ratio of the gas mixture

- To be repaired

The basis of the product is a solenoid valve. The design involves supplying gas to the rod through a hole located close to the seat, perpendicular to the locking part. As a result, it is not possible to blow through the solenoid rod; it is subject to temperature loads and can easily be coked with dirt.

At the same time, the rods are relatively heavy, which leads to faster wear of the rubber bumpers. At the same time, the valve opening speed is at least 2 milliseconds, which is low performance.

Such injectors need repair after 20-50 thousand kilometers and wear out after 70 thousand. There are isolated cases of longer work, but this is not a common occurrence.

The procedure for repairing LPG rod injectors is simple:

- The ramp needs to be removed and disassembled

- Clean from the inside

- Replace elements (rubber bumper, rod)

- Assemble the structure

- Calibrate the rod stroke to 0.45 mm using a micrometer

However, it is recommended to carry out diagnostics at a service station. It is not always possible to immediately determine what exactly needs to be repaired in the injector. For example, the cause of excessive consumption of the gas mixture can be either overheating of the fuel, which affects the physical parameters of the parts, or carbon deposits on the injector.

The injector can only be cleaned on a stand in a special pressure environment. When washing directly in the engine compartment, there is a high risk that all the contamination will remain on the cylinders and other parts. Correction of the rod stroke occurs along with diagnostics of all equipment components. The repair results are checked at the stand. In this case, the operation of each node is recorded. A more advanced model is OMVL. The design is made lighter through the use of composite plastic. The rod responds better to magnetic impulses due to a special alloy. This made it possible to more accurately dose fuel injection. The service life of such injectors reaches 100 thousand kilometers.

Needle nozzles

Another type is needle gas injectors. Such elements, for example, are produced in Japan by Keihin, in Korea by Hana, and in Poland by Barracuda. These injectors are expensive and cannot be repaired. Their wear resistance is affected by timely replacement of phase filters for the vapor state of gases (approximately every 10,000 kilometers).

Valtek Type 30 (Italy)

Valtek TYPE 30 gas injectors are manufactured in the form of strips of 3 or 4 nozzles. A distinctive feature of these injectors is a replaceable nozzle, which is drilled to the required diameter, allowing the use of such injectors on engines of different power and volume. Most modern LPG control units (CU) are compatible with TYPE 30 injectors, which means that the software of these CUs has the necessary settings to work with these injectors.

Valtek Type 30 are equipped with a metal rod with a rubber tip, the latter actually functions as a valve that stops gas leaks. The screws for adjusting the height of the injector rod are located above the coils; the coils themselves are secured using special clamps. Motorists often confuse the above-mentioned adjusting screws with mounting screws and tighten them to the limit. As a result, there is a complete blockage of gas, or an uneven supply, due to which the engine operates intermittently or does not work at all.

Technical characteristics of Valtek Type 30 injectors

- These gas injectors are ideal for power units with idle injection times exceeding 3 ms. On such engines, these injectors will be able to fully realize their potential, however, one should take into account the fact that the response of gas injectors should be at least 4-5 ms, despite the fact that the manufacturer recommends setting the response to 3 ms.

- Coil resistance is 3 Ohms, coil power supply is 12 V.

Service life and maintainability

There are cases where Valtek Type 30 injectors served faithfully for 200 thousand km, after which there was a need to adjust or repair the gas injectors. As a rule, the reason for the repair of these injectors was excessive consumption of gas fuel and the appearance of loud sounds while lifting the injector rods.

4th generation HBO injectors: operating principle and features

Euro 4 gas injectors for HBO are similar in principle to the design used in gasoline injectors. But the similarity of this detail does not mean that they work the same.

The peculiarity of the operation of this part is that after the fuel evaporates in the gearbox, 250 times more gas is supplied to the device of the 4th generation LPG gas injector than would be the case with gasoline. This suggests that the flow area of the holes is much larger - this is necessary in order for the throughput to be better.

Another feature is reduced resistance in electrical circuits:

- for gas - from 1 to 3 OM;

- for gasoline - from 15 to 17 ohms.

This is dictated by the fact that the element’s parts need to pass an incomparably larger volume of propane or methane in a short period of time, unlike gasoline.

Therefore, the implementation of injector control in LPG is arranged differently. In the case of gasoline, the part makes an opening if the pulse is 12 V, but if you apply such voltage to a gas part, it will fail, or simply burn out.

After the first impulse is given, the opening is carried out and the impulse is immediately interrupted, but then, after a short break, it resumes. The interruption removes a strong load from the winding, and it does not have time to burn out, but the break is so short that it does not have time to close.

This is the peculiarity of the work.

What to consider when choosing gas injectors

4th generation gas injectors are primarily distinguished by their price. But there are also many other technical characteristics that are worth paying attention to.

- compatibility with the vehicle's power unit;

- life time;

- are they repairable?

- opening time of the receiving element and maneuverability of a particular engine;

- endurance.

So, before deciding which are the best 4th generation gas injectors, it’s worth looking at the reviews and ratings of these parts.

Choice depending on the generation of HBO or by brand

Here everything depends on what generation of gas equipment is chosen, since the mechanisms that manage fuel delivery have strong differences in their design. This must be taken into account when choosing a model, otherwise problems will arise during operation.

A variety of HBO generations is mainly a conditional compliance of the installation package with standards and typical differences in internal combustion engine injection:

- Generation II follows the Euro 2 standard and is suitable for carburetor engines;

- III and IV generations for separate injection, that is, for an injector;

- The V and VI generations are already for engines with diagnostic and management systems based on the use of electronics.

Read how the 4th generation gas injector works.

If you make the wrong choice of components for different types of LPG generation, you can waste money and purchase unnecessary materials. And then you will have to dismantle the supplied gas injectors and buy new ones, those that directly fit.

So, in order not to replace gas injectors, you need to buy a complete set for gas equipment after the fourth generation. And for an earlier version, you can choose gas injectors from those manufacturers who produced the LPG system installed on the car.

And also, in addition to technical characteristics, the mechanisms that regulate injection differ in cost.

More expensive brands differ in the following points:

- quality of parts manufacturing;

- use of high quality materials;

- accuracy of elaboration of individual important points;

- a large life resource;

- outstanding reliability.

When thinking about which nozzles to choose, it is best to seek advice from a specialized center where the equipment was installed.

Rating of gas injectors

- The Italian company Valtek TYPE 30 makes these parts in the form of unique plates from several nozzles. Their peculiarity is that they have a replaceable jet, which, if necessary, can be expanded to the desired size. Therefore, they can be installed in cars with units of different capacities. These elements for HBO come with a metal rod and end with rubber fasteners.

- The company is OMVL, also from Italy. They offer the consumer parts where the body is made of composite plastic material. This allows the gas supply system to be installed on both sides. The jet here can be changed, so they are suitable for most cars with LPG.

- Korean specialists from the HANA company make these parts in a metal case, and the needle-type valve is distinguished by high-precision dosage when supplying fuel.

Valtek Type 30 (Italy)

Gas injectors Valtek TYPE 30

are made in the form of strips of 3 or 4 nozzles. A distinctive feature of these injectors is a replaceable nozzle, which is drilled to the required diameter, allowing the use of such injectors on engines of different power and volume. Most modern LPG control units (CU) are compatible with TYPE 30 injectors, which means that the software of these CUs has the necessary settings to work with these injectors.

Valtek Type 30 are equipped with a metal rod with a rubber tip, the latter actually functions as a valve that stops gas leaks. The screws for adjusting the height of the injector rod are located above the coils; the coils themselves are secured using special clamps. Motorists often confuse the above-mentioned adjusting screws with mounting screws and tighten them to the limit. As a result, there is a complete blockage of gas, or an uneven supply, due to which the engine operates intermittently or does not work at all.

Technical characteristics of Valtek Type 30 injectors

- These gas injectors are ideal for power units with idle injection times exceeding 3 ms. On such engines, these injectors will be able to fully realize their potential, however, one should take into account the fact that the response of gas injectors should be at least 4-5 ms, despite the fact that the manufacturer recommends setting the response to 3 ms.

- Coil resistance is 3 Ohms, coil power supply is 12 V.

There are known cases where Valtek Type 30 injectors

served truth and faith for 200 thousand km, after which it became necessary to adjust or repair the gas injectors. As a rule, the reason for the repair of these injectors was excessive consumption of gas fuel and the appearance of loud sounds while lifting the injector rods.