Signs of piston ring wear

The heart of the car is the engine, the individual service life of which consists of many indicators.

Its production properties depend on the quality of its constituent parts, timely replacement of oil and filters, and whether technical inspection is carried out on time. In an engine, the piston rings wear out first.

As a result of ignoring the first signs of wear and tear, the pistons and then the crankshaft fail, which leads the car to expensive repairs. The question arises:

How to determine the degree of piston ring wear

The main action that needs to be taken in this case is to look at the exhaust gases coming out of the muffler when the car is running, at idle speed.

Next you need to pay attention to the spark plugs, or rather to their condition. Oil deposits and the presence of oil on the spark plug threads indicate a violation of the mixture formation cycle in the combustion chamber, which is wear on the piston rings or cylinders.

Then you need to check the condition of the air filter, carefully inspect for oil in its housing and the air outlet corrugation. The presence of signs of its presence indicates wear of the PG.

You should look at the installation locations of oil seals, gaskets, and seals of the unit. Are there any oil leaks? If such a phenomenon is detected, then this is a sign of unacceptable wear of the PG, as a result of which a strong pressure of crankcase gases is created in the engine and oil is released.

It is also necessary to listen to the engine running at idle. If the engine does not run smoothly, the gear shift lever shakes, then this indicates the presence of different pressures in the engine cylinders, due to obvious wear of the CPG. Extraneous noises and knocks in the working engine indicate obvious malfunctions of the device; driving such a machine is strictly prohibited.

The crankcase ventilation system should be checked. To do this, you need to remove the gas outlet hose (breather) from the system and see how the exhaust vapors and gases come out of the hose. If they come out in time with the operation of the cylinders, then there is a presence of rings in the piston.

All of the above features are signs of worn-out engine PG, due to improper use, engine overheating or prolonged operation without proper lubrication.

Installing rings on the piston

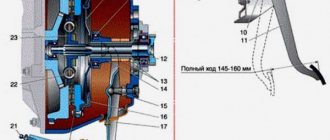

Once again, to what was said above, I repeat - this instruction implies that replacing the piston rings of a VAZ 2101 is done only with your own hands, in a private garage. Therefore, by default, we do not have any “sophisticated” tools and use available materials to install the rings on the piston and the entire piston with rings into the cylinder. In our case, this is... a tin can.

We cut out metal strips from a tin can and install them around the entire circumference, at even intervals;

Advice! One strip should be under the “lock” of the ring to prevent scratches.

- We move the desired ring along the metal strips to the bottom until it is opposite its seat;

- We lift the strips up, while the rings fall into the groove;

- The operation is then repeated for all rings.

Of course, you can perform this action with your bare hands, but the risk of breaking the rings and scratching the piston is too great.

Installing a piston into an engine cylinder

Lubricate the piston rings with oil, insert them into the cylinder block from above and, using a homemade mandrel, insert the piston into the cylinder.

Attention! During this procedure, make sure that each piston fits exactly into the cylinder from which it was taken and is in the same position as before. Cylinder markings must be on the lower connecting rod heads

Assembly process

Next we assemble in reverse order:

We install the oil pump;

Oil pump installation

- We install a new pan gasket and the pan itself;

- We lower the engine into place and fasten the left support;

- Having previously lubricated it with graphite grease, install a new cylinder head gasket, guiding it along the center bushings;

- When installing the cylinder head, following the manufacturer’s instructions, tighten the cylinder head mounting bolts in a certain order and with the indicated force, in four steps:

- In the established order, we tighten the bolts with a torque of 20 N/m (about half the force);

- The same, but with more force, with a torque of 70 N/m;

- In the same order, all bolts are tightened;

- And once again we stretch it to .

Cylinder head tightening procedure

- Using the marks, we establish the position of the crankshaft and, aligning the marks with the help of an asterisk, mount the camshaft bed;

- We put the sprocket itself in place with the chain on it and tighten the bolt securing it;

- We tighten the chain and turn the engine a couple of revolutions to make sure that the crankshaft and chain tension marks are installed correctly;

- In the final part, we install all the “attached” equipment in place, install a new oil filter, fill in coolant and oil, install the battery terminal and start the engine.

I hope that in this article I have clearly outlined how to replace piston rings on a VAZ 2110 with your own hands. In conclusion, I would like to give one last piece of advice regarding running in the engine after repairs.

Since we have the same diagnosis - we are the owners of domestic Zhiguli cars, the selection of spare parts must be approached with special attention. No one is immune from purchasing low-quality components

Therefore, to prevent possible deviations (shrinkage, foreign inclusions in the metal structure, temperature deformation), it is recommended to drive the first thousand kilometers with a load of no more than 50% of the nominal load, after which the oil should be changed.

Attention! It is the load, not the engine speed! Of course, the revolutions should also not be raised by more than half of the maximum permissible, but you must admit that the engine can be fully loaded even at two thousand if the gas pedal is pressed to the floor. And those who are especially suspicious are allowed to extend the break-in period to five thousand, with oil changes at the first and fifth thousand kilometers.

And those who are especially suspicious are allowed to extend the break-in period to five thousand, with oil changes at the first and fifth thousand kilometers.

Piston rings, their types and purpose

By design, each piston ring is an elastic spring part in the form of an open ring, made of durable, wear-resistant metal, which is installed with a slight gap in special grooves on the piston heads.

Piston rings solve three main problems:

There are two types of piston rings:

Almost all modern gasoline and high-speed diesel automobile engines have only 3 rings on one piston - 2 compression rings and 1 oil scraper ring, which is installed below the compression rings.

How to properly install piston rings

To answer the question of how to replace piston rings without removing the engine, it is necessary to troubleshoot the CPG at the initial stage. To do this, you will need to remove the cylinder head, after which the general condition of the pistons and cylinder walls will be assessed.

This is done to identify possible defects (scores on the walls, wear, destruction or melting of the piston, etc.). Let us add that there are engines on which it is impossible to assess the condition of the CPG without removing the pan. There is often a high probability that simply replacing the rings with new ones may not be enough, since if serious wear is detected, it is necessary to bore the cylinder block.

Moreover, the rings wear out both the cylinder bore and the inner surface of the piston groove. For these reasons, new piston rings, which are installed without replacing the pistons and repairing the cylinders, either do not grind in at all, or the grinding in occurs very slowly and ineffectively.

Taking into account the above, the best option would be to bore the cylinder block, perform honing of the cylinders, after which new repair pistons and piston rings are installed. It is not possible to carry out such repairs without removing the engine. At the same time, the positive results of repairs involving engine removal are much more predictable.

Piston ring clearance

There is a gap of certain sizes between the ends of the piston (open) rings. After they are installed in the grooves of the piston, they, taking its shape, are compressed, and the piston ring gap is reduced to 0.15 - 0.5 mm. The technical documentation for the engine indicates the required size of this gap.

It is very important that it be followed. Because with an increased gap, gases may penetrate into the engine crankcase and, as a result, reduce its power. And the consequences of a reduced gap can be much more serious - up to the jamming of the rings in the cylinder. Therefore, a slight increase in the gap is allowed, but its decrease is unacceptable.

Possible malfunctions of piston rings, their external signs and causes

The main malfunction of piston rings is wear (premature wear) during prolonged (incorrect) operation of the car. Rings from domestic manufacturers are designed for 150, and from leading world manufacturers - for 300 thousand km. However, sometimes they last up to 500 thousand km.

But improper use of the car can significantly reduce these miles. Moreover, an avalanche-like destruction of the piston rings is also possible as a result of severe overheating of the engine or its operation with insufficient lubrication.

The first sign of ring failure may be:

Moreover, they are interconnected. Please also note that these signs MAY indicate possible ring failure. But it is not necessary to be the culprit of these disturbances in engine operation.

How to do it correctly?

Before starting the process, you need to carry out a number of actions that are mandatory for any type of work. They are standard and apply in any case. At the very beginning, the following procedures are done:

- Be sure to fully charge the battery;

- Before leaving, you need to carry out the next cycle. We start the engine, heat it to 80°C, then turn it off. As soon as it cools down to 40°C, warm it up again. In total you will need to do 7-10 cycles. During which thermal expansion of parts will occur, as well as their initial preparation;

- After all the above steps, be sure to inspect the engine for leaks of oil, antifreeze and other technical fluids. If we find such a phenomenon, we will definitely eliminate it;

- Regardless of the reason for which the procedure is performed, movement with height differences should be avoided;

- At the last stages of lapping, strictly follow the manufacturer’s recommendations regarding optimal engine operation during travel.

These rules apply to all types of engine running-in, regardless of what you did in the car. Now let's take a closer look at the procedure after replacing the piston rings. A mileage of 1,500 kilometers is considered optimal. Moreover, you must immediately drive about 300 kilometers, maintaining 2500 rpm

. It is advisable to do this in third gear. Such a trip will allow you to achieve optimal initial running-in of the rings to the piston and cylinder. The next 700-800 kilometers

You can drive in the same mode, but not at once. That is, you can freely use the car for business trips, but just do not load it. The last 500 kilometers adhere to the manufacturer's recommended operating mode, but at the same time avoid stressing the engine. After this, the oil and filter must be changed. Then you can safely operate the car in your usual mode.

Replacing piston rings

In principle, piston rings cannot be repaired and only need to be replaced. This means you will need to purchase new ones. When choosing them, first pay attention to the packaging. Manufacturers of high-quality rings pay considerable attention to it: this includes the design itself, complete information about the manufacturer, production date, material of manufacture, etc.

You should carefully inspect the rings themselves for defects and whether the top is indicated on them. Are installation instructions included, etc. We would recommend purchasing certified spare parts for engines from the world brand MAHLE original.

* Please check the applicability of parts specifically for your car with our managers by phone (calls within Russia are free).

| Manufacturer | vendor code | Name | Applicability* |

| MAHLE | 03319N0 | Piston rings | Audi |

| MAHLE | 00114N0 | Piston rings | Mercedes-Benz |

| MAHLE | 03316N1 | Piston rings | Audi |

| MAHLE | 01108N1 | Piston rings | Opel |

| MAHLE | 01170N0 | Piston rings | Opel |

| MAHLE | 01195N1 | Piston rings | Opel |

| MAHLE | 01317N0 | Piston rings | Ford |

| MAHLE | 02158V0 | Piston rings | Renault |

| MAHLE | 02162N1 | Piston rings | Renault |

| MAHLE | 08316N0 | Piston rings | BMW |

You can buy piston rings from most famous world brands and other spare parts for foreign cars in the IXORA hypermarket. Our managers will always provide advisory assistance in choosing a product.

Signs of worn or stuck engine piston rings

The service life of car engine piston rings can vary widely.

For engines of VAZ 2108, 2109, 21099, 2105, 2107 cars this is 150-200,000 km. In many ways, the wear rate of piston rings depends on the severity of engine operating conditions, the use of high-quality or, conversely, low-quality engine oil, the correct operation of the engine (presence of overheating, detonation), and the quality of manufacture of the rings themselves. Signs of wear (breakage, jamming) of engine piston rings

Heavy smoke from the muffler

The smoke is gray-blue (gray). It smokes constantly: both during startup, and when idling, and when driving. Short-term smoking during startup or re-gasping is a sign of wear on the valve stem seals.

Reasons: engine oil is poorly removed from the cylinder walls when the engine is running and, together with exhaust gases, is released through the exhaust valves into the exhaust tract and then into the muffler. Hence the blue smoke. Drops of oil can be felt on your hand by placing it near the muffler outlet while the engine is running.

Engine oil in the air filter housing

Worn or stuck rings allow gases generated in the combustion chambers during engine operation to pass into the sump (engine crankcase). The pressure of gases increases in the crankcase, which are released through the engine crankcase ventilation system into the air filter housing. They are saturated with engine oil and clog the engine air filter and carburetor.

Engine oil leakage under oil seals and engine seals

Increased gas pressure in the engine crankcase causes engine oil to ooze out from wherever possible (camshaft and crankshaft seals, valve cover gasket and oil filler neck, pan gasket).

Strong smoke from the breather

It will be noticeable if you remove the cover from the engine air filter housing. Here a strong stream of bluish smoke pops out of the crankcase ventilation hole. We see a similar picture when we remove the hose from the engine breather.

Its air jets GDS of both chambers

— Black carbon deposits on spark plugs

Black carbon deposits on the electrodes of the spark plugs plus oiling of the threads.

— The engine “troits” at idle

— Dips when pressing the gas pedal

— Increased noise when the engine is running

If, after measuring compression, it is determined that the indicated symptoms are caused by wear or jamming of the piston rings, then we first decoke the piston rings and if that does not help, then we replace them (on the engines of cars 2108, 2109, 21099, you do not need to remove the engine to perform this procedure , and at 2105, 2107 it will have to be removed).

Notes and additions

— Associated faults with piston ring wear can be: cylinder wear, piston wear.

— The occurrence of piston rings is their loss of elasticity as a result of overheating or coking of the ring grooves as a result of the use of low-quality motor oil. As a result, the rings cease to perform their function - to effectively remove engine oil from the cylinder walls and create a certain pressure when the piston moves upward (compression).

— There are situations when only the oil scraper rings fail or fail, while the compression rings work. In such a situation, the engine will smoke and consume oil, but compression will be normal.

Source

Checking the clearance between the piston and cylinder

If in the morning, when you started a cold engine, a metallic knock was heard, which disappeared when the engine warmed up, then this only indicates that the clearance between the piston and the cylinder was broken. Why is it violated, and what permissible standards are applied for the clearances between the piston and cylinder? You will find the answer below.

How does the gap between the piston and cylinder change during operation?

The reduction in clearance occurs due to natural wear of the working parts of the piston and cylinder. This change in the shape of the metal is associated with its ability to be influenced by temperature changes.

In addition, a decrease in the gap can also occur if the engine is assembled incorrectly. For example, the installation of the connecting rods is incorrect or the cylinders are misaligned. Overheating of the engine is also an issue, since high temperatures tend to expand materials. This is especially true for aluminum, which, unlike cast iron, has a high expansion coefficient.

Like any other defect, a violation of the gap between the piston and the cylinder has a negative impact on engine performance. The contact of the piston and cylinder at the wrong angle leads to dry friction, which occurs without lubricant and increases the temperature of the parts. The consequence of such friction in almost all cases is the appearance of various scratches on the working surfaces of the cylinders.

After this, any engine will definitely undergo repair. To carry out diagnostics, it is necessary to completely remove the cylinder head and as soon as the piston group is visible, you can begin the corresponding measurements. During the measurement process, you will need a micrometer to show the piston clearance and a bore gauge to determine the cylinder diameter.

How to remove the cylinder head?

- First of all, it is necessary to immobilize the car. Wheel chocks are installed under the wheels, and the gearshift lever is set to the “first gear” position. Open the hood of the car and find the location of the cylinder head.

- First, all parts that interfere with free access to the head are removed. These can be: an air filter, a carburetor (or injector), “pants”, as well as various cables, pedal drives and electrical sensor wiring. The spark plugs are unscrewed from the cylinder head and, if necessary, the distributor is removed.

- Drain the engine oil and coolant. Open the timing cover and remove the belt. This is necessary in order to free the camshaft. After this, unscrew the nuts securing the cylinder head cover and remove it along with the gasket. It is recommended to install a new gasket before assembly.

- Now you can proceed directly to dismantling the cylinder head. Unscrew the special fastening bolts and remove the head along with the gasket. After this, you will have open access to the cylinder block.

Before carrying out appropriate repairs to the piston mechanism, you need to know that there are certain clearance standards, which are listed in tables and must be strictly observed.

Piston diameter is divided into only five classes: ABCD E. Each new class determines an increase in diameter by 0.01 millimeters. In addition, there are special categories that determine the diameter of the piston pin hole. They change every 0.004 millimeters. All these numbers and markings are necessarily marked on the bottom of the piston.

There are corresponding standards for various parts. For example, new pistons should be installed with a gap of 0.06 millimeters around its entire circumference. If the part has already covered quite an impressive mileage, then its gap should not be more than 0.15 millimeters.

In cases where the clearance begins to exceed the established standards, you should select and purchase those pistons that will provide the required clearance. It is not necessary to adjust the piston with high precision. It is enough just to have a sample with approximate dimensions.

First, it is imperative to bore the cylinders to repair sizes and leave a margin of approximately 0.03 millimeters. It is necessary for further honing of the surface. During honing, be sure to maintain the accuracy of the diameter so that when installing a new piston, the clearance meets the requirements for installing new parts.

The diameter of the cylinder is measured in four zones, as well as in two perpendicular planes. The bore gauge must be installed strictly perpendicular to the cylinder block. In this way, any deviations from the correct measurements can be eliminated.

Video - How to measure the piston correctly

In addition to the size of the pistons, their mass is also a very important indicator. The weight of the pistons can be normal, or with a change of plus (minus) 5 grams. In addition, it is necessary to select the correct oil scraper rings for the pistons, which must be of repair sizes.

After the pistons have been selected and installed, it is necessary to check the size of the gaps again. If it is within normal limits, then you can begin reassembling the engine. The cylinder head is installed, then the gas distribution mechanism drive. After this, the cylinder head cover with a new gasket and all the attachments are screwed on. Don't forget to add oil, coolant and adjust the gas distribution mechanism. After this, most likely, you will have to set the ignition timing. The car is now completely ready for use.

This completes checking the gap between the piston and cylinder. No matter how simple this complex procedure may seem to you, it is still recommended to perform it only in specialized service stations, since assembling a cylinder block is a responsible task and it is better to entrust it to professionals. Good luck on the roads!

What is the expression “the rings are stuck”?

First, let's figure out how the cylinder-piston group works. While the engine is running, the piston moves back and forth inside the cylinder. There must be a gap between these parts so that friction does not interfere with movement.

At the same time, the contact between the piston/cylinder parts should be as tight as possible in order to:

To meet these conditions, in most cases of passenger cars, three rings are installed on each piston: two compression rings and one oil scraper ring. Compression rings are usually “solid” in cross-section, while oil scraper rings have a slot in which a spring is installed, and on the outside they have a removal edge and slits for removing oil. Thanks to this design, the rings are springy and fit tightly to the cylinder walls.

The piston has three grooves, the width of which is hundredths of a millimeter greater than the thickness of the piston rings. Therefore, the rings are always fixed and have freedom of movement, tightly closing the gap.

When carbon or coke accumulates in the piston grooves, it acts as glue. The rings simply stick to the grooves, lose mobility and cannot elastically press against the cylinder walls, resulting in a violation of the tightness of the piston/cylinder pair. This phenomenon is called bedding or coking. We figured out why the rings lie, now we’ll find out how to diagnose it all.

Engine oil additive "Suprotek Active Standard"

For naturally aspirated petrol engines up to 1.6 litres. Restores and equalizes compression, reduces fuel and oil consumption due to waste, protects friction surfaces in the CPG and gas distribution mechanism from wear during startup and overheating.

Checking the condition of the piston group - logbook Mercedes-Benz S-class Unhidden 1984 on DRIVE2

Since the engine had to be disassembled without even trying to turn it, it was not possible to measure the compression. The more I analyze, the more the question arises: is the game worth the candle?

Since the bottom cover of the engine has been removed, you can see the scoring marks on the cylinder walls from the inside. Of course, this will not clear up the whole picture, but serious wear and tear can be noted.

Visually it looks OK!

It’s not bad anymore, for a detailed analysis I’ll borrow a snake camera from work and look through the spark plug compartments.

What about the rings? Well, most likely they are intact, but they could have stuck. On the advice of the guys from the service, I decided to do the test with KEROSENE. I struggled with finding such a rare liquid in our era... I found it in a hardware store and another gas station. In general, pouring kerosene into the cylinders can be determined by how large the gaps between the ring, piston and cylinder wall are. Of course, it will flow, but not like a stream. Still, there should be gaps. At the same time, wash out all the settled fuel oil.

Substituting the basin, he began to fill it with a syringe... let it sit for half an hour, poured it in again, and began to gradually turn the crankshaft with a wrench. Using filtration, the kerosene was passed through the cylinders a couple of times in this way. The result... it was dripping, but not critical. KOLKHOZ check is so-so, but it won’t get any worse. Everything took about 1 liter of kerosene. As I was told later, it was necessary to mix 1:1 KEROSENE and ACETONE. An excellent soot remover!

Signs of buried rings

Previously, we found out that when the rings are stuck in the engine, the tightness of the piston to the cylinder is broken. It follows from this that gases from the combustion chamber partially “fly” into the resulting gap, without performing useful work, they enter the crankcase.

Symptoms of stuck rings are mainly caused by a drop in compression in the combustion chamber due to gaps between the piston cup and the liner wall. Problems begin with a deterioration in the dynamic characteristics of the car. The engine does not respond well to the gas pedal. This is the main sign.

If the oil scraper rings are stuck, a film of lubricant remains on the inner surface of the cylinder (by the way, compression rings get stuck much less often). During the power stroke of the piston, when fuel vapors ignite, the lubricating fluid burns out. The oil is wasted, and bluish smoke comes out of the exhaust pipe. This is the second sign.

Difficulty starting the engine in any weather is another sign of stuck rings. The crankshaft with counterweights has a large mass and requires significant force to turn it. In addition, the oil flows into the oil pan; at the first revolutions, the friction force also impedes the movement of the piston. If one or more cylinders are not firing, starting is difficult.

Increased fuel consumption may also be a sign that there are rings in the engine. Due to the gap between the piston and the cylinder, the energy of the fuel is not fully used: compression is insufficient. Therefore, the on-board computer overestimates the enrichment of the air-fuel mixture to compensate for the lack of thrust. This leads to excessive consumption of fuel.

What should the piston ring clearance be? Detailed analysis

A topic of interest to many car enthusiasts is how to set the gap between the piston rings, and this is especially interesting to those who are going to carry out repair work themselves

Everyone knows that any car owner (experienced or not) tries to learn more about the damage that may occur during the operation of the car, as well as the precautions to take.

What should the piston ring clearance be?

We will look at various features and specifics of the topic, and also get acquainted with the basic techniques and techniques for repairing this part.

Firstly

, the very first step will be the fact that is associated with inspecting the pistons. It is necessary to check and carefully inspect the piston for cracks or minor mechanical damage on the surface. If you notice even a small defect, you should immediately replace the piston with a new one. To avoid an unpleasant situation or a larger breakdown.

Secondly, if your engine is disassembled, you should also pay attention to the pistons. Such preventive measures include cleaning the piston head from existing carbon deposits, cleaning and processing the grooves that are located under the piston rings

Third

, after the piston has been cleaned, be sure to inspect the gaps between the grooves and rings. In solving this problem, a table that will indicate the nominal piston ring clearances is more suitable than ever.

This:

- The parameters of the upper compression ring should be 1-0.04-0.075 mm;

- The compression ring, which is located at the bottom, should be 2-0.03-0.065 mm in size;

- Oil scraper ring with a gap of 3-0.02-0.055 mm.

Remember that each gap has its own parameters and distance, the most important thing is not to confuse them. The permissible gap should be 0.15 mm. If it is difficult to accurately determine the distance between the piston gaps by eye, you can use a special device - a micrometer.

How to properly use a micrometer to determine the size of the piston ring gap? It is necessary to measure the diameter of the piston in several places around its circumference. Then measure the width of the grooves using special feeler gauges.

After measurements, the average value of the gaps should be calculated. If the indicators differ from each other, then the piston should be replaced, if the indicators are the same, then everything is in order.

Fourth

, measuring gaps in piston ring locks. This measurement can be performed either using a special frame or with a simple cylindrical object. Indicators and parameters of the gap should be measured using a special probe. The parameters of the gap suitable for use have the following proportions - 0.25-0.45 mm.

In this case, an error of 1.0 mm may be allowed, which may arise as a result of wear of the part. If the gap size is higher than normal, the piston must be replaced. If the measured gap is less than the specified parameters (0.25 mm), then all that is needed is to simply sharpen the ends to the desired size.

Fifthly

, measuring the gap between pistons and cylinders. This measurement is based on establishing a correspondence between the already measured diameters of the piston and cylinder. Here the standard values are from 0.025 to 0.045 mm, with possible wear of 0.15 mm.

What is the danger of a situation where rings are stuck in the engine?

The main danger is that when the piston rings are stuck, the engine operates in abnormal mode:

Long-term engine flushing "Suprotek Aprokhim"

Over the course of 200 kilometers, it gently and gradually cleanses all parts of the engine from contaminants and helps restore the mobility of the piston rings. Safe for rubber and plastic parts.

These seemingly minor faults lead to serious problems and expensive repairs.

When aggressive exhaust gases enter the oil pan, they react with the oil. The chemical composition of the lubricating fluid changes, it cannot perform its functions. As a result, wear of rubbing parts accelerates and heat dissipation deteriorates.

Oil that is not removed by the stuck oil scraper ring burns, causing local overheating of the parts. With prolonged use in this mode, scuffing will appear on the liner and piston skirt. When the oil burns, it leaves carbon deposits, which often causes detonation and possible piston burnout.

What to do if rings are stuck in the engine

Engine oil additive "Suprotek Active Plus"

Restores compression, reduces fuel consumption and oil waste, reduces wear rate and extends the life of internal combustion engines of any type. Facilitates cold starts and protects against overheating in traffic jams.

Let's look at each procedure in more detail. We will not mention “folk methods” associated with the risk of damaging the gaskets and seals of a modern car engine.

Mechanical decarbonization

This method involves partial or complete disassembly of the engine, because the pistons on which the rings are located must be removed. Parts must be cleaned manually using soft brushes, rags and solvent, kerosene or acetone.

Places that are difficult to reach with a brush must be thoroughly cleaned using small pieces of cotton wool or rags soaked in solvent. Craftsmen often use tweezers and other devices to remove all carbon deposits. Only in this case the decarbonization is considered to be of high quality.

This method requires a good knowledge of the car structure, and the power unit in particular. It is necessary not only to disassemble, but also to reassemble the motor correctly. This is the reason why it is better to entrust such work to professional car mechanics, even though it is a considerable pleasure.

Chemical decarbonization

This method will help if the oil scraper rings are stuck, but you don’t know what to do - you have neither the skills nor the tools to disassemble the engine, and there is no way to contact a car service center. To decarbonize an engine using chemicals, you only need to be able to unscrew the spark plugs.

Algorithm for chemical decoking of stuck rings:

The main disadvantages of this method:

Decarbonization using additives

This is the simplest and safest option for cleaning the engine if the rings are stuck and you don’t know what to do. All you need to do is add a special additive to the fuel or engine oil - you don’t need to twist or twist anything, hang it out and wait. Simple and convenient. Today, the market offers products of imported and domestic production. Brands from the EU and US countries traditionally enjoy authority, but are relatively expensive. Products from domestic manufacturers are cheaper and often not inferior to Western counterparts.

For example, the Russian company has developed a line of tribotechnical compounds that allow you to comprehensively clean a car engine. Flushing quickly removes the most stubborn contaminants, and additives in gasoline and motor oil maintain the effect of a “clean engine” for a long time. Suprotec “fuel system cleaner” comprehensively flushes the combustion chamber and fuel system of gasoline engines. Flushing is added to the fuel tank. Due to its high chemical activity, it is recommended for one-time cleaning when symptoms are noticed that rings are stuck in the engine. The product effectively removes all types of carbon deposits from the combustion chamber, eliminating problems associated with them.

Source