Torque and sequence of tightening the camshaft bed

Camshaft cover tightening sequence

Correct tightening of the camshaft bed, as well as other parts of the cylinder head, determines the normal functioning of all components and assemblies. So, in order to tighten threaded connections, a standard tightening pattern and a torque wrench are used.

Before installing the bolts in place, they must be washed thoroughly and lubricated with silicone grease.

In order to properly tighten the bolts, you need to know the sequence. It starts from the middle part and gradually moves directly to the edges. The detailed sequence can be seen in the photo below.

Tightening diagram for each camshaft bed bolt with numbering

As for the tightening force itself, it is 8.0-10.0 Nm . After the bed is installed on the block head, the connection bolts are tightened by hand or without much force using a ratchet with a head.

We tighten all the bolts by hand, but do not tighten them

When all the bolts are in place, you need to take a torque wrench and tighten them according to the standards in the order indicated above.

Torque wrench for tightening threaded connections

In what cases is it necessary to tighten the camshaft bed?

The bolts are tightened. Marked with arrows

Tightening the camshaft bed will be necessary if it was previously dismantled for restoration and repair work. So, in what cases will you need to remove the bed, let’s look at it in more detail:

- Replacing camshafts, lifters or valve seals.

- Overhaul of the block head.

- Engine repair operations.

- Replacement of individual elements of the cylinder head.

Consequences of improper bed tightening

The consequences of improperly tightening the camshaft bed include the following:

- Oil leakage due to a gap or loose connection.

- Passing air inside the cylinder head.

- Malfunction of the engine or cylinder head.

- Ingress of foreign objects (water, dirt, dust).

All these factors can negatively affect the performance of the cylinder head and main power unit.

Crankshaft oil seal

Today we will talk in more detail about the crankshaft oil seal, a spare part that is designed to seal (seal - approx.) connections in this moving part of the engine, as well as prevent engine oil from leaking. Below, we will describe in detail how to replace this element as quickly as possible.

Signs of crankshaft oil seal failure

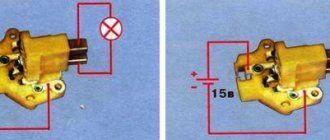

The very first and main sign of failure of the crankshaft oil seal is considered to be the loss of its tightness.

Oil leak due to leaky crankshaft oil seal

And if in the case of oil seals on other engine elements it doesn’t look so bad, then if there is a malfunction on the crankshaft, oil can leak from the system in liters per 1000 kilometers.

Main causes of wear

Please note that with an increase in oil consumption, due to leaks of the crankshaft oil seal, traces of oil will certainly be observed under the car; they are clearly visible and will not leave any owner unnoticed.

Also think about the presence of oil seal leaks and slight slipping of the clutch. This effect can be observed due to oil getting on the clutch disc and basket located near the gearbox.

Engines ZMZ-402 and ZMZ-4021

Bolt for fastening the cover of the timing gears 11-16 (1.1-1.6) Nut for fastening the cover of the timing gears 12-18 (1.2-1.8) Nut for fastening the cover of the pusher box 12-18 (1.2-1.8 ) Cylinder head mounting nut 85-90 (8.5-9.0) Cylinder head rear cover mounting bolt 11-16 (1.1-1.6) Connecting rod cover mounting bolt nut 68-75 (6.8- 7.5) Flywheel mounting nut 78-83 (7.8-8.3) Crankshaft pulley mounting bolt 11-16 (1.1-1.6) Crankshaft pinch bolt (ratchet) 170-220 (17-22 ) Bolt for fastening the thrust flange of the camshaft 11-16 (1.1-1.6) Bolt for fastening the camshaft gear 55-60 (5.5-6.0) Nut for fastening the rocker arm axle rack 35-40 (3.5- 4.0) Bolt securing the rocker cover 4.5-8.0 (0.45-0.8) Nut securing the exhaust manifold to the intake pipe 44-56 (4.4-5.6) Nut securing the intake pipe and exhaust manifold to the block head 40-56 (4.0-5.6) Oil sump mounting nut 12-15 (1.2-1.5) Oil pump mounting nut 18-25 (1.8-2.5) Drive mounting bolt ignition distributor 6.0-8.0 (0.6-0.8) Main bearing cover mounting nut 100-110 (10-11) Oil filter mounting nut 12-18 (1.2-1.8) Fuel filter mounting bolt pump 12-18 (1.2-1.8) Fine fuel filter mounting nut 12-18 (1.2-1.8) Water pump mounting nut 18-25 (1.8-2.5) Pulley mounting bolt water pump 12-18 (1.2-1.8) Clutch housing mounting bolt 28-36 (2.8-3.6) Clutch housing mounting nut 40-56 (4.0-5.6) Pressure plate mounting bolt clutch 20-25 (2.0-2.5) Generator bracket mounting nut 44-62 (4.4-6.2)

Generator mounting nut 44-56 (4.4-5.6) Spark plug 30-40 (3.0-4.0) Fan mounting bolt 14-18 (1.4-1.8)

Gas distribution diagrams

The timing belt of a passenger car consists of the following elements:

The drive belt or chain is put on the crankshaft and camshaft gears, and transmits movement from the crankshaft (CV) to the r/shaft. The cams PB open and close the valves, thereby ensuring that the cylinders are filled with the working mixture. At the moment of compression, the mixture ignites and a working cycle occurs in the internal combustion engine cylinders.

Many modern cylinder heads have 4 valves per cylinder. To drive a large number of valves, you need quite a lot of cams, so often two valves are installed in the gas distribution mechanism.

Camshaft VAZ 2106

The camshaft is an integral part in the design of the gas distribution mechanism (GRM) of any engine. It is made in the form of a cylinder on which necks and cams are located.

Description

On the sixth model Zhiguli, the timing mechanism shaft is installed in the cylinder head (cylinder head) of the engine. This arrangement allows you to repair and change the part, as well as adjust the valve clearances without any difficulties. The shaft is accessible after removing the valve cover. The camshaft (CV) is assigned the role of controlling the opening and closing of valves in the engine cylinders - at the right moment it admits the fuel-air mixture into the cylinder and releases exhaust gases. A gear is installed on the camshaft, which is connected to the crankshaft sprocket through a chain. This design ensures simultaneous rotation of both shafts.

On the camshaft there are cams and journals, by means of which the shaft is held on supports

Since the crankshaft and camshaft have gears of different sizes, the rotation speed of the latter is halved. A complete operating cycle in a power unit occurs in one revolution of the camshaft and two revolutions of the crankshaft . The valves in the cylinder head open in a certain order under the influence of the corresponding cams on the pushers, i.e., when the camshaft rotates, the cam presses on the pusher and transmits force to the valve, pressed by the springs. In this case, the valve opens and admits the fuel-air mixture or releases exhaust gases. As the cam rotates further, the valve closes.

The cylinder head consists of the following parts: 1 - cylinder head; 2 — exhaust valve; 3 — oil deflector cap; 4 — valve lever; 5 — camshaft bearing housing; 6 - camshaft; 7 — adjusting bolt; 8—bolt lock nut; A - gap between the lever and the camshaft cam

More about the design of the VAZ 2106 engine: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/ne-zavoditsya-vaz-2106.html

Options

The “six” camshaft has the following characteristics:

- phase width - 232˚;

- intake valve lift height - 9.5 mm;

- intake valve lag - 40˚;

- exhaust valve advance is 42˚.

On the sixth model Zhiguli, the timing mechanism has eight valves, i.e. two for each cylinder, the number of cams is equal to the number of valves.

Which camshaft is better to install

Only one gas distribution shaft is suitable for the VAZ 2106 - from the Niva. The part is installed in order to increase the power and dynamic performance of the car. It is possible to achieve the desired results, albeit small ones, by increasing the width of the phases and the lift height of the intake valves. After installing the RV from Niva, these parameters will have values of 283˚ and 10.7 mm. Thus, the intake valve will be open for a longer time and raised to a greater height relative to the seat, which will ensure that more fuel enters the cylinders.

When replacing the standard camshaft with a part from a VAZ 21213, the engine parameters will not change dramatically. You can install a “sports” shaft intended for tuning, but it is not cheap - 4-10 thousand rubles.

To improve the dynamic performance of the car, a “sports” camshaft is installed

Table: main parameters of “sports” camshafts for “classics”

Purpose of the camshaft

The camshaft is a moving element located inside the cylinder head and is responsible for the operation of the valves (their opening and closing). Thanks to it, the intake and exhaust strokes are controlled and, as a result, the entire operation of the engine is synchronized.

The camshaft itself is connected by a drive to the crankshaft, but rotates twice as slow as it. The cams mounted on the camshaft alternately act on the intake and exhaust valves, bringing them either open or closed.

Camshaft VAZ 2114

At the same time, the VAZ 2114 8-valve camshaft has one significant drawback - it does not provide the car engine with good “throttle response” at low speeds (less than 3,000 rpm). This is caused by the shape of its cams, leading to “stretching” of the working phases.

The solution to such a problem can be either regrinding (it is worth remembering that for camshafts of domestic cars it practically does not help) or installing a special camshaft (we will talk about this a little later).

Signs of Camshaft Wear

The operation of the camshaft is associated with constant exposure to high loads, as a result of which the part gradually wears out and requires replacement. The need for repair arises when characteristic symptoms appear:

- knocking when the engine is running under load;

- reduction in power indicators.

There are a number of reasons why the RV fails:

- natural wear and tear;

- low-quality motor oil;

- low oil pressure in the lubrication system;

- insufficient oil level or so-called oil starvation;

- engine operation at high temperatures, which leads to deterioration of the lubricant properties;

- mechanical damage (wear or broken chain).

The main malfunctions that impair the performance of the camshaft are scuffing on the working surfaces (journals and cams) and deterioration of the limiter.

Over time, the camshaft's cams and journals wear out.

Knock

It is quite problematic to determine from the sounds coming from the engine compartment that the problem is related specifically to the camshaft, but it is still possible. The knocking sound of the engine resembles the dull blows of a hammer, which become more frequent as the engine speed increases. However, the best way to diagnose a shaft is to dismantle, disassemble and troubleshoot it. During inspection, the shaft should not move in the housing relative to the axis, otherwise a dull sound will be produced when hitting the limiter.

Video: reasons for the longitudinal play of the VAZ camshaft

Power reduction

The drop in power on classic Zhiguli cars is a phenomenon caused by wear of the camshaft and rockers. With proper engine operation (timely oil changes, monitoring its level and pressure), the problem only appears over long vehicle runs. When the cams wear out, the required phase width and valve lift at the intake are no longer ensured.

When the shaft and rockers wear out, the motor power may decrease several times

Deformation

The RV can become deformed under extreme heat, which is caused by problems in the cooling and lubrication systems. At first, the problem may manifest itself as a knocking sound. Therefore, if there is a suspicion of this breakdown, for example, the motor has overheated, then it is recommended to diagnose the shaft in order to avoid more serious troubles with the engine timing belt.

Phase sensor on a 16-valve engine

The whole procedure is generally similar, but there are some differences:

This completes the repair. After installing a new sensor, the engine begins to operate in ideal mode, gasoline consumption returns to its previous level, detonation and “triple” disappear. It is worth paying attention to the fact that on eight-valve engines, replacement is a little easier - there is no need to dismantle the radiator grille. After completing the repair, be sure to check the engine operation using diagnostic scanners.

If you check and remove the DF yourself, under such conditions the motorist will only have to spend money on purchasing a new DFSV. This device, namely the camshaft position sensor for the VAZ 2114, will cost around 300 rubles. When purchasing a position regulator, pay attention to the quality, because parts from certified stores for VAZ are best suited. If the driver wants to entrust his car to service station specialists, such repairs will cost at least twice as much. In any case, the decision will be made by the owner of the car.

Thus, if the driver has skills in working with hand and power tools, and also knows the design features of the VAZ 2114, he can painlessly dismantle and repair the camshaft sensor. Despite its modest size and ease of operation, the DPRV is an important component of the machine, which affects its power and driving performance. If the driver wanted to make the repairs himself, he should stock up on the necessary tools.

Camshaft replacement tools

The presence of these tools will simplify the procedure:

- a set of wrenches and sockets, including a ratchet;

- a set of screwdrivers - a slotted screwdriver for working with the seal or tweezers is required;

- micrometer;

- knob for clamping and rotation;

- dynamometer - a wrench for tightening threaded connections with a precisely specified torque;

- mount;

- puller and mandrel for pressing;

- hammer.

Before replacement, be sure to prepare a repair kit, which includes, in addition to the product itself: liners, oil seal, fastening bolts. If the system has hydraulic compensators, then these parts also need to be replaced.

conclusions

The torque and sequence of tightening the camshaft bed on the 16-valve VAZ-2112 engines must be correct, since this factor affects the operation of the cylinder head and the engine as a whole. Thus, incorrect implementation of the procedure can lead to more serious consequences. If the car enthusiast is not able to do this on his own, then it is necessary to contact a car service, where everything will be done quickly and efficiently.

Sources used:

- https://carfrance.ru/moment-zatyazhki-posteli-raspredelitelnyx-valov-vaz-2112-16-klapanov/

Approximate cost of replacement at a car service center

As you can see, replacing the camshaft is done with your own hands, in a home garage. You don't need any special equipment. On the other hand, this is an intervention in the engine design, which, if unsuccessful, can damage the power unit. One of the signs of malfunction is that after replacing the camshaft, the engine begins to trip. Therefore, in order to avoid major repairs and large expenses, many car owners trust the procedure to car services.

The price of replacing a camshaft starts at approximately 4,000 rubles. If you only need to replace the oil seal, the service station will charge the same amount. Replacing the shaft sensor costs 500 rubles. Replacing the timing chain of a passenger car equipped with a 4-cylinder engine is usually estimated at 6-7 thousand rubles. On SUVs and crossovers, this procedure costs more - 10-11 thousand rubles.

The camshaft is most often installed in the upper part of the cylinder head, but there are also systems with a lower location. The latter option is found mainly on old cars or cars with weak engines. The upper location of the element, on the contrary, is the calling card of powerful internal combustion engines with high operating speeds.

Procedure for replacing the cylinder head gasket on a VAZ 2109-2108

The gasket may remain either on the surface of the head or stick to the block itself. You can try to remove it by hand without using any tools, and if that doesn’t work, you can carefully pry it off with a flat-head screwdriver without damaging the surface of the part.

Carefully inspect the surface of the cylinder head and if pronounced traces of corrosion are found on it, especially in close proximity to the coolant channels, then it is necessary to repair it: milling, grinding, etc. If everything is normal, then we remove traces of the old gasket using special means:

We wait a few minutes until the whole thing has cooled down and remove the residues that have not succumbed to the chemicals, if any remain, with a razor blade. Then we wipe everything dry and you can even degrease it so that no foreign traces remain on the surface:

The engine block also needs to be cleaned and then a new gasket installed on it.

It is important that the holes in the gasket coincide with the guides, which are located at the corners of the block:

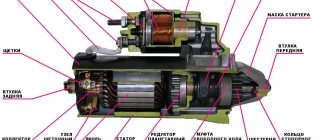

What are plain bearings

To better understand why engine bearings need to be tightened to a certain torque, let's take a look at the functions and purpose of these elements. Let's start with the fact that these sliding bearings interact with one of the most important parts of any internal combustion engine - the crankshaft. In short, the reciprocating motion of the piston in the cylinder is converted into rotational motion precisely thanks to the connecting rods and crankshaft. As a result, torque appears, which is ultimately transmitted to the wheels of the car.

The crankshaft rotates constantly, has a complex shape, experiences significant loads and is an expensive part. To maximize the service life of the element, connecting rod and main bearings are used in the crankshaft design. Taking into account the fact that the crankshaft rotates, as well as a number of other features, conditions are created for this part that minimize wear.

For the manufacture of liners, softer materials are used compared to those from which the crankshaft itself is made. The liners are also additionally coated with an anti-friction layer. Lubricant (motor oil) is supplied under pressure to the place where the liner is connected to the crankshaft journal. The specified pressure is provided by the oil pump of the engine lubrication system. In this case, it is especially important that there is the required clearance between the crankshaft journal and the plain bearing. The quality of lubrication of the rubbing pair, as well as the engine oil pressure in the engine lubrication system, will depend on the size of the gap. If the gap is increased, then the lubricant pressure decreases. As a result, rapid wear of the crankshaft journals occurs, and other loaded components in the internal combustion engine also suffer. In parallel with this, a knock appears in the engine.

How to tighten main bearings and connecting rod bearings

So, taking into account the above, it becomes clear that the tightening torque of the main and connecting rod bearings is extremely important. Now let's move on to the assembly process itself.

- First of all, molar liners are installed in the bed of the molar necks. Please note that the middle liner is different from the others. Before installing the bearings, the preservative lubricant is removed, after which a little motor oil is applied to the surface. After this, the bed covers are placed, after which the tightening is carried out. The tightening torque should be that recommended for the specific model of the power unit. For example, for engines on the VAZ 2108 model, this figure can be from 68 to 84 Nm.

- Next, the connecting rod bearings are installed. During assembly, it is necessary to accurately install the covers in place. The specified covers are marked, that is, their arbitrary installation is not allowed. The tightening torque of the connecting rod bearings is slightly less compared to the main bearings (the indicator ranges from 43 to 53 Nm). For Lada Priora, the main bearings are tightened with a torque of 68.31-84.38, and the connecting rod bearings have a tightening torque of 43.3-53.5.