The correct ignition installation, which ensures that the engine is in working condition, is responsible not only for its stable operation, but also for its power and the amount of fuel it consumes. The ignition may not be set correctly, causing the spark to appear too early or too late. Therefore, every car enthusiast should know how to determine the correct ignition timing and adjust it as necessary.

Determination of early and late ignition

If the ignition is too early or too late, the engine may not function properly. In order for a motor to guarantee specific power, a spark must be supplied to the cylinder when the energy of airless displacement is compressed in it (especially if the device operates on a diesel engine) and can be used to its maximum.

If the spark is not supplied on time, the mixture will ignite too late (because of this, energy will escape through the exhaust pipes) or too early (then some of the energy will work against the piston movements). Car owners need to learn to recognize ignitions and prevent them. Now it’s worth moving on to a detailed overview of each process.

Early ignition is different in that the combustion process of the engine ends before the piston reaches a specific point. The area contained within the loop is considered equivalent compared to the negative work. This is due to the following: gas compression implies the expenditure of more forces than those arising after expansion. We can talk about obvious signs of early ignition if:

- There is a metallic, ringing noise that appears not only in the cylinder, but also in the engine, and also provokes overload of engine parts and increased development of bearings.

- The power of the units and the number of revolutions in the power cylinders are reduced.

- The engine runs unstably at low speeds.

- Fuel consumption increases.

- The wear of the motor elements increases.

Late ignition is considered not as dangerous as earlier. Its key specificity is as follows: combustion of the mixture occurs at a low pressure level and an increased level of cylinder volume. In this case, the cylinder mixture burns out during the expansion process. Late ignition is also determined by certain signs. We are talking about:

- Increased consumption of combustible material.

- High level of cylinder carbon deposits.

- Loss of power.

- Severe engine overheating.

Signs of early ignition

Signs of early ignition

What is early ignition

Pre-ignition is a term that refers to the ignition of the fuel mixture in the cylinders of a car engine before the piston reaches top dead center on the compression stroke. Early ignition is essential for engine operation. It allows you to burn the fuel mixture most completely and efficiently and get the maximum return from this process, which is expressed in power, throttle response and speed.

In the ignition system of a carburetor car engine, in addition to the initially set early ignition timing (0-5 degrees), there are several devices that allow you to automatically make the timing earlier depending on the increase in engine load (for example, centrifugal and vacuum ignition timing regulators).

In the ignition system of an injection engine, determining the optimal ignition timing when the car engine is running is “managed” by the electronic control unit (ECU) of the engine control system. He calculates how much earlier to set the ignition based on data received from sensors (DPKV, DS, etc.).

If some problems arise in the operation of the car engine, ignition too early can be considered a malfunction. Next, we’ll figure out how to independently understand whether the ignition is too early (we diagnose a malfunction) or not.

Symptoms: Ignition too early

Several signs, when they appear, make sense to check the ignition timing and the operation of the devices responsible for increasing or decreasing it.

It is even possible for the crankshaft to rotate in reverse after turning off the ignition.

On a carburetor engine, the idle speed may not be adjustable with the carburetor adjusting screws.

At the same time, starting and accelerating can be quite acceptable, but at speed the engine’s power and throttle response are insufficient (“it’s as if someone is holding the car from behind”).

Constant detonation (fractional, chattering sound from the engine) when the car is moving, increasing when the gas pedal is pressed and does not disappear after it is released.

If the ignition is set incorrectly

If the ignition is early, it is because the spark appears early. At the moment when the piston just began to rise, the fuel-air mixture ignited and this explosion goes against the rising piston, resulting in a waste of energy.

Because the gasoline mixture ignites early, the piston experiences a greater force against its movement. This reduces the life of the crankshaft, pistons, connecting rod and pins.

The signs of early ignition can be determined by the following points:

- During operation of the internal combustion engine, a metallic noise appears, as if something is hitting the cylinder.

- The idle speed fluctuates and there is instability.

- If you press the gas sharply, the engine seems to choke and does not immediately respond to the supply of more fuel.

As for the installed late ignition, it also negatively affects the performance of the engine and the service life of its component parts.

In this case, the mixture is ignited late, that is, when the piston is already going down. The fuel burns out, if it has time, when the piston moves back (up).

Signs of late ignition:

- The internal combustion engine cannot reach speed. Reacts poorly to pressing the accelerator pedal.

- Fuel consumption is higher than normal.

- Carbon deposits and coke form on the piston and cylinder walls, which then, even with the ignition set correctly, interferes with operation.

- Due to uneven combustion of the fuel-air mixture, the internal combustion engine quickly overheats.

What are the dangers of an incorrectly set OZ?

So, we have already found out that if the ignition of the fuel assembly in the form of a spark generated by the spark plug occurs earlier than usual, the expansion of the compressed mixture as a result of its combustion will begin to occur even before the piston has passed TDC, that is, at the stage of its ascent. This means that it will be more difficult for the piston to travel the rest of the way up before it begins to move downwards, during which the optimal release of energy from the exhaust gases occurs.

With late ignition, the amount of useful work performed by the piston also decreases, since part of the path it will travel by inertia, and part of the energy will be wasted and sent to the exhaust system, warming it up instead of increasing the efficiency of the power unit.

The consequences of an incorrectly set ignition can be very serious. If you allow the engine to operate for a long time at a late ignition, all the conditions for the optimal combustion process will be violated. In particular, at the moment at which the exhaust gas pressure peaks, the piston is already moving downwards, so the entire fuel assembly does not have time to burn, which leads to the deposition of unburned particles on the cylinder walls. Accumulating, such deposits can lead to coking of the engine, which can lead to its breakdown and the need for major repairs.

But one should not assume that earlier ignition is less dangerous. In this case, the energy released during the combustion process is directed against the movement of the piston, braking it on the way to TDC, and this causes serious shock loads, and not only on the cylinder head - the crankshaft may also suffer. It is these impacts that manifest themselves in the form of clearly visible metallic knocks. If you do not respond to such symptoms, further operation of the power unit risks deformation of the connecting rods, burnout of the pistons, as well as accelerated wear of the crankshaft liners. And these problems are more serious than the consequences of late ignition.

So the correct OZ is a guarantee of long-term and trouble-free operation of the engine. However, on modern injection engines, the on-board computer is responsible for the correct installation, so you will not be able to adjust the ignition timing yourself. The only option in case of problems is to reflash the ECU, or enter corrective information into the control unit.

You may ask why electronics allow ignition failures? There are objective reasons for this. The fact is that the ignition timing is controlled based on data coming from numerous sensors. Based on this information, the ECU determines in what volume and at what moment to supply fuel and air into the combustion chamber, as well as when to supply a spark to ignite the mixture. In this case, malfunctions in the operation of the sensors are the main reason for changes in the SOP, and the on-board computer does not always react correctly to such situations. A secondary, less common reason for changes in SOP is a violation of the geometry of the components of the power unit.

In such situations, all that remains is to check the proper operation of the sensors. And, of course, the marks on the crankshaft/camshaft match. However, on early versions of injection engines, the ECU is only responsible for the functioning of the fuel supply system, so adjustment work on setting the ignition is carried out in approximately the same way as on carburetor engines.

Briefly about the ignition operation

In previous generation gasoline engines, sparking and ignition of fuel is organized as follows:

- When the cam on the rotating shaft of the distributor passes the Hall sensor, the latter sends a pulse to the commutator, which interrupts the circuit of the primary winding of the high-voltage coil.

- Due to the circuit break, the secondary winding of the coil generates a short-term high voltage pulse that is fed back to the distributor.

- Getting on the rotating contact of the distributor (in common parlance - a slider), installed on the same shaft, the impulse is directed to one of the 4 high-voltage wires.

- The wire supplies current to the spark plug electrodes of the cylinder in which the compression stroke of the air-fuel mixture ends.

- A spark jumps between the electrodes, igniting the fuel. The hot gases push the piston down - the power stroke begins.

Reference. In very old ignition systems, the role of electronic switch and Hall sensor is played by a mechanical contact breaker.

The sparking circuit described above is configured manually. If the adjustment was carried out by an ignorant car enthusiast, the symptoms of late or early ignition appear, described below. The reason is untimely ignition of the fuel mixture when a spark is produced in the middle of the compression stroke or at the beginning of the piston stroke.

In diesel power units there is no spark - diesel fuel flares up due to strong compression. The moment of ignition coincides with the injection of fuel into the cylinder (during the compression stroke, the piston compresses the air). In outdated power units, this parameter was also adjusted manually.

Diesel car

Many symptoms of incorrect operation on gasoline cars are also transferred to diesel. The main difference between these two cars is the method of ignition of the fuel. Ignition of diesel fuel occurs due to close contact of the fuel with compressed, hot air.

Adjustment on a diesel engine

Ignition tuning on diesel cars consists of finding the required advance angle for diesel fuel injection; it must be supplied specifically at the peak compression moment.

If the angle is set incorrectly, the injection will be untimely. This will lead to poor-quality combustion of the mixture, and the engine will not operate properly.

Operating principle of the ignition system

It may seem to many that ensuring fuel assemblies are ignited is a trivial task. In reality, the ignition system consists of many interconnected components. The main problem is that it is necessary to ensure the ignition of the combustible mixture at very high piston speeds, that is, very high accuracy of synchronization of the operation of all components included in the ignition system is required.

We recommend: 9 best spark plugs

Modern non-contact SZ work according to the classical scheme, when the moment of ignition of the compressed mixture is determined by the position of the crankshaft. Although the speed of fire spread in the combustion chamber is quite high - about 30 m/sec (one thousandth of a second is enough to travel 3 cm), it is finite, that is, there is some delay between the supply of a spark and the complete combustion of the next fuel damage. That is why this spark must be initiated at a strictly defined point in time, monitored by a sensor.

Consequences of an incorrectly set ignition angle

Both late and early ignition negatively affects the operation and service life of the engine. It should be added that not only power and fuel consumption depend on the correct ignition timing. If a spark on the spark plug forms earlier than expected, then the pressure of the expanding gases begins to counteract the piston rising to TDC (pre-ignition). Ignition of the working mixture after the piston has begun to move down from TDC leads to the fact that the released fuel energy “catches up” with the piston and enters the exhaust, rather than doing useful work (late ignition).

In the case of early ignition, the rising piston requires a great deal of force to compress the resulting gases as a result of premature combustion of the mixture. The load on the CPG and the crankshaft in such conditions increases significantly.

Signs of early ignition appear in the form of the following symptoms:

- the appearance of a metallic ringing sound during engine operation, which is localized in the area of the cylinder block;

- idle speed fluctuates, the engine is unstable;

- after pressing the “gas” there is a pause, the engine does not “pull” and overuses fuel;

Late ignition also causes significant damage to the engine. In this case, combustion of the mixture occurs under conditions of decreased pressure and increased volume in the internal combustion engine cylinder. The combustion process of the fuel-air mixture itself is disrupted, which burns out during the working stroke of the piston. As a result, signs of late ignition are:

- the engine loses power, you need to press hard on the gas to accelerate;

- there is a significant increase in fuel consumption;

- the engine is heavily coked by deposits and carbon deposits;

- improper combustion of the mixture leads to engine overheating;

Why do you actually need to advance the ignition?

I highly recommend, if you haven’t seen it yet, to see how an internal combustion engine works.

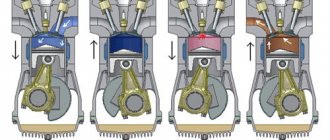

The fact is that in order to obtain maximum power and torque from the engine, it is necessary that the gas pressure, after combustion of the working mixture, reaches its maximum value at a point 10-12°

after top dead center. Then the force of gas pressure on the piston will be most efficiently converted into mechanical energy of rotation of the crankshaft. Contrary to popular belief, the fuel-air mixture (hereinafter referred to as FA) does not burn instantly and certainly does not explode in the cylinders. The oxidation reaction, which is what happens during fuel combustion, has a certain speed. So, in order to obtain the maximum gas pressure at the point we need, we need to coordinate the speed of the piston (read engine speed) and the combustion rate of the fuel assembly. Next, let me delve a little deeper into the theory of fuel assembly combustion. The flame propagation front begins with a small source when a spark jumps between the electrodes of the spark plug. The average duration of spark burning is 1 - 1.5 milliseconds (one thousandth of a second). The temperature in the breakdown cord in this negligibly short period of time reaches 10,000° C. The small volume of fuel assembly that is located in this breakdown interval burns out almost instantly. Further, from the heat released during combustion, the flame front further spreads throughout the combustion chamber. The initial burning speed is not high at all - about 1 m/s. Further, as the front spreads, the burning speed reaches 50-80 m/s. The last portions of fuel assemblies located near the relatively cold walls of the combustion chamber burn out at a much lower rate. Thus, the entire combustion process takes about 30° of crankshaft rotation angle. Now let's take a closer look at what happens in the engine cylinder at different ignition timing angles. Below is an indicator diagram of the dependence of pressure in the cylinder on the angle of rotation of the crankshaft at a normal ignition timing angle (hereinafter referred to as ignition timing). Here, the maximum gas pressure occurs almost immediately (10 - 15°), as soon as the piston passes the top dead center. The power and torque of such an engine are at maximum. Now let's see what happens if we shift the OZ to a later direction. As you can see, the peak of the maximum gas pressure has also shifted to a later direction and in itself it is much lower than with normal SOP. That is, it turns out that the fuel assembly, as it burns, seems to catch up with the outgoing piston. The efficiency of such an engine leaves much to be desired. Sometimes the mixture can continue to burn even after the exhaust valves open, then the hot exhaust gases can prematurely ignite the incoming fresh fuel assembly charge. In this case, with late ignition, popping noises in the intake manifold may be observed. And the opposite case is when the ignition is too early. The peak of maximum gas pressure occurs at the top dead center of the piston movement or even earlier. That is, at the initial stage of fuel assembly combustion, gases press against the piston in the opposite direction, which naturally also reduces engine power and can cause such an undesirable phenomenon as detonation.

Determination of ignition timing

Ignition timing is the moment when a spark is formed between the electrodes of the spark plug, which ignites the working air-fuel mixture in the engine cylinders. In other words, this is the amount of time it takes for the system to ignite the compressed working mixture. Early or late ignition can cause significant harm to the engine, since it leads to increased heating of its components and places a significant load on them.

What is the ignition system?

The ignition system is a set of interconnected complex mechanisms and structures that, when turned on, create electric sparks that ignite the fuel mixture in the cylinder of an internal combustion unit. Domestic cars are often equipped with a classic ignition system consisting of three key elements. We are talking about a lock, a contact part and an anti-theft element. As for the modified models, they are equipped with contactless ignition systems.

How to check ignition timing?

The process of setting the required ignition timing is considered the most important point in the overall functioning of the vehicle. Ensures normal operation of quite important characteristics. This includes power, fuel consumption, and idle speed along with throttle response. Therefore, it is worth monitoring these indicators and checking regularly. By the way, it is recommended to perform this procedure when servicing a car.

To determine whether the above-described structure is working properly and whether it is installed correctly, you should take a test lamp and a strobe light. And then you need to follow specific instructions.

- You need to connect the device in parallel to the capacitor.

- Turn the crankshaft using the crank. This should be done until the spacer plate joins the contact on the distributor cap, which is additionally connected to the spark plug of the first cylinder.

- Turn on the ignition.

- Until the lamp lights up, gradually turn the crankshaft.

- The marks must match. If the lamp lights up before the marks match, it means that the ignition is installed incorrectly.

Car owners often use the following technique to check: they drive out onto a flat road, accelerate the car well and start moving in fourth gear at a speed of about 50 kilometers per hour. At a certain moment you need to press the brake hard and all the way. If, as a result, small, short-lived engine detonation sounds appear, it means that the ignition timing is set correctly. In the case where the sounds are incredibly strong, there is a problem with early ignition. If there is no noise at all, it’s too late.

How to set the ignition timing with your own hands

Setting the ignition correctly means that you need to find the desired ignition timing (IAF). The tuning is done at idle, although this is understandable, but suddenly someone decided to put the car on a jack and tune it at speed.

To adjust the ignition, you need to know that the optimal good engine crankshaft speed at idle is from 850 to 900 rpm. The ignition timing angle should be between -1 and +1 degrees. This is a degree relative to top dead center (TDC).

A popular device used to set the ignition is a strobe light. With a strobe, the settings are more precise. But, if it is not there, then set it up using a control light.

If a light bulb is used for adjustment, it is connected to the positive terminal on the ignition distributor (distributor), and the light bulb base is connected to ground. Let's look at the configuration options separately.

Now we have begun to disassemble the power units of automobiles. Please write in the comments what kind of car you have and with what engine. Later, materials on such engines will be published with useful information, for example, if the timing belt breaks, whether the valves are bent, also technical characteristics, design, on which cars such engines are installed, etc. We have already reviewed the ZC engines from the Honda plant, 3UZ-FE, 3S-FE, 1AZ-FE.

Strobe setting

- Start the engine, heat it to operating temperature and turn it off.

- Connect the strobe light to the car's network.

- Unscrew the nut securing the distributor cap - ignition breaker.

- Place the alarm sensor on the high-voltage wire of the first cylinder.

- If there is a vacuum corrector hose on the distributor, then it must be disconnected and plugged.

- Direct the strobe light onto the engine crankshaft pulley.

- Now start the engine and leave it idling.

- Now you need to turn the distributor body and fix it so that the mark on the crankshaft pulley coincides with the mark on the timing mechanism.

- If the marks match, tighten the nut.

How to set the ignition with a control light

- Rotate the engine crankshaft until the mark on its pulley coincides with the timing mark.

- In this case, the ignition distributor slider should be directed to the first cylinder.

- Now you need to loosen the distributor nut.

- One wire is connected to the core of the warning lamp (control) and to the ignition coil wire (bobbin).

- The second wire connects the ground and the light bulb base. The light should light up.

- After this, you need to turn on the ignition by turning the ignition key and turning the distributor body clockwise. When the distributor rotates, the light will go out in some position. In this position, tighten the distributor clamping nut.

Other methods of setting the ignition

Method by ear

Some people set the ignition by ear. Rotate the distributor and determine how the engine operates. This method is the simplest:

- Start the engine.

- Loosen the distributor nut.

- Rotate the distributor and determine for yourself how the internal combustion engine works. The engine should operate smoothly in the found position, without vibration. At the same time, the engine should develop the highest idle speed.

- After this position has been found, you now need to turn the distributor a couple of degrees clockwise and secure it with a nut.

Spark method

Another tuning method is using a spark. To do this, you need to align the marks on the crankshaft pulley with the timing mark. The slider mark points to the first cylinder. After this, you need to loosen the distributor nut and pull out the central high-voltage wire from the distributor cover.

Afterwards, bring this wire closer to ground so that there is 5 mm between them, and turn on the ignition. Rotate the distributor body 20 degrees clockwise. 20 degrees is 1-1.5 cm. Now you should slowly turn the distributor counterclockwise until a spark appears between the disconnected distributor wire and ground. In whatever position the spark appears, we leave the position of the distributor in that position and tighten it.

We recommend: The car jerks when driving - tips for diagnosing and eliminating the causes yourself

After using one of the methods for adjusting the ignition of domestic carburetor cars (VAZ, UAZ, Volga, NIVA, etc.), drive around and check how the adjustment affected the operation of the internal combustion engine.

For diagnostic accuracy, you need to:

- First warm up the engine.

- Then accelerate to a speed of 45 km/h.

- Turn on speed 4 and press the gas pedal all the way.

- At the same time, we evaluate how the engine behaves, whether it detonates or not.

- If the ignition timing is set well, after switching to 4th gear at a speed of 45 km/h, a short-term detonation will appear for 2-3 seconds and disappear after pressing the gas pedal.

- If detonation does not disappear quickly, then early ignition has occurred.

- If there was no detonation at all, then the ignition turned out to be late, you will have to set it “early”.

If it was not possible to set the ignition to the optimal mode the first time, then repeat again and again until the correct result appears. By repeated adjustments, you can achieve automaticity and learn how to adjust the ignition with your own hands, without instruments, by ear.

Difference between injection and carburetor ignition systems

Therefore, it is very important that the ignition timing is set correctly. And you can do this yourself.

Let us immediately note that gasoline power plants use different power systems - carburetor (outdated and no longer installed on new cars, but still very common) and injection.

In modern injection cars, such an operation as setting the ignition angle is not required. This is because the electronic control unit is responsible for the operation of the ignition system.

It contains all the information regarding the ignition timing, and it follows it completely.

In such a car, everything works like this: numerous sensors installed on the engine transmit data to the ECU.

Based on them, it issues commands to the engine systems - power supply and ignition.

For the power system, the ECU shows how much and when to release fuel and air into the cylinders, and for ignition, at what moment to apply a spark.

But it is worth noting that damage to the sensors or a violation of the geometry of the position of the component elements of the motor can lead to a change in the advance angle.

Therefore, even on a fuel-injected car, signs of a faulty ignition may appear.

At the same time, it is not possible to change the angle manually, since the data is entered into the ECU, the only thing is that you can reflash the unit and “fill” information with the changed data into it.

As for the mechanical part, the car owner can only check the functionality of the sensors, as well as the coincidence of all marks on the crankshaft and camshaft.

Note that not all injection cars have an electronic unit that is responsible for the operation of the ignition system.

On older cars with such a power system, the ECU only controls the fuel supply; as for ignition, they have a separate system and all adjustment work is done separately, that is, the same as on a carburetor car.

Consequences of driving with incorrect settings

In addition to deteriorating vehicle performance, ignition too early causes other detrimental consequences:

- Detonation is the worst enemy of the engine. Due to constant impacts on the pistons, the fingers become loose and play forms in the connection. As a result, the connecting rod bushings are broken and the production of cylinders is accelerated.

- Shooting at the carburetor damages the bushings on which the valve axles rotate. The latter do not close tightly, causing the engine to suck in excess fuel at idle.

- The power unit tends to overheat and if the cooling system malfunctions, the cylinder-piston group may fail.

Modern electronically controlled engines are equipped with knock sensors. When the element detects vibration, the control unit automatically adjusts the ignition timing.

Early injection of diesel fuel into a diesel engine is fraught with damage to the high pressure fuel pump (HPF) and injectors. Imagine: a pump pumps fuel in one direction, and it is counteracted by a piston moving towards TDC. It's not hard to guess who will get the hit.

Signs of late ignition are no less dangerous. Ignition of the fuel mixture at the expansion stage leads to a decrease in engine efficiency and an increase in the load on the main parts - pistons with rings, cylinders and connecting rods. The result is easy to predict - intense heating and accelerated wear.

Shooting into the exhaust tract, caused by delayed sparking, destroys the walls of the exhaust pipe and the muffler partitions. Elements will have to be repaired by welding, or even replaced.

Ignition on diesel installations

Above we looked at everything related to the ignition of gasoline engines.

But the ignition timing is also present in diesel engines that do not have an ignition system as such.

The theory of this internal combustion engine is this. Ignition of the air-fuel mixture in a diesel engine occurs due to the effect of high pressure at the moment of fuel injection into the cylinder. Air comes in earlier.

From this we can understand that the ignition moment is the moment of fuel injection into the cylinder. And the high pressure fuel pump is responsible for all this.

Then everything is the same as with a gasoline engine - to obtain maximum efficiency, ignition must occur before the piston passes TDC, that is, the injection pump plunger must supply a portion of fuel a little earlier so that the air-fuel mixture has time to fully burn.

A diesel engine also has late and early ignition, or more precisely, fuel injection. The symptoms of such phenomena are the same as those of a gasoline engine.

But with a diesel unit, early injection is accompanied by very distinct detonation and metallic knocking, and with late injection, the amount of exhaust gases increases greatly, and they change color.

The importance of correct ignition adjustment

The fidelity of the set ignition on carburetor engines is carried out using a strobe light

The quality and efficiency of engine operation depends on the nature of the ignition installation . Therefore, it is the installation of the ignition that is an important action that allows you to configure the power unit. If the ignition is installed incorrectly, both in the direction of increasing the advance angle and in the direction of decreasing it, the engine immediately feels a negative impact.

That is why setting the ignition timing should be approached responsibly and very carefully.

Ignition operating principle

A gasoline engine has certain factors that affect the quality and timing of the spark required to ignite the combustible mixture. These factors are combined into a separate mechanism called a distributor; it is also sometimes called a distributor-breaker.

Classic ignition circuit

It is installed in the area of the cylinder block; the distributor shaft is driven by the engine camshaft. There are cams located on the distributor shaft, they open the circuit at the required moment, and then a spark is formed.

Distributor diagram

The main disadvantage of the distributor is its tendency to mechanical wear, as a result of which the quality changes, as well as the timing of the spark..

Of course, this affects the performance of the engine, which will require further intervention and adjustment.

Ignition adjustment on carburetor engines

Adjusting the ignition by turning the distributor

It is produced by turning the ignition distributor housing (distributor), the shaft of which is driven by transmitting torque from the engine through intermediate gears. On engines of the VAZ 2108 family, the distributor shaft is rotated by direct engagement with the camshaft, but this is not of fundamental importance. The most important thing is the exact coordination of the ignition system with the mechanics of the internal combustion engine.

Regardless of whether the distributor is installed - contact or non-contact (with a Hall sensor), turning its body against the direction of rotation of the rotor increases the ignition timing. That is, to make the ignition “early”, you need to determine in which direction the rotor rotates - you can remove the cover from the distributor and turn the crankshaft. It will be clearly visible where to turn the distributor for early ignition. But the required ignition timing is not always determined by the engine characteristics specified by the factory. Its value is also affected by the octane number of the fuel.

This is very clearly visible when using gas equipment on cars with carburetor engines. When switching from petrol to gas for the first time, the car refuses to accelerate. To achieve normal engine operation, you have to not only turn the ignition on early, but turn the distributor as far as it can go in the opposite direction. And vice versa, when switching back to gasoline, such ignition advance will be unnecessary - the knocking of the piston pins caused by detonation will “tell” this. This is due to the large difference in octane numbers between gas and gasoline. A very simple but effective way to check the accuracy of setting the advance angle is to test the operation of the motor in motion. When you sharply press the gas pedal, a slight short-term knock of the piston pins should appear in the engine gaining speed.

What needs to be turned in the distributor to adjust the ignition timing.

The distributor itself, there is a scale on the side of it, you release the bolt and turn it. towards the plus side in advance towards the minus side towards later. and if you write 0 in this matter, buy a book on your car from the publishing house “behind the wheel”, everything is clearly detailed there with pictures, how to assemble, how to disassemble, how to adjust, it’s impossible not to understand. I once started with them myself

The distributor itself. The pictures are on the fence.

Turn the distributor itself, but before turning it you need to decide in which direction the crankshaft rotates, depending on how the engine is installed on your car, for example, a VAZ nine, if you stand facing the distributor on the driver's side, then turning the distributor to the left you will install the ignition later, to the right earlier, respectively, but on the distributor itself there is an area - markings on the body - a mark in the form of a stick on the left - a minus is drawn to the right of it - a plus, here on the right side there is an area for early ignition, a field for late, but despite this you are in the area of early ignition You can turn to the right and place even earlier. Well, something like this, using the nine as an example, the distributor itself is screwed onto 3 nuts, release them and twist

Nothing complicated. I did this: I took the socket with the lamp, + threw it on the distributor at the lamp, - to ground. And he spun it. The lamp lights up - the ignition is turned on. Try it. Maybe it will be clear without pictures.

The operation of a modern engine is influenced by many factors, but no one will deny that the ignition system plays one of the leading roles in this. The efficiency, stability, power and other parameters of the power unit depend on how well it copes with its tasks.

In theory, the fuel assembly on four-stroke engines should be ignited an instant before the piston reaches the top position. This short period of time should be enough for the mixture to burn, releasing the necessary portion of energy to ensure cranking of the crankshaft.

But in practice, ignition of the air-fuel mixture does not always occur precisely at the end of the compression stroke. There can be many reasons for this, and today we will try to figure out why this happens, how to diagnose and deal with such a phenomenon.

Ignition installation methods

It is important to know where and how much to turn the housing in order to install the ignition correctly.

There are several methods for setting the ignition timing on a car, where the ECU is not responsible for the operation of the ignition system, and all work is done manually.

The most accurate method of setting the ignition is using a strobe light.

The technology for setting the advance angle with its help is very simple, and to perform it you only need:

Adjustment work should be performed on a warm engine. Let's look at how everything is done using the example of a VAZ-2107 with a carburetor.

Note that the described method is suitable for almost any car with a carburetor, as well as injection models in which installation is performed manually.

The principle of adjustment using a strobe light is almost the same for all cars. The only thing is that the marks can be combined not only along the pulley, but also along the flywheel (they are there too), this is more convenient for everyone.

Unlike the strobe method, the lamp will not allow you to accurately set the angle.

And yet this method is quite applicable, especially since it can be used to adjust the ignition even on the road. An example is the VAZ-2108.

The only tools you need are a 12-volt incandescent lamp, two wires and a set of keys.

To adjust the ignition by the light bulb you need:

. Additionally, you can check the correct installation by looking at the flywheel through the inspection window on the housing;

Some craftsmen do not use any devices at all to set the lead angle, but do everything “by ear”.

Moreover, everything is done very easily: start the car, set the idle speed.

And then the distributor mount is simply loosened, after which the body rotates in different directions, while listening to the behavior of the power plant. When rotating, due to the changing angle, the revolutions will begin to float.

The essence of this method is to set the engine speed to the highest possible speed, and it should be stable. After this, the distributor is fixed in the selected position and that’s it.

How to determine early or late ignition of a car?

Diagnostics and repairNovember 30, 2017

For normal operation of a gasoline and diesel engine, timely ignition of the fuel in the combustion chambers of the cylinders is important. If the moment of the flash does not correspond to the end of the compression stroke - it is delayed or occurs earlier, the motor does not function correctly and significantly loses power. It is worth noting that the problem is relevant for power units with a mechanical spark distributor (distributor) and old diesel engines. In new cars, the process is completely controlled by electronics. It is useful for owners of outdated cars to know how to determine early or late ignition and troubleshoot the problem.

Briefly about the ignition operation

In previous generation gasoline engines, sparking and ignition of fuel is organized as follows:

- When the cam on the rotating shaft of the distributor passes the Hall sensor, the latter sends a pulse to the commutator, which interrupts the circuit of the primary winding of the high-voltage coil.

- Due to the circuit break, the secondary winding of the coil generates a short-term high voltage pulse that is fed back to the distributor.

- Getting on the rotating contact of the distributor (in common parlance - a slider), installed on the same shaft, the impulse is directed to one of the 4 high-voltage wires.

- The wire supplies current to the spark plug electrodes of the cylinder in which the compression stroke of the air-fuel mixture ends.

- A spark jumps between the electrodes, igniting the fuel. The hot gases push the piston down - the power stroke begins.

We recommend: Engine water hammer. Causes and consequences

Reference. In very old ignition systems, the role of electronic switch and Hall sensor is played by a mechanical contact breaker.

The sparking circuit described above is configured manually. If the adjustment was carried out by an ignorant car enthusiast, the symptoms of late or early ignition appear, described below. The reason is untimely ignition of the fuel mixture when a spark is produced in the middle of the compression stroke or at the beginning of the piston stroke.

In diesel power units there is no spark - diesel fuel flares up due to strong compression. The moment of ignition coincides with the injection of fuel into the cylinder (during the compression stroke, the piston compresses the air). In outdated power units, this parameter was also adjusted manually.

How does early sparking manifest itself?

What happens when, due to incorrect settings, the spark plug discharges ahead of time:

- the air-fuel mixture will not have time to compress to the required degree, since the piston is halfway to the combustion chamber;

- the fuel will flare up when the intake valve is open, causing some of the gases to rush back into the manifold;

- Due to the early flash and too high combustion rate, the piston receives a strong blow, which responds with a finger knock.

Uncontrolled combustion of the fuel mixture, causing shock to the pistons, is called detonation.

How can you recognize the signs of pre-ignition:

- The first symptom is the appearance of popping noises in the carburetor. It makes it clear that fuel outbreaks in the cylinders occur when the intake valves are open.

- As a result, smoke escapes from the air filter pipe. If you remove the housing cover, you can see the flames when firing from the carburetor.

- You can hear the ringing sound of the piston pins when you press the accelerator pedal sharply. This is how detonation manifests itself.

- The engine loses power and acceleration dynamics, fuel consumption increases.

If the ignition timing is exceeded slightly, popping noises will not occur in the intake tract. But detonation and deterioration in the car’s driving performance will still appear. An indirect sign is a spontaneous increase in idle speed.

Symptoms of improper ignition on diesel engines are similar to gasoline engines. Injecting diesel fuel in the middle of the compression stroke leads to similar consequences - detonation and reduced power. The difference is the difficult cold start of the engine and the absence of pops. The reason is insufficient compression of the combustible mixture, which entered the cylinder a split second earlier.

Ignition timing is delayed

Misaligned distributor adjustments can lead to the fact that a discharge on the spark plug electrodes forms too late - when the piston is already at top dead center (TDC) or has begun to move downwards - the working stroke. In this case, the following characteristic signs are observed:

- The crankshaft speed at idle is reduced.

- The power of the power unit drops noticeably, the car accelerates very sluggishly. The reason is the loss of flash energy of fuel burning during the working stroke of the piston.

- A strongly delayed spark causes the engine to shoot into the muffler. Gases rush through the opening exhaust valve.

- It is more difficult to start the engine when cold.

- Fuel consumption is increasing.

Reference. Symptoms of late sparking are more noticeable on vehicles equipped with gas installations. The moment of flash is very important here, since more propane is supplied to the cylinders and if the discharge is delayed, it burns out already in the manifold.

The consequence of late ignition on a diesel engine is difficult starting even on a warm engine and “sneezing” of black smoke from the exhaust pipe. Since fuel injection occurs at the very beginning of the power stroke, diesel fuel does not burn completely and is thrown out in the form of soot. If the fuel supply occurs too late, the power unit will not start at all.

Consequences of driving with incorrect settings

In addition to deteriorating vehicle performance, ignition too early causes other detrimental consequences:

- Detonation is the worst enemy of the engine. Due to constant impacts on the pistons, the fingers become loose and play forms in the connection. As a result, the connecting rod bushings are broken and the production of cylinders is accelerated.

- Shooting at the carburetor damages the bushings on which the valve axles rotate. The latter do not close tightly, causing the engine to suck in excess fuel at idle.

- The power unit tends to overheat and if the cooling system malfunctions, the cylinder-piston group may fail.

Modern electronically controlled engines are equipped with knock sensors. When the element detects vibration, the control unit automatically adjusts the ignition timing.

Early injection of diesel fuel into a diesel engine is fraught with damage to the high pressure fuel pump (HPF) and injectors. Imagine: a pump pumps fuel in one direction, and it is counteracted by a piston moving towards TDC. It's not hard to guess who will get the hit.

Signs of late ignition are no less dangerous. Ignition of the fuel mixture at the expansion stage leads to a decrease in engine efficiency and an increase in the load on the main parts - pistons with rings, cylinders and connecting rods. The result is easy to predict - intense heating and accelerated wear.

Shooting into the exhaust tract, caused by delayed sparking, destroys the walls of the exhaust pipe and the muffler partitions. Elements will have to be repaired by welding, or even replaced.

Adjustment recommendations

The simplest way to adjust the ignition timing is to connect a 12-volt car light bulb to the high-voltage coil circuit. How to make the adjustment:

- When turning the crankshaft, align the mark on the pulley with the mark on the cylinder block. Remove the distributor cap and check the position of the slider - it should point to the contact of the first cylinder.

- Find the wire leading from the distributor to the high-voltage coil. Connect a light bulb to this contact, and connect its base to the ground of the car.

- Loosen the nut pressing the distributor body and turn on the ignition (the light will light up).

- Slowly turning the distributor housing, catch the moment when the lamp goes out. Tighten the nut.

Note. For the system to operate correctly, the spark must jump before the piston reaches TDC. The advance is 2–5 degrees of crankshaft rotation angle.

The question of which ignition is better - late or early - is incorrect from the very beginning. The moment of ignition of the fuel must be optimal. If necessary and there are no diagnostic instruments, the adjustment is made “by ear”: with the engine idling, the nut is released and the distributor is slowly turned by hand. Having caught the moment of the most stable operation of the engine, tighten the nut and press the gas several times to provoke popping or detonation. When you hear one of the signs, turn the distributor 1–2° in the desired direction.

Pro tip on how to check the quality of ignition timing adjustment (UOS)

To check whether the ignition timing is set correctly, you must be guided by the following signs:

- In the operation of a warmed-up power unit, no “dips” should be felt at idle.

- A short detonation (about 3-5 seconds) should be present if you press the gas pedal with a sharp movement, the movement should occur on the most even section of the road surface in fourth gear and a speed of approximately 50 kilometers per hour. That is, the sound of fingers should be heard. If this does not happen, it means the ignition is too late. If this phenomenon is observed, but does not go away, then the ignition is too early.