The main gasket of the car is located between the head and the engine cylinder block. Its rather complex design and very tight clamping of the head bolts mean a long service life, but it also takes loads that are prohibitive by the standards of gas and liquid seals of other machine components. Therefore, sudden or, on the contrary, predictable damage after human errors occurs - breakdowns and burnouts.

Signs of a broken cylinder head gasket

Lubrication and cooling channels pass through the junction of the head and the block. The main task of the gasket is to prevent gases from entering the block from the cylinders, as well as mixing antifreeze with engine oil and fuel.

Depressurization of the block - a breakdown of the combustion chamber edging - adds variety to the manifestation of problems with the internal combustion engine. Therefore, the malfunctions can be the most ambiguous:

- unprovoked increase in engine temperature;

- decreased compression and misfires, vibration, engine “troubles”;

- an increase in the oil level in the crankcase, the appearance of an emulsion, an indication of the emergency oil pressure light;

- swelling of the cooling system hoses, activation of the protective valve in the expansion tank cap and clouding of the antifreeze;

- failure of the interior heater due to air in the system;

- white or bluish thick smoke from the exhaust pipe;

- oil and antifreeze leaks on the cylinder block.

All of these symptoms are very dangerous for the engine, although they affect its service life to varying degrees.

How long can you ride?

If there is a suspicion of a breakdown, then the engine must be turned off immediately, without waiting for further damage.

Driving with a burnt gasket leads to the need to repair those components that are not yet damaged:

- breakdown of the hot joint between the cylinders causes the breakthrough of hot gases bypassing the gasket, there is not enough heat removal, and the light alloy of the head and block begins to collapse;

- oil getting into the cooling jacket leads to a deterioration in heat transfer due to deposits on the walls, which are then very difficult to wash off in hidden cavities;

- antifreeze in oil causes the formation of an emulsion, loss of lubricating properties, a decrease in pressure and disruption of lubrication of loaded parts, sliding bearings overheat and melt, pistons and rings become coked;

- An increase in temperature will cause deformation of large castings of the head and block, which cannot always be restored by repair milling of the planes.

After traveling with a faulty gasket, you often have to change the head, crankshaft, piston group, oil pump, the engine practically becomes completely unusable, the cost of repairs is comparable to the price of a new engine.

Why does the cylinder head gasket break?

The cause of the breakdown may be natural aging of the engine, but more often it is due to violation of operating rules or gross errors during repairs.

Engine overheating

The engine head and cylinder block are made of materials with very similar thermal expansion coefficients. Therefore, massive parts tightly pulled together behave as one whole. But this is only possible with uniform heating within acceptable limits.

In practice, there may be cases where overheating is local in nature. Heat removal from some areas is more effective, others heat up more, and thermal deformations occur.

The aluminum head suffers especially; its lower plane, theoretically ideal to within hundredths of a millimeter, becomes more like an airplane propeller.

On topic: How to bleed a car’s clutch yourself

An unevenly pressed gasket cannot correct such a defect; breakthrough of gases and liquids is inevitable. Curvature appears precisely when overheating, since in normal mode and at the design temperature, uniformity is inherent in the design.

Aluminum cylinder blocks are also as lightweight as possible; their rigidity is not enough at extreme temperatures, and recently cast iron blocks are no longer produced. As a result, irreversible violations of the geometry occur, which immediately leads to failure of the gasket, which is not able to seal the joint of two surfaces of arbitrary shape.

Incorrect torque when tightening the head bolts

In order to qualitatively and evenly press the gasket material onto both planes, a strictly defined technique for tightening powerful head bolts is used.

The fastener is pulled sequentially in several steps, gradually compressing the joint. The force here is such that apparently massive parts are deformed, and this process cannot be brought to irreversible levels.

To maintain uniform tension, the bolts are made using a strictly defined technology, which requires that they begin to reach the yield threshold of the material at the moment the calculated longitudinal force is created.

The tightening is carried out first by increasing torque, and then by turning it at certain angles. The bolt rod leaves the zone of elastic deformation and begins to “flow”, that is, further turning does not cause an increase in the torque on the key. Once in this zone, it is guaranteed that the bolt will no longer loosen during engine operation and will not require post-break-in pulling.

Violation of this technology in order and torque will lead to uneven pressure, deformations, loosening of fasteners and subsequent burnout.

Poor quality material

When purchasing a gasket as a spare part, you can easily end up with a known counterfeit product or simply a cheap, low-quality product.

Reasons for gasket burnout

There are few reasons why a cylinder head gasket burns out, but with a new engine there is only one – overheating. Even a short time of engine operation at temperatures above normal can cause this malfunction. In this case, the gasket may burn out quite a bit, and inexperienced motorists will not notice the first symptoms that appear. With further operation, the burnout increases, and the symptoms become more pronounced. Due to the fact that many car owners turn to specialists not after overheating, but after some time of operation, when the malfunction becomes a clear fact, they do not connect the burnout of the gasket with the recent overheating and demand from motorists other explanations why the cylinder head gasket burned out.

If the volume of coolant is insufficient, you may not notice a slight overheating of the head, since the liquid, circulating in the system, manages to cool in the radiator, but does not have time to remove heat in the required amount. Instruments in a car show the temperature of the coolant, not the temperature of the engine parts. Thus, when operating a car with an insufficient level of antifreeze, you can burn the gasket without realizing that the cause was overheating.

Burnouts occur due to poor-quality gaskets, but this mostly applies to engines after repair. This happens extremely rarely on new cars. Even on repair engines, the cause of such a malfunction may be factors related to the quality of the repairs performed:

- unsatisfactory condition of the mating surfaces (remains of the old gasket, shells or scratches on the surfaces are poorly cleaned, head deformation);

- incorrect tightening torque of the cylinder head bolts;

- the order of tightening the cylinder head bolts is incorrect;

- the thickness of the gasket is incorrectly selected (on engines where they come in different sizes).

When filling the cooling system with liquid, it is important to remove all “air plugs”! Otherwise, you can “burn” the gasket the first time you start the engine.

How to identify a blown cylinder head gasket

If you suspect a problem with the mechanical part of the engine, it is best to contact a mechanic. But you can independently carry out express diagnostics using available means if you understand the physics of what is happening and have some experience in checking engines.

The main symptoms have already been listed above; you just need to try to localize the fault. Without going too deep, since the head will most likely have to be removed anyway, after which a lot will become clearer visually.

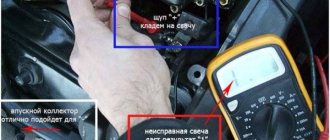

Using a condom, glove or balloon

The passage of gases into the cooling system can be determined by smell, but this does not always stand out easily against the background of other aromas.

But if you put a rubber bag on the neck, which can be used for anything from a baby balloon to a condom, then the gases released from the combustion chamber will begin to inflate it while the engine is running.

It’s hard not to notice this effect. Just not at operating temperature, otherwise the antifreeze will start to boil, it is held back by the pressure of the sealed system.

Bottle check

Using the same principle, you can use a transparent bottle of water with a piece of hose inserted into it. Its second end is hermetically connected to the space above the liquid in the expansion tank using any of the available methods.

Obviously, the same gases that inflated the balloon in the previous test will clearly reveal themselves when coming out of the hose into the water.

Diagnostic methods

When direct or indirect signs are detected, a new task arises for the car owner. He needs to figure out how to check the cylinder head gasket for a breakdown.

There are several methods in total. Moreover, the diagnostics are quite simple and can be used in garage conditions. Experience does not play a key role here, since even novice motorists can cope with the task.

If you are interested and need to know how to check whether the cylinder head gasket on a car engine has been broken, perform the following manipulations. Any of the presented methods is suitable for obtaining an accurate answer regarding the integrity and current condition of the seal between the block and the head.

All methods have been used for decades, but continue to be effective, simple and quite accurate. Yes, you can spend extra money and go to a car service for diagnostics. But in order to save money, it is better to determine the fault yourself, and then entrust the replacement to specialists or do everything yourself.

Replacing the gasket yourself is potentially complex and difficult to do without the appropriate experience and special tools. Also, you should not trust garage service stations that do not have a license. Here it is better to spend more money, but put the car in the safe hands of specialists who will provide guarantees for the work performed.

How to troubleshoot

There should be no minor repairs here. Gone are the days when the gasket was changed without even removing the head from the engine, but only by lifting it. So, at best, you can only simply destroy the new part.

Even when asking for repairs, you cannot ask to change the gasket. The correct wording here is to eliminate the cause.

- After removing the cylinder head, you need to find out exactly what happened and for what reason. Without finding a specific sequence of events, it is better not to assemble the motor. And only after understanding everything, you can begin to eliminate it.

- The surfaces of the head and block must be cleaned and brought into perfect plane using measuring tools and machine tools, if necessary. There is no need to hope that the gasket will fix everything by adjusting to the unevenness. It doesn't work like that.

- The fastening bolts are replaced with new ones; those that have worked in the fluidity zone of the material are unreliable, even if the dimensions are still normal. The threads must be clean, oil and antifreeze from the blind holes must be completely removed by blowing.

- Installation is carried out strictly according to technology; there is no need to do any experiments or transfer of outdated fastening methods from the last century.

- In some engines, it is necessary to take into account changes in the volume of the combustion chamber due to repeated milling of surfaces - the compression ratio changes.

- The cooling and lubrication systems will have to be thoroughly flushed; no traces of emulsion should remain. Of course, oil and antifreeze are replaced.

At first, operation should be carried out as if the engine were running in, without heavy loads and with temperature control. It is quite possible that something was missed during the repair; there is no need to aggravate the situation.

Dealing with a Potential Fault

A failed head gasket is an expensive repair. Not to mention that while the work is going on, you will in no way be able to use your car.

If you do experience this issue, be sure to find out the cause of the problem before installing a new one to prevent the new gasket from failing as well.

Unfortunately, there can be many reasons why it might fail. Modern car engines include many systems, and a malfunction in several of them can have bad and devastating consequences for the fuel pump. However, now you know about the common reasons that can cause such a failure.

Which cylinder head gasket to choose

If the engine specification specifies a metal gasket, then that is what should be used. It will be most reliable to use an original spare part, but if you experiment, then for the better.

Many manufacturers produce products of even higher quality, not being limited by the peculiarities of mass production of cars. Their brands are easy to find through online reviews.

Usually they are also factory suppliers, but the goods are supplied according to their own catalog numbers. A list of analogues is available in the catalogs of major suppliers.

Tips for choosing gasket material

The question often arises which cylinder head gasket is better to use - metal or paronite. In fact, there are three options on sale, and each has its own characteristics:

- The difference between iron cylinder head gaskets is their high strength and wear resistance. They are durable, distribute the load evenly, but they are expensive and this option is not sold for many models.

- Paronite cylinder head gaskets are distinguished by fire resistance and elasticity. In the most important places they are reinforced with metal elements. At the same time, their properties deteriorate over time. The products are afraid of temperature changes and emit harmful asbestos.

- Non-asbestos or composite options are a modern solution characterized by strength, good fit and long service life. They are also reinforced with metal where necessary, making this type the most preferred type today.

There is no point in choosing between paronite or metal; it is much easier and cheaper to take the composite option, which has almost no disadvantages. If installed correctly it will last for many years.

Finding out that the cylinder head gasket is broken is much easier than it seems at first glance. If you know the main signs and check according to the recommendations of specialists, then in 99% of cases the car owner will be able to determine the problem on his own. The main thing is to replace the gasket in time.