07/19/2021 12,789 VAZ 2110

Author: Ivan Baranov

In order for the transmission system to operate without breakdowns, it is necessary to monitor the serviceability of all its components. One of these elements is the clutch fork. It is important to be able to perform repairs yourself. The article describes the function of the clutch fork and how to change it on a VAZ 2110.

[Hide]

Features of replacing the clutch fork on a VAZ-2110, 2111, 2112

The clutch drive fork is necessary for the proper operation of the entire transmission system.

This mechanism is a lever, when pressed, the following occurs: when the pedal is depressed, the clutch and release bearing move, this leads to the inner edge of the spring moving forward, and the clutch is disengaged. When the pedal moves back, the clutch is engaged, so sometimes this spare part is called the release or engagement fork, respectively. Typically, the clutch fork is found in mechanical gearboxes, and is occasionally included in hydraulic ones. The drive fork is a metal rod on which a lever and two legs are attached.

What are the usual malfunctions of the VAZ-2110 clutch fork that require replacement?

The clutch fork is subject to wear and tear, just like other parts. Factory defects are also possible, but due to the simplicity of the design, they are much less common.

- The clutch fork breaks. In this case, the pedal drops sharply, making it almost impossible to continue forward.

- Crack. The clutch grabs lower and lower, adjustment is almost ineffective. As the crack gets larger, the clutch pedal goes down again.

- Curvature.

- Paw wear.

- Defects of the paws at the point of contact of the liner coupling.

You need to change the fork in any case, since this part is necessary for the movement of your car. Without it, gear shifting is impossible.

The cost of spare parts is 300-500 rubles. When choosing, pay attention to the quality of the material and the thickness of the metal. Very often, a fork made of thin iron bends almost immediately.

Although the part is simple in design, it may not be so easy to replace it yourself. When contacting a car service center to replace the clutch drive fork of a VAZ-2110, you will have to pay from 1,500 to 2,500 rubles.

Replacing the clutch on a VAZ 2110 with your own hands

The car owner of a "tens" may be taken by surprise by a breakdown of the clutch system. This means that there will be unplanned expenses for spare parts and auto repair shop services. Replacing a VAZ 2110 clutch is not cheap, from 3,500 to 5,000 rubles, not counting the cost of spare parts. However, there is an option to save a significant part of your personal savings and replace worn-out parts with new ones - yourself. Let's face it, this is not an easy procedure. But, following the instructions, it is possible to deftly manage it in one day.

On a note! Do not rush into a global repair, since in some cases it is too early to change the clutch on a VAZ 2110. It is possible to eliminate the formation of a defect by adjustment. On the top of the gearbox housing there is a drive cable mounting bracket with two nuts. By tightening one of the nuts, it is possible to install new pedal travel. After this, the mechanism will serve some more.

Replacement

If you change the fork on a classic without removing the gearbox, you can still do it, but you won’t be able to do the same on a VAZ-2110. The replacement will take 3 to 4 hours depending on experience.

- Remove the gearbox.

- Remove the pressure bearing.

- The next step is to remove the rubber cover by hooking it with a screwdriver. Pull it off the power plug. It also needs to be replaced if it becomes warped, cracked or hard.

- Use pliers to squeeze the locking tabs on one side of the crankcase. Using a screwdriver, pry up the plastic bushing of the fork axle. If there is noticeable damage or signs of wear on the cap, then it also needs to be replaced.

- We unfasten the clutch fork itself: by lifting it, you need to remove its axle from the bushing. First, the axle, then the lever, are removed from the outlets in the crankcase.

- You need to squeeze the ends of the fork spring retainer and remove it. A deformed retainer needs to be replaced.

- We replace the fork that shows signs of wear.

- It is usually recommended to replace the metal bushing as well, especially if it is noticeably worn.

- Before installing a new part, you need to lubricate both the metal and plastic bushings.

- Next, install the shutdown plug. Assembly is carried out in the same order, starting from the end. Carefully secure the plastic sleeve. The protrusion on it should be in the recess on the crankcase. The petals should firmly secure the sleeve, preventing it from falling out.

If you use a spare part of proper quality when replacing, the clutch drive fork will last a long time. Replaced accompanying elements will protect the mechanism and improve its operation.

Source

Transmission diagram for the VAZ-2110 and reasons for wear of the clutch fork

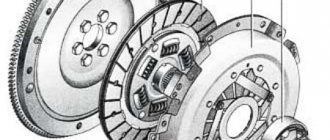

Clutch fork design.

Before proceeding directly to the repair and restoration operation itself, it is worth considering the reasons for changing the clutch fork on the VAZ-2110.

So, let's look at the reasons for changing the part:

- Deformation of the clutch fork.

- Cracks in the body.

- Foot defect or wear.

This is what it looks like when it was just removed from the car.

Replacement process

When all the reasons have been considered, you can proceed directly to the process of changing the part:

- First of all, it is worth dismantling the gearbox. Without this, it is quite difficult to change the clutch fork.

- We pry off the cover and dismantle it. If it shows signs of wear, it is recommended to replace it.

Remove the rubber boot.

We take out the plastic sleeve.

Remove the clutch fork from its seat.

Clutch fork mounting location.

Remove the spring retainer. When worn, we replace it.

The assembled unit after repairs.

Part selection

There are no special options when choosing a clutch fork for a VAZ-2110.

There are only two manufacturers - the Russian Federation (original) and China Road Map (not recommended because the quality is below average). Both parts are produced under the original catalog number - 21101601200 . The average cost in the automotive spare parts market is 1000 rubles.

New clutch fork.

Photo gallery

Pull out the rubber boot

We take out the plastic sleeve

Removing the clutch fork

Checking the metal bushing

Remove the spring clip

Checking the correct installation

Clutch fork function

The clutch fork (CL) is an important element of the vehicle transmission system. It is a lever with which the pressure plate is retracted, resulting in the clutch being released. The BC is sometimes called the cut-off plug.

BC is mainly part of a mechanical gearbox, less often in hydraulic drives. The design of the VS in the gearbox on a VAZ 2110 is quite simple: a metal rod on which a lever and two legs are attached.

At number 5 VS

When you press the clutch pedal (CS), thanks to the BC, the release bearing clutch moves, thus, the inner edge of the spring moves forward and the device turns off. Naturally, the correct engagement and disengagement of the clutch depends on the serviceability of the aircraft.

Aircraft replacement is required in the following cases:

- Deformation of the part is detected;

- cracks were detected on the body;

- curvature of the aircraft;

- Defects in the tabs were identified at the points of contact with the release bearing coupling;

- paws are worn out.

The photo shows a broken down aircraft.

Aircraft with a broken lever

If there are cracks on the aircraft, then this reduces the quality of the PS operation, late setting occurs, the machine may slip, and the pedal may sink when pressed. There is a need to regulate free play. Along the crack, the aircraft deviates from the release bearing. Regulation is enough for only a few days, and in case of a significant defect it is necessary to adjust after a few hours

Damage must be corrected immediately, as this can lead to rapid wear. If the aircraft breaks down completely, the pedal will fail and the vehicle will be unable to move.

Clutch fork VAZ 2110 disengagement

The clutch system is designed to smoothly transfer torque from the crankshaft to the gearbox.

The clutch is single-plate, with a central pressure spring. Drive – cable. The housing is attached to the flywheel and pressure plate. There is also a driven disk.

The VAZ 2110 (BC) clutch drive fork is part of the vehicle’s transmission system; without it, the effective operation of all auto mechanics is impossible. The BC has the form of a lever, with the help of which the pressure plate is retracted, as a result of which the clutch is released. Sometimes the term “shift fork” is used to refer to the aircraft, since in the opposite direction, when the pedal is released, it engages the clutch.

When squeezing the pedal, this spare part helps move the clutch and release bearing, which ensures that the inner edge of the spring moves forward and then turns off the device.

Innovations affected the clutch of the VAZ 2110, but the mono-disc housing, dry type transmission and spring diaphragm in the center remained familiar. This unit was considered to be of high quality if it had produced more than 100,000 km.

Characteristic features of the structure of this unit in model 2110 include the following:

The specific structure of the diaphragm spring, which guarantees a reduction in the force to disengage the clutch. This quality creates favorable conditions for driving a car at medium and high speeds, and also affects the conversion of force on the clutch pedal in the area of partial/full starting. This design feature allows an inexperienced motorist to start moving smoothly, reducing the level of fatigue when driving in the city, where frequent engagement of the clutch is the norm.

Rational choice of the shape of the diaphragm spring, the number of blades, the proper structure of the spring supports, which is subject to mandatory control during production.

The nonlinear properties of the spring are carefully calculated taking into account the preservation of car parts: if the clutch begins to slip, it happens shortly before the critically acceptable degree of wear of the friction linings. Thus, the flywheel and clutch disc of the VAZ 2110 are protected from damage from the rivets of the linings and is a distinctive indicator for repairing the VAZ 2110 clutch.

Mechanized finishing of main disk blanks made of cast iron, which is carried out in order to optimize wear-resistant and friction properties. Their processing takes place on semi-automatic lathes with high precision, followed by monitoring the surface quality of the working surface.

Replacement process

The difficulty of replacing an aircraft with a VAZ 2110 is that it is necessary to dismantle the gearbox; the procedure for replacing the part itself is simple.

Required Tools

To carry out the aircraft replacement procedure, it is necessary to install the machine on a lifting device or inspection groove. You can lift the car with a jack and place it on supports.

From tools and materials you need to prepare:

- new aircraft;

- a set of keys;

- pliers

- screwdriver;

- flashlight;

- jack.

Having prepared all the tools, you can begin the replacement process.

New replacement part

Stages

In order to change the aircraft to a VAZ2110, you need to remove the gearbox. After dismantling the box, the following steps are performed:

- First you need to remove the clutch release bearing.

- Then, using a screwdriver, you need to pry up the protective cover of the aircraft and remove it. If it has signs of wear, abrasion, or has lost elasticity, it should be replaced.

- Next you need to remove the plastic sleeve BC. To do this, use pliers to squeeze the tabs securing the bushing and remove it.

- Next, you need to assess the condition of the bushing. If there is damage, signs of wear, or the locking tabs are broken, the part should be replaced.

- Then you need to lift the BC and remove it from the bushing located in the clutch housing (CC), and also remove the fork lever from the holes of the CL.

- Next, you need to remove the spring retainer from the aircraft. If it is damaged or has lost elasticity, it must be replaced.

- It is advisable to replace the metal sleeve pressed into the KS with a new part.

- Before installing a new aircraft, all bushings inside should be lubricated.

- Installation of the aircraft is performed in reverse order.

- When inserting a plastic bushing, you need to make sure that the petals securely hold the bushing in the joint.

Thus, replacing the aircraft together with removing the gearbox will take about 3-4 hours. The main thing is to have at least a little experience in locksmith work and know the structure of the VAZ 2110 car.

Clutch disc for VAZ 2110: purpose and replacement

Clutch VAZ 2110

The clutch of a car, and in particular the VAZ 2110, is one of the important elements of the transmission. Its purpose is to briefly disconnect the engine from the transmission. Then smoothly connecting them when the gears are engaged, and protecting other elements (parts) of the transmission from overload, as well as damping vibrations. The car's clutch is located between the gearbox and the engine. Replacing the VAZ 2110 clutch disc, as well as repairs, is carried out when the following malfunctions occur: the appearance of specific sounds when the car is moving, problems with gear shifting, the clutch disappears when overtaking, and some others. Contacting a car service center will require the car owner to have a tidy sum of money, so many people strive to make repairs and replacements with their own hands. Our article will help you with this.

Tip: If suddenly on the road you experience characteristic sounds when disengaging the clutch, you can insert an open-end wrench between the cable guide and the clutch fork. This temporary measure will allow you to get to the garage without any problems. Ninety percent of the time, clutch repair will require you to remove the transmission.

Replacing a VAZ 2110 clutch without removing the box and draining the oil

The clutch plays the role of a link in a car between the transmission and the engine. This element of the internal combustion engine takes on the “impact” and all the loads that arise when transmitting torque from the engine to the gearbox. Therefore, the clutch can be conditionally classified as consumables, since it wears out quite often and requires immediate replacement. It is impossible to influence the wear of the clutch, unless you manage to change gears without its participation, although in this case it will not go unnoticed in relation to other parts of the engine.

VAZ 2110 – clutch: possible faults and their elimination. Replacing the VAZ 2110 clutch

Perhaps the most important components in any car are the engine and gearbox. But an equally important element is the clutch. It is located between the engine and transmission and serves to transmit torque from the flywheel to the input shaft. Clutch can be of several types - dry and wet.

What is the cost of a clutch on a VAZ-2110? It belongs to the first category and is single-disc. The design is quite simple and reliable, but over time it can cause problems. So, let's look at the causes of malfunctions and a description of the process of replacing the clutch on a VAZ-2110.

Clutch replacement is necessary in the following cases:

- If the clutch begins to “lead”, that is, when engine power decreases.

- If the clutch is not fully engaged, that is, it “slips.”

- If you hear extraneous sounds when turning on - clicks, jerking, etc.

- In case of unauthorized disengagement of the clutch.

- In case of vibration when pressing the clutch pedal.

In this article I will tell you how to replace the VAZ 2110 clutch at home without removing the box and draining the oil.

To work you will need:

- Jack;

- Inspection pit or lift;

- Set of socket and open-end wrenches: “19”, “17”;

- Mount or amplifier pipe.

When is it necessary to install a new clutch on a VAZ 2110 car and why?

Restoring a car on your own has always required not only some effort, but also financial investment. It is precisely because of the last factor that car owners try to carry out repairs themselves, thus saving on payments to service station workers. Clutch repair, of course, is not comparable in labor intensity to changing the working cylinder , but even if you have basic skills, it is quite doable in a garage.

To prevent replacing a VAZ 2110 clutch disc from becoming a waste of time and money, it’s a good idea to find out the symptoms indicating the need for repairs; experienced car enthusiasts already know them, but it will be useful for beginners:

- Loss of engine power.

- Vibrations when pressed or a “cotton” pedal.

- Switching on gears occurs with slipping or is accompanied by crunching and jerking.

- Spontaneous gear shutdown.

- Difficulty switching on speeds.

- Friction lining smell.

It is important to clearly identify the source of the problem; for example, a “stuck” pedal may also indicate that drive cable . Experienced motorists regularly check the condition of the friction mechanism every 80,000 km so that the installation of the VAZ 2110 clutch is fully justified.

Replacing the VAZ 2110 clutch step by step instructions

1. “Tear off” the left wheel mounting bolts, then jack up the front of the car and place it on the sawhorses.

2. Remove the wheel and unscrew the two lower ball joint bolts.

3. Remove the “-” terminal from the battery.

4. Remove the mass air flow sensor, then loosen the clamp securing the mass air flow sensor corrugation and remove the air filter.

5. Now you need to remove the clutch cable from the clutch fork. Loosen the two mounting nuts that secure the cable to the bracket on the gearbox.

6. Unscrew the bolt securing the starter to the box, then unscrew the first bolt securing the gearbox.

7. Head on “19” amplifier pipe. There is another gearbox mounting bolt nearby.

8. Loosen this nut and the upper starter mounting bolt.

9. Remove the connector from the speed sensor, then unscrew the speedometer cable.

10. Remove the longitudinal brace paired with the lever.

11. Now unscrew the lower starter mounting bolt.

12. Unscrew the 3rd gearbox mounting bolt; in the area of the right CV joint there is another nut that needs to be unscrewed.

13. Unscrew the two torque rod mounting bolts.

14. Loosen the nut located on the clamp of the gearbox control drive rod, then remove this rod from the box.

15. Place a support under the engine, then unscrew the two nuts securing the rear cushion. This is done just in case, so that if the engine lowers too much, your hoses do not break.

16. Carefully move the gearbox away from the engine and lower it to the floor, it will hang on the axle shafts.

17. I recommend replacing the clutch release bearing at the same time.

Assess the wear, replace the disc, and if necessary, the clutch basket, check whether the petals are normal.

Further assembly is carried out in reverse order. Thank you all for your attention, this is actually the simple way to replace a VAZ 2110 clutch without removing the box and draining the oil.

Do-it-yourself VAZ 2110 clutch replacement video:

Types of car wheels: their pros and cons

Replacing the Lada Kalina speed sensor with your own hands

Technology for replacing the clutch disc on a VAZ 2110 car on your own

Some zealous car owners are starting to look for an accessible solution, for example, in the form of welding a layer of metal onto the legs of the basket. However, it is difficult to increase the same thickness; misalignment occurs, which again leads to uneven wear of the unit. Therefore, it is more reasonable to immediately install a new part, for which we will consider the procedure for implementing the repair:

- To prevent a short circuit, remove the negative terminal from the battery.

- Disconnect the mass air flow sensor connector, loosen the clamp securing the corrugated pipe and remove the air filter housing to gain access to the gearbox mounting bolts.

- Loosen the left wheel mounting bolts and lift the car on a lift or jack up the front part and install supports.

- Remove the front left wheel and remove the engine protection (if equipped).

- Using two 19mm wrenches, loosen the two cable fastening nuts and remove the cable from the bracket to the gearbox.

- Unscrew the top bolt securing the autostarter to the box using a 17mm wrench, then use a 19mm wrench to unscrew the nearby gearbox mounting bolt.

- Remove the speed sensor connector and disconnect the speedometer drive cable.

- Remove the torque rod of the gearbox drive, having previously made marks at the place where the clamps are attached, so as not to have to adjust the gear shift lever later.

- Unscrew the second starter mounting bolt and remove it.

- Unscrew the lower bolts securing the left ball joint.

- Before replacing the clutch disc on a VAZ 2110, dismantle the longitudinal extension with the transverse link.

- Using a pry bar, remove the drive from the gearbox, and instead insert some kind of plug (rolled newspaper or old hinge) to prevent rotation of the satellites. Repeat the same operation with another drive. Tie the drive with a rope to the stabilizer.

- To prevent the engine from twisting during repairs, place a support under it.

In the process of installing a new clutch on a VAZ 2110 car, it may turn out that you will have to change not only the friction mechanism, but, for example, the drive fork. In this case it is necessary knot adjustment torque transmission, which can be done independently.If there is an overpass or lift, the operation is carried out quickly and efficiently, and when there is a reliable assistant, it is also fun. However, not everyone has such capabilities, and this is where engineering ingenuity comes into play.

Some car enthusiasts practice repairing the clutch without removing the gearbox; for this purpose, instead of the upper standard mounting bolts, they screw in longer bolts. For this, for example, two bolts from the upper arm of the front suspension of the “VAZ classic” are suitable. By screwing them into the upper holes, the box can be moved back by 14-15 cm with a pry bar. In this case, the transverse rod should not be unscrewed, because the rear part of the gearbox will lie on it. These conditions are quite enough to replace faulty parts.

If repairs are necessary, experts recommend doing a complete replacement of the entire assembly along with the release bearing, especially since the choice of clutch kits is quite wide. This position is explained simply - an old part left behind threatens to fail at any moment. The procedure, as you yourself saw in the video, is quite labor-intensive, and repeating it over and over again is not a pleasant pleasure, except for real “homemade people.”