The condition of the cylinder-piston group (CPG) is determined by the magnitude of the compression or vacuum pressure, the results of measuring leaks in the combustion chamber and the liner-piston interface, the amount of air leaks and gas breakthrough into the crankcase, as well as oil loss during engine operation.

Diagnosis of diesel CPG is carried out during TO-3 and before repair or receipt of a request from the driver. The main indirect signs of a faulty state of the CPG are increased oil consumption due to waste and gas breakthrough into the crankcase, difficult starting, and decreased engine power.

The most widely used method for assessing CPG is measuring the amount of gases breaking into the crankcase. The amount of gases is measured with a KI-13671 indicator. To measure the amount of gases, the engine is warmed up to a liquid temperature in the cooling system of 70 - 90 ° C, the breather hole and the hole for the oil gauge are plugged, and the indicator is connected using an adapter to the filler neck of the engine crankcase. Gas flow measurement is carried out at the nominal crankshaft speed. The gases that break into the crankcase pass through the indicator and raise piston 2 of the alarm to the upper position. By smoothly turning cover 5 and thereby closing the throttle hole of the indicator, ensure that the mark on the oscillating piston 2 coincides with the mark on tube 1. Using the dial on cover 5 opposite the pointer, the gas flow rate is determined.

If the gas flow is more than 170 l/min, open one or two additional openings by unscrewing plugs 4.

Rice. Determination of crankcase gas flow using the KI-13671 indicator: 1 — signaling tube; 2 — signaling piston; 3 - extension; 4 - plug; 5 - cover; 6 — body; 7 - adapter

In this case, it is necessary to add 100 or 200 l/min to the indicator reading, respectively.

During resource diagnostics of tractors before TO-3, which precedes scheduled current or major repairs, the obtained value of gas consumption is compared with their permissible values and a decision is made on the possibility of further operation of the engine.

A comparative assessment of the technical condition of the cylinders can be given by the vacuum in the space above the piston.

To measure the vacuum, remove the injectors from the engine, install the tip of the KI-5315 vacuum analyzer into the injector hole and turn the crankshaft using a starting device. When the piston moves downward during the expansion stroke, a vacuum is created in the space above the piston, under the influence of which the inlet valve of the device opens. The maximum vacuum value is recorded using a vacuum gauge. The nominal value of the vacuum in the cylinder is 0.088, the permissible value is 0.07, the maximum value is 0.068 MPa.

In the case where the gas flow does not exceed the permissible value, but the vacuum in the cylinders is below the permissible value, it is necessary to restore the tightness of the valves of the gas distribution mechanism. If the gas flow exceeds the permissible value, it is necessary to replace the rings or cylinder-piston group.

The condition of the CPG of automobile engines is assessed by the breakthrough of gases into the crankcase or by air leakage from the above-piston space (compression). Compression in each cylinder is measured with a KI-861 compression meter (for diesel engines) or a modified KI-179 device (for carburetor engines).

Diagnostics of the engine cylinder-piston group

Wear of the rubbing parts of the cylinders and the outer edge of the piston rings is what the engine eventually comes to as a result of its operation.

The cylinder-piston group (CPG) no longer provides normal compression. The consequences are:

- difficulty starting the engine,

- reduction in its power,

- increased consumption of fuel and lubricants above the norm,

- high exhaust pollution (the car “smokes”).

Diagnostics allows you to evaluate new parameters of the motor system and determine ways to normalize it.

Auto cylinder-piston group repair price:

Standard hour cost: 1500 rubles ; On your first visit: 1275 rubles (15% discount): With a car club card: 1200 rubles (20% discount)

The cost of repairing your car is calculated according to the original programs of automobile manufacturers and depends on the make and model of the car. To reduce the cost of repairing your car, look at the PROMOTIONS .

In order for the production of the power unit to be durable and reliable, it is necessary to have a good position of the cylinder and piston group. It directly affects the compression level in the internal combustion engine cylinders. And the required pressure of a gasoline or diesel engine provides power and strength, as well as other important components.

Sooner or later, drivers encounter interruptions in the operation of this system, and then repair of the cylinder-piston group is simply necessary.

Signs of a malfunction of the cylinder-piston group:

In order to eliminate all problems in the CPG, you just need to replace or repair the necessary parts.

Diagnostic methods

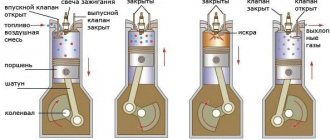

Measuring pressure inside cylinders.

The most common method among diagnosticians.

The compression pressure that the pistons develop is determined by a compression gauge. The device is a hollow metal tube. A pressure gauge is screwed onto one end of it. On another it may be:

- rubber adapter for the holes of diesel injectors;

- threaded thread for screwing into spark plug sockets (for carburetors).

There are also universal devices. They are designed to be used in both settings.

How are measurements taken?

- the engine starts, warms up to average temperature (75-90C);

- all spark plugs (injectors) are removed

- a compression gauge is inserted into their sockets (one by one),

- the crankshaft with the CPG attached to it is turned by the starter,

- the pressure in the combustion chamber is measured (mainly on the “compression” and “power stroke”),

- the data is compared with standards.

Disadvantages of the method

Measuring the pressure inside the cylinders states the effects, but does not explain the reasons for their occurrence.

Typical causes of reduced cylinder pressure

- Problems in the valve system: - worn bushings; — burnout of the pressure end of the piston; — the appearance of excessive clearance between the seat and the adjacent part of the valve.

- Defects in the area of the head associated with the cylinder block (BC): - curvature of the geometry of the plane adjacent to the block; — damage or insufficient tightening of the gasket.

- Piston rings: - wear, - breakage into small fragments, - loss of flexibility (“coking”).

- Inner surface of the cylinder: - wear in the working area, - mechanical damage to the “mirror” due to broken rings.

Auxiliary methods for assessing the performance of the central heating system

By crankcase gas consumption

Readings are taken with indicator devices such as KI-13761.

Signs of a piston group malfunction

Careful operation and timely maintenance ensure long, uninterrupted operation of the engine, but each motor has its own resource, and over time, parts wear out due to constant friction.

Read how to properly operate a car engine here.

During operation, the piston rings (PR) and the inner walls of the cylinders are subject to wear, and the piston partitions burst due to constant load.

The main symptoms of a faulty CPG are as follows:

- the car's dynamics are gone, there is no normal traction;

- a metallic knock has appeared in the engine, which increases under load;

- white or bluish smoke appears from the exhaust pipe;

- Oil is consumed in excess of the prescribed norm, it has to be constantly refilled.

Overhaul technology

The work begins with disassembling the entire engine.

Disassembly sequence

- Antifreeze and oil are drained

- The following are disconnected: — exhaust pipes (“pants”); — thermostat, radiator, interior heater, pump

- Unscrew: - crankcase, - cylinder head, - gearbox, - oil pump and rear cover of the crankshaft, - connecting rods with pistons, - the crankshaft itself;

- The connecting rods are released (the pins are knocked out of the pistons).

Defect detection

CPG wear is determined visually, as well as using a micrometer. The most common flaws:

- in rings: - breakage, - thinning (increased gap in joints);

- in the pistons: - burnout in the upper part, - breakage of the inter-ring partitions;

- on the sleeve: - wear, - mechanical damage (from broken rings, fragments of partitions).

Troubleshooting

Replacing the piston group is the main, but not the only link in engine overhaul. She is accompanied by:

- Boring the cylinder block to one of the standard sizes (larger than the previous one);

- Selection of kits: - repair rings, - pistons with mounting pins for connecting rods;

- Boring for crankshaft repair standard;

- Purchase appropriate inserts.

Piston repair. We identify and eliminate malfunctions of engine parts

see also

One of the most important working elements of an internal combustion engine is the cylinder-piston group (CPG), which includes a piston with compression and oil scraper rings, as well as a cylinder liner.

CPG parts operate under conditions of high temperatures and increased loads. As a result, scuffing occurs on the working surfaces of the pistons and cylinders, they quickly wear out and require repair.

In this article we will look at the most common causes of failure of engine pistons, ways to prevent problems and eliminate them.

The internal combustion engine is assembled in the reverse order of disassembly:

- The piston group is assembled: - pistons with connecting rods, - oil scraper rings are put on, then compression rings (the gaps should not match);

- The pistons are immersed into the cylinders through a special device that presses both rings into the piston grooves;

- The crankshaft is installed;

- The connecting rods with liners are fixed to it one by one by arc-shaped plates with bolts;

- The following are returned to their place: - cylinder head (with a new gasket), - oil pump, rear crankshaft cover, - gearbox, - crankcase, - exhaust and cooling pipes;

- Fill in: - fresh oil (with installation of a new oil filter), - antifreeze;

- The engine is cranked manually (by pushing the car) or by briefly running the starter. In this case, the rubbing surfaces of the cylinders are lubricated, eliminating scuffing from friction of a dry CPG.

- The spark plugs (injectors) are screwed in;

- The ignition is set.

- The engine starts.

- In the “idling” mode, the following are detected: - uniform operation of the piston group, - the presence of extraneous sounds (for example, an insufficiently drawn intake manifold), - oil leaks through the seals and gaskets, - tightness of the cooling system pipes.

The absence of complaints regarding the estimated parameters indicates that the engine is fully operational and ready for use.

Diagnostics of the cylinder-piston group of gasoline and diesel engines

Diagnostics of the engine cylinder-piston group: quickly and reliably determine a malfunction in its operation. A correct diagnosis is not even half the battle; in many cases, making an accurate diagnosis is the lion's share of the entire repair. The repair itself may simply consist of replacing a “penny” sensor or, for example, restoring a soured contact and will take a matter of minutes.

The main thing is to figure out what the cause of the “illness” is: an electrical malfunction or the engine hardware is to blame, due to its wear and tear or contamination.

Online store XADO-North Caucasus

Diagnostics of the cylinder-piston group allows you to assess the current condition of engine components and parts, this allows you to identify the malfunction that has arisen, which in turn will help save time and money when carrying out repairs. To diagnose the condition of the engine cylinder-piston group, diagnostic instruments are needed. The simplest of such diagnostic equipment is compression gauge….Measuring compression (compression pressure in the cylinder) is the simplest existing method for diagnosing the condition of the cylinder-piston group. Unfortunately, it is not very informative, but nevertheless, based on the deviation of the pressure in the cylinder from the nominal parameters, it allows one to identify a malfunction in the CPG, then the diagnosis can be continued with more specialized diagnostic equipment. Compression measurements are carried out to identify a “sick” cylinder. Almost any car owner can carry out such diagnostics if there is a desire to unscrew the spark plugs on a gasoline engine (provided that the spark plugs are easily accessible). For this purpose, you can buy a simple compression meter for 400-700 rubles (it is usually enough for 2-3 diagnostics). The main thing is to choose a threaded tip, i.e. so that the compression gauge is screwed into the spark plug hole, and not pressed into it. Then the diagnostic measurements will be more accurate. Also check that the compression gauge pressure release valve is located in the head, which is screwed into the spark plug hole, and not located under the pressure gauge. This way you will avoid underestimating compression values when measuring. For owners of diesel cars, we recommend contacting a car service center, because... Removing injectors or glow plugs requires special skills and special tools.

How to check engine compression correctly? When measuring compression, the following simple rules must be observed: - the engine must be “warm” (70-90 degrees). The fuel supply must be turned off. You can, for example, turn off the fuel pump, injectors, or use other methods to prevent large amounts of fuel from entering the cylinders; - You need to turn out all the spark plugs. Selective dismantling of spark plugs, practiced at some service stations, is unacceptable, as it increases the resistance to rotation and arbitrarily reduces the speed when the engine is cranked by the starter; — the battery must be fully charged and the starter must be in good working order. Sometimes, when measuring compression, a starter charger is used.

Compression is measured with both the throttle valve open and closed. Moreover, each method gives its own results and allows you to identify its own defects. So, when the valve is closed, little air will obviously enter the cylinders, so the compression will be low and will be about 0.6-0.8 MPa. Air leaks in this case are comparable to its entry into the cylinder. As a result, compression becomes especially sensitive to leaks - even with small leaks, its value drops several times. This value allows us to draw conclusions or assumptions about the following engine defects: not entirely satisfactory fit of the valve to the seat; valve freezing, for example, due to improper assembly of the mechanism with hydraulic pushers; defects in the camshaft cam profile in designs with hydraulic lifters, including uneven wear or runout of the back side of the cam; leakage caused by a burnout of the head gasket or a crack in the wall of the combustion chamber. When measuring compression with the throttle open, the picture will be different. A large amount of incoming air and an increase in pressure in the cylinder, of course, contribute to an increase in leaks. However, they are obviously less than the air supply. As a result, the compression does not drop so significantly (to approximately 0.8-0.9 MPa). Therefore, the measurement method with an open damper is better suited for determining more “severe” engine defects, such as breakdowns and burnouts of pistons, breakdowns or sticking (coking) of rings in the piston grooves, deformations or burnouts of valves, and serious damage (scuffing) to the surface of the cylinders. In both measurement methods, it is advisable to take into account the dynamics of pressure growth - this will help to establish the true nature of the malfunction with greater probability. So, if on the first stroke the pressure measured by a compression meter is low (0.3-0.4 MPa), and during subsequent strokes it increases sharply, this indirectly indicates wear of the piston rings. In this case, pouring a small amount of oil into the cylinder (3-5 cc) will immediately increase not only the pressure on the first stroke, but also the compression.

On the other hand, when on the first stroke the pressure reaches 0.7-0.9 MPa, and on subsequent strokes it almost does not increase, most likely there is a leak in the valve or head gasket. Of course, the cause can be more accurately determined using other diagnostic tools. If you decide to use both methods of measuring compression, we recommend that you first measure compression on all cylinders with the throttle valve open, then tighten the spark plugs and start the engine. Let it run to recharge the battery and warm up the engine, and then measure the compression with the throttle closed.

Compression test on a cold engine. If it is difficult to start the engine, we recommend measuring the compression “cold” (the engine temperature is the same as the ambient temperature). In this case, due to severe wear of the CPG parts or when the piston rings are stuck, the pressure in several cylinders of a gasoline engine is usually reduced by half (to 4.5-5.5 atmospheres). After starting and warming up, compression usually increases by several units. That is why such a malfunction can only be seen during a comprehensive inspection. “Cold” measurements are especially indicative when diagnosing diesel engines - if the compression does not exceed 17-18 atmospheres, it is almost impossible to start such an engine. In addition, in diesel engines, compression is highly dependent on the presence of oil in the cylinders, so before diagnostics the engine must “settle” for several hours so that excess oil drains into the crankcase. If the compression does not exceed 24 atmospheres, then the engine will need to be overhauled.

So, the measurements have been made. The cylinder in which the compression is noticeably different from the others is the “sick” one. If the difference is less than 1 atmosphere, then go back to the ignition, fuel supply, air intake, etc., in search of the reasons for the “tripleting”. A spread of 1 atm will most likely indicate some uneven wear of the CPG, which is quite acceptable for engines with a mileage of more than 50-70 thousand km. The compression amount should be approximately equal to the compression ratio multiplied by 1.3. You can find the engine compression ratio in the technical specifications of your car. Why approximately? Because this value depends on many variable factors - engine temperature, oil viscosity, battery charge, etc. And the spread in the accuracy of the readings of various compression meters reaches 2 - 3 atm. So our main guideline is a comparison of compression values between cylinders. The compression in the “sick” cylinder does not have to be less than in the others. For example, excessive oil entering the engine cylinder increases compression, which can be confirmed by a spark plug that is turned out of it and has build-up from the combustion of this oil. And the reasons for excess oil getting into the cylinder can be a broken oil scraper piston ring and a defect in the valve-guide bushing pair, etc.

The operating compression values of the engine of a working car are indicated in the relevant instructions for servicing and repairing the car. For gasoline engines with a working CPG, the compression measured “on hot” should be at least 9.5-10 atmospheres for AI-760-80, 11-14 atmospheres for higher octane gasoline, for diesel engines - 28-45 atmospheres (for modern for diesel engines it is closer to 45, for “oldies” it is closer to 28), and the spread of its values among the cylinders should not exceed 0.5-1.0 atmospheres (for diesel engines - 2.5-3 atmospheres).

- a case of loss of compression in one of the engine cylinders. This defect can be found most often. First of all, pour 5 - 10 ml into this cylinder. clean oil (trying to get it on the walls of the liner and not on the piston bottom), and again measure the compression in it. If the pressure has increased noticeably and even exceeded the readings in the remaining cylinders, this indicates a breakdown, severe coking or sticking of the piston rings. If the readings have not changed, then the reason for the drop in compression in this cylinder may be a loose fit of the valves to the seats (burnout or incomplete closure due to improper adjustment of the gaps), damage to the cylinder head gasket, burnout of the piston or a crack in it. To more specifically determine the cause of the drop in compression, set the piston of this cylinder to a position close to TDC (top dead center) on the compression stroke and supply compressed air into the cylinder at a pressure of 2 - 3 atm. (Use a compressor or car cylinder). At the same time, do not forget to engage 4th or 5th gear and secure the car from moving with the handbrake or chocks. Damage to the cylinder head gasket can be determined by the hissing of air from the adjacent spark plug hole. Air escaping through the carburetor will indicate a loose intake valve. Increased air output from the oil filler neck (with the plug removed) indicates a burnout or crack in the engine piston. Air escaping through the car's muffler indicates a problem with the exhaust valve. Most often, the exhaust valve burns out - this “trouble” occurs with a “triple” engine in 90% of cases.

PROCEDURE FOR MEASUREMENT OF COMPRESSION ON A VAZ car 1. Before taking measurements, warm up the engine to operating temperature (coolant temperature is about 80°C). The battery must be fully charged. We recommend checking the condition of the air filter. If it is very dirty, it must be replaced. It is possible to temporarily disconnect the air supply line from the intake manifold. 2. Disconnect the ignition system by disconnecting the low voltage supply wire to the ignition coil from the breaker. For engines with an ignition distributor, remove the central high-voltage wire from the coil and connect it to the vehicle ground. Prevent fuel supply. In engines with a mechanical fuel pump, disconnect the fuel supply line from it and turn it off. If the fuel pump is electric, de-energize the fuel pump relay. 3. Clean the spark plug niches from dust and remove the wire tips, unscrew all spark plugs. 4. Set the gearshift lever to neutral and apply the parking brake. In cars with automatic transmission, set the selector lever to position “P”. Crank the engine several times with the starter to remove any remaining carbon and soot from the cylinders. 5. Connect the compression gauge to the first cylinder. The assistant should, with the gas pedal fully depressed, crank the engine with the starter for 4-5 seconds until the maximum reading on the device is established, which should be recorded. Depressing the gas pedal is necessary in order to fully open the throttle valve, which reduces the resistance of the intake tract. Check the compression in the remaining cylinders of the engine one by one. 6. Return everything to its original position.

This is the procedure for measuring compression in gasoline engines. Compression testing for diesel engines has its own characteristics . To turn off the fuel supply in diesel engines, you must either press down the cut-off lever located on the high-pressure pump, or de-energize the fuel cut-off solenoid valve located on the fuel line. The compression gauge is connected to the combustion chamber through holes for screwing in injectors or glow plugs (depending on ease of access or recommendations in the Repair Manual...). Do not forget that it is necessary to use a diesel compression meter with an increased measurement limit (usually up to 60 atm). For most diesel engines, there is no need to depress the gas pedal, since there is no throttle valve as such. The exception is for engines equipped with a valve in the intake manifold to create a vacuum used to operate the vacuum brake booster and vacuum regulator. If you have received answers to all your questions, feel free to get to work. Much more information about the condition of the engine cylinder-piston group is provided by diagnostics using the AGC device according to the method of Doctor of Technical Sciences.

V. Chechet. Diagnostics with this device is simple and does not differ from measuring compression. Instead of a compression gauge, an AGC is connected to the spark plug or injector hole, the crankshaft is cranked with the starter and the readings are taken. Only it is not the compression pressure in the cylinder (compression) that is measured, but the vacuum. The AGC accurately determine the current malfunction in the CPG: coking or stuck rings, broken piston partitions, valve leaks, piston or valve burnout, degree of liner wear.

All you have to do is take measures to eliminate the problem. DECOKING PISTON AND OIL RINGS

Engine decoking - removal of carbon deposits (coke), i.e. deposits formed during the combustion of the fuel-air mixture and oil in the combustion chamber during engine operation. Oil enters the combustion chamber from the cylinder walls because oil scraper piston rings cannot remove it perfectly clean. It is washed away from the intake valve stems by the flow of the fuel mixture sucked into the cylinders. These are only the main ways oil gets into the cylinders on “healthy” and new engines. And when the car’s mileage exceeds 100,000 km and you notice that adding oil to the required level has become more frequent, and smoke with a specific odor begins to appear from the muffler, it means that other elements have become involved in adding oil to the combustion chambers. A competent engine mechanic will determine exactly what is causing the smoke and oil consumption based on the condition of the spark plugs. There are two main culprits: 1 — stem seals ; 2 - cylinder-piston group (rings, pistons, cylinders). On the first point, the oil seals are definitely replaced. On the second point, if you are offered to overhaul the engine and replace the rings, there is no need to rush. In most cases, it is possible to get by with “therapeutic” treatment rather than “surgical” treatment. In any case, the mileage before overhauling the engine or capital increases by 50-100 thousand km, or even more. In any case, before disassembling the engine, you should try “therapy” i.e. decarbonization, you may save money and protect the engine from unnecessary opening. Why do decoking? you ask. Decarbonization removes carbon deposits formed not only in the combustion chamber, but also in the grooves under the rings on the pistons. And because of this carbon deposits, the rings (primarily oil scraper rings) lose mobility and do not adhere well to the cylinder walls, which in turn reduces the efficiency of removing oil from their walls. More oil enters the combustion chamber, more carbon deposits are formed, and the rings become coked even more deeply into the flesh until they are deposited. And the following things also contribute to this negative process: long-term parking of the car - winter, for example (and if the car has been sitting for more than one year after an accident, then decarbonization is categorically recommended before starting operation, and naturally the oil should be changed), the use of low-quality oil, untimely replacement, overheating of the engine (for example, the electric fan failed and the engine “boiled”), engine operation at elevated thermal conditions (the thermostat is not working well, the coolant level is low, the cooling system is clogged, etc., constant operation of the car only in the urban cycle and frequent engine operation idling. And so, once again - briefly. If oil consumption has noticeably increased (more than 300 grams per 1000 km), and judging by the total mileage, it is too early to do a major engine overhaul (for VAZ the service life is 100-150 thousand km, for foreign cars 200 thousand or more), and there are no obvious signs of oil seal leakage (these signs are described at the end of the article), then we strongly recommend decoking.

How decarbonization is done

The essence of decoking is to loosen carbon deposits on the surfaces of combustion chamber parts and remove it. For this, various chemicals are used, of which many are now on sale, and different technologies for this process. The most common method is to pour (spray) a certain “autochemistry” into the engine cylinders through the spark plug holes. A less troublesome technology, but no less effective, is adding certain drugs to the oil or fuel ( Vita flush , Atomex Total flush ) , the instructions for these drugs tell you where, how and how much to pour. The most common option for decoking (through spark plug or nozzle holes) is described here. It is usually used when the rings are heavily coked, stuck, or the engine does not start after the car has been parked for a long time. 1 – With the engine warm, unscrew the spark plugs or remove the injectors from the diesel engine. The procedure is quite long and tedious, but there’s nothing you can do about it. 2 — Set all pistons to approximately the middle position. (We jack up the front wheel on front-wheel drive cars or the rear wheel on rear-wheel drive cars and engage 4th, or whatever the last gear is, and crank the engine by this wheel, determining the position of the pistons with a suitable screwdriver through the spark plug holes. Who has a “ratchet” wrench, the easier it is). 3 — through the spark plug holes, pour Anticoke into the cylinders (10 ml tube) one tube for each cylinder of a passenger engine, or spray aerosol anticoke into each cylinder for 5 seconds). And lightly wrap the candles (preferably unusable ones). 4 - within 20 minutes. carbon deposits “soak” near the piston rings, on the walls of the combustion chamber, the piston bottom and the valve plate. During this time, it is necessary to help the liquid reach the rings. To do this, move the pistons up and down, turning the hanging wheel left and right by 5-10 degrees. Just don’t pull the wheel non-stop all this time. Move it back and forth 4-5 times every 3-5 minutes. If the car is not jacked up, you can simply move it a meter. 5 – unscrew the spark plugs, remove the high-voltage wire from the ignition coil (on the injectors, de-energize the coil, breaking the quick-release connection). 6 - crank the engine with the starter for 5-10 seconds. (remembering to turn off the gear) This is necessary in order to throw out the remaining liquid, possibly there, and exfoliated carbon from the cylinders. If a lot of decoking fluid is poured into the cylinder, and this is not done and the spark plugs are tightened, then a water hammer may occur during starting, which will damage the engine!!! We recommend placing a cloth over the spark plug holes if the spark plugs are not located deep, otherwise dirt will fly out of the spark plug holes and stain the entire engine compartment. If it gets on the paint it will damage it. 7 — put everything back together and start the engine, helping it with the gas pedal, because It will be difficult to start after such an event. Don’t be alarmed when terrible smelling smoke comes out of the exhaust pipe, that’s how it should be. After starting, let the engine run at high speed for 10-15 minutes. After that you can drive, for the first 5-10 km you will still scare people with smoke, then everything will pass. After a run of 50 km, it is advisable to change the oil. After 200 kilometers, start monitoring oil consumption and comparing the compression results, what happened and what happened. It is useful for comparison to measure the compression before decoking and after, again after 200 kilometers. Why not immediately, because sometimes the rings separate only after a while, or they separate and seal again, but this happens rarely and only on very old engines, where It really needs a major overhaul.

But it is best not to bring the engine to the point of using this type of “decarbonization”. Usually, after this, the spark plugs and engine oil should be replaced (decarbonization reagents seeping through the rings into the crankcase can change the structure of the engine oil). But the most unpleasant thing is that after long-term operation of the engine with severe coking or stuck rings, after decoking, the rings suddenly gain mobility and often burst.

To prevent the result of decarbonization from quickly being reduced to zero due to fuel overflow from clogged nozzles (injectors) or carburetor, we recommend flushing the vehicle’s fuel system, i.e. flush the injectors or carburetor using our fuel preparations. This is the fastest and most effective way to flush the engine fuel system. The technique for doing it is simple. The preparations are poured into the car tank and, together with the fuel, enter the injectors or carburetor, thoroughly washing them of carbon deposits. Dirt and deposits in the tank are not affected in any way.

PS Signs of oil seal leakage:

1. Smoke from the exhaust pipe when changing gas

2. Presence of oil on the threaded part of the spark plugs (“wet” thread on the spark plugs)

If compression measurements after decarbonization of the engine showed that it has not been fully restored to the “nominal” pressure or its scatter across the cylinders remains due to wear, then we recommend using revitalizant gels or atomic metal conditioners with

Stage for the engine and fuel equipment. This will help restore the geometry of the surface of the “mirror” of the cylinder, optimize the gap in the liner-ring interface and the compression will rise and level out to “nominal” in all cylinders, at the same time the oil pressure in the engine will increase by restoring the gap between the liners and the crankshaft journals, in the timing belt. These drugs also have a beneficial effect on turbine bearings, hydraulic compensators, and the oil pump.