Rating of the best winter tires based on general parameters

Which tires are in our top best solutions for winter? Below are presented only the highest quality options, which are not only recommended by experts, but also by experienced car owners.

Bridgestone Blizzak Ice

| Country: Japan Brand: Bridgestone Price: 6760 rubles Rating: 5 |

Description

These “Velcro” from the famous Japanese company are distinguished by high wear resistance and directional stability. Among other advantages, it is worth noting effective braking. Bridgestone tread pattern is asymmetrical, due to which the noise level is lower than that of competitors.

No less attractive is the upgraded rubber compound, which makes the rigidity in the outer layer optimal for winter. This solution without spikes, which is considered the best among Velcro for 2019-2020, provides the car with ideal cross-country ability.

Pros:

- reliability;

- low noise level;

- high wear resistance;

- excellent handling, including on ice;

- good drainage.

Minuses:

shallow tread, often clogged with snow.

Reviews

Alexander: “Control in any mode, braking on ice, almost silent.”

Alexey: “Excellent Velcro, in any driving mode, in any weather conditions, even on snow, even on wet and dry asphalt. When maneuvering sharply, the car does not yaw and follows a clearly defined trajectory.”

Yokohama Ice Guard IG60

| Country: Japan Brand: Yokohama Price: 5050 rubles Rating: 5 |

Description

Another solution for passenger cars, which can be safely called ideal in all respects. The presented version, produced by a popular brand, is distinguished by a thoughtful tread pattern. Thanks to this, there are no problems with water drainage during periods of temperature changes, which are not uncommon in Russian realities. The fine-bubble outer layer makes these tires comfortable to ride. They do not “freeze”, hold the car well on the road and maintain an optimal level of softness.

Pros:

- optimal grip on asphalt and ice;

- excellent maneuverability;

- reliability;

- reasonable price.

Minuses:

average wear resistance.

Reviews

Mikhail: “I braked a couple of times on frozen asphalt, very slippery. But everything worked! There was no feeling that it was leading, but there was a hook. Roughness plays a role.”

Rating of the best winter tires 2020

| Place | Name | Characteristics in the rating |

| The best winter tires based on general parameters | ||

| 1. | Bridgestone Blizzak Ice | Ideal Velcro |

| 2. | Yokohama Ice Guard IG60 | Optimal ratio of ideal quality and reasonable cost |

| The best winter non-studded tires | ||

| 1. | Nokian Hakkapeliitta R2 SUV | Exemplary handling |

| 2. | MICHELIN Pilot Alpin 5 | The most reliable option without spikes |

| The best winter tires for crossovers | ||

| 1. | Continental ContiViking Contact 6 | Ideally holds the car on dry and snowy roads |

| 2. | Dunlop Grandtrek Ice02 | The most confident behavior on the road |

| The best budget winter tires | ||

| 1. | Nokian Nordman RS | The most reliable and durable tires in the budget category |

| The best winter tires 14 radius | ||

| 1. | Continental IceContact 2 175/65 R14 | Perfect handling |

| The best winter tires 15 radius | ||

| 1. | Gislaved Nord Frost 200 195/65 R15 | The quietest studded tires |

| The best winter tires 16 radius | ||

| 1. | Goodyear Ultra Grip Ice Arctic 205/55 R16 | Ideal grip on ice |

| The best Chinese winter tires | ||

| 1. | LingLong LL8 | Good balance between availability and quality |

properties of studded tires, operating conditions

Studded tires: design - Avtonov

Metal studs on car tires appeared already at the beginning of the twentieth century. Then they were installed not only for better grip on the road, but also to increase the wear resistance of tires, which in those days were made of leather or solid rubber. Later, after the invention of pneumatic tires, interest in studs waned. Their widespread use was hampered by imperfect design and low wear resistance of steel pins. However, in the 1930s, sports car tires were often equipped with studs. As a rule, to install them, through holes were made in the tires - a steel bolt - a fungus - was inserted from the inside, and it was fixed from the outside with a regular nut. Imagine how much those tires weighed!

Radical anti-slip agent

Only at the end of the 50s in Scandinavia did studs of the design traditional for today appear. The basis was an ordinary steel rivet, into the body of which a carbide insert was pressed. In this form, the spike was mounted into the tire tread. The undeniable advantages of studded tires in winter conditions were quickly appreciated by drivers not only from Scandinavian countries, but also from other European countries. In pursuit of safety, not only passenger cars, but also trucks, buses, and heavy construction equipment were fitted with studded tires.

And then the road workers sounded the alarm - with the advent of studded tires, they had more work to do! At the end of the winter season, ruts remained on the asphalt - the studded wheel worked like a milling cutter. The impact of studded tires on German autobahns, which were cleared of snow and ice for most of the winter, was particularly detrimental. It is not surprising that the Germans were the first to rebel against studs - since 1975, the use of studded tires in Germany has been prohibited. Many European countries soon followed their example - they either completely banned the use of studded tires or introduced a number of restrictions.

In addition, as research by scientists has shown, studded winter tires pose a serious risk to human health. Particles of the road surface that are torn out by the spikes turn into dust harmful to breathing, which primarily affects asthmatics. Scientists believe that asphalt dust particles are more dangerous than exhaust fumes.

Now in Europe there are not many countries where you can use anti-skid studs. Accordingly, there are few companies involved in their production. As a rule, studded tires are purchased when frequent trips are expected on snowy and icy roads. In this case, studded tires will be irreplaceable. On bare asphalt, studded tires are inferior in handling and braking to regular winter tires.

Design

Design of car tire studs Anti-skid studs consist of two parts: a body and a carbide insert. The job of the casing is to keep the stud in the tread body throughout the entire life of the tire. And the pin should bite into the road surface, increasing the coefficient of adhesion on slippery surfaces. For the manufacture of inserts, tungsten carbide (WC) with an admixture of titanium and niobium carbides (TiC, NbC) and a number of other compounds is used. It is not reported which ones: each manufacturer, of course, has its own proprietary recipe for hard alloy. But it is known that such rare earth additives make it possible to achieve a hardness of 1500 Vickers units (for comparison, gears in a car gearbox have three times less surface hardness!). It is clear that such strength is not needed to work on ice or snow, but on asphalt the carbide insert wears out with the same intensity as the tire tread. Naturally, taking into account the difference in contact areas.

The main object of improvement is the body of the stud, or rather its shape and material. At first, the stud bodies were made of steel. But as soon as the struggle to preserve the road surface began and the mass of studs was limited, models with plastic bodies appeared. The weight of the plastic stud assembly with insert is only 0.7 grams, while the lightest steel studs weigh 1.1 grams. Unfortunately, the plastic sometimes cannot withstand the loads combined with low temperatures, and the studs fall out of the tread body. Recently, almost all stud manufacturers have introduced models with aluminum bodies. Alloyed aluminum is similar in strength to steel and in weight to plastic. And besides, it is coated with Teflon - to facilitate installation in the mounting hole and increase corrosion resistance.

By the way, corrosion is the scourge

carwheelblog.ru

A type of thorn. Repair spikes. Do the wheels need to be changed?

It's time to change into winter tires. In the last article we wrote about what winter wheels are, and also talked about studded tires. Today we’ll talk a little about the thorns themselves, about their variety.

The studs are installed at tire and tire manufacturers' factories. By type, the following are distinguished: with a core in the form of a tube, with an aluminum or steel body, in a plastic “jacket”, with a different number of flanges, with a core in the form of a rod, etc.

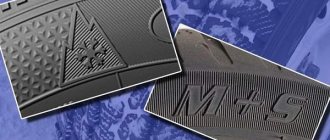

Previously, the studs were almost the same shape, but now tire manufacturing technologies are progressing and the studs have appeared in various shapes, such as: diamond, tetrahedral, round, oval.

For example,

A diamond spike has a large number of edges and provides better grip on ice, but there is a disadvantage to it: such a spike wears out quickly. The tetrahedral spike has better “biting” into the ice. And one more plus, the tetrahedral tenon has a reliable seat. The round tenon is in great demand. All inexpensive wheels are equipped with a round stud, which is why they are considered more common. Oval studs are also common, due to their oval design, they have less noise, and their large area improves grip on the ice in the transverse direction. The oval spike also pleases with its pricing policy.

After two seasons

studs have the ability to wear out and in the process they lose their shape, and of course their performance; some of these worn studs fly out of the tire, and some remain in it, but no longer have the desired characteristics. Such studs must be disposed of from the tire hole. And then what? Do our wheels need to be changed? Here we find an alternative to replacing wheels, and this is simply replacing the studs and the cost of replacing the studs is again encouraging in relation to replacing the wheels completely. What kind of spikes are used for studding in this case? On repaired tires, wider studs are used and they look as shown in the figure below.

The diameter of such a spike is one and a half times larger than the factory design. It is largely thanks to such a wide cap of this tenon that it stays in the old seat. Such spikes are usually called “repair spikes”. Such studs are installed in tire shops, where specialists, using certain technology and special tools, will provide you with the service of studding the wheels of your car.

One more question,

How many studs can you put on tires? First, let's look at the types of tires: European, Asian and Russian. More recently, studded tires were not allowed in Europe; today such tires exist for European countries, but there are regulations or restrictions on the number of studs, namely 50 pieces per linear meter.

In our regions there are no such restrictions, but there is still some kind of standard and it depends on weather conditions and on the tire manufacturers. The number of studs on car wheels in our regions ranges from 96 to 190 pcs. In regions with the most difficult weather conditions in winter, wheels with the maximum number of studs on the tire are used. That's all, we talked a little about the main thing. To all motorists who enjoy good weather and comfortable travel on winter roads.

about the author

Name

A type of thorn. Repair spikes. Do the wheels need to be changed?

Description

In the last article we wrote about what winter wheels are, and also talked about studded tires. Today we’ll talk a little about the thorns themselves, about their variety.

Author

Anna Andreichenko

Website

Instrumenty.info

Photo

Norm of thorns

The number of spikes is regulated in each country by regulatory documents:

- In the countries of the Scandinavian Peninsula, the location of studs on winter tires is regulated by a standard of 50 studs per 1 m of wheel circumference. At the same time, tire manufacturers can install a larger number of studs, provided that the road surface is preserved;

- states in the Asian region do not provide standards for the placement of spikes. Leading tire manufacturers from Japan, Korea, and China place on average up to 130 studs on one wheel;

- in Russia the maximum number of studs is no more than 60 pieces per linear meter of tread surface. In terms of unit of product – from 130 to 160 studs.

Important!

Spikes are effective when driving in conditions of ice crust formation and snowfall.

The norm of 50 studs per linear meter of the wheel reveals a proportional relationship between the number of metal parts and the tread diameter. The larger the cross-sectional size of the wheel, the more studded the tires.

The regulation of the number of studs in winter tires is related to the preservation of the top layer of roads. There is an opinion that more studs will provide better traction and safety. This causes the road surface to deteriorate faster. New models of studded tires developed by leading manufacturers are equipped with fewer studs. Test results of modern tires showed better vehicle handling. This is achieved by improving the properties of the rubber shape and changing the amount of protrusion of the studs.

Bridgestone studded tire models: which one is better?

Bridgestone is the largest Japanese tire concern, owning the rights to many tire brands, including one of the most popular, which, by the way, has the highest cost among the tire brands in the world.

From this article you will learn:

Brand tires

Under the famous name, all kinds of rubber products are produced, as well as several hundred types of tires for all types of wheeled vehicles and aviation.

As for tires for passenger cars, in Russia tires under the Bridgestone brand are considered one of the most reliable and best suited for difficult operating conditions, both in big cities and in the Russian outback.

Studded tire models

Today in Russian stores you can find several models of “spikes” from the famous Japanese brand, and each of them has its own purpose.

The brand's most famous and best-selling studded model is the Ice Cruiser, already in its third generation and positioned by the manufacturer as a tire specially designed for the harsh Russian winter and severe Siberian frosts.

The vast majority of car owners who have tried the tires are absolutely satisfied with their driving characteristics, and note that a car on these tires is actually capable of driving very confidently on any winter surface, both on compacted snow or clean ice, as well as in deep snow.

In addition to excellent driving characteristics, the model also boasts a large number of standard sizes (from 13″ to 20″), suitable for almost any car, which partly explains its popularity.

Another famous model with studs from Bridgestone is the Noranza. Initially, the model was developed for light, small city cars and had small standard sizes (from 13″ to 16″) and was not as famous as the Ice Cruiser.

But against the backdrop of the wild popularity of “real tires for the Russian winter,” buyer interest in the Noranza model was constantly growing.

The management of the Japanese manufacturer decided to expand the range of model sizes with a special version of the “Noranza Van”, designed specifically for use in vehicles with a high center of gravity - crossovers and minivans.

The driving characteristics of the tire also left customers with the most flattering reviews, and with the growing popularity in Russia of family all-wheel drive cars with high ground clearance, its “special” version began to disappear from stores just a few days after its appearance.

The latest and most technologically advanced winter studded model - Blizzak Spike-01 - developed using the latest innovations in the field of computer modeling, having studs of a very unusual design.

According to many experts, it is Bridgestone studs (received their own name “Cross-Edge Pin”) that are one of the most interesting, bright and advanced developments that have appeared on winter tires in recent times.

Their working surface, “cut” into four parts, is capable of “biting” into the ice and providing as many as four “fulcrum points” instead of one, like a standard stud, which can significantly improve the tire’s grip on slippery surfaces.

The model embodies the maximum number of innovations, as well as all the best developments of Japanese engineers that were made when designing the Ice Cruiser tire.

And today we can say with confidence that the driving characteristics of winter tires Blizzak Spike-01 can rightfully be considered one of the best in the world.

1tire.ru

How many studs must remain in a stud to be safe to ride on? | Service | Auto

Studs in winter wheels significantly improve the car's behavior on icy roads. There are always 8-9 metal teeth in the contact patch that bite into the ice and prevent slipping. On hard surfaces, the studs can be hidden in their sockets, allowing the rubber tread with sipes to provide traction. Finely cut lomels envelop the surface of the road and seem to stick to it. In this case, the studs stop working, and the traction properties of the wheel are determined by the characteristics of the tread and the composition of the rubber mixture.

How many spikes should there be?

In domestic legislation there is no clear indication of how many studs a tire should have. The traffic rules also do not contain any requirements for the number of studs. Only some European countries have approved regulations that studs cannot contain more than 50 studs per linear meter of the tire in order to avoid high wear on the surface layer of asphalt roads. This is approximately 100 studs on one R16 wheel. Meanwhile, in Russia there are no such strict restrictions, and tires for icy roads with 120, 180 and even 190 studs can be supplied to us.

The lower limit of studding is also not specified in the regulations. Only the list of faults and the technical regulations of the Customs Union indicate the requirement for the tread height of a winter tire. It must be at least 4 mm. However, manufacturers have standards for studs, and, guided by them, it is possible to assess the ability of a wheel to provide the declared driving characteristics.

How many studs does a wheel lose?

Typically, in the first year of operation, a new tire loses no more than 5% of its metal teeth. This means that the weakening of grip on an icy road will be observed in negligibly short periods of time. This does not affect the movement characteristics.

In the second season of operation, frequent trips on asphalt during thaws lead to the same number of studs falling out, namely 5-10 pieces. The wheel has already lost 10% of its teeth, which is why loss of adhesion in the contact patch will be observed more often. However, 90% of the studs are enough to provide the characteristics declared by the manufacturer.

After the third season, the tire is missing about 20% of teeth, and after the fourth year - already 30-40%. The fourth year of use of studs is considered critical. The rubber mixture, when exposed to road chemicals and solar radiation, loses its elasticity, and the studs quickly fall out. The car holds the road worse, since the contact patch is almost always missing a couple of teeth. Although in everyday operation, changes in the behavior of the machine are practically unnoticeable and can only be recorded by instruments at specialized sites.

High wear

After the fifth year of use, a tire may lose more than 50% of its studs. Such a wheel in the contact patch has a constant deficiency of teeth. Instead of 8-9 pieces, only 4-5 studs work, which is why the adhesion properties are noticeably reduced

The braking distance is increasing, drivers have to take this into account and not drive as recklessly as before. However, you can drive on such a tire

After the sixth year of operation, a good imported studded tire may lose 60-70% of its metal teeth, which is why there are noticeable dips in its characteristics. If previously it clung to the ice well, now it does so lazily, allowing large slippages during braking. Although there is nothing critical. According to their characteristics, studs are close to ordinary Velcro and can be used in winter, although not as actively as before.

Manufacturers determine the service life of any wheel at 7 seasons. Therefore, after the seventh winter, when approximately 30-40% of the spikes remain on the spike, it is necessary to replace it with a new one. By that time, the tread wears down to 4 mm, and the use of such a wheel is already prohibited by traffic regulations.

aif.ru

How many studs are on winter tires?

- home

- All about the tire

- How many studs are on winter tires?

Studded tires are winter tires equipped with metal inserts (studs). They provide rubber grip on ice or snowy roads. Car studs have two components:

- An interspersed rod responsible for reliable fastening of a metal insert to a car tire. The more serrations the rod has, the less risk it will fly out of the wheel.

- The core of the insert, which consists of an alloy of the most durable metals to ensure high-quality adhesion of the tire to the road surface. The core, as the main part of the inclusion, protruding from the rubber, is its main part, because it clings to ice or compacted snow.

Standards for the number of studs in a car wheel

The number of spikes until 2013 was determined as follows:

- For tires with diameters R13 and R14 – up to 90 metal inserts per wheel.

- For tires with a diameter of R15 – up to 110 studs per tire.

- And wheels with a diameter of R16 could have up to 130 inserts.

The Scandinavian countries made changes to these values in 2013. The permitted volume of studs per tire was changed due to the need to reduce the negative impact of metal inclusions on the quality of the road surface. The second reason for the adjustments was the harm caused to the health of citizens due to dust flying from the sites of road destruction. The editorial addressed the following points:

- Reducing the volume of metal inserts on a tire to 50 pieces per linear meter.

- Test resolution proving that the density of metal inserts, higher than the previous recommendation, does not harm the road surface.

Types of studded wheels

Taking into account the listed instructions, the following types of tires are distinguished depending on the number of studs installed:

- Tires with steel inserts up to 50 pieces per linear meter.

- Tires that have retained the same number of metal inserts, namely about 130 pieces per wheel.

- Rubber that has a significant number of studs, i.e. from 170 pcs to 190 pcs per tire.

What does the number of inserts in rubber affect?

The main point of impact of the studs is the adhesion of the car tire to the road. According to various tests, a predictable conclusion has been revealed: the more metal inserts on the wheels of a car, the shorter its braking distance. However, currently this parameter is achieved by manufacturers with a number of studs of 96 pcs. How? A car tire is equipped with other factors that affect grip: high-quality rubber composition, a unique stud installation or a different lamella pattern.

Behind the wheel: Tests of winter studded tires size 175/65 R14 (2013)

When and where

We answer the question that readers ask on the forum. ZR conducts tests of winter tires in winter and spring (asphalt part) in order to present the results in the fall, when you are thinking about switching to winter tires. As a rule, we test winter and summer tires in the Volga region - at the AVTOVAZ test site or nearby.

This February turned out to be unusual: the Moscow region and St. Petersburg were covered with snow, and the Volga region suffered from its absence. In Tolyatti, very little fell in January alone and not a single flake of snow in February. For the first time in 17 years, we were unable to complete the “rearrangement on compacted snow” exercise: there was nothing to roll. And the snow used for acceleration and braking and other disciplines was unusually dry, very similar to foam.

Due to the lack of rearrangement on the snow, the weighting coefficients of other exercises were changed so that the maximum possible total score remained the same as before - 1000. For this reason, we do not recommend comparing the overall results of the current test with the previous ones - it will not be entirely correct.

List of tested tires:

- Amtel NordMaster ST

- Continental ContiIceContact

- Cordiant Polar 2

- Gislaved Nord*Frost 100

- Kama EURO 519

- Michelin X Ice North 2

- Nokian Hakkapeliitta 8

- Nokian Nordman 4

“Spikes” are in their places!

Ahead of the rest is the new product from Nokian - HKPL 8. The most expensive tires on the market, they are also the best in our test. We divide 3,700 rubles by 949 points and get a price-to-quality ratio of 3.90.

“Continental” with the no longer new “ContiIceContact” takes second place in the price rating: 3590 rubles per piece. In our table of ranks, this tire with 906 points is also in second position. The gap in characteristics from the leader is greater than the difference in price, which is why the price-to-quality ratio is the highest (even more than that of Nokian) - 3.96.

Third on the price podium with RUR 3,120 was Michelin with the outdated X-Ice North 2. The new model has already been presented, but is not yet on sale, and, apparently, for this reason, the price of the “second” has been slightly reduced. In the final results, the tire also came in third place, scoring 891 points. The price-to-quality ratio is the most attractive in the top three – 3.50.

The new “Gislaved-Nord Frost 100” with a price tag of 2975 rubles has gone not so far. According to the results of our tests, it also takes fourth place: 873 points. The price-to-quality ratio is not far behind the Michelin rating - 3.41.

In fifth place is the familiar Nordman-4

Good tires, taking into account the fifth result in the competition: 858 points. The difference with Gislaved of more than 500 rubles and only 15 points gave a price/quality ratio of 2.84 - it will be a very profitable purchase!

The sixth place is taken by the domestic product Cordiant-Polar 2. This tire can be bought for 1950 rubles. 824 points is not the worst result. The price-to-quality ratio (2.37) whispers: “Buy!”

The most inexpensive of the popular tires is the old Amtel-NordMaster ST: only 1,790 rubles. Perhaps it’s time for her to retire: a low 814 points in the final ranking. The price-to-quality ratio is the lowest in the test – 2.20.

The Kama-Euro 519 stands apart. It has not been released in size 175/65R14 before, but you can’t call it a new product – it’s been on the market for years! She achieved very good results in the tests, scoring 836 points. But it didn’t make it into the overall standings, because on the samples that we tested, o. If exactly the same ones go on sale, it will be very nice!

TEST RESULTS

Braking distance (35-5 km/h) on ice (Maximum 140 points)

Time to complete the ice circle (Maximum 120 points)

Acceleration time (0-35 km/h) on ice (Maximum 50 points)

Braking distance (35-5 km/h) on snow (Maximum 130 points)

Acceleration time (0-35 km/h) on snow (Maximum 40 points)

Braking distance (60-5 km/h) on wet asphalt (Maximum 110 points)

Braking distance (80-5 km/h) on dry asphalt (Maximum 90 points)

Fuel consumption at a speed of 90 km/h (Maximum 40 points)

Fuel consumption at 60 km/h (Maximum 30 points)

Table of expert assessments (Score/Points)

Expert opinions on each tire are presented below

About European manufacturers

As I wrote above, spikes are allowed only in Scandinavian European countries; I would like to emphasize once again that in warm European regions spikes are prohibited by law! To avoid damaging the road surface.

However, in the Scandinavian countries, since July 1, 2009, a technical regulation has been in force that regulates the number of studs on one linear meter of a tire - THERE SHOULD BE NO MORE THAN 50 PIECES.

There is a caveat to the truth; the manufacturer can present tests in which they prove that a larger number of studs does not destroy the road surface.

In average tires R14 - R15, the number is about 96 pieces. Although, for example, the same Nokian Hakkapeliitta 8 has as many as 190 pieces, but they have proven that the destructive effect is reduced here.

How many studs must there be in a tire by law?

After driving for three or four seasons on winter studded tires, there is a need to replace these tires due to their natural wear. However, when you get to a tire center, you can find that there are fewer studs in completely new tires. What is the reason for this and how does a smaller number of studs affect the performance properties of the wheels?

Game by new rules

Relatively recently, namely on July 2013, new rules regarding tire manufacturers came into force. According to the new regulations, there should not be more than 50 studs per linear meter of rubber, and the figure does not depend on the width of the tire. This means that, for example, the most popular winter tire of 16 radius will have 96 studs, although up to this point there could have been 130... At the same time, the protrusion of the studs above the tread is still 1.2 millimeters.

It is unlikely that the new standards will have a positive effect on the grip qualities of tires. But the initiators of the restrictions were not faced with the task of bringing this parameter to a new level. The main emphasis of using winter tires with fewer studs is to maintain the good condition of asphalt roads

True, not all tires are available with a limited number of studs. There is also an option with 190 spikes (16th radius). It is worth noting that the spikes themselves in this case are smaller in size, which means that this configuration will still be of little use.

Comparative tests

Methodology

And yet, tires with what number of studs are most preferable? To understand this, you need to look at the test results. The tests were carried out by a group of experts using a method developed by a Scandinavian institute.

The essence of the test is to drive a car over a special granite tile: two hundred runs in one direction, two hundred in the other, opposite direction. First, a car with the allowed number of spikes (96) passes, and only then the subjects (130, 190). After one run, consisting of a set of passes in two directions, the tiles are weighed.

If the races on the test tires were not able to reduce the weight of the tiles more than on the approved tires, then tires with a large number of studs are allowed for mass production. Below are the test results for 16-radius wheels.

| Number of studs in a tire | 96 | 130 | 190 |

| Braking distance on ice from a speed of 25 km/h (m) | 11,8 | 10,5 | 10,7 |

| Acceleration on ice up to 25 km/h (sec) | 4,9 | 4,1 | 4,4 |

| Timed lap, ice surface (sec) | 26,8 | 26,6 | 25,8 |

| Braking distance on snowy surfaces from a speed of 50 km/h (m) | 26,5 | 25,9 | 26,1 |

Result: During the tests, it was clearly demonstrated that tires with 190 studs are a compromise option - they show good results in both acceleration and braking. Therefore, for use in winter conditions it is better to prefer just such wheels, provided they are available in tire centers.

shiny-info.ru

Is it possible to ride on tires if the studs have fallen out?

To answer the question whether it is possible to drive on tires on which some of the studs have fallen out, you need to understand exactly how much, as a percentage of the total number of studs, the rubber has lost. To do this, we calculate the percentage of remaining spikes using a simple formula:

100 * number of spikes remaining / total number of spikes = percentage of spikes remaining

Having obtained, after a simple calculation, the percentage of remaining studs, you can assess the suitability of the rubber for use in winter weather conditions. According to general recommendations from manufacturers, you need to focus on the following figures:

5% of spikes dropped. Good result even for new tires. Often 5% of the studs are lost during transport of tires. The grip properties of such a tire do not suffer much.- 10% of the spikes have fallen out. This type of tire is suitable for use, often 10% of the studs are lost in the first two seasons. The loss in grip properties on such tires is minimal.

- 20% of the spikes have fallen out. Normal wear and tear for tires that have been in use for about 3 years. You can continue driving on these tires in winter.

- 30%-40% of thorns fell out. Studded tires with medium wear. The grip properties of such a tire with the road are noticeably reduced. The braking distance on such tires will increase slightly compared to a new tire, and the car will behave less confidently at high speeds when cornering. But manufacturers still allow the use of such tires.

- 50%-60% of the thorns fell out. The rubber is heavily worn and is recommended to be used only as a last resort. In this case, tires with such wear can only be installed on the driven axle of the car; more “live” tires should be on the drive axle.

- More than 60% of the thorns have fallen out. You cannot drive a car on tires that have lost more than 60% of their studs. The grip properties of such tires with the road are reduced, and the behavior of a car on such tires is unpredictable.

It is important to remember the rule that the most worn tires must be installed on the driven axle. It is recommended to count the studs before “changing shoes” in order to determine the less and more damaged tires.

( 406 votes, average: 4.48 out of 5)

Energy-saving tires - what are they?

How do Eurozima tires differ from studded and friction tires?

Related Posts

How many studs are there in the popular Michelin and Nokian tires?

Number of studs in Michelin tires

The Michelin company is one of the few that began to develop technologies to reduce the total volume of studs and maintain performance, before the introduction of updated standards.

As a result, this led to the fact that on all models of this brand, grip, handling and other properties depend not only on the studs, but also on the rubber composition, tread pattern and other components. They all complement each other, providing decent performance.

The first model that passed the new standards was Michelin X-Ice North 2. During its development, the number of studs was reduced to 50 units per linear meter.

At the same time, no deterioration in adhesion was observed, since at the same time the structure of the rubber with various additional features was changed. elements that, together with the spikes, caught on the road surface.

Nokian

The Nokian manufacturer has gained popularity in Russia largely due to its winter tires that can be used in difficult conditions. Almost every winter model of this brand has spikes.

For example, there are 190 of them on the Nokian Hakapelita 7 tread. At the same time, they do not destroy the road surface when driving, but provide excellent grip and other indicators.

Compared to other tires, they usually have no more than 120 gripping claws, and the impact on the asphalt is much greater. Here it was possible to reduce it by changing the shape of the elements and their location.

Each manufacturer decides during the development process how many studs can be present in the winter tires produced at its factories.

In general, this indicator is currently not limited, but on the condition that the impact on the road surface should not exceed permissible standards.

After my article about flying studs, an interesting question arose - how many studs are there on winter tires? That is, the quantity is banal? After all, now tires can be restored and quite effectively, by installing, say, repair studded elements. But realistically, how many of them are needed? Take, say, the popular sizes R13, R14, R15 or large sizes such as R17. Personally, I looked for information, but I couldn’t find it anywhere, I had to go back to the service station and actually count manually...

Actually, you don’t have to look for a specific number, everything here is very individual! A lot depends on the specific manufacturer, as well as on the country of manufacture. The thing is that in some European countries the number of spikes is limited at the legislative level, while in other warmer countries they may be prohibited altogether, only “Velcro”.

Established standards for the number of studs on a tire

Until recently, the number of studs in a new tire was set quite simply:

— tires of the 13th and 14th landing diameter: no more than 90 studs per tire;

— tires of 15th landing diameter: 110 studs per tire;

— tires of 16-th diameter and above: no more than 130.

However, since 2013, a new rule has been adopted in the Scandinavian countries. Its essence is a change in studded tires to reduce the negative impact on the asphalt surface and on the health of people suffering from the dust that studs produce, destroying the road surface. The proposed changes were as follows:

— limit the number of studs, the limit is 50 studs per linear meter of circumference;

- reduce the impact on the road surface without complying with the limit, but with passing a special test that will prove that failure to comply with the limit on the number of studs did not in any way increase the destructive impact on the road surface.

Comparative tests

Methodology

And yet, tires with what number of studs are most preferable? To understand this, you need to look at the test results. The tests were carried out by a group of experts using a method developed by a Scandinavian institute.

The essence of the test is to drive a car over a special granite tile: two hundred runs in one direction, two hundred in the other, opposite direction. First, a car with the allowed number of spikes (96) passes, and only then the subjects (130, 190). After one run, consisting of a set of passes in two directions, the tiles are weighed.

If the races on the test tires were not able to reduce the weight of the tiles more than on the approved tires, then tires with a large number of studs are allowed for mass production. Below are the test results for 16-radius wheels.

| Number of studs in a tire | 96 | 130 | 190 |

| Braking distance on ice from a speed of 25 km/h (m) | 11,8 | 10,5 | 10,7 |

| Acceleration on ice up to 25 km/h (sec) | 4,9 | 4,1 | 4,4 |

| Timed lap, ice surface (sec) | 26,8 | 26,6 | 25,8 |

| Braking distance on snowy surfaces from a speed of 50 km/h (m) | 26,5 | 25,9 | 26,1 |

Result: During the tests, it was clearly demonstrated that tires with 190 studs are a compromise option - they show good results in both acceleration and braking. Therefore, for use in winter conditions it is better to prefer just such wheels, provided they are available in tire centers.

How many studs should there be on average on a tire, depending on the size?

In Europe, studding is prohibited. In Scandinavian countries, certain standards have been introduced, where the permissible number of studs on each tire has been reduced to minimize their negative impact on the road surface. However, this also caused the grip to deteriorate.

As a rule, there are only two options for changing and improving tires:

1). Attach a smaller number of spikes to each, leaving their original shape. Of course, this will reduce the impact on the track surface, but at the same time the grip on it will also deteriorate.

2). Leave the “number” the same, but change the shape and some other properties, ensuring that the impact on the road surface is reduced, but the tire performance remains the same or even improved. After such changes, tires can go on sale only after passing tests.

In Russia, in general, approximately the following standards for studding of winter tires are accepted (the numbers may vary):

| How many studs are there in a tire? | |||||

| r13 | r14 | r15 | r16 | r17 | r18 |

| up to 110 | up to 110 | up to 110 | 108 | 130 | 100 |

Which tires are better - BRIDGESTONE or Nokian Tyres?

In May 2021, on PartReview, BRIDGESTONE tires were overall better than Nokian Tyres.

- Nokian Tires received a PR score of 77 out of 100, and BRIDGESTONE managed to score 81 points.

- Nokian Tires took 20th place in the ranking of the best manufacturers, and BRIDGESTONE took 16th place.

- The average review score for BRIDGESTONE (4.1) is higher than for Nokian Tires (4).

- BRIDGESTONE tires have better property ratings than Nokian Tyres:

- Noise - owners believe that BRIDGESTONE has this property better than Nokian Tires.

- Wear resistance - car enthusiasts claim that this property of BRIDGESTONE is superior to Nokian Tires.

- Manageability - based on reviews it is clear that Nokian Tires is no different from BRIDGESTONE in this property.

Number of studs on tires of different sizes

Although there should be more studs as the tire diameter increases, this is not always the case. Oddly enough, an increase in diameter does not lead to a directly proportional increase in their number, but remains approximately at the same level. So, for tires with size r14 there can be an average of 110 of them, and this is quite a lot. On such a tire they are installed in at least three rows. On tires size r15 (the most popular size on budget foreign cars at present), the number of studs also remains the same, even if they are tires of the same model, because the size of the “checkers” on the tread increases. So the diameter of the tire does not greatly affect their number. Wheels with r16 tires (most C class cars) have the same number, and it all depends on the manufacturer.

How many spikes should there be?

In domestic legislation there is no clear indication of how many studs a tire should have. The traffic rules also do not contain any requirements for the number of studs. Only some European countries have approved regulations that studs cannot contain more than 50 studs per linear meter of the tire in order to avoid high wear on the surface layer of asphalt roads. This is approximately 100 studs on one R16 wheel. Meanwhile, in Russia there are no such strict restrictions, and tires for icy roads with 120, 180 and even 190 studs can be supplied to us.

Question and answer Why is it better to choose stamped wheels for the winter?

The lower limit of studding is also not specified in the regulations. Only the list of faults and the technical regulations of the Customs Union indicate the requirement for the tread height of a winter tire. It must be at least 4 mm. However, manufacturers have standards for studs, and, guided by them, it is possible to assess the ability of a wheel to provide the declared driving characteristics.

Rating of winter tires for crossovers

What are the best winter tires for crossovers? Below are the highest quality solutions that have received positive reviews from car owners. They are suitable for serious 4x4 SUVs, but they can also be installed on the Niva.

Continental ContiViking Contact 6

| Country: Germany Brand:Continental Price: 6000 rubles Rating: 4 |

Description

These winter tires are not noisy at all and are very soft. German production allows you to get ideal quality at a fairly reasonable price. All tire tests pass very successfully, so they are often mentioned in car magazines. Also, these German tires always delight with ideal surface grip and excellent road behavior.

Pros:

- does not tan in cold weather;

- holds the car well when cornering;

- ensures vehicle stability on snowy roads.

Minuses:

wears out quickly.

Reviews

Alla: “I was pleased with the braking distance and the good, stable grip on snow and ice.”