Today, car owners are accustomed to turning to a tire shop in case of problems with their wheels. But such services can only be found in big cities, and there are many “out-of-the-way” places where it is difficult to find a tire repair shop. In such a situation, a spare tire can help out the driver, but sometimes problems occur with several tires at once. Therefore, the car owner must know how to trim wheels with his own hands. Moreover, many drivers do not trust tire mechanics and prefer to carry out such work themselves.

How to rim a wheel with a jack and cable

This is one of the simplest ways to disassemble and trim a wheel yourself. If you follow the instructions below, you can easily do this job yourself.

- Remove the wheel from the car and clean off any dirt.

- Unscrew the nipple and bleed air.

- Place the wheel with the nipple facing up.

- Tie the tow rope to the disk and jack, as shown in the photo.

- Place the jack closer to the rim on the tire. If it is chamber, then you cannot place the jack next to the fitting, otherwise it will come off when disassembling.

- Securely fasten the ends of the cable together.

- Raise the jack up by pulling the cable and moving the tire sidewall down. Do this until the tire comes off the rim.

- If you only need to replace or seal a punctured tube, then lift the sidewall of the tire with mounting blades from the side of the fitting and place it on the edge of the disk.

- Push the fitting into the inner cavity and pull the tube out of the tire.

Attention! If the nipple is in good condition, then it can be unscrewed and used for a new camera, or put in stock.

Installing a new camera

Boarding work takes less time and effort, but it also needs to be done in a certain order.

- Take the new camera and unscrew the nipple from it; release the air pressure by forcing it out.

- Move the rubber sidewall away from the location of the fitting.

- Place the tube part with the fitting into the tire and insert it into the hole in the rim.

- Reinstall the entire camera.

- Pump the camera without nipple slightly so that it straightens and takes its place. This is also necessary so that when trimming it does not get caught by the mount and damage it.

- Using mounting blades, carefully trim the tire around the perimeter.

Now all that remains is to install the nipple, inflate the tire to the pressure required by the manufacturer, and place the wheel on the car.

Romance of the highway: tire service on the edge

Do-it-yourself tire mounting on the track can be done using two mounting blades and a special device to tear the tire off the rim. But it will be more convenient and civilized if you have a jack and a tow rope. And you will find them.

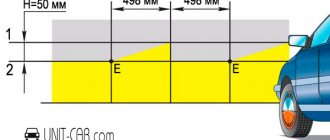

Drawing of a tire changing machine.

Therefore, we continue to work according to this algorithm:

- We remove the wheel, clean it and place it with the nipple facing up.

- Let the air out of the wheel.

- We insert the towing cable into the disc hole and place the jack close to the rim.

- We throw the cable over the jack bracket and fasten the ends of the cable to each other.

- It is necessary to rotate the handle so that the jack pulls the cable up, and the seat ring moves down until the tire separates from the rim.

- If the tube needs repair or replacement, you need to lift the side of the tire onto the rim near the fitting, which we push in and remove the tube under the tire.

- We take out the nipple and remove the air.

- Now we place it under the tire, but first we insert the fitting into the hole inside.

- We pump up the inserted camera a little, without the nipple for now.

- We make a bead, insert the nipple into the fitting, fully inflate the chamber and put the wheel in its place.

All ten of these points are easy to describe, but very difficult to do. And if the weather conditions leave much to be desired, then it becomes completely sad; you will remember such tire fitting for the rest of your life. The quality of such installation will never be perfect.

It would be smarter to acquire some kind of mechanized device for independent tire fitting. There are many options for such devices - you can find a wide variety of design solutions on the Internet.

Dismantling by hitting a wheel

The main difficulty of the work is that even the weight of a person is not enough to separate the tire from the rim. This is also affected by the decrease in elasticity of rubber over time. Drivers sometimes use a car to hit a defective wheel when there is no other way to repair it.

To distribute the load more evenly, you can use a piece of wide board at least 1 meter long. This method is good because there are no shock loads, but often the rubber becomes unusable. It is recommended to perform this work with an assistant to regulate the impact speed and the force generated.

Manufacturing of a wheel beading machine

The first stage of removing the tire from the rim

To produce a frame that will act as a base, we recommend using profile pipes. There must be a distance of at least 70 centimeters between these pipes. We will need this distance so that the equipment has a high level of stability.

We connect two pipes that are parallel to each other using a steel angle. A profile design of a smaller cross-section can also go here. As an additional component, we can make adjustable legs.

After we have made the frame, we should do the following:

- weld the pipe to the frame. The diameter of such a pipe can vary from twenty to thirty millimeters. Before welding the pipe, we first weld the flange to a height of 40-60 centimeters;

- on the vertical area we make a fastening element, which is made in the form of a steel plate. We will need this plate in order to install a tool such as a lever.

The main purpose of the lever is to remove tires from wheels. The lever is presented in the form of two main parts. Here we see the lever arm and the paw with which we will act on the tire itself.

Dismantling with a sledgehammer

The most common method of beading wheels has become impact. It uses a metal corner, a sledgehammer or a large hammer. This method was used by tire mechanics and drivers when there were no special devices.

Attention! The corner should not have sharp edges so as not to damage the rubber.

DIY tire changing machine

To manufacture the machine you will need the following materials and tools:

- Electric drill.

- Welding machine.

- Grinder with abrasive wheel.

- Rectangular steel pipe.

- Round pipe 1.5 meters, diameter 2 inches.

- Old wheel hub.

- Steel sheet at least 4 mm thick.

- Rod with a diameter of 20 mm.

The whole device consists of 2 parts: bead beating and tire mounting.

The base of the frame is made from a rectangular profile.

A 2-inch round pipe is attached to the jumper by welding at a distance of 30 cm from the edge. The height should be about 150 cm. To enhance the strength of the welds, you can use triangular scarves. To make it possible to install the wheel, the hub is welded at the height of a person’s waist.

The upper edge of the pipe should be located above the wheel at a distance of 30 cm. A bracket must be welded under the hub to fix the breaker device. It is made from a sheet of iron in which a hole is drilled. The pipe that will play the role of a lever must have a sufficient diameter so that an extension lever can be inserted into it. The tips for it should be made of a steel circle 20 mm in diameter.

Description of design

Homemade wheel beading machine

If you look at the procedure for changing tires, at first glance it will seem very simple. In order to make a replacement, you should simply remove the old tire from the rim and then install a new one. At the same time, when fitting tires, we are faced with a small problem.

Dismantling requires enormous effort. Of course, we can use special tools presented in the form of a “travel kit”. In this set we will find several mounts that have different shapes, as well as special wedges. Such tools can make wheel trim a little easier. At the same time, if you have been using the tire for quite a long period, then separating it from the wheel will be very difficult. Therefore, the best way out of the situation would be to use a tire changing machine. This tool will help you in solving such problem.

The design of such a do-it-yourself machine should be presented in the form of such components as:

- frame. It is often presented in the form of two rectangular profile pipes, which are located parallel to one another. These pipes are connected by means of a steel angle;

- vertical riser, attached to the frame. This device is designed to perform several functions. It is presented in the form of a lever attachment, which is intended for carrying out work on tire dismantling, and also plays the role of a platform on which the disc is installed;

- the pipe to which we weld the handle. This pipe acts as a lever when removing tires.

To make such equipment with your own hands, we recommend purchasing high-quality rolled metal. This is due to the fact that during use such a tool will take on a huge load.

Advice from professionals

Beading wheels is not an easy job that requires certain skills. Therefore, you need to follow the recommendations of specialists for beading your tires yourself.

- If you only need to replace one tire, you cannot install another type of tire. It is especially not worth changing a summer tire for a winter one and vice versa.

- It is important to consider the size of tubes, wheels and tires.

- After purchasing new tires, it is better to install a new one as well.

- Do not allow dirt into the inner cavity of the tire.

- You can use a jack, mounting blades and other suitable tools to separate and remove the rubber from the wheel without damaging the wheel.

- Wheels must be periodically inspected in order to detect defects in time and eliminate them.

- It is not allowed to use sharp objects for disassembly that could damage the tire. For example, drivers with little experience sometimes use screwdrivers for such purposes. This leads to additional costs.

If on the road a tire starts to go flat and you find a sharp nail in it, do not rush to pull it out right away. It will allow you to maintain pressure for a while and get to the nearest auto repair shop.

Re-flashing takes a lot of time and effort, and requires convenient mounting blades. Beginners often use a sharp screwdriver and a hammer for dismantling, which is strictly prohibited. At first, the damage may not be noticeable, but later it will show itself. The mounts must have rounded ends so as not to damage the rubber.

Attention! To repair wheels, it is convenient to use a piece of metal corner with a section of 40x40 mm. It is used to insert between the disk and the tire.

Advice from experienced people

Design of a tire changing machine.

How to make a machine with your own hands:

- The angle between the beading tip and the lever must be made sharp: the smaller it is, the better the rubber will fit on the disc. But this angle cannot be made too sharp, in which case the lever will scratch the disc when beading. We need to find the optimal degrees of angle.

- It is better to do a homemade tire changing machine with your own hands using drawings. You are quite capable of preparing them.

- Consider mounting it to the floor. The machine itself is lightweight, so it must be attached securely. If the floor is concrete, secure the machine with anchor bolts. If the floors are wood, use self-tapping screws.

- To reduce damage to rims and wheels, lubricate the tips and wheel rim with a thick soap solution. And don't forget to wash the wheel before work.

- Sometimes wheels may differ in the number of holes for fastenings and the distances between them. For such cases, we make metal adapters with studs 1 cm thick.