Carburetor DAAZ 2107

The “seven” carburetor, like any other, mixes air and gasoline and delivers the finished mixture to the engine cylinders. To understand the structure and operation of the carburetor, as well as to identify and eliminate possible malfunctions with it, you need to familiarize yourself with this unit in more detail.

The carburetor is installed in the engine compartment on top of the intake manifold

Who produces and on what VAZ models it is installed

The DAAZ 2107 carburetor was manufactured at the Dimitrovgrad Automotive Component Plant and installed on different Zhiguli models, depending on the product modification:

- 2107–1107010–20 were equipped with engines of the latest versions of the VAZ 2103 and VAZ 2106 with a vacuum corrector;

- 2107–1107010 was installed on “fives” and “sevens” with engines 2103 (2106);

- carburetors 2107–1107010–10 were installed on engines 2103 (2106) with a distributor without a vacuum corrector.

Carburetor design

DAAZ 2107 is made of a metal body, which is characterized by increased strength, which allows to minimize deformation and temperature effects, and mechanical damage. Conventionally, the body can be divided into three parts:

- the top one is made in the form of a cover with fittings for hoses;

- middle - the main one, which contains two chambers with diffusers, as well as a float chamber;

- lower - it contains throttle valves (DZ).

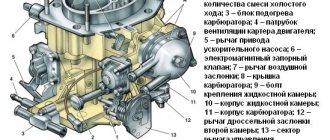

The DAAZ 2107 carburetor consists of three parts: upper, middle and lower

The main elements of any carburetor include jets, which are designed to pass fuel and air. They are a part with an external thread and an internal hole of a certain diameter. When the holes become clogged, their throughput is reduced, and the proportions in the process of forming the working mixture are disrupted. In such a situation, cleaning the jets is necessary.

The jets are not subject to wear, so their service life is unlimited.

Each nozzle has a passage hole of a certain cross-section

The “seven” carburetor has several systems:

- float chamber - maintains fuel at a certain level for stable engine operation at any speed;

- main dosing system (GDS) - operates in all engine operating modes, except idle (idle), supplying a balanced gasoline-air mixture through emulsion chambers;

- XX system - is responsible for engine operation when there is no load;

- starting system - ensures a confident start of the power plant when cold;

- econostat, accelerator and secondary chamber: the accelerator pump contributes to the instantaneous supply of fuel during acceleration, since the gas station is unable to provide the required amount of gasoline, and the second chamber and econostat come into operation when the engine develops maximum power.

DAAZ carburetor diagram: 1. Accelerator pump screw. 2. Plug. 3. Fuel jet of the transition system of the second chamber of the carburetor. 4. Air jet of the transition system of the second chamber. 5. Econostat air jet. 6. Econostat fuel jet. 7. Air jet of the main metering system of the second chamber of the carburetor. 8. Econostat emulsion jet. 9. Diaphragm mechanism for pneumatic drive of the throttle valve of the second chamber of the carburetor. 10. Small diffuser. 11. Jets for the pneumatic drive of the throttle valve of the second chamber of the carburetor. 12. Screw—valve (discharge) of the accelerator pump. 13. Acceleration pump nozzle. 14. Carburetor air damper. 15. Air jet of the main metering system of the first chamber of the carburetor. 16. Damper jet of the starting device. 17. Diaphragm trigger mechanism. 18. Air jet of the idle system. 19. Fuel jet for idle system.20. Fuel needle valve.21. Carburetor strainer. 22. Fuel fitting. 23. Float. 24. Idle speed adjustment screw. 25. Fuel nozzle of the main metering system of the first chamber.26. Screw for the “quality” of the fuel mixture. 27. Fuel mixture “amount” screw. 28. Throttle valve of the first chamber. 29. Thermal insulation spacer. 30. Throttle valve of the second chamber of the carburetor. 31. Diaphragm rod of the pneumatic drive of the throttle valve of the second chamber. 32. Emulsion tube. 33. Fuel nozzle of the main metering system of the second chamber. 34. Accelerator pump bypass jet. 35. Accelerator pump suction valve. 36. Accelerator pump drive lever

Find out how to choose a carburetor: https://bumper.guru/klassicheskie-modeli-vaz/toplivnaya-sistema/kakoy-karbyurator-luchshe-postavit-na-vaz-2107.html

The principle of operation of the carburetor

The operation of the device can be described as follows:

- Fuel from the gas tank is pumped by a gas pump into the float chamber through a filter and valve, which determines its filling level.

- From the float tank, gasoline is supplied through nozzles into the carburetor chambers. Then the fuel passes into the emulsion cavities and tubes, where a working mixture is formed, which is supplied to the diffusers through atomizers.

- After starting the engine, the electromagnetic valve closes the XX channel.

- During operation at XX, fuel is taken from the first chamber and passes through a nozzle connected to the valve. When gasoline flows through the XX nozzle and part of the transition system of the primary chamber, a flammable mixture is created, which enters the corresponding channel.

- At the moment the throttle body is opened slightly, the mixture is injected into the carburetor chambers through the transition system.

- The mixture from the float tank passes through the econostat and enters the sprayer. When the motor operates at maximum frequency, the accelerator begins to function.

- The accelerator valve opens when filled with fuel and closes when the mixture supply is stopped.

Video: design and operation of the carburetor

Maintenance and adjustment of DAAZ 2107

Basic maintenance and adjustment of the carburetor:

- inspection for visible defects;

- cleaning and washing the surface;

- washing the float chamber;

- cleaning the mesh filter;

- cleaning (purging) or replacing jets;

- float chamber adjustment;

- idle speed adjustment.

If you have never encountered such a task, it is better to entrust it to a specialist, but if you have at least some understanding of the principle of operation of a carburetor, you can do it yourself.

1. Let's start with the simplest thing - washing and cleaning. To do this, remove the carburetor from the engine and clean it outside.

2. To do this, it is better to buy a special aerosol with a tube. You can buy it at any auto store. The average price is a little more than 100 rubles.

3. Next, remove the cover of the float chamber and clean the float bath with a toothbrush and the same aerosol.

4. Visually inspect the float mounting bracket and check its movement.

5. We adjust the float chamber. We take the lid with the float and hang it strictly vertically.

6. Measure the distance from the cover to the side surface of the float. It should be 6-7 mm.

7. If you do not have the appropriate measuring device, use a 6 mm drill bit, inserting it between the cover and the float. If the distance is greater or less than specified, we achieve the desired value by bending the bracket in one direction or another.

8. Now, in a vertical position, move the float all the way to the side. The distance between its surface and the lid should be 15 mm. If the distance does not correspond to this value, bend or bend the float tongue.

9. After adjustment, do not put the cover back in place.

10. Move on to the mesh filter.

11. Unscrew the plug and remove it. We wash with an aerosol and blow through with a compressor or pump. We put the filter back.

12. Now carefully unscrew the air and fuel jets.

13. We wash and blow them through, after which, without mixing them up, we put them in their places.

14. Now we assemble the carburetor and install it on the engine. All other work will be carried out when the engine starts.

15. To adjust the idle speed we need an electronic tachometer and a slotted screwdriver.

16. Use a screwdriver to tighten the screws for adjusting the quality and quantity of fuel until they stop. After this, release the quality screw by 2-3 turns, the quantity screw by 3-4.

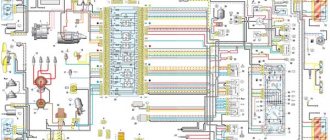

17. Start the engine and warm it up to operating temperature. We turn it off, connect the tachometer as indicated in the photo, and start it again.

19. Now we release the quality screw (counterclockwise), and check whether these revolutions are the maximum for the quantity we have set, rotating it left and right.

21. To adjust the idle speed as accurately as possible, the use of special equipment, such as a CO2 and CH analyzer, is required. Such adjustment work can only be carried out in a specialized service.

Did you like the article? Save so you don't lose!

Features of jet markings

- At the factory, the SOLEKC 21083 carburetor is equipped with jets marked 21 (chamber No. 1) and 23 (chamber No. 2). These numbers show the outer diameter of the dosing element.

- Below on the fuel jets there are numbers 95 and 97.5, respectively. They show the productivity (throughput) of the jet, which is determined at the factory by the pouring method.

- Airborne models are marked 155 and 125, which also indicates the performance of the jet.

Main types of DAAZ carburetors

Of course, carburetor feed mixture supply systems are considered obsolete today. However, according to a number of criteria they are superior to injection designs. A small number of electronic components increases the reliability of the unit and ensures ease of repair work. In addition, carburetor engines do not have high requirements for fuel quality.

Carburetors can be of three types.

- Bubbler. These devices are no longer used. The principle of operation of the unit was to prepare and supply a mixture of air with the vapor fraction of the fuel.

- Membrane-needle-shaped. The assembly consists of several compartments that separate the membranes. They are connected to each other by a rod ending in a needle. This device locks the valve seat through which the fuel mixture is supplied.

- Float This type is most widely used due to its reliability, good quality of the fuel-air mixture and ease of setup. Structurally, it consists of a float-type chamber necessary for the influx of fuel and a compartment where it is mixed with oxygen.

CXX

When the power plant operates at low speeds, the damper closes almost entirely. In this case, the diffuser vacuum drops to such an extent that the supply of fuel from the gas pressure zone stops.

At XX, to prepare the fuel assemblies, the air hose zone under the diesel protection is put into operation, and the fuel is supplied by a separate part of the carburetor.

Idle system

Fuel liquid enters through nozzles from the float chamber. Air is mixed with it, sucked through a separate jet. As a result, a normal fuel mixture is supplied, capable of powering the internal combustion engine.

CXH is often called an autonomous system, and rightly so. Its influence on the main characteristics of internal combustion engines is well known. Many people think that CXX is the most simplified carburetor system, however, in fact this is not the case. It is with idle speed that problems and abnormalities often arise, requiring the motorist to intervene and adjust the screws.

The CXX operates when the damper of the first chamber is completely locked, when the GDS is turned off. It turns out that the idle system is a kind of separate mini-carburetor that complements the main one. Fuel liquid and air are supplied to it, the necessary fuel assembly is created, which is sucked into the inlet. Thus, in XX mode the device is entirely dependent on the mini-carburetor.

Adjusting screws are mandatory elements of the CXX. They interact with the dispensing needle. For example, using the quality screw you can adjust the gas supply, and using the speed screw you can adjust the number of shaft rotations per minute.

Among the other important parts of the SHS, we can also highlight the bypass channel. Without it, it is extremely difficult to regulate the fuel assembly, since the element is very sensitive and responds to any error in the location of the needle valve.

Selection of jets

- First of all, when selecting jets, it is important to take into account the volume of the power unit. For engines with a larger volume, it is better to install air jets with a small cross-section, since more air will pass through it at the same time. At the same time, fuel consumption will increase.

- The selection of jets should begin with the fuel jet, and only then move on to the air jet. In this case, first the selection is made for the first camera, and after installing the jets on it, you can move on to the second. In this case, professional auto mechanics recommend that before starting work, find a factory carburetor Colex 21083, designed for the volume of the car engine for which installation is being carried out, and try installing jets from it.

- first chamber - fuel jet 102.5, air jet - 155;

- the second chamber is a fuel jet of 110, an air jet of 125 or 135.

Problems with the DAAZ 2107 carburetor

There are many small parts in the carburetor design, each of which is of great importance because it performs a specific job. If at least one of the elements fails, the stable operation of the unit is disrupted. Quite often, problems arise when starting a cold engine or during acceleration. The carburetor is considered faulty when the following symptoms appear:

- when operating at XX, the engine operates with dips, i.e., is unstable;

- when trying to overclock, there is some delay;

- increased fuel consumption;

- Difficulty starting the engine after a long period of inactivity.

Each of these signs indicates the need for repair or adjustment work. Let's look at the most common malfunctions of the “seven” carburetor.

Pouring gasoline

The essence of the problem comes down to the fact that gasoline enters the mixing device in greater quantities than necessary, and the check valve does not drain excess fuel into the gas tank. As a result, drops of gasoline appear outside the carburetor. To eliminate the malfunction, it is necessary to clean the fuel nozzles and their channels.

Shoots

If you hear "shots" coming from the carburetor, the problem is usually caused by excessive fuel entering the carburetor. The malfunction manifests itself in the form of sharp twitching while driving. The solution to the problem is to flush the unit.

Gasoline is not supplied

The occurrence of a problem may be due to clogged nozzles, a breakdown of the fuel pump, or malfunction of the gasoline supply hoses. In such a situation, you should blow out the supply pipe using a compressor and check the fuel pump. If no problems were identified, you will have to dismantle the unit and flush it.

Lack of gasoline supply may be caused by clogged nozzles

The second camera does not work

Problems with the secondary camera manifest themselves in the form of a decrease in vehicle dynamics by almost 50%. The malfunction is associated with jamming of the remote control, which has to be replaced with a new part.

Accelerator pump does not work

If there is a problem with the accelerator, fuel may not flow or may be supplied in the form of a short and sluggish stream, which leads to delays during acceleration. In the first case, the reason lies in a clogged fuel nozzle of the accelerator pump or a ball sticking to the check valve sleeve. If the jet is poor, the ball may become stuck or the diaphragm connection between the carburetor body and the cover may leak. The way out of the situation is to clean the parts and check their condition.

The engine stalls when you press the gas

If the engine starts and runs flawlessly at idle, but when you try to move off it stalls, most likely there is insufficient gasoline level in the float compartment. As a result, it is only enough to start the power unit, and at the moment the remote control opens, the level becomes too low, which requires its adjustment.

For normal engine operation, there must be a certain level of fuel in the float chamber.

The principle of operation of the carburetor

The functioning of the power unit is largely determined by the quantity and quality of the incoming fuel mixture.

How the 2107 carburetor works:

Fuel enters the float chamber, the level of which is regulated by a valve or float. After this, the gasoline, divided into droplets, enters the mixing chamber through nozzles, where mixing with the air occurs. The econostat further enriches the mixture when the engine is running at full load. Diffusers optimize the flow of fuel, which is supplied to the manifold through the throttle valves. When the engine runs at high speeds, the accelerator pump turns on.

Video lectures about the Colex carburetor

- How to correctly adjust the position of the secondary camera flap in the garage if it has already been touched?

For throttle spraying: what diameter hole should I drill in 21083? At what distance from the edge of the damper should the edge of the hole be, that is, how wide should the “bridge” be?

For Alexey: We adjust all sizes without haste until an acceptable result is obtained.

I am very glad to have new knowledge! Thank you BAM. Everything is simple and clear! But at my VAZ I have a problem with fuel consumption, it has increased from 6.5 to 18. I can’t find the problem. Karb did it, I don’t know the reason.

I’ve been fiddling with them a lot, now it’s just become clear what’s what, I’ll go throw out number 4, and for knowledge of this material at the service station they’ll charge 2000 rubles for adjusting the carburetor

put the new 21083 on the classic 1.5 with the screw fully tightened, the quality of the engine does not stall

I have a Lexus on a Mitsubishi Mirage! The transmission is automatic, but I can’t get it right, and our craftsmen can’t help!

A lot became clear to me and it helped. THANK YOU.

Thank you very much, the information is great, I’m looking forward to more information on tuning the Lexus car

Everything is great, thank you. The question is, the wire is not connected to the idle sensor, the engine does not stall, the rpm is 2000.

Kpacavchik! Thank you very much, live long and prosper.

I drive around the city without problems, but as soon as I drive around the roundabout, there is no idle speed at the first traffic light. BCE RESOLVED.

Is it possible to put it on 2 liters? engine and how to choose jets?

Installing the Moskvichevskaya frog on Golf 2 revealed a problem with the damper freezing. It is most optimal to leave the air box from the 2E2 carburetor with minor modifications and, accordingly, with a working air flow distribution system. Thank you very much for the accessible and detailed information, good luck to you.

Tell me, I installed a carburetor on the B3 with 2.l.d. 21083, but the idle speed after high speeds drops to zero while driving

Please tell me what the problem is. I remove the wire, epxx engine does not stall, epxx cheeks are present

Hello, please tell me what jets should be installed, engine 1.5

How to fix the problem of floating idle speed on a classic, 1.2 liter. costs 8x8, repair kit 2108.

Pyslan. As I understand it, the problem is that either the needle does not normally block the flow of fuel (there is debris or burrs inside), or the jet itself is not fully screwed in (it may be damaged) and the fuel is running out gives into channel XX through the slot. Another option is that gasoline finds its way into the collector some other way. For example, through the main system, the throttle may be slightly open.

Please tell me. On the 83 carburetor what jets should be installed. According to the video, everyone was talking about 73. Thank you in advance.

Please tell me. How to connect the solenoid valve if the car was initially running without the solenoid valve, but now it is simply broken and works without it? BAZ 2106 with engine 1.6. There was a factory carburetor. I installed SOLEKC 83, now I want to connect the solenoid valve to the power supply, but I don’t know how, because... There was no electric valve at home, so there is no wire for it. How to conduct it and from where? Thank you!

Mikhail. Connect the wire from the valve to the ignition relay, as soon as you turn on the ignition the valve turns on. It is possible to install EPXX for a small saving of gasoline, but here you already need to know the circuit and buy an EPXX electronic control unit

what jets to screw into the 83. Moskvichevsky 412 engine volume 1.8

Audi 100 dv.1.8 dc carburetor SOLEKS main fuel jets from Nivsky carb. Is it possible to install relatives to reduce consumption? Thank you.

Thank you very much for the video lessons. Everything is set up, it works great

I installed the Solex 21083 on a Mazda 626 2.0 liter, 8 valves. I bought it at the disassembly for 1000 tenge (5 tenge - 1 rub.), the seller swore that the carb was good and did not deceive the devil, but before installing it I took it apart, washed it, adjusted the elephants and I realized that the main fuel jets cannot be removed constructively. It is stamped on the carb: made in USSR. Is this possible or did I not understand how to unscrew them?

Please tell me what kind of jets should be installed, carb. Lex 83, engine 1.5

Tell me: let’s start from the beginning, I bought a 1.5-volume Solex carburetor for a VAZ 2107, installed a 1.6 engine, everything was super traction, acceleration, but then, when I pressed the gas hard, the engine started running. starts to get choked up as soon as he lets go and starts to exasperate again. I went into the garage and figured it out, the first camera works well, and when the second camera opens, it feels like someone is holding their ass. I can’t find the reason, tell me what could be. I changed the accelerator pump diaphragm, blew out the jet, and all to no avail.

which jets are better for 1.8

What is the difference: the accelerator is on the first or two cameras and how does it better affect the consumption? What markings should the diffusers of the first and second chambers on 083 have? There are 5 7 and 12.

for Yaposlav, there are both elephants in the first chamber, the flow rate is less, but not by much, the intake is much greater; the main thing is to set up the elephants correctly.

Jet markings

When choosing jets for a carburetor, inexperienced car enthusiasts are often perplexed by the presence of several numbers in the jet markings. These symbols are deciphered as follows:

- The Solex 21083 carburetor as standard is equipped with jets marked 21 (for the first chamber) and 23 (for the second chamber). The numbers indicate the diameter of the dosing elements.

- On the bottom of the “original” fuel jets there are numbers 95 and 97.5 (the first and second chambers, respectively). This data displays the throughput of the jets.

- The air jets are marked in exactly the same way as in the previous example, only in this case they will be marked 155 and 125, indicating the performance of the parts. Naturally, these numbers will change on jets with different throughputs.

The marking of carburetor jets is quite simple, but simply recognizing the numerical values is not enough - you also need to understand how and what these indicators influence.

How to replace the rear wheel hub bearing can be found in our material.

See how to independently adjust the amount of light from your car headlights. Read more here.

An important parameter that affects the operation of the jets is the ratio of the amount of air and fuel in the chamber. The normal ratio is 14.9:1, at which fuel consumption and power are in balance. To determine the combination suitable for a particular driving style, it is enough to understand what the ratio of air and fuel in the combustible mixture will be.

The factory fuel jets of the Solex 21083 carburetor are designed for economical driving and have a fairly small cross-section . The original jets do not need to be changed unless there is a particular need to increase engine power. In addition, as a result of replacing the jets, the mixture may become too lean, and the engine simply will not have enough combustible mixture for normal operation.

If the engine is not running smoothly, and the problem clearly lies in the composition of the fuel mixture, you can think about the options: different configurations of fuel and air jets make it possible to choose the most efficient scheme and use it in your car to achieve suitable results.

Introduction

The normal operation of a car engine directly depends on the quality of the fuel-air mixture. On modern cars, the task of properly preparing the mixture is successfully handled by the electronic control unit, collecting information from many sensors. Although the “injector” has practically replaced carburetor engines, there are still many cars on the roads that use this particular method of preparing the mixture.

Such carburetors are installed on VAZ-2107 series cars. Although their production has been discontinued for a long time, they are still very popular among car enthusiasts. This is especially noticeable in rural areas and small towns. The reason is clear: low cost of maintenance, quick repairs, availability of spare parts.

Ozone

This sample originates from the sixth Lada model. About 30 years ago, designers stated that it would be a sales leader in domestic car markets. Such prospects were explained by its design features.

Unlike the Solex and DAAZ samples, this prototype had a vacuum drive for the damper, which is responsible for the flow of fuel into the second chamber. Its drive did not depend on the float, but was driven by a rod located on the diaphragm. Such a device was supposed to provide fuel savings.

OZONE model

His design had nothing special: 2 chambers (primary and secondary), four jets, 2 throttle valves, etc. But still, it occupied a leading position in the market.

In addition to the standard carburetor 2107, there was a modification “Ozone” 1107010. Its difference is that it was installed exclusively on the “Zhiguli” 2103 and 06 engines, which were installed on the Lada 2105 and 07. Since this mechanism had a vacuum damper drive, the modification 1107010, was subdivided into 1107010 - 20. The number “20” meant that this device was installed only on the latest Lada 2107 models with a “Six engine.

Adjusting the throttle valve drive (“gas”)

If this drive is not configured correctly, the acceleration dynamics and throttle response of the engine deteriorate. This setup must be done with an assistant. You will need an 8-mm open-end wrench, a screwdriver, a flashlight and a caliper. We will completely “drown” the “choke” or air damper drive.

Now your assistant presses the gas pedal all the way to the floor. This opens the throttle valve completely, as shown below; to be sure, you can illuminate the first chamber with a flashlight. After releasing the pedal, the damper should completely close the first chamber without gaps.

To adjust, use a caliper to measure the length of the rod; it should be exactly 8 cm. By rotating the tips, we “adjust” the length of the rod to this size by unscrewing the “locking” nuts.

After this, we put the rod in place and repeat the test. Modern rods are often made of very poor plastic, which shrinks. Therefore, you need to check the “break-in” of the thrust after a week or two. You may not know how to adjust the carburetor of a VAZ 2107, but anyone can set the length of the thrust. We have considered only a few possibilities for adjusting the carburetor with our own hands. In general, there is an entire profession called “carburetor mechanic,” which implies full mastery of this necessary and complex technology. It is simply impossible to describe all the nuances of this process in one article. But we hope that the basic principles were clear and useful to you.

Main malfunctions of the Ozone carburetor

Like any mechanism, the VAZ 2107 carburetor sooner or later begins to act up, reduces its productivity and, in the end, may completely fail. The driver will be able to promptly notice the onset of a breakdown or malfunction if he carefully monitors the operation of the engine and carburetor. Thus, the following signs are considered symptoms of future breakdowns for Ozone:

- sharp pops when pressing the gas pedal due to detonation;

- high engine speed at idle;

- “floating” engine speed at idle, which indicates the need to adjust the idle speed;

- a long period of time between pressing the gas and accelerating the car. This is a sign of a malfunction in the drive of the second chamber of the carburetor or accelerator pump (or more often, both);

- black exhaust from the muffler, which is the first sign of clogged jets.

Black smoke from the muffler on a car with a carburetor engine is a sign of clogged jets

Engine won't start

The biggest problem with the carburetor is that the engine may simply not start - both cold and hot. This may be due to the following faults:

- valve depressurization;

- trigger wear;

- damper drive jamming;

- air damper axis play;

- ruptures in the diaphragm.

Video: what to do if the engine does not start

Overflows fuel

This malfunction is visible, as they say, to the naked eye. Spark plugs filled with gasoline do not produce a spark, and there may be puddles of fuel under the engine crankcase. The reasons lie in the following defects in the carburetor:

- breakdown of the starting device;

- instability of the accelerator pump;

- throttle valve sticking;

- clogging of jets;

- high fuel level in the float compartment.

More information about the VAZ 2107 carburetor: https://bumper.guru/klassicheskie-modeli-vaz/toplivnaya-sistema/karbyurator-vaz-2107.html

Video: correct setting of the fuel level in the carburetor

No idle

Another problem typical for Ozone 2107 carburetors is the inability of the engine to idle. This occurs due to the solenoid valve being displaced from the workplace or due to its severe wear.

The solenoid valve on the Ozone carburetor is responsible for the idle speed of the engine

High idle speed

With this problem, there is a jamming of the throttle valve axis of the second chamber. The damper must always be in a strictly defined position, regardless of the operating mode of the carburetor.

Video: Troubleshooting Engine Idle Problems

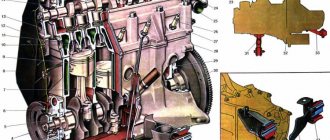

DAAZ 2107 carburetor design

The DAAZ 2107 carburetor is installed on a VAZ 2107 car. The diagram below gives an idea of its structure.

Design of the DAAZ 2107 carburetor for VAZ 2107 and VAZ 2105 cars

Previously, such a carburetor was installed on the VAZ 2105. The purpose of this unit is to mix gasoline and air in a certain proportion. The resulting mixture is then fed into the combustion chambers of the engine.

The main elements of the DAAZ 2107 carburetor are listed below:

- econostat;

- accelerator pump;

- fuel level support system;

- idle speed support system;

- engine starting system;

- jets for air and fuel;

- fuel-air mixture atomizer.

Procedure for adjusting DAAZ 2107-1107010-20

Adjustment is carried out only on a serviceable and serviced carburetor. It is highly desirable to have a device that can measure harmful CO emissions. Let's look at the procedure:

- We check the level in the float chamber. This is done using a template, which you can make yourself or purchase at a specialized store.

- We check the gaps of the contact group of the ignition distributor (look in the technical book of your car) and visually inspect the spark plugs. The latter must strictly correspond to the engine model according to the heat rating.

- We start the engine and let it warm up to operating temperature.

- We use a screwdriver to adjust the screw for the amount of combustible mixture. With its help, you should set the speed within 820-900 rpm . We control their number using a tachometer (built-in or separate).

- We tighten the fuel mixture quality screw. At the same time, it is important to monitor the amount of CO in the exhaust gases (a working engine at a temperature of 20 degrees Celsius produces 0.5-1.2% CO ).

- Use the mixture quantity screw again and set the idle speed.