Advantages of diesel

For off-road use, a diesel engine is preferable. The advantages of a diesel engine over a gasoline engine in an SUV are obvious :

- greater torque achieved at low speeds;

- The fuel consumption of a diesel engine will be lower under similar operating conditions, due to the engine operating in optimal mode;

- The service life of a modern diesel engine before overhaul is higher;

- atmospheric diesel engines without electronic injectors can run on cheap, low-quality diesel fuel;

- The installation of a diesel engine allows the use of large wheels and other main pairs.

At the same time , any diesel engine has its drawbacks : the engine is demanding of high-quality fuel, and the cost of repair and maintenance of fuel equipment will be noticeably higher than that of gasoline. A more powerful engine requires modifications to the gearbox, transfer case, and axle gearboxes. Starting a heavy fuel engine in winter has its own characteristics and often requires special heaters.

Technical characteristics of engines on Niva

Since the domestic car has been so advertised, let's take a look at the technical characteristics of the Niva 2121 internal combustion engine. They are all recorded in the table.

| Parameter | Meaning |

| Power | 87 horses |

| Engine capacity in liters | 1,7 |

| Ecoclass | Different models have different classes. For example, 21214-41 – Euro 3. 21214-30 – Euro 4. |

| Torque | 129 Nm |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Max speed | 142 km/h |

| Cylinder diameter in mm | 82 |

| Piston stroke in mm | 80 |

| Nutrition | Distributed |

| BC | Cast iron |

| cylinder head | Aluminum alloy |

| Lifetime of the power unit | 150,000 km |

| Fuel for operation | AI 95 |

| Cylinder operation | 1-3-4-2 |

| Tact | 4 |

Attention! The closer the Niva engine is produced to the year in which it lives, the higher the environmental class.

The Niva's fuel consumption is as low as all small cars. Car owners often change their gasoline engine to a diesel engine for their Niva Chevrolet. Let's take a look at the advantages obtained by installing this engine and the negative aspects that the owner has to face.

The plant's attempts to introduce a diesel engine

AvtoVAZ considered the option of installing a diesel engine from a foreign car together with the GM concern , however, things did not go further than developments and prototypes.

The following modifications of the Niva are known::

- Version with installation of a 1.9 liter diesel engine from Peugeot. The first experiments were carried out on a 3-door Niva, and a modern turbocharged engine with a power of 120 hp was already installed on the Chevrolet Niva. The engine proved itself to be excellent and showed good dynamic characteristics, while requiring a minimum of modifications under the hood. It did not go into production due to the high cost and complexity of production on the assembly line.

- An attempt to install a Fiat diesel engine with a volume of 1.9 liters and a power of 90 hp. together with the experimental enterprise Tema Plus. The internal combustion engine was combined with a Japanese Aisin gearbox and a native transmission. The resulting hybrid was sold under the designation TURBO-DIESEL until 2009. Production was soon curtailed, and the reasons were poor build quality, poor dynamics, noise, design flaws and inflated prices.

Repeated attempts were made to introduce Chevrolet Niva and other foreign engines , but they did not receive factory approval and certification.

Advice . Niva VAZ212151 with a French internal combustion engine, which had a certificate of conformity and all the necessary modifications, were exported. If you can find such a car, then it will be easier to transfer the power unit from it to the Chevy Niva.

Installation on Niva Chevrolet 2010, 2 liter engine

There is a 2010 Chevrolet Niva with a 1.7 liter engine. We need to install a 2 liter engine. Which engines are suitable (without replacing the gearbox). I heard that I installed an Oplevsky 2-liter engine + transmission from a Suzuki Grand Vitara.

Post edited by slbeliy

— Jun 9 2011, 20:37

I've already seen the Chevrolet fam-1. It is planned to buy a new 2-liter engine (I would like to do this without replacing the gearbox. I saw on the Internet an already tuned VAZ 21213 engine (but it is carburetor). Apart from the engine itself, what else will have to be changed from the electronics (it is enough to change the firmware or completely change the ECU). The gearbox and transfer case So should I change it or not?

Post edited by slbeliy

— Jun 9 2011, 21:54

Messages: 10 211 From: Cheboksary

Do-it-yourself diesel for Niva

The owner of the car chooses which engine can be installed in a Chevrolet Niva, based on the availability of donor units and services that can perform this work. You will have to choose between Japanese or European manufacturers .

Optimal motor characteristics:

- 4 cylinders;

- weight without gearbox – 100-130 kg;

- turbocharging;

- power 90-120 hp

Approximate sequence of installing a foreign engine under the hood of a Chevy Niva:

- Preparing the internal combustion engine and gearbox for installation . Further work will require alterations: a new exhaust system, an engine power system, a cooling radiator and pipes to it, adapters from standard supports to a new engine.

- We dismantle the old engine along with the gearbox and try on a new one in its place. We determine the location of the engine and gearbox supports. If you replace the gearbox with an imported one and leave the old transfer case, then alteration of the transmission is reduced to a minimum. Only the flexible coupling and intermediate shaft will need to be replaced.

- We install the diesel engine in its place , lay out the exhaust tract, fuel pump, and connect the interior cooling and heating system.

- The most difficult stage is connecting the wiring and ECU from the new engine to the standard mounting block and ignition switch. This operation is best left to a qualified auto electrician. If everything is assembled correctly, the engine will start immediately.

- Registration with the traffic police . It is possible to officially register a diesel engine, but you will need an official conclusion from NAMI with expertise. There is no other way to register an internal combustion engine, so it is better not to throw away the old engine; it may be useful for registration actions.

Advantages and disadvantages of a diesel engine

- Good traction performance at low speeds, which allows the Lada 4×4 to overcome off-road conditions even easier.

- Economical. Fuel consumption and its price are significantly lower.

- Increased service life compared to a gasoline engine.

- Increase in vehicle weight.

- Increased vibrations.

- More expensive maintenance (some spare parts are already imported).

One of the available options is the independent installation of a diesel engine on the Niva. To do this, you can use the services of large tuning studios or private professionals who modify cars. You can also install a diesel engine on a Niva yourself if you have some experience and specialized tools.

In the process of selecting a diesel unit, many people wonder which diesel engine to put on the Niva. There are a sufficient number of diesel engines that can be installed on this car. Diesel engines of Japanese and European brands are most often installed on Niva with their own hands. The main requirement is the suitable physical dimensions of the power unit for placement in the engine compartment of the Niva.

The need to make changes to the design begins with the mounting features of the diesel engine. The second nuance is the increase in load on the front axle after installing a diesel internal combustion engine on the Niva, since an engine of this type is often heavier. For this reason, it is necessary to further strengthen both the suspension and the body after placing the engine. Almost always, the standard gearbox will also need to be replaced.

The list of general changes to the design of the Niva for a diesel engine includes: replacement of front engine mounts, modified sump, changes to the exhaust system. The engine cooling system is also subject to modernization. The cooling radiator is often changed (a radiator from a GAZ Gazelle car is suitable).

Changes are also being made to the chassis, individual elements are replaced with reinforced ones. For a regular Niva, they can be borrowed from Niva-Chevrolet. As for the operation of diesel engines, it is separately recommended to install a diesel fuel heating system.

The easiest option for replacing an engine for a Niva car is the Peugeot xud9sd diesel engine. The main advantage of this diesel engine is its fastenings, which are similar to the standard gasoline unit. This feature greatly simplifies the installation of a diesel engine on the Niva. Also, the Peugeot XUD9SD does not require a mandatory change of gearbox, allowing you to use the original VAZ gearbox.

You can also install a Peugeot diesel engine with the xud 11 index on the Niva, but in this case the gearbox will need to be changed. The VAZ gearbox with this engine will not last long. The solution is a gearbox from the Fiat Polonez model. Additionally, you will need to install another clutch. No less often, diesel engines from Japanese cars are installed on the Niva.

The best option would be a diesel engine and gearbox, which were originally designed to work in tandem. In this case, the task is simplified due to the correspondence of all attachment points, as well as the coincidence of the axes of the internal combustion engine and transmission shafts. This approach eliminates difficulties in the process of combining a diesel engine and gearbox, and also significantly increases the service life of the associated components. There is no need to calculate what torque a particular gearbox with different diesel engines can withstand.

Which diesel engine to install on GAZelle and UAZ

Advantages of installing a diesel power unit instead of gasoline or LPG. Choosing a suitable diesel engine for GAZelle and UAZ (UAZ) to replace a gasoline engine.

What to choose - diesel or gasoline engine?

Comparison of gasoline and diesel engines. Advantages and disadvantages of diesel, reliability of diesel engine, features of its maintenance and operation.

Diesel engine efficiency | Why is diesel efficiency higher?

Why does a diesel engine have a higher efficiency compared to gasoline engines? Torque and speed, diesel fuel energy.

Breather oil: cause and solution to the problem

Why oil leaks from the engine breather: signs and main causes of such a malfunction. How to understand why oil is flowing through the breather, troubleshooting.

Gasoline engine works like a diesel engine

Causes of noises and knocks when operating a gasoline engine in different modes. Detonation, knocking of hydraulic compensators, ignition faults and other reasons.

Power increase unit: chip box for diesel internal combustion engine

Diesel engine power increase module. Types of chip boxes, features of connection and operation of these blocks. Advantages and disadvantages of a tuning box.

Disadvantages of the VAZ 21214 engine

Frequent manufacturing defects (defects) of hydraulic supports of valve levers (hydraulic compensators). Due to the low level of technological discipline and technical control at the enterprises of manufacturers of precision pairs for hydraulic mounts, parts are produced with a high number of defects, and when assembling heads at the parent enterprise (machining tolerances are not maintained, foreign objects are present, the clamping of the plunger in the hydraulic mount housing results in non-compliance with the tightening torque when installing into the head). For this reason, if the hydraulic mounts wear out, you have to install a new head complete with hydraulic mounts.

Also interesting: Niva Chevrolet speed sensor - Auto magazine MyDucato

The latest engine modifications are equipped with time-tested hydraulic valve lever mounts from INA. From them we can say for sure that the risk of deformation of the housing during tightening is reduced to zero. The photo below shows a new type of hydraulic support (with M 24×1.5 thread) in detail (body, plunger) and in assembly.

Low service life before major overhaul. Saving on the quality of the materials used, along with the unreliability of components, parts and assembly units, negatively affects the reliability of the motor and its service life.

PS Dear car owners! What weak points and shortcomings did you encounter with this engine?

Replacing Chevy Niva engine components

So, the first method is engine tuning, which involves replacing some components. First of all, this concerns the cylinder-piston group (CPG) and the crank mechanism (CPM), which requires boring of the liners. All this allows you to increase the working volume and, as a result, the power indicator.

First of all, boring is carried out, allowing the inner diameter of the liners to be increased. After this, a selection of pistons and piston rings of appropriate size is made. In addition, the engine is equipped with a crankshaft with elongated arms, as well as shortened connecting rods. Thanks to this, it is possible to increase the piston stroke. All this leads to an increase in volume from 1.7 liters, which the factory Chevy engine has, to 1.9 liters.

But replacing only the crankshaft and CPG motor is not enough. An increase in volume entails the need to increase the combustible mixture supplied to the cylinders and to better ventilate them. For this purpose, the cylinder head (cylinder head) is also subjected to tuning. First of all, the intake and exhaust windows are bored, and the valves are replaced with larger ones. At the same time, the valve seats are bored out and replaced.

Boring of inlet and outlet windows

Additionally, you can completely change the exhaust system by increasing the diameter of the exhaust pipes, and also replace the catalytic converter (catalyst) with a flame arrester.

Note that design changes to the engine will entail the need to reconfigure the operation of the fuel supply system, since with standard configurations and an increased volume, there will not be enough fuel supplied to the cylinders. That is, it will still be necessary to carry out chip tuning.

All this tuning, associated with changes in geometry, allows you to increase engine power by 15% of the nominal. But it is worth noting that an increase in volume will also entail an increase in fuel consumption.

VAZ 21214 engine modifications and their differences

| Motor modification | Availability of power steering | An exhaust manifold | EURO environmental class |

| 21214-41 | welded from stainless steel become | 3 | |

| 21214-34 | _ | cast iron | |

| 21214-33 | |||

| 21214-32* | |||

| 21214-31 | welded from stainless steel become | 4 | |

| 21214-30 | — |

*21214-32 – has fuel pipes with quick connectors, a flywheel for the clutch of 215 mm (200 mm on other models).

The geometry of the cylinder block 21214 and 21213 is the same. There are no liners in the cylinders. Due to the use of an ejector, the configuration of the front engine cover has been changed to accommodate the installation of a crankshaft position sensor. To mount the power steering, a hole is made on the block for installing a bracket; in addition, there is a threaded hole for installing a knock sensor, as well as threaded holes with studs for mounting the ignition module bracket.

The ShPG came from 21213. Crankshaft 21213-1005015 sets the piston stroke to 80mm. The crankshaft pulley is distinguished by the presence of teeth along the outer diameter for the operation of the crankshaft position sensor. The latest internal combustion engine models are equipped with a damping pulley (21214-1005058-10). The presence of a damper made it possible to reduce the load on the crankshaft to prevent cutting of the key, and also make the operation less noisy.

Cylinder head 21214-1003011-30 (36) was modified from the head from 21213. For modification, it was necessary to introduce holes for installing a phase sensor and studs for mounting the intake receiver. To install hydraulic compensators, bosses are cast in the head and have threaded holes in them. With the introduction of hydraulic thermal gap compensators, adjusting bolts were eliminated from the head design.

Oil under pressure is supplied to the hydraulic compensators through separate pipes. There are two types of heads: Russian 21214-1003015 and Canadian 21214-1003015-30. The differences between the heads are as follows: in the first, the diameter of the threads in the holes for hydraulic compensators is M18/1.5, the wells for hydraulic compensators do not have drainage holes;

Also interesting: How to properly use the transfer case on Niva 2121

the second ones have M24x1.5 holes, and the wells have drainage holes (the markings are made in the casting). Interchangeability of heads, as well as hydraulic supports of old and new designs, is not possible. A new oil rail 21214-1007180-30 made of stainless steel is used, supplying oil to the hydraulic compensators. Interchangeability with ramp 21214-1007180 is maintained.

Valve levers 21214-1007116-30, in contrast to the previous 2101-1007116, have a smaller radius (11 mm) of the platform support interacting with the camshaft cam, as well as an additional groove on the side of the hydraulic compensator. Both lever options are interchangeable.

In the timing camshaft drive, instead of a double-row chain, a single-row chain 21214-1006040-03 is used on rollers and bushings. Single-row sprockets for the chain are taken from the 2123 engine. The oil pump sprocket has the number of teeth reduced to 30 to increase the performance of the oil pump and improve the operation of the hydraulic chain tensioner and hydraulic compensators.

The camshaft 21214-1006010 is original with a modified cam profile and can be interchanged with the shaft from 21213.

The 80 amp generator is the same as the 2112, with a slight difference in the diameter of the pulley 80 mm for the drive belt 2107-1308020 (944 mm).

The exhaust manifold can be made of cast iron or stainless steel. The cast iron manifold is made by casting. The stainless steel manifold version has a welded design. A welded manifold is lighter and heats up quickly, which is good for the operation of the catalyst located in the manifold. In addition, an oxygen sensor is installed in the exhaust manifold.

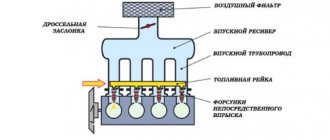

The intake manifold and fuel rail (2123-1144010-11) were borrowed from the 2123 engine. The injectors of the fuel injection system are SIEMENS VAZ 20734 (yellow), injectors (0280 158 110) were installed on early engines.

Ignition module from engine 2112.

Electronic control is carried out by the BOSCH MP 7.9.7 ECU. or JANUARY 7.2 depending on the year of manufacture and modification of the internal combustion engine.

The cooling system began to be assembled using gaskets with an elastic polymer bead, which improved the tightness of the system. The water pump (pump) includes an oil seal (cuff) that is more resistant to wear and loss of properties.

Which diesel engine is suitable for Chevrolet Niva

The dimensions of the engine compartment will not allow installing an engine with a volume of more than 1.5-2 liters . Therefore, diesel engines for the Chevrolet Niva are modifications of engines from passenger cars and small delivery trucks. Among the successful models there are both with and without turbocharging.

The most popular option for replacing a diesel engine is the installation of a Peugeot engine of the xud9 SD, xud11 SD models with a volume of 1.9 liters . A popular option is with a Toyota 3c series engine and a Noah gearbox. There are options for implanting propellers from Fiat, Toyota, Volkswagen and other foreign cars.

The main difficulty in installing an engine on a Niva is adapting the imported unit with a domestic gearbox and placing it in the engine compartment. The design features of the Chevrolet Niva (all-wheel drive, original transfer case) do not always allow the placement of the desired engine.