Intake manifold removal process

Dismantling the intake manifold is carried out with the car cooled down for safety reasons. So, this operation can take about an hour and will require some knowledge of the car’s design, namely the injection system. So, let's consider the sequence of actions for dismantling the unit:

- We dismantle the throttle. To do this, it is not necessary to disconnect all the pipes and pipes; it is enough to disconnect the unit from the manifold and move it to the side. Of course, at the same time, it is still recommended to remove the throttle valve completely for cleaning.

- Disconnect the throttle cable from the intake manifold.

- Disconnect the wires from the ignition coils. This is easy to do; you just need to disconnect the connectors.

- Disconnect the camshaft position sensor wires.

- Disconnect the wiring harness from the absorber purge valve.

- Disconnect the brake booster hose from the intake manifold.

Unscrew the clamp and disconnect the vacuum brake booster tube

- Unscrew the clamp and disconnect the crankcase ventilation pipe.

Unscrew the crankcase ventilation tube clamp

Unscrew the clamp and pull the tube out of its seat.

- Unscrew the self-tapping screw securing the guide tube of the oil level indicator.

Using a Phillips screwdriver, unscrew the oil level indicator guide tube

- We take out the dipstick along with the guide tube.

Dismantling the dipstick

- Using a socket or a 10mm wrench, unscrew the nuts securing the intake module and the ignition coils of cylinders 1, 2 and 3.

Unscrew the ignition coils and receiver

- We dismantle the ignition coils of cylinders 1, 2 and 3.

- Now, you can unscrew the direct fastenings of the intake manifold to the cylinder head.

Unscrew the bolts securing the manifold to the block head

- Move forward and remove the manifold.

Pull the collector towards you and dismantle it

It is worth noting that installation of the intake manifold is carried out in the reverse order and does not require any additions or changes.

Video

This is interesting: Replacing a windshield is an opportunity to tune a car

Device

Although from the outside the intake manifold appears to be just a pipeline of a specific shape, in fact a whole team of engineers works on its geometry, calculating the cross-section, length and volume.

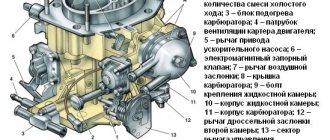

Plus, it includes:

- Throttle valve;

- Supply chamber;

- Air filter;

- Inlet valve;

- Discharge chamber.

For engines with distributed fuel injection, injectors are additionally installed in the intake manifold, due to which the mixing of fuel and air masses occurs directly in the discharge chamber.

The pipeline itself can combine from 2 to 12 channels, depending on the number of cylinders in the engine block. At the same time, for a 4-cylinder engine, a manifold with three pipes is sometimes used.

It is also worth noting that most modern intake manifolds over the past 5 years have been made from special high-temperature plastic, while the exhaust manifold can still only be made from metal.

How to check engine air leaks

Finding air leaks will be difficult if you don’t have a special device at hand to show leaks. One of these devices is called a smoke generator; it makes diagnostics much easier and is not that expensive.

Previously, air leaks were determined by eye. We spilled liquid on the intake manifold while the engine was running and looked for bubbles. If you have extensive experience working with a given brand of car, then you can use this method. The downside is that while the engine is running, liquid spilled on the collector will also bubble due to temperature and you can make a mistake. If at this moment the internal combustion engine is shaking, the situation becomes more complicated. If there is a slight loss of tightness, this test option may not help.

You can check the air leaks on the carburetor by covering the top with your hand or a rag, having first removed the housing with the filter. If the engine stalls, there are no leaks. If it continues to work, then there is an air leak and it needs to be eliminated. As a rule, on the carburetor, a lower plate leads along the plane, which is tightened with the manifold. It can be sanded or replaced with a new one. This procedure is sufficient to determine whether the carburetor is leaking.

Let's return to modern cars, where checking air leaks can take a long time and detecting a leak is not easy. The basic principle of detecting air leaks in the engine is to inject smoke into the intake manifold, which will come out where there is a crack, a loose pin or a torn rubber band. Checking an internal combustion engine with a smoke generator takes some time and takes place in several stages:

- Finding the inlet fitting or any other location on the intake manifold. This is necessary to connect the device itself and supply smoke. It can be difficult to find such an input and you have to use the vacuum booster channel on the intake manifold. With this connection, it is impossible to determine the air leakage from the shaft.

- Next, you need to fill the smoke generator with engine oil. The operating principle is based on heating the oil with a diesel glow plug. You can use any motor oil you have on hand. The main thing is not to overheat the candle, constantly turn the power on and off, or install a pulsed source.

- The standard design of the smoke generator involves supplying air to build up pressure through a compressor. You can use an electric pump from a car, or any other that creates a pressure of at least 1 atm.

- Plug the inlet pipe between the throttle body and the air filter. You can use the housing from an old mass air flow sensor. Fill it with polyurethane foam and you will get an excellent plug.

- Having completed all the preparatory procedures, turn on the device. After smoke under pressure fills the receiver and intake manifold, an air leak will immediately appear. It is advisable to use a flashlight to better see the smoke coming out and the location of the leak.

A smoke generator can be used not only for diagnosing cars and air systems. And also for finding leaks in mattresses, inflatable pools, etc.

Thus, it is easy to check air leaks with a smoke generator. This is a very important and convenient procedure for troubleshooting the engine. Many diagnosticians ask questions about fuel correction when air leaks occur. This is one of the general indicators on the scanner and can indicate not only a leak, but also low compression and shifted valve timing.

There are other ways to check for air leaks with smoke. One of them is using a cigarette. There is even a special tool for this. It is a pistol for a compressor with an internal clip into which a cigarette fits. When you press the trigger of the pneumatic pistol, the cigarette lights up and emits copious smoke. The disadvantage of this method is that it burns out very quickly and there may not be enough time to catch air leaks in the engine and injector. But this option of checking air leaks with a cigarette also has its place.

You can determine air leaks in any engine using the old-fashioned method, by spilling liquid on the intake manifold and the injector area. Or the option with a cigarette, but all these methods are not accurate and not convenient.

The smoke machine itself costs a lot of money. Therefore, if your internal combustion engine shakes or the speed fluctuates, go to a service center that has a smoke generator. They will definitely help you identify the cause without extra costs.

What are swirl flaps used for?

As you know, it is not the fuel itself that burns in the cylinder, nor the air. The air-fuel mixture is burning. And the more homogeneous this mixture is, the better it burns, the higher the efficiency and economy of the engine. Accordingly, the question arises: what is the best way to mix this very fuel in the cylinder? Nozzles that supply fuel not with one large and thick stream, but even with a dozen small streams protrude from one side. And on the other side we have air supplied. And if this air is applied with force, and even at a tricky angle, you get a whirlwind. Which will mix everything perfectly and burn just as well.

But then the engineers faced a question: if they make the hole for the air supply narrow, then at low speeds the vortices will be excellent. But when the speed increases, too much air deficiency will form and too much energy will be spent on its supply. If you make the hole wide enough to operate at medium and high speeds, then there will be no swirl at low speeds, and the engine efficiency will again decrease.

Therefore, for optimal engine operation in all modes, the air supply was divided into 2 parts. In one part there are no dampers, and it is always freely blown, while the second part has the same damper that is completely closed at low revs and opens wider the higher the revs.

The figure shows a diagram of the operation of swirl flaps at low speeds. Air is supplied through only one channel. The second channel is completely closed.

As the engine speed increases and the engine requires more air, the second damper gradually opens slightly, controlling the strength of the air flow. A fully open throttle at high speeds is shown in the figure below:

The position of the swirl flaps is controlled by an integrated sensor and a corresponding drive that changes the angle of inclination of these flaps.

Check Engine

Often, a decent amount of air leaking through the joints of the intake pipe even causes the Check Engine indication to appear.

The corresponding error code will indicate that the air-fuel mixture is too lean. Other culprits for this problem are worn gaskets at the junction of the pipeline and the cylinder head. Often, a decent amount of air leaking through the joints of the intake pipe even causes the Check Engine indication to appear. The corresponding error code will indicate that the air-fuel mixture is too lean. Other culprits for this problem are worn gaskets at the junction of the pipeline and the cylinder head.

Constructive

Metal intake manifolds are cast as a single unit or made into multiple parts. In the latter case, the connections are sealed with sealant or gaskets are installed. Accordingly, they can always be updated by halving the composite manifold.

Plastic collectors are always composite. Production technologies do not allow producing such units as monolithic ones. In most cases, such collectors are actually non-separable: the joints of the connections are soldered. Although there are still more thoughtful designs with the ability to painlessly separate into parts and replace rubber gaskets.

Action plan

As a rule, the joints of plastic elements are more capricious. If the collector is dismountable, then its tightness can be easily restored. True, in most cases the assembly has to be removed from the engine. And in the case of a “monolithic” collector, you will have to think about ways to seal it.

The most reliable option is plastic welding. This is a technology that, for example, is used to repair cracks and tears in bumpers. However, this option can be expensive when it comes to large restoration areas. In this case, it is sometimes cheaper to buy a new or used manifold. If you do this on your own, you will have to spend money on expensive equipment: a special construction hair dryer and a Dremel (straight grinder or drill).

A simpler option is to arm yourself with a soldering iron and solder a plastic seam onto the joint. For example, pieces from a plastic measuring bucket for liquids are suitable for this. All you really need here is patience.

The quickest and easiest way is to seal the joints with sealant. True, this method is least preferable for supercharged engines. Their intake air pressure in some operating modes is significantly higher than that of atmospheric engines. Therefore, any sealants can weaken, and soldering is more suitable for a supercharged engine.

Restoring the tightness of the intake system on the editorial Kalina

Oil leaks through the joints of the intake pipe not only spoil the appearance of the engine compartment, but also affect the operation of the engine. However, you should not rush and immediately change the leaky element.

LADA > Kalina

Even with a working crankcase ventilation system, a certain amount of oil will get into the intake manifold - as this system is commonly called in everyday life. There is nothing criminal about this. Over time, the tightness of its joints is broken and liquid can seep out. In addition to the aesthetic aspect, this is also reflected in the operation of the motor. Through the cracks not only oil presses, but also air leaks. Most often, this leads to uneven engine operation (slight tripping) at idle speed.

Tuning

Tuning and changing geometry are two different things. When people talk about modifying the intake manifold, they usually mean increasing the incoming air volume and reducing the resistance along its path.

For this purpose the following procedures are provided:

- Replacing the air filter with a zero resistance filter. Thanks to the macroscopic holes in the latter, air is retained less and, accordingly, the speed and volume of passage increases;

- Enlargement of the throttle pipe. It also aims to increase air permeability. Usually, for this purpose, a damper is installed from another engine, which is more powerful than the original;

- Installation of a sports receiver. Short tubes with a larger cross-section, when properly configured, can reduce the pulsation of air masses, which allows the engine to gain speed faster.

There is also a tuning option when the intake manifold is completely removed and short pipes tuned to high speeds are installed instead. This option is provided only for naturally aspirated engines and is called a multi-throttle intake (that is, each cylinder essentially has its own manifold).

By the way, any changes in the intake system usually entail upgrading the exhaust manifold, camshaft and firmware of the electronic control unit.

This is interesting: Antifreeze - domestic antifreeze in all its details

We remove the manifold ourselves

Basically, to repair or replace a part, you need to know how to dismantle the intake manifold. In principle, this task is not difficult, and you can cope with it in literally 10 minutes. We find the fuel pump and remove the fuse from it, and then start the engine. This will cause the pressure in the system to drop and the engine will gradually stall. After this, you can disconnect the battery and remove the decorative casing from the engine. Now you should remove the pipes from the air filter and remove it. Then you should unscrew the throttle assembly, but without touching the damper fasteners. Now you have reached the collector.

Next, in case of detachment of the square tube, it is necessary to drill two holes in the manifold (the drill diameter is taken to be 4 mm) so that this tube can be reached through them. Then we screw screws into these holes, fixing it. The dampers and control valve cannot be replaced separately or repaired, so you have to buy and install a new part entirely. If the cause of the breakdown is found in the sensor, then the failed element needs to be replaced.

Source

Malfunctions

Like any other mechanical part, the intake manifold is susceptible to failure. Given the simplicity of the design, there are not many options for malfunctions.

Basic:

- Violation of tightness. Vibrations, pressure and high temperatures destroy seals over time. Depressurization affects the quality of the fuel mixture, loss of traction and speed. The problem is solved by replacing the gaskets, after which engine operation should return to normal;

- Collector contamination. Plaque accumulates on the walls, gradually reducing the cross-section of passing air masses. Requires disassembly and cleaning of tubes, throttle and discharge chamber;

- Mechanical damage. If the collector is made of plastic, it is only a replacement. If it is made of aluminum and the damage is small, argon arc welding will help;

- Excessive temperature in the manifold. There are a lot of reasons and you need to look for them in the cooling system, clogged radiator, damaged sensor, ECU error. Also, high temperature occurs due to the banal heat outside;

- "Clap." When forming the fuel mixture, the system must be sealed. If there are disturbances in the ignition system, the gas distribution mechanism, problems in the fuel mixture formation chamber, or the tightness of the intake manifold itself is broken, you can hear those same pops. It is worth looking for reasons in all of the above places.

In the latter case, of course, it is easier to rely on the errors reported by the ECU or sign up for a comprehensive diagnostic service.

Differences in collectors by motor type

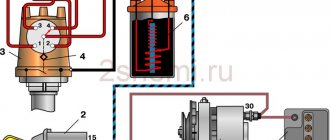

The main difference between intake manifolds on diesel power units is that only air moves through them. On a gasoline engine, everything is a little different. In a carburetor engine, there will be a ready-made fuel mixture in the manifold. If the engine is injection, then the mixture is formed directly inside it.

On carburetor and diesel engines, the intake is simply a system of pipes, inside of which there is minimal aerodynamic resistance. In an injection engine, the intake manifold is created by analogy with a Venturi tube. This is an ordinary sprayer, where the air flow carries the liquid with it and then sprays it. Due to this, it was possible to achieve better atomization and mixing of the air-fuel mixture than direct injection of liquid gasoline into the combustion chamber.

Types of installed collectors

There are a huge number of different types of collectors. The main classification is carried out according to the type of material used in the manufacture:

- Cast iron.

- Aluminum.

- Iron.

All of these designs have their own operational features that need to be taken into account. For example, cast iron is considered the most durable material, but at the same time it significantly increases the weight of the car. Aluminum versions are lightweight, but when heated, due to increased ductility, they become less durable.

Recently, composite materials have been used in the manufacture of the element in question. This is due to the fact that they can withstand loads and mechanical stress, have low thermal conductivity and are lightweight. The surface of such materials does not accumulate pollutants due to its smoothness.

In most cases, heating of the manifold leads to deterioration in engine performance when operating at high speeds. Heating may occur due to clogging of the structure.

Too high a temperature of the air that enters the cylinder block leads to a lean mixture and increased fuel consumption. Cleaning the collector eliminates the possibility of such a problem occurring.

Lada Kalina from ZR park

Lada Kalina 2 from the ZR park

Lada Kalina 2 from the ZR park

Are there any volunteers?

Armed with theory, we will repair the intake system on the editorial Kalina. The composite plastic path of the 1.6 naturally aspirated gasoline engine (106 hp) leaks around the perimeter of the wells for the ignition coils. Apparently, these are the consequences of frequent tests on the Smolensk Ring race track, in which the car and especially its engine were driven to the limit of their capabilities.

How does he work

The intake manifold is a complex structure that allows fuel and air into the engine.

Upon arrival, they are distributed into streams depending on the number of cylinders in the engine. Moving pistons create a vacuum that reaches a maximum at its lowest point. This creates a virtual vacuum, which neutralizes the crater gases.

The intake system has changed greatly during the evolution of the automotive industry.

So, its structure has come to us in its current form:

- frame;

- air intake;

- pipe branch;

- throttle valve;

- muffler;

- intake manifold;

- pad.

It turns out that the collector itself is part of an important system that ensures the proper functioning of the engine. Its place is on the left side of the cylinder head. To monitor the pressure and temperature inside, sensors are installed on it. The calculations are carried out by the control unit, which also generates commands.

One of the functions of the intake manifold is the redistribution of the fuel-air mixture between the cylinders in the engine.

The main problem for all car enthusiasts was overheating of the intake manifold; for this reason, heated air expands, and its input volumes are significantly reduced. Thus, fuel consumption increased, and the quality characteristics of the engine decreased. Then the technicians decided to make most of the structure from plastic, which alleviated the problem. But still, in order to avoid breakdowns and other troubles, this compartment must be cleaned in a timely manner.

Why you need to clean the intake: diesel and frequent problems due to soot

Owners of cars with a diesel engine are well aware that any malfunctions and deviations in the operation of this type of internal combustion engine require immediate diagnosis and elimination. The fact is that even short-term operation of a diesel engine that has begun to bleed, smoke, etc. can soon lead to much more serious consequences.

Taking into account the fact that repairing a diesel engine is more difficult than a gasoline engine, and many spare parts are significantly more expensive, it becomes clear that during operation it is necessary to regularly check the injection pump and injectors, as well as carry out preventive diagnostics of other expensive elements (for example, a turbocharger).

However, even if certain malfunctions suddenly become noticeable (thrust is lost, speed jumps appear, black thick smoke comes out when changing the gas, etc.), such signs do not always indicate that complex and expensive repairs are necessarily necessary. In other words, the owner should not get upset right away, since the solution to the problem may turn out to be very simple.

The fact is that in many cases, the culprit of diesel engine malfunctions is banal dirt and deposits that accumulate in the intake tract. In this case, the diesel engine behaves as if the unit has reached critical wear.

- As for the reasons for intake contamination themselves, there are quite a lot of them. In the CIS, the culprit can usually be considered to be low quality diesel fuel, low cetane number, and the presence of additional impurities. As a result, all conditions are created for increased carbon formation and coking.

- Also, do not forget that to reduce exhaust toxicity, all modern diesel engines have an EGR system, that is, there is a special EGR valve in the intake manifold, which allows for exhaust gas recirculation.

In short, when the engine is running under light load, this valve allows some of the exhaust to enter the intake and mix with the air that is supplied to the cylinders. As a percentage, about 15% of the exhaust gases make up a share of the total mass of the fuel-air charge.

Due to the fact that there is no oxygen in the exhaust added in this way, the combustion rate of the fuel-air mixture slows down, as a result of which the combustion temperature also decreases. This leads to a decrease in nitrogen oxides (NOx) in the exhaust gases.

In addition to environmental objectives, the recirculation system also reduces the risk of detonation in those modes when the diesel engine operates at extremely lean mixtures. The USR system is turned off (the valve for supplying the exhaust to the intake is closed) occurs when the engine is under high or constant loads, that is, an exclusively “rich” power mixture is needed.

In practice, the engine does not operate often in such modes, especially in the urban cycle. It turns out that the constant supply of exhaust to the intake occurs very often and leads to the fact that a lot of soot settles in the intake manifold, which accumulates on the walls. Thus, contamination of the intake tract in a diesel engine is inevitable and the owner needs to be prepared for this.

- Let us also add that the breather of the crankcase ventilation system, which also discharges excess crankcase gases into the intake, is also involved in additional contamination of the intake manifold. As you know, there is oil mist in the crankcase, and oil traps are not completely capable of retaining all lubricant particles.

It turns out that not just soot accumulates in the intake, but oily dirt, which actively contaminates all surfaces and the EGR exhaust gas recirculation valve itself.

It is important to understand that if the valve begins to “hang” or jam, exhaust gases can be constantly supplied to the intake manifold, that is, this will happen in all modes. Naturally, in such a situation one should not expect traction from the engine, but acceleration dynamics from a diesel car.

- Let's move on. Having highlighted the USR system and crankcase ventilation among the common causes of contamination of the intake tract of a diesel engine, it is also worth adding faulty glow plugs. The fact is that if the spark plugs do not work correctly, then starting a cold diesel engine becomes very difficult. Diesel fuel begins to enter the intake manifold, which further pollutes the intake.

Taking into account the above, it becomes quite obvious that over time the intake manifold becomes covered with a dense oily layer of dirt, as a result of which the diesel engine begins to operate unstably, loses power, produces smoky exhaust, etc.

Main signs of pollution

It is recommended to periodically clean the interior surface. This is due to the fact that it is almost impossible to avoid the formation of soot on the surface; during long-term operation of the car, the collector becomes covered with a layer of soot several millimeters thick. Some signs may also indicate the need for cleaning:

- All carbon deposits that form remain inside the structure and accumulate over time, reducing throughput.

- Fuel consumption increases significantly. In order for the consumption to be within the normal range, the combustible mixture must consist of a certain amount of fuel and air. In addition, an incorrectly enriched mixture reduces the main performance indicators of the internal combustion engine.

- Power decreases and acceleration dynamics are lost. It is quite difficult to determine the drop in engine power, since it occurs gradually. Only when diagnosing a vehicle can the power rating be determined.

- At low speeds, vibration and shaking may occur. Due to a decrease in throughput, pressure increases, which leads to vibration.

- The car idles poorly and the revs drop. A situation often occurs when the engine almost completely stalls at idle. This also occurs when the fuel mixture is poorly enriched.

- In some cases, contaminants crystallize, break off, and end up on the valve. Contamination of the valves complicates their movement, causing strong knocking and noise. The accumulated mass on the valves complicates their movement.

If you continue to operate the vehicle when the manifold and valves are heavily contaminated, there is a possibility of damage to the hydraulic compensator. Experts recommend performing the cleaning procedure every 2-3 years.

Severe contamination of the intake system occurs due to high oil consumption when the cylinder-piston group is damaged. This further aggravates the current situation; the engine finally loses its quality.

Cleaning the intake tract of a diesel engine

As you can see, it is almost impossible to get rid of all the factors and causes that lead to intake contamination. It turns out that to solve the problem, the best way is to comprehensively clean the intake manifold and other intake elements.

You can go two ways:

- disassemble the intake and physically remove dirt and soot;

- use cleaning methods without disassembling the internal combustion engine;

We also recommend reading the article on how to clean the particulate filter on a diesel engine. From this article you will learn about the features and nuances of the particulate filter cleaning process.

Naturally, most drivers will choose the second method. So, to achieve the desired result, an intake tract cleaner for diesel engines is used, which is a specially designed product to combat oily deposits of dirt and soot.

The product is supplied to the inlet under pressure using a special installation with a compressor. This allows you to carry out all cleaning work without having to disassemble the motor and remove parts. In this case, it is possible to clean the intake manifold, remove deposits, remove soot and carbon deposits from the intake valves, etc.

Simply put, the device is connected to the intake system, then the engine is started and the engine is allowed to run for about 120 minutes. At the end of the cleaning procedure, the diesel engine begins to operate more stably, fuel consumption decreases, the power unit stops smoking, power returns, and throttle response appears.

silicone sealant

Universal silicone sealant.

Most of these tubes are equipped with a convenient nozzle. By cutting off part of the spout, you can select the desired diameter of the hole so that the sealant fits well into the joints. Universal silicone sealant. Most of these tubes are equipped with a convenient nozzle. By cutting off part of the spout, you can select the desired diameter of the hole so that the sealant fits well into the joints.

Ramp

Replacing the cathode collector on a VAZ 2110

The ramp is removed as an assembly with the fuel pressure regulator:

- It is necessary to disconnect the vacuum hose from the regulator.

- Using 2 open-end wrenches 17, unscrew the fittings securing the gasoline supply pipes to reduce pressure.

- Disconnect the ramp voltage connector.

- Using a screwdriver, unscrew the screw of the bracket for fastening the gasoline supply and outlet pipes and disconnect it.

- Using a No. 5 hexagon, unscrew the 2 screws for fastening the ramp.

- Pull the ramp in the axial direction of the injector from the seat, remove the ramp towards the left side of the hood.

Note: follow the direction of travel of the vehicle.

Replacement cathode collector for VAZ 2110

- Unscrew the nut from the left intake manifold bracket and loosen the lower bolt.

- Remove the bracket from it.

- Perform the same operation with the right bracket and remove it.

- Unscrew the 2 nuts from the eye stud.