Rear axle gearbox on VAZ 2107: design, repair, replacement

The occurrence of extraneous noise in the rear part of the VAZ 2107 engine (humming) while driving may be a signal of problems in the rear axle gearbox or axle shafts. Even if the oil change in the rear axle is carried out in accordance with the requirements of the regulations, wear of its parts is inevitable. In order to ensure that the diagnosis is correct, a number of additional measures should be performed:

- When driving on a flat road, you should ensure smooth acceleration of the VAZ 2107 from 20 km/h to 90 km/h. In this case, it is necessary to note for yourself the appearance and disappearance of extraneous noises in the rear, the driving speed at which they appear and disappear. Next, you should release the gas pedal and apply engine braking. In this case, it is again necessary to monitor the appearance and disappearance of noise.

- Having accelerated the car to a speed of approximately 100 km/h, you need to switch off the gear, turn off the engine and let the car roll by inertia. Again, we notice a change in noise in the chassis. If the chassis hums as noted when performing step 1. - this indicates that there are no problems in the main gear and rear axle differential. If the noises detected in step 1 are absent when performing step 2, then everything is not so good with the rear axle of your car.

- Having placed the VAZ 2107 on the handbrake and secured it with wheel chocks, start the engine and ensure a gradual increase in speed. If the noise is the same as in step 1, it means that the gearbox is fully operational and you should look for the problem elsewhere.

- If the noise that you heard during the first test could not be repeated using another method, then you will have to take a closer look at the gearbox. You can verify that the conclusions drawn are correct by starting the engine, engaging the gearbox in fourth gear and releasing the clutch, thereby activating the entire chassis. This will allow you to hear the gearbox hum.

Removing the gearbox

Before starting work, that is, before starting to remove the rear axle gearbox of the VAZ 2107, it is necessary to drain the used oil from it. To do this, you need to unscrew the drain plug at the bottom of the rear axle, first placing a container to collect the oil. Typically, repairs involve replacing used oil with new oil.

Next, unscrew the screws securing the propeller shaft flange and disconnect it from the shank. Jack up the rear of the car and remove the rear wheels. After unscrewing the guide screws, remove the brake drums to gain access to the axle shafts. Having unscrewed the bolts securing the axle shafts (4 pcs.), we remove the axle shafts from the rear axle, thereby completely freeing the gearbox. All that remains is to unscrew the bolts securing the gearbox to the rear axle beam and remove it. After removing the axle shafts, it is recommended to check whether the bearings require replacement.

Repair and adjustment

Both repairs and subsequent adjustments require special skills and professional equipment; stands, pullers, special tools. Therefore, we will consider only the general principles by which repairs and post-repair adjustments of the gearbox are carried out in order to assess the required amount of work and the costs of purchasing spare parts.

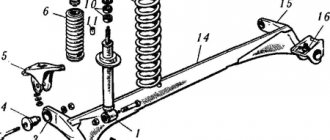

The gearbox structure can be viewed in the following diagram:

Disassembling the gearbox begins with unscrewing the shank nut. After removing the flange, the drive gear with adjusting rings, oil seal, oil deflector, and inner bearing ring are removed. Then we press out the outer rings of the bearings. Lastly, the drive gear and differential are disassembled. When completely disassembled, the spacer sleeve is discarded.

It is not recommended to carry out the work described above related to disassembling the VAZ 2107 gearbox, due to its complexity. This is a rare case when you shouldn’t skimp on the services of specialists.

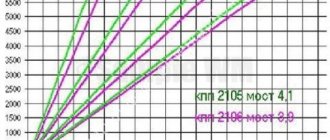

Most often, the bearings and the main pair of this unit fail, for which replacement with new ones is provided. It should be noted that it is the main pair that determines the gear ratio. There are three standard varieties of the main pair, with different gear ratios. The higher this number, the higher the power; the lower, the higher the speed of the gearbox. When replacing these parts, the spacer sleeve must be replaced, since it is disposable.

Some car enthusiasts use final drives as a way to tune their cars. By installing a main gear with a reduced gear ratio in the VAZ 2107 gearbox, they significantly increase the maximum speed of their car. In principle, the gear ratio can be selected for all rear-wheel drive cars without exception, guided only by your own needs. The gearbox of the VAZ 2102 had the largest gear ratio - 4.4. But after it was discontinued, finding a main pair with the same gear ratio became extremely problematic.

Repair is not advisable in all cases. For a rear axle gearbox that is too worn, it is more profitable to completely replace it with a new one. The difference in price will be compensated by the reduction in the cost of work performed by specialists and the durability of the new unit.

How much does it cost to repair and replace the rear axle gearbox of a VAZ 2106

In 90% of cases when contacting a car service center with problems with the rear axle and, in particular, the gearbox of classic Zhiguli cars, the owners are refused. The maximum that most experts can offer is to buy a new VAZ gearbox. There is only one reason for this - basic technical ignorance, because only a few will be able to correctly diagnose and adjust the rear gearbox of a classic. A new gearbox can be bought for 6-7 thousand, it will be a branded factory mechanism, after disassembly the price of the unit will be about 3 thousand, and on hand or on the market a gearbox with traces of long-term use will cost about 2000 rubles.

Only a few can correctly diagnose and adjust the rear gearbox of a VAZ 2106

It’s easier to sell a new one than to adjust or restore an old one, especially since this requires certain knowledge, and it costs the same as a qualified adjustment. Therefore, we decided to theoretically educate the owners of classic Zhiguli cars, so that if something happens, you can confidently remove, adjust, repair and install a full-fledged working unit with your own hands. But first, a few words about the design of the gearbox.

About replacing the rear axle gearbox of a VAZ 2107

Extraneous noises that arise under the bottom while driving signal the occurrence of troubles with the gearbox “adjacent” to the rear axle. Even timely replacement of lubricant in the axle does not affect the failure of its parts, so replacing the rear axle gearbox of the VAZ 2107 is inevitable. In order to verify whether the “diagnosis” is correct, it is necessary to dismantle the gearbox, disassemble it, if necessary, carry out repair work, reassemble it, reinstall it and configure it. But here's the question...

Features of replacing the rear axle gearbox

If you are convinced that such an important unit is faulty, then only replacing the rear axle gearbox of the VAZ 2107 can help out. In principle, this work can be easily done with your own hands:

- Drive the car onto the overpass (you can work in a pit in the garage).

- Place wheel chocks under the wheels (if you don’t have them, you can put regular stone or brick).

- Drain the oil from the gearbox (before doing this, it is advisable to drive the car a little to warm up the lubricant).

- Wait until all the oil has drained from the assembly.

- Remove both rear wheels one at a time and install supports.

- Remove the brake drums and axle shafts (it is better to remove the latter rather than leave it dangling from the car).

- Unscrew the gearbox and cardan.

- Make sure the gasket is intact and, if necessary, treat it with sealant.

- After 10-15 minutes, install a new gearbox and assemble everything in the reverse order.

- Add oil.

That's all. Now you know why a rear axle gearbox is needed, how to determine its malfunction and replace it. Good luck on the roads and of course no breakdowns.

The rear axle of the VAZ 2107 must be removed to repair the gearbox or to completely replace it in the event of its complete failure. It is most convenient to carry out work in a pit, and the car must be installed in such a way that the rear axle gearbox is not above the pit.

Having driven the car into a pit, hang the rear part of the body so that you can remove the wheels. Place a jack under the gearbox and raise the rear axle slightly. In this situation, do the following:

- Disconnect the rear shock absorber lower mounting brackets.

- Drain the transmission oil from the gearbox into a previously prepared clean container.

- Disconnect the brake pressure regulator mounting bracket, then disconnect the tee with brake pipes from the bridge. Remove the rubber hose for the hydraulic brakes.

- Next, you need to disconnect the driveshaft from the gearbox drive flange. Before unscrewing the nut of the fastening bolts, apply a mark to the propeller shaft and the gearbox flange, which you will use as a guide during assembly if the axle is removed for repair and not replacement.

- Lower the rear axle a little with a jack to loosen the rear springs and remove them along with the rubber gaskets.

- Disconnect the parking brake tips from the brake flaps.

- At the final stage of removing the rear axle, all that remains is to disconnect the upper and lower reaction rods, as well as the transverse rod. Place shims under the axle so that when the axle is disconnected, it rests on them and remove the rear suspension rods.

Where is the gearbox located?

On the "sevens", as on all representatives of the rear-wheel drive family, the gearbox is located at the rear, under the bottom of the car. It connects the cardan to the VAZ 2107 axle and causes the wheels of the car to rotate. Rotation occurs thanks to axle shafts engaged in the gearbox, which, due to the technical features of the rear axle of the VAZ 2107, will have to be removed later. If the car is lifted, or when viewed from a garage pit, the gearbox is simply impossible not to notice.

Signs and malfunctions of the classic rear axle gearbox

Replacing a gearbox with your own hands is a labor-intensive process, which includes not only the purchase of a new unit (quite expensive), but also time costs. Therefore, before you start, you need to make sure that the gearbox is faulty. You can define the signs like this:

- gradually accelerating the car, listen carefully and remember at what moment the noise appears;

- while driving, start engine braking (remove your foot from the gas pedal at speed), at this time listen to the gearbox and note the moment the noise appears;

- accelerate the "seven" to hundreds, switch to neutral and turn off the engine - listen to how the gearbox behaves while coasting.

“If the bridge is noisy both in neutral and at speeds, the gearbox has nothing to do with it. If the hum occurs only at speed (regardless of the number), repairs, or, as a last resort, replacement of the gearbox are inevitable.”

When the signs are identified, it is necessary to carry out another check:

- park the car, secure the front wheels with shoes;

- jack up the rear so that the bridge hangs over (it is necessary that the wheels come off the surface);

- start the engine and accelerate the “seven” to the point at which noise occurs, while the wheels should spin without load.

If the noise has not changed, then the gearbox is clearly in good working order and it is not the cause of the trouble. Here other drive units are checked. Well, if there is no noise when driving without a load, then we are talking about worn gears of the gearbox, which make noise only when driving with a load.

Repair of rear suspension of VAZ 2107

Before starting repairs, the car must be lifted on a lift or placed on an inspection hole and the front wheels must be secured with wheel chocks.

The main difficulty in repairing the rear suspension is that the threads of the fastening elements are often dirty and damaged by corrosion. Therefore, before you begin to unscrew the threaded connections, they must be cleaned with a wire brush and moistened with a penetrating liquid. It is better to replace parts one at a time so that the rear suspension remains securely attached to the body at all times.

To replace the reaction and longitudinal rods, only wrenches are needed. The jet rod is removed after the fastening bolts are unscrewed and removed.

To remove the longitudinal ones, you must first unscrew the lower fastening of the shock absorbers. It's easy to do:

- Unscrew the nut.

- Remove the bolt.

- Remove the shock absorber spacer.

- Unscrew the longitudinal link fasteners.

- Remove traction.

It is better to change the rubber bushings of the rods and shock absorbers as a set. Their price is low, so it is better to do everything at once, so as not to return to the labor-intensive procedure of disassembling and assembling the suspension.

The rubber bushings of the rods are changed after pressing out the metal bushings of the hinges using a special mandrel. The latter, if necessary, must be cleaned of corrosion using a round file.

New rubber bushings are moistened with soapy water before installation. This reduces friction when installing parts. When pressing in the spacer sleeve, it is necessary to protect the rubber sleeve from cuts.

The rubber joints of the shock absorbers consist of two parts. They can be removed by prying them off with a screwdriver. Once the new shock pivot parts and steel tube are installed, the shock is bolted into place. You need to pay attention when installing. So that the concave sides of the fastening washers are facing the rubber. The shock absorber mounting nuts are tightened until they stop at the ends of the steel hinge bushing.

Important: to facilitate the pressing of rubber bushings, it is unacceptable to use oil or increase the diameter along the edge of the hole. This will greatly reduce the life of the joint.

Design and principle of operation

The rear axle of the VAZ 2107 consists of two parts: a driveshaft and a rear axle with a gearbox. Cardan – consists of two axle shafts with a movable joint. It is located under the bottom, along the entire body, from the gearbox to the gearbox. It rotates together with the gearbox gears, and when the rear axle moves up or down, the cardan also changes its position in order to ensure further rotation of the rear wheels.

Gearbox - consists of a metal casing in which two gears are located. One of them is located at the end of the driveshaft, perpendicular to the second, located on the rear axle beam. They have a diagonal cross-section, which allows them to come into contact with each other, thereby ensuring the transmission of rotation.

Since a gearbox is a device in which parts constantly move and, accordingly, heat up, it must have a liquid inside it that provides lubrication of the rubbing parts and removes heat from them. Typically, this fluid lasts for quite a long time, and is replaced very rarely. This stability of the beneficial properties of the oil is ensured by maintaining the correct atmospheric pressure inside the rear axle gearbox, which is provided by the “breather”.

Gearbox for rear-wheel drive models

The “breather” consists of two parts: a glass, inside of which there is an elastic balloon. It is he who connects the gearbox to the crankcase.

In addition to the two main gears, the gearbox includes two pulleys responsible for rotating the left and right rear wheels. At this point, the structure and operating principle of the rear axle are completed.

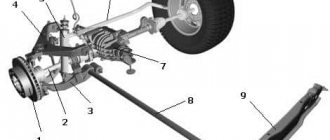

Rear suspension design of VAZ 2107

The rear suspension of the VAZ 2107 has a fairly simple design. Its main element is the rear axle. This part connects the rear wheels, forming a single axis of rotation. The beam is secured to the body by 5 reaction rods: 4 longitudinal and 1 transverse. Longitudinal ones do not prevent the beam from moving back and forth, while transverse ones do not allow it to move under lateral loads. The connection of the rods with the body and beam occurs through hinges with rubber bushings - silent blocks.

The lower parts of the suspension springs rest against the bowls on the beam through thick rubber gaskets, the upper parts are located in the body support bowls. An insulating gasket is installed between the springs and body bowls.

To absorb the load that occurs when the car drives on uneven roads, three rubber compression buffers are installed on the body. Two of them are located in the springs, the third is on the bottom above the rear axle housing.

To dampen vibration, the rear suspension device includes a pair of telescopic shock absorbers.

Malfunctions and their elimination

The design of the gearbox, and the rear axle as a whole, is quite resistant to wear, and malfunctions with this unit occur quite rarely. But, nevertheless, there are cases when one of the mechanisms fails. What breakdowns happen most often, and what to do in such a situation, we will consider later in the article.

The first thing that tells the driver about a breakdown is noise in the area of the rear axle. It can come from two sources: the gearbox and the wheels. If the noise is heard from the rear wheels, then you need to check the axle mounts to the wheels themselves. Sometimes there are cases when the fasteners are not fully tightened, and during the ride, due to constant vibration, they unwind and play appears. It is this that contributes to the noise.

A more serious problem may be breakage or wear of the ball bearing located on the axle shaft. In this case, movement is strictly prohibited, since the wheel may fall off at any moment. To fix this problem, you need to lift the damaged part of the VAZ 2107 car using a jack and replace the bearing.

Malfunctions of the rear axle of VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107 cars

Increased noise from the rear wheels

— The wheel mounting bolts are loose

The bolts need to be tightened.

— Wear or destruction of the axle bearing

The axle bearing needs to be replaced.

Constant increased noise from the rear axle

— The rear axle beam is deformed

Replace the rear axle stockings or the entire axle.

We replace bent axle shafts with new ones.

— Wear of splines on axle shafts

— The rear axle gearbox is incorrectly adjusted, its gears or bearings are damaged or worn

The gearbox needs to be repaired or replaced.

— Not enough oil in the rear axle

Bring the level to normal, eliminate leakage.

Noise when accelerating a car

— Shock absorbers are faulty

Check and replace shock absorbers.

— Incorrectly adjusted gearing of the main gears after gearbox repair

Adjust the engagement by selecting the drive gear adjusting ring.

— Damaged axle bearing

— Not enough oil in the rear axle

Bring the level up to normal.

Noise when the car engine brakes

— Incorrect lateral clearance in the mesh between the final drive gears

Disassemble the gearbox and set the gap to 0.08 - 0.13 mm.

— Increased clearance in the drive gear bearings due to loosening of the flange nut or wear of the bearings

It is necessary to check the technical condition and moment of resistance to rotation of the drive gear.

Noise when accelerating and braking the car engine

— Wear or destruction of drive gear bearings

They need to be replaced.

— There is no lateral clearance between the teeth of the main gear gears

Disassemble the gearbox and set the gap between the teeth to 0.08 - 0.13 mm.

Noise when cornering

— Tight rotation of the satellites on the axis

Disassemble the differential, replace damaged and deformed parts.

— Seizures on the working surface of the satellites

Small scuffs can be eliminated by sanding or replacing the satellite axis.

— Jamming of the axle gears in the differential box

It is necessary to check the condition of the gears and mating surfaces in the differential box. In case of minor damage, clean the surfaces with emery cloth or replace the damaged parts with new ones.

— Incorrect adjustment of differential gears

By selecting adjusting washers, set the axial clearance within 0 - 0.10 mm.

Knock when starting to move the car

— Increased clearance in the spline connection of the drive gear shaft with the flange

— Wear of the hole for the pinion axle in the differential box

Replace the differential box.

— The tightening of the rear suspension tie rod bolts is loose

The bolts need to be tightened.

Oil leak from rear axle

— Worn or damaged drive gear oil seal

— Wear of axle shaft seals

It is necessary to check the runout of the axle shafts, the deflection of the beam, and replace the oil seal.

— The gearbox housing bolts are loose, its sealing gaskets are damaged

Tighten the bolts and replace the gaskets.

Notes and additions

Rear axle gearbox parts for VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107 cars

1. Drive gear flange. 2. Flat washer. 3. Nut securing the drive gear flange. 4. Oil seal. 5. Oil deflector. 6. Front bearing. 7. Spacer sleeve. 8. Gear housing. 9. Bolt securing the gearbox to the rear axle beam. 10. Gasket. 11. Spring washer. 12. Cover fastening bolt. 13. Rear bearing. 14. Drive gear adjusting ring. 15. Axle gear support washer. 16. Axle gear. 17. Satellite. 18. Satellite axis. 19. Driven gear. 20. Differential box. 21. Drive gear. 22. Differential box bearing. 23. Adjusting nut. 24. Bolt securing the locking plate. 25. Locking plate. 26. Locking plate. 27. Bolt securing the driven gear to the differential box.

More articles on “classic” VAZ cars

Rear axle housing oil seal

The rear axle housing oil seal (55*82*10*15.5) FACTORY protects the device gearbox from oil leakage. If the oil seal begins to leak, it urgently needs to be replaced. Otherwise, problems will begin with the gears of the mechanism and they will quickly fail.

Main functions

The rear axle is one of the types of automobile suspensions, which is distinguished by its simplicity of design and its reliability. The rear axle is available on such cars as VAZ 2101–2107, Volga, Kamaz, UAZ, MAZ, ZIL, GAZ, Gazelle.

An important mechanism in the design of the rear axle is the gearbox. This device is designed to transmit torque from the motor to the wheels located on the rear axle. This principle underlies the actions of the driven rear axle. The transmission of rotation from the gearbox to the driven gear is provided by the gearbox shank. To lubricate the gears and bearings, transmission oil is poured into the gearbox.

An oil seal is used to tightly mate the drive gear to the rear axle shank. This is a rubber element with an internal sealing spring ring that ensures the tightness of the gearbox where it connects to the driveshaft, preventing transmission oil from leaking from the unit.

Reasons for failure

The oil seal is a consumable item. Any rubber products begin to wear out during operation and lose their original sealing properties.

The reasons for oil seal wear can be:

- physical wear is the main reason when an element needs to be replaced;

- pouring an aggressive composition of transmission oil into the gearbox, which can be purchased uncertified or of low quality;

- a leak may appear due to the poor quality of the oil seal itself, it itself was defective or its sealing spring ring;

- wear of the bearing on the shank.

When the oil seal wears out, an oil leak appears in the place where the gearbox is attached to the driveshaft. If protruding drops of oil appear at the junction of the components, the oil seal should be changed immediately. Often it is impossible to get by with just replacing the oil seal, but you have to disassemble and repair parts in the gearbox. An oil leak may indicate a bent shaft or broken gear teeth.

If only a thin oil film appears at the mounting location, the oil seal may not need to be replaced for now. But you will have to constantly monitor for signs of oil leakage.

Buy an oil seal

LLC "Company RTIOPT" has been engaged in wholesale trade of rubber products from leading Russian manufacturers since 2003.

The advantages of working with us are:

- Individual approach to each client;

- willingness to provide discounts and a flexible payment system, which is directly related to sales volumes;

- relationships with clients on mutually beneficial terms;

- supply of rubber goods to all regions of Russia by a variety of transport companies, free delivery in Moscow and the Moscow region;

- the period of shipment of goods is up to 5 days, which depends on the volume of the order;

- We never let our clients down, we fulfill all obligations efficiently and on time;

The key to the team’s work is a serious approach to working with clients on mutually beneficial terms.