Subscribe to topic

Notification by e-mail about replies to a topic during your absence from the forum.

Subscribe to this forum

Notification by e-mail about new topics on the forum during your absence from the forum.

Download/Print theme

Download the theme in various formats or view a printable version of the theme.

What is the first thing they do when diagnosing an engine? That's right, they measure the compression in the cylinders. Many believe that its value determines the health of the engine. The authors find out whether this is so during the next analytical examination.

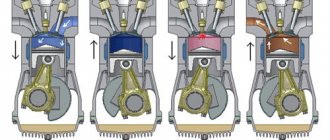

Compression is a vulgarism. That's right - the pressure at the end of the compression stroke. This is the pressure that is created in the cylinder when the ignition is turned off (or without fuel supply - for a diesel engine) with the piston position at top dead center. So, many diagnosticians, based on the measured compression (sorry, science, for the jargon!) give a conclusion: “the patient is alive” or “to the morgue,” that is, for major repairs.

According to many advanced motorists, compression is almost everything for an engine! But is it?

Compression and compression ratio are the same thing: the first fairy tale

No not like this! Compression is the pressure in the cylinder, the compression ratio is a dimensionless parameter that describes the geometric parameters of the cylinder: it is the ratio of the total volume of the cylinder to the volume of the compression chamber (the compression chamber is the volume of space above the piston at its position at TDC (it is also called the volume of the end of compression - this is the same thing). Calling it a combustion chamber is incorrect, since fuel combustion occurs throughout the entire volume of the cylinder.) Compression depends on the compression ratio, but the compression ratio does not depend on compression! Compression also depends on a bunch of parameters: compression start pressure, valve timing adjustment, temperature at which the measurement is carried out, leaks from the combustion chamber. And leaks are determined by wear of the rings and cylinders.

“Compression” is the maximum pressure that we measure in the cylinder when the ignition is turned off.

Increased compression - increased power: the second fairy tale

Not certainly in that way. Compression can be increased in two ways - increasing the compression ratio or reducing leaks from the combustion chamber. Let's see what happens in each case: we have a stand at our disposal.

First, let's reduce the volume of the compression chamber. The easiest way to do this is to grind the bottom plane of the cylinder head. The base engine of the “eleventh” VAZ has a cylinder displacement of slightly more than 370 cubic meters. With a standard compression ratio of 9.8, the volume of the compression chamber will be 42.6 cm³. You can calculate that by removing 2 mm from the seating surface of the cylinder head, we reduce the volume of the compression chamber by 5.1 cm³. The new compression ratio will be 11 units, that is, 1.2 higher than that of the base engine. Now, just out of interest, let's remove another 2 mm. The compression ratio increases to 12.6. In the textbook we find the required formula and get: the thermal efficiency of the piston engine cycle should theoretically increase in the first case by at least 4%, in the second - by 9%. Great!

Now we put these heads on the bench motor and take the torque characteristics. The reduction in fuel consumption is significantly less than the theory promised - by 2.5% in the first case and by 4.5% in the second. Moreover, the effect is more pronounced in the zone of low loads. The increase in power is even less: 2–3% at most, and in the low and medium speed zone. And at high levels there is no effect.

Everything is clear: with an increase in the compression ratio, the pressure in the cylinder increases sharply, this increase provokes detonation, the corresponding sensor catches it and shifts the ignition timing back. Consequently, the power drops. And therefore the theoretical effect is significantly reduced. But the exhaust temperatures increase, which means that the risk of burning valves and pistons with such an engine is much higher.

The second method is to reduce leaks. Let's start from the opposite: let's compare what will happen to the torque characteristic if we replace the rings so that the gaps in them become, say, twice as large.

Done. For a new engine everything is fine, compression is 13.2 for all cylinders. 13.4 bar. For one damaged by rings with large gaps - 10.8. 11.1. What did the power measurements show? In the low speed zone, the power of the damaged motor dropped slightly, but when we reached 2500 rpm, the torque curves almost merged. This is because leaks from the combustion chamber into the crankcase, which should reduce power, are noticeable only at low speeds, and at high speeds their mass per cycle drops sharply, because with a decrease in cycle time and an increase in crankshaft rotation speed, the time for leakage also decreases .

Compression increased sharply, but power did not. Along with compression, detonation arose, and the ignition timing had to be shifted back. And it affects the power more.

How to measure compression correctly

To measure compression, you need to install a compression gauge instead of a spark plug (ignition or glow plug). This device is a pressure gauge connected by a hose to a fitting and a check valve. As the engine crankshaft rotates, air is forced into the hose until the pressure in the hose equals the maximum pressure in the cylinder. Its value will be recorded by a pressure gauge.

When measuring compression, important rules must be followed. Firstly, the engine must be “warm”. The fuel supply must be turned off. You can, for example, turn off the fuel pump, injectors, or use other methods to prevent large amounts of fuel from entering the cylinders. Secondly, you need to turn out all the candles. Selective removal of spark plugs, practiced at some service stations, is unacceptable, as it increases the rotational resistance and arbitrarily reduces the speed when the engine is cranked with the starter. Thirdly, the battery must be fully charged and the starter must be in working order.

Compression is measured with both the throttle valve open and closed. Moreover, each method gives its own results and allows you to identify its own defects. So, when the valve is closed, little air will obviously enter the cylinders, so the compression will be low and will be about 0.6-0.8 MPa. Air leaks in this case are comparable to its entry into the cylinder. As a result, compression becomes especially sensitive to leaks - even with small leaks, its value drops several times.

When measuring compression with the throttle open, the picture will be different. A large amount of incoming air and an increase in pressure in the cylinder, of course, contribute to an increase in leaks. However, they are obviously less than the air supply. As a result, the compression does not drop so significantly (to approximately 0.8-0.9). Therefore, measuring compression with an open valve is better suited for determining more “severe” engine defects, such as piston failures, ring coking, valve burnouts, and cylinder surface scuffing.

In both measurement methods, it is advisable to take into account the dynamics of pressure growth - this will help to establish the true nature of the malfunction with greater probability. So, if on the first stroke the pressure measured by a compression meter is low (0.3-0.4), and during subsequent strokes it increases sharply, this indirectly indicates wear of the piston rings. In this case, pouring a small amount of oil into the cylinder will immediately increase not only the pressure on the first stroke, but also the compression.

The most common device for checking compression is the compression meter mentioned above. Unlike simple domestic designs, foreign companies produce entire sets with a set of adapters (adapters) that allow measurements to be taken on cars of any make and model.

Modern engine testers quickly and efficiently measure compression. These devices actually record not the pressure, but the amplitude of the pulsation of the electric current consumed by the starter during cranking. After all, the higher the pressure in the cylinder, the greater the expenditure of starter power to rotate the crankshaft. This makes it possible to simultaneously measure compression in all cylinders in just a few revolutions, without resorting to turning out spark plugs, which is especially important for multi-cylinder engines.

The disadvantage of measuring with a motor tester is that the results obtained are expressed in relative units, for example, as a percentage of the cylinder that works better. Only the most expensive engine testers are capable of measuring the absolute value of compression in each cylinder, but this is only possible on the basis of a large number of statistical data for a specific engine model and their comparison with the actual pressure in the cylinder.

The basic rule to remember: in most cases, the results of compression measurements are relative. This means that, first of all, it is necessary to rely on the difference in compression values of different cylinders, and not on its absolute value itself.

No compression - straight to capital: the third tale

Typically, a mechanic who discovers low compression immediately declares: “The engine is worn out and needs some capital.” Is everything so clear?

Of course not! For argument's sake, we can name twenty possible reasons for decreased compression. There are problems with the gas distribution mechanism, mechanical or thermal damage to engine parts, and coking of the piston rings. And only one of them will be associated with catastrophic wear of the engine. It is important to be able to distinguish between these causes, understand the degree of their danger and know methods to combat them. But this is a topic for a separate article.

What are the reasons for poor gear shifting?

Difficulty shifting gears can occur as a result of improper operation of the gearbox, or due to operation of the vehicle on bad roads. Problems with the gearbox sooner or later occur in used cars.

If you have difficulties when trying to switch to another gear, you cannot shift or it takes a lot of effort, then there is clearly a malfunction. Most often, car owners turn to a car service when they have difficulty engaging first or reverse gear. A fairly common problem on VAZ and Ford Focus cars.

Let's look at the faults that lead to difficult gear shifting:

- Clutch malfunction. In this situation, the gears will engage either poorly or not completely. A common occurrence in VAZ cars that have fur cables. the clutch is moving away from the mount.

- Problems in the drive of the switching mechanism. Broken traction leads to difficult engagement of 1st and reverse gears.

- The jet thrust is faulty.

- Wear of plastic parts in the box control drive.

- The slide is incorrectly positioned. A weighty element, incorrect adjustment leads to malfunctions.

- Bearing wear. This is a fairly rare occurrence; anyone can experience this, especially when you have a manual transmission. In such a situation, it is usually difficult to engage first gear.

- The box shaft is faulty. By itself, it is not subject to heavy loads, which could lead to wear. A factory defect may cause the entire unit to be replaced.

- Clutch failure. Often found among owners of cars with an automatic transmission. The malfunction is eliminated by replacing the clutches.

- Faulty synchronizers are the most common problem among gearbox breakdowns. They are made of brass, and this metal itself is quite soft. During use, it wears out and wears out. The breakdown is usually accompanied by a grinding noise when switching to another speed.

Some faults can be diagnosed and fixed independently, but failure of the bearings or shaft cannot be determined. For these purposes, you need special tools and equipment, as well as experience. In this situation, if you have problems shifting gears, it is best to go to a service station.

The higher the compression, the better: the fourth tale

Often, from apologists for various additives, you hear how the compression jumped after the next treatment of the engine. Growth up to 15 bar, up to 17 bar! But we must keep in mind that in normal condition, even after restoring the gaps to the state of a new engine, you will not get compression higher than standard.

Where do the numbers come from? Usually, on a disassembled engine, it is clear that after processing the combustion chamber is overgrown with something unknown and, as a result, the volume of the compression chamber has decreased. But these deposits interfere with heat removal from the combustion chamber. Hence detonation, glow ignition, etc. So we shouldn’t rejoice at the unprecedented increase in compression, but vice versa.

Change in specific fuel consumption at fixed speeds (2500 rpm) in two engine variants - basic and with rings in which the gaps are increased. Compression has dropped, but in terms of consumption this is noticeable only at low loads.

And it’s not a fairy tale at all.

So what does compression do? For a lot! The main thing is the starting properties of the motor, especially at low temperatures.

This primarily applies to diesel engines, where the pressure and temperature at the end of compression determine whether the fuel in the cylinder will ignite or not. But gasoline engines in a cold state are also sensitive to changes in compression: it affects the volatility of the fuel, which, during a cold start, should only theoretically evaporate on the way to the cylinder. But in reality, it gets there in the form of non-flammable liquid drops.

Reduced compression increases crankcase gas pressure. In this case, a larger volume of oil vapor flies through the ventilation system to the engine inlet. This is bad: toxicity increases, and the rate of combustion chamber contamination increases sharply.

Uneven compression across the cylinders causes engine vibrations, especially noticeable at idle and at low speeds. And this, in turn, harms both the transmission and the engine suspension. And to the driver himself.

In short, the role of compression as a diagnostic sign, largely characterizing the condition of the engine, is very great. And our “fairy tales” in no way call for giving up on her - on the contrary! But the desire for an unbridled increase in it in search of additional “horses” is generally futile.

The compression in the engine has dropped - will SUPROTEC compounds increase the compression in my engine?

So, we know what compression is, how to measure it correctly and how it can be measured, we know the factors influencing the measurement results, and now we can talk about the possibility of partial or complete restoration of compression using the SUPROTEC lubricant composition.

The SUPROTEC lubricant composition is not an additive or additive to the lubricant, since it does not improve its characteristics, but interacts directly with the metal surfaces of the contact zones (friction surfaces) of parts of components and mechanisms.

SUPROTEC compositions help the “friction couple” system (for example, piston ring - liner, shaft journal - bearing liner, etc.) reach a new qualitative level of energy balance (more optimal contact conditions for friction parts), they act as a catalyst and initiate process of adaptation of the friction pair system. SUPROTEC compositions have the effect of restoring friction surfaces (forming a protective layer up to 15 microns thick) and the effect of optimizing the geometry of friction surfaces. In addition, the created metal structures (protective layers) have increased oil-retaining ability - the protective layer holds oil on the surface much stronger than a normal surface, which shifts the friction mode to the region of semi-fluid or hydrodynamic friction (the work of an “oil wedge”).

Engine oil additive "Suprotek Active Plus"

Restores compression, reduces fuel consumption and oil waste, reduces wear rate and extends the life of internal combustion engines of any type. Facilitates cold starts and protects against overheating in traffic jams.

more reviews

Figure 1 shows all the parts and mechanisms of the engine that are directly related to the amount of compression; all of them are, to one degree or another, subject to friction processes, and accordingly, SUPROTEC compositions can have an effect on them (only the cylinder liner is not shown).

Rice. 1

Friction parts of such units as the cylinder-piston group, crank mechanism, gas distribution mechanism primarily determine the condition and service life of the engine, and, in addition, are the most expensive spare parts.

During normal operation of the engine, SUPROTEC compositions form a new structure layer by layer on the “base metal”, which is based on a crystal lattice of iron.

But this happens only in zones of direct contact of rubbing surfaces, and the load and temperatures in the contact zone must be significant.

Different, low and high engine compression: causes and solutions

Engine compression indicates its condition. If everything is in order with it, then the car has a large reserve of power and torque. The compression of the VAZ 2114 should be checked every 20 thousand kilometers, as well as after purchasing the car. How to measure compression in an engine correctly? This article is devoted to answering this question.

Basic concepts and norms

Compression characterizes the pressure created in the engine cylinders at the end of the compression stroke. In other words, compression is the compression ratio of the engine. The compression ratio is determined by the ratio of compression to the volume of the combustion chamber. What should the compression be on a VAZ 2114? Normally, its value should be at least 10 bar, and the difference between the engine cylinders cannot exceed 1 bar. Thus, if in a car its indicator in four cylinders is at around 11 bar, then this is considered to be the norm. However, every 2.5 thousand km it should be checked manually. If the compression of four cylinders is uneven and is, for example, 11/9/12/11 Bar, then the cause of this failure should be found and repairs carried out. Driving in such conditions will lead to irreversible engine damage. Ideally, on an 8-valve engine on each cylinder, the compression should be at 14 bar with small deviations. Heading 2: Measurement To find out what compression should be on a VAZ 2114 8 valve, you should purchase a special a measuring device called a "compressometer". There are four types of such devices: clamping, universal, threaded and flexible. Before you start taking measurements, you need to prepare a spark plug wrench, a battery and a pressure measuring device. You should also invite an assistant. The sequence of actions will be as follows: 1. First of all, the engine must be warmed up to operating temperature.2. Next, you will need to turn out all the spark plugs.3. A compression gauge is placed in the resulting spark plug hole.4. At this moment, the assistant needs to press the gas pedal all the way, and then start the engine for 6-10 seconds.

5. At this moment, the desired value will appear on the device screen.

Motor repair or replacement with a contract one?

In general, any malfunctions that lead to a decrease in compression in the engine cylinders can be eliminated. If the problem lies in the valves/cylinder head, then repair and restoration will cost 300-600 rubles. A liner for one cylinder will cost 80-120 rubles. If the pistons are damaged, they must be replaced. The price of the issue varies greatly depending on the engine and piston manufacturer. For example, for TFSI engines that suffer from oil burns, a Kolbenschmidt piston costs about 200 rubles, and the original costs 650 rubles apiece (these pistons come complete with all rings).

To these amounts should be added the costs of removing and installing the motor, disassembling and reassembling it. As a result, it turns out that the overhaul of the 2-liter TFSI/TSI engine, which is popular in terms of CPG problems, will cost about 3,600 rubles. This is if you change all four pistons. A contract engine costs from 2,500 to 3,000 rubles (plus replacement work, as well as consumables - 1,000 rubles). In this case – and we are talking about TFSI/TSI engines – many people go for a major overhaul, during which they install modernized pistons, with which the problem of “oil leakage” disappears.

Also, owners of cars whose engines chronically suffer from CPG wear: the appearance of scuffing on the cylinder walls also undergo major repairs with the block liner. This applies to many gasoline engines from BMW, Mercedes (and the Audi/VW engines mentioned above), as well as the widespread G4KD/4B11 engine (Kia, Hyundai, Mitsubishi), which is practically not offered in disassembly shops. Here it is advisable to solve the problem once and for all.

If the compression problem is associated with cylinder head wear, then you can also safely consider the option of restoring it. The work will cost, as we mentioned, 300-600 rubles, plus about 200-400 rubles for its removal and installation with replacement of the gasket.

In a large number of other cases, if a decrease in compression was caused by an accident, maintenance errors or huge mileage, you can safely consider the option of replacing the engine with a contract one. Motors that are not in great demand will cost 1000–2000 rubles, plus about 600–1000 rubles for removal and installation with oil change and necessary consumables.

Hi all! The situation is this: about 2 weeks ago, standing in a traffic jam on the way to work and looking at the car in front, I noticed that the low beam was flickering slightly. Then I didn’t attach much importance to it, I just decided to observe. A couple of days later, when I arrived home and parked, I turned on the interior lamp to illuminate the frame of the radio. which I was going to remove in order to later dismantle the radio and extend the AUX to the plug next to the cigarette lighter. So, when I turned on the lamp, I discovered that the light was not even, but flickering. I got out of the car, looked at the front dimensions - it was the same story. Then I discovered another interesting point. If on a warm car in neutral you spin the engine at 1100-1150 rpm, you will feel vibration on the steering wheel, seat... and in general on the body. And if you briefly raise the speed in neutral on a cold car, it continues to shake at idle. At the same time, when the car warms up after parking overnight, for example, the following sounds are heard from the exhaust pipe:

But I tried to remove the flickering of the light, but the vibration in the cabin is more visible when it’s cold:

As a result, I made an appointment with the OD and arrived. They held an interactive reception. They confirmed that this is not my invention and, indeed, there is a place for unstable engine operation. It was decided to measure the compression. After 20 minutes everything was ready:

1 — 13.4 2 — 15.0 3 — 14.2 4 — 14.9

Those. The compression is clearly increased. I already measured the compression a little less than a year ago and then these figures were about 3 less for each cylinder. The verdict was reached - the crankcase ventilation valve

, namely, a torn membrane. Well, there’s nothing to do, it’s undesirable to drive like that, and I agreed to replace it - fortunately I have discounts there and the price for the part will not differ from the price at the same existential, for example. I ordered and paid for everything on Friday, and a replacement arrived on Monday morning. An hour and a half later, after I dropped off the car, they called me back with the news that everything was ready, come over. I picked up the car at lunchtime. And the first thing I noticed was that the vibration when picking up speed in neutral was and remains. The mechanic responded to my complaint: I wasn’t the one who carried out the diagnostics, that technician will come out on Wednesday, if you want, leave the car. And in general, the oil just has to burn out from the cylinders... In short, I decided to pick up the car and think about what to do next. The phrase “not much should burn out of the cylinders” somehow did not convince me and even outraged me. How much oil should there be?) If it is there, it will burn out in 5 minutes of driving, but they told me to drive 500 km... So in the end I sit and think what to do and what could be the reasons for all this disgrace. Since excessive compression has been detected, options with crankcase protection supporting the engine, a dangling exhaust system, and an engine mount that has failed should seem to disappear. Next, you can consider gasoline and oil. I just changed the oil from Castrol 5w30 to the original SPECIAL PLUS 5W-40 and have already driven 8 thousand on it. I also started refueling at a BP gas station closer to home (previously I refueled at a gas station on the way out of Moscow), i.e. A purely theoretical reason can be found here.

Here are the questions running through my head right now: But what other options could there be and how to diagnose them?

Is it possible to drive with increased compression and what consequences does this have for the engine? Has anyone encountered this problem on a Polo Sedan?

The engine pulls confidently, there seems to be no jerking during acceleration. Fuel consumption is as usual (I do not observe an increase in consumption).

Engine compression and compression ratio - what is it?

Almost all motorists are well aware of engine compression, but many confuse this concept with the compression ratio. In fact, these values indicate completely different engine parameters. Let's try to figure out what compression and engine compression ratio are, and we'll also figure out how to increase compression and why is it needed?

Compression in engine cylinders

Compression is the pressure that is created at the end of the compression stroke of the air-fuel mixture by the cylinder. The higher the engine compression, the more power it can develop. The fact is that increasing this value promotes better compression of the fuel, and therefore its ignition occurs much more efficiently, which gives a good push to return the cylinder to bottom dead center. The rotation speed of the crankshaft directly depends on the speed of movement of the cylinders, and therefore the engine power is determined.

Compression is measured in various quantities, but the most widely used are atmospheres. The main difference between compression and a value such as the compression ratio is the change in the constancy of this value. The fact is that as various engine parts wear out, the pressure in the cylinders decreases, and accordingly, the engine power decreases.