LAVR › Blog › Cylinder head gasket failure: signs, repair, prevention after

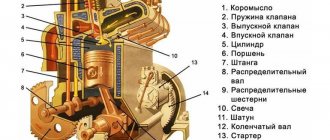

The cylinder head gasket performs a number of important functions: it ensures the tightness of the block and the flow of the gas-air mixture only into the combustion chamber, and also facilitates the circulation of coolant, fuel and oil.

All these functions are vital for the normal operation of the internal combustion engine, so a gasket failure is a serious malfunction that requires immediate service. Most car owners do this, but not everyone thinks that a breakdown is also insidious because of its consequences. Read our material about what needs to be done after replacing the cylinder head gasket. Causes of cylinder head gasket failure

A blown cylinder head gasket is a car nuisance that can happen to absolutely any engine. Of course, this happens more often in engines with aluminum heads. Mainly due to overheating: under the influence of high temperature, the lid loses its working position and depressurization occurs. The second most common cause, which is already common to all motors without exception, is improper tightening of the cover bolts. The third is banal wear and tear. After all, the gasket, like everything, has its own service life.

Signs of a cylinder head gasket failure

You can usually suspect a cylinder head gasket failure based on such signs as white smoke from the exhaust pipe, engine overheating, interruptions in the operation of the heater, tripping, and starting problems. After this, you can carry out diagnostics yourself.

The very first way is to open the hood, start the car and see if there is smoke coming from the engine or if you hear popping noises. If the burnout or gasket breakthrough is significant and it is located along the outer contour, you will see and hear it. In addition, you can inspect the engine for oil leakage outward from under the cylinder head. This, of course, is not an unambiguous sign of a gasket failure, but it is definitely a reason to urgently go to the service center.

If the gasket between the combustion chamber and the cooling jacket is defective, a breakdown can be determined by the emulsification of the coolant. This is also not difficult: just unscrew the cap of the radiator or expansion tank, and you will notice if something is wrong there. If exhaust gases break into the cooling system, boiling begins and the antifreeze “beats” into a dense emulsion or foam. With this development of events, it is also indicative that the engine quickly heats up and tends to boil, because the cooling system does not work efficiently.

What else needs to be checked? Oil level dipstick. If it is mixed with the coolant, an emulsion will also appear there, and oil stains will appear in the expansion tank.

But not only gases enter CO, but also vice versa. This is where the white smoke comes from the exhaust pipe. In this case, the problem can be diagnosed by coolant leakage from the expansion tank and wet carbon deposits on the spark plugs and in one of the cylinders.

If a breakdown occurs between the cylinders, the air-fuel mixture from one is mixed with exhaust gases in the adjacent one. Externally, it looks like tripping plus problems with starting and a big difference in compression.

With a breakdown of the cylinder head gasket, the car can move independently, but it is still not recommended to drive tens of kilometers, since the operation of other important mechanisms and systems is disrupted, and even short-term operation of a car with a breakdown leads to the penetration of technical fluids into places where they are not supposed to be.

Replacing the cylinder head gasket

The gasket itself - be it metal or paronite - is inexpensive, but it is difficult to predict the cost of replacing it. The fact is that this malfunction may be accompanied by a number of others: deformation of the cylinder head mounting bolts, defects in the plane of contact between the head and the block, cracks in them. And their restoration is a much more complex and expensive operation.

After replacing the gasket

If your car has had the cylinder head gasket replaced, it is important to follow a few recommendations. First of all, do not overload the engine with high speeds so that the new part gets used well. Without leaving the service center, flush the combustion chamber, lubrication and cooling systems, which have been exposed to a cocktail of oil and antifreeze. This is necessary to avoid further coking of the CPG, problems with overheating and the lubricating properties of the lubricant, as well as accelerated wear. Professionals recommend three effective procedures.

1. Engine bracing.

If antifreeze gets into the cylinder-piston group, it negatively affects the engine. The coolant does not burn during a flash and carbonizes on the cylinder, piston crown and rings. These contaminants harden quite quickly and lead to ring sticking, hose scuffing, loss of compression and cylinder failure. That’s why, even with minimal leakage, we recommend not just decoking the engine, but doing it with the powerful LAVR 203 NOVATOR compound.

2. Flushing the oil system.

What happens in the engine lubrication system as a result of coolant entering? Insoluble solid “flakes” appear there, which settle in the recesses of the system and clog the channels. Flushing the oil system will remove all contaminants and clean the internal hydraulic drives. You can choose a cleaning agent yourself, depending on the condition and operating load of the car. We talked in detail about the LAVR range and the differences between the washes, of which we have 6, in a separate article.

3. Flushing the cooling system.

If oil and exhaust gases break into the antifreeze, the cooling system also needs to be flushed: the emulsion will not go away simply by draining the old fluid and can damage the thermostat, pump, or simply clog the thin channels of the cooling jacket. We recommend performing a LAVR "Full Cooling System Clean" and then flushing several times with distilled water to ensure the safety and functionality of the system. There is a cool video about this washing on our YouTube channel.

A blown cylinder head gasket is a breakdown from which no car owner is immune, but now more people know how to identify this fault and minimize its consequences.

Source

How to find out if the cylinder head gasket is blown

You can determine whether the cylinder head gasket is blown by using one of several methods. In this case, diagnostics are simple and can be done by anyone, even a novice and inexperienced driver.

To check the integrity of the gasket, you must do one of the following:

- With the engine running, visually inspect whether smoke is coming from the gap between the cylinder head and the cylinder head . Also listen to see if there are loud ringing sounds coming from there that were not there before.

- Inspect the surfaces of the radiator caps and expansion tank of the cooling system, as well as the neck for filling oil into the engine. To do this, you just need to unscrew them and visually inspect them. If antifreeze gets into the engine, there will be a reddish emulsion on the oil filler cap. If oil gets into the antifreeze, then there will be oily deposits on the radiator or expansion tank caps.

White smoke from the exhaust pipe

How to check a cylinder head gasket using a condom

One of the effective and popular testing methods is the method using a balloon or a condom. It is put on the neck of the expansion tank, having first unscrewed the cap. The main thing is that the condom sits tightly on the neck and provides a tight seal (instead of a condom, you can use a bag or a balloon, but the diameter of the condom is usually ideal for the neck of the tank). After you put it on the reservoir, you need to start the engine and let it run for a few minutes at 3.5 thousand rpm. Depending on the level of depressurization, the condom will fill with gases quickly or slowly. It depends on the specific situation. In any case, if it begins to fill with exhaust gases, this means that the cylinder head gasket is broken.

Checking the cylinder head gasket with a condom

Checking the gasket with a bottle

Another method for determining whether the cylinder head gasket is broken is often used on trucks . To do this, it is enough to have a small bottle of water (for example, 0.5 liters). As a rule, expansion tanks have a breather (a tube that helps maintain the same pressure as atmospheric pressure in a closed container). The method is very simple. With the engine running, place the end of the breather in a container of water. If the gasket is broken, air bubbles will begin to come out of the tube. If they are not there, then everything is in order with the gasket. If at the same time coolant begins to appear from the breather, this also means that everything is in order with the gasket.

Checking the cylinder head gasket on trucks

Testing with a bottle

The two methods described above are suitable for diagnosing a malfunction when exhaust gases break into the cooling jacket. These methods are very effective and have been used by motorists for decades.

Symptoms, causes and signs of a blown cylinder head gasket (cylinder head)

There are a number of “classic” breakdowns that affect cars of all makes and ages. One of these breakdowns is when the cylinder head gasket burns out. The breakdown is unpleasant and requires immediate repair.

The cylinder block gasket ensures the tightness of the combustion chamber, oil channels and cooling jacket at the junction of the cylinder block with the head. Failure of the gasket leads to a violation of the tightness, followed by failure of the internal combustion engine.

Most often, burnout occurs between one of the cylinders and the water jacket, spreading further along the plane. But there are other options, for example, between the oil channel and the cooling channel.

What is a cylinder head gasket and its functions?

The main purpose of the gasket is to increase the tightness of the connection between the cylinder head and the main part. This element also stabilizes the pressure in the oil system necessary to retain fluid. Since the gasket belongs to the category of disposable parts, the need to replace it arises every time an intrusion into the mentioned area of the motor occurs.

Repeated use of the gasket reduces the tightness. The following types of gaskets are considered to be the most popular:

- metal ones are the strongest and most durable;

- asbestos, designed to withstand high temperatures;

- non-asbestos ones are capable of immediately returning to their original shape at the slightest deformation.

Among the key functions of the gasket are the following:

- ensuring optimal gas exhaust conditions;

- preventing light impurities from entering the oil;

- protection of the connection area from the appearance of engine oil.

We are talking about a malfunction and urgent replacement if at least one of the mentioned functions is not performed.

Symptoms of a burnt cylinder head gasket

Most drivers do not know how to check whether the cylinder head gasket is blown. It's actually quite simple. The following symptoms indicate a failure of the cylinder head seal:

Important note: the first four symptoms are the same when cracks appear in the cylinder head or block. It is possible to determine what actually happened only after removing the head from the engine, which is inevitable when replacing the gasket.

Knocks out coolant

Problems with coolant, without signs of leakage from the system, are clear signs of a violation of the integrity of the gasket. When the gasket between the combustion chamber and the coolant channel burns out, high-pressure gases break into the cooling system, create excess pressure and squeeze the coolant through the expansion tank plug.

If the tank cap is tightened tightly, as it should be, and the safety valve in it is faulty, the rubber pipes of the cooling system may burst due to excess pressure, or the burnout area will expand, with gases escaping into the oil channels. More often the latter option happens.

Step-by-step guide to replacing the cylinder head gasket of a VAZ-2107

To replace the cylinder head gasket in a VAZ-2107, you should perform the following manipulations:

- The initial stage involves dismantling the filter that filters the incoming air flows. If the VAZ-2107 is equipped with a carburetor, this is easier to do than performing the same work with an injector. Your task is to unscrew and disassemble all the parts of the entire system; this is the only way to get to the cylinder head.

- Remove the carburetor.

- Unscrew absolutely all pipes that remain visible.

- Get rid of the cylinder head cover by disconnecting the fasteners. Put the nuts and clamps aside, do not lose them, otherwise you will not be able to assemble the mechanism into a single whole.

- Place a container under the hose and carefully drain the remaining coolant in the car.

- Protect your health from electrical current by removing the battery.

- Place the ignition distributor cap aside.

- Pull out the hoses from the carburetor - one responsible for heating, and the second coming from the vacuum format regulator, which distributes the ignition.

- Remove the air collector and remove the throttle linkage.

- With your own hands, remove the sensor that controls the temperature regime from the cylinder head of the VAZ-2107.

- Connect the indicators on the camshaft drive sprocket with the markings located on the camshaft bearing housing. This simple technique will avoid re-installation of the distribution phase at the time of assembly.

- Next, bend the edges of the sprocket fixing washer in different directions and unscrew the bolt. Let the star remain in its place.

- Loosen the tensioner nut half a turn and use a screwdriver to press out the shoe. As the chain loosens, tighten the fasteners again.

- All that remains is to disconnect the bolt holding the sprocket and remove it. To prevent the timing chain from falling, support it with a soft wire.

- Remove the housing base from the bearing located on the camshaft and disconnect the nuts of the VAZ-2107 cylinder head.

- When the head cover comes off easily, position the new gasket.

- Assemble the components into a single whole, following the reverse order of the proposed instructions.

- Correct valve operation.

We recommend: Removing and replacing the rear axle axle seal of the Niva Chevrolet

Reasons for gasket burnout

There are few reasons why a cylinder head gasket burns out, but with a new engine there is only one – overheating. Even a short time of engine operation at temperatures above normal can cause this malfunction. In this case, the gasket may burn out quite a bit, and inexperienced motorists will not notice the first symptoms that appear. With further operation, the burnout increases, and the symptoms become more pronounced. Due to the fact that many car owners turn to specialists not after overheating, but after some time of operation, when the malfunction becomes a clear fact, they do not connect the burnout of the gasket with the recent overheating and demand from motorists other explanations why the cylinder head gasket burned out.

If the volume of coolant is insufficient, you may not notice a slight overheating of the head, since the liquid, circulating in the system, manages to cool in the radiator, but does not have time to remove heat in the required amount. Instruments in a car show the temperature of the coolant, not the temperature of the engine parts. Thus, when operating a car with an insufficient level of antifreeze, you can burn the gasket without realizing that the cause was overheating.

Burnouts occur due to poor-quality gaskets, but this mostly applies to engines after repair. This happens extremely rarely on new cars. Even on repair engines, the cause of such a malfunction may be factors related to the quality of the repairs performed:

When filling the cooling system with liquid, it is important to remove all “air plugs”! Otherwise, you can “burn” the gasket the first time you start the engine.

Start of work

The very first step is to remove the air filter. Of course, on a carburetor engine it is somewhat easier to remove it. If you have an injector, you will have to tinker with its rubber fasteners. But the essence remains the same - it is necessary to disassemble the fuel system completely to get to the cylinder head. But we will look at the example of not an injection, but a carburetor seven. Still, there are many more classic cars with such a power system.

It is advisable to dismantle the carburetor, since if you remove the head along with it, you can accidentally damage it. On all classic series cars, the carburetor is removed in the same way. This procedure is quite simple, but it will take some time. Now you can unscrew the nut securing the distributor and remove the distributor along with the wires. Getting closer to the engine, all that’s left to do is drain the antifreeze from the system.

And then turn off all the pipes that you see. After this, it will be possible to dismantle the cylinder head cover. It is secured with nuts and shaped washers. Don't lose them during repairs. That's all, the preparation is complete, you can begin the most difficult part - dismantling and installing the cylinder head.

We recommend: How to properly check oil scraper rings and what is needed for this?

What are the dangers of a blown cylinder head gasket?

When a cylinder head gasket burns out, the consequences depend on the time the malfunction was discovered and when the vehicle was stopped from being used. If the gasket only burns out, then you can get by with minimal losses - replacing the gasket itself and related work. When driving with a burnt gasket, the following are possible:

The consequences of engine seizure may be the need to grind or replace the crankshaft, replace liners, connecting rods or pistons. In the worst case scenario, the cylinder block may need to be repaired.

Considering the consequences that occur after a cylinder head gasket burns out, if any of the above symptoms occur, you should immediately contact a specialist. » alt=»»>

Source