VAZ 2107 injector does not start

With an injection engine, everything is a little simpler and more complicated at the same time.

In principle, there are again two directions: gasoline and spark. Well, compression, respectively. For starters, there is a “check engine” light that will light up if the ignition system is faulty. The error code in this case will begin with P03XX. That is, misfires in the cylinders. Of course, you must first check whether there is a spark. There are several diagnostic methods that are worth paying attention to:

- Diagnostic scanner. There is nothing complicated here. If there is an error, then everything is much simpler than when there are no errors at all. In this case, we check the part itself, and then the reasons, if it is working.

Ignition module. There are several methods worth trying to check, but the most reliable is to go to the store and take it with a receipt for verification. You can immediately talk about returning it if your own is in working order. Of course, not all stores will do this, but most will agree. The VAZ engine does not start for one reason. This is quite common among car enthusiasts. The control unit contains two transistors, each of which is responsible for a pair of cylinders. Most often they burn out at the same time, and the spark disappears completely.

If everything is fine with the spark, you need to check the power supply to the engine. Again, unscrew the spark plugs and see if they are wet.

- If the spark plugs are dry, then you need to see if voltage is supplied to the injectors, first. To do this, remove the connector from one, connect the tester probes to the connector and ground.

After you are convinced of this, you need to measure the pressure in the fuel rail.

Most likely this is the problem. Therefore, you need to check the fuel pump, first of all, the fuse that is responsible for it.

It is easier to check the fuel pump by replacing it with a known good one, as with the ignition module.

If the VAZ carburetor does not start

Cars with this type of installation were produced until 2004. In this design, there are many more reasons that prevent the engine from starting.

The main factors due to which the VAZ does not start at all or does so unstably are:

- fuel pump failure;

- breakdowns in the carburetor itself;

- ignition failure;

- starter malfunction;

- Battery low.

In the latter case, the battery is checked with a tester. It is necessary that it shows at least 9-11.5 volts. If this is not the case, then its power will not be enough to start the starter. When everything is in order with the voltage, then examine the last node. Most likely, the breakdown lies there.

Checking the crankshaft sensor

Misfire causes VAZ 2107 injector

On most cars, a faulty DPKV usually causes a fault code, so use a diagnostic scanner. Or check the crankshaft sensor itself.

Magnetic DPKV

Crankshaft magnetic sensors can be tested by disconnecting the electrical connector and measuring the resistance between the corresponding terminals. If the resistance is not within specifications, the sensor is faulty and must be replaced.

Magnetic crankshaft position sensors produce alternating current when the engine is started, so checking the output voltage is another test that can be performed.

With the sensor connected, measure the output voltage at the sensor terminals when the engine starts. If you see at least 20 mV on AC, the sensor is good and there is probably a problem with the module.

If the output voltage is low, remove the sensor and inspect the end for rust or debris (magnetic sensors will attract metal particles). Clean the sensor, reinstall it and test again.

Make sure it has the proper air gap (if adjustable) as the distance between the end of the sensor and the ring gear or notches in the crankshaft will affect the sensor's voltage output. If the air gap is correct and the output voltage is still low, replace the sensor.

DPKV on the Hall effect

Hall effect crankshaft position sensors typically have three terminals. One is for current supply, one is for grounding and one is for output signal. The sensor must have voltage and ground to produce a signal, so check these terminals first with a multimeter.

The sensor output can be checked by disconnecting the DIS module and cranking the engine to ensure that the sensor is producing a voltage signal. The voltmeter voltage should change each time a prong passes in front of the sensor. When observed on an oscilloscope, you should see a square wave shape. The absence of a signal indicates that the sensor is faulty.

Previous post Error P0016 - what it means, symptoms, causes, diagnosis, elimination

Next entry Error P0113 - what it means, symptoms, causes, diagnosis, solution

Removal and installation of distributor VAZ-2107, 2104, 2105, 2106

Preparation

Throttle sensor for car VAZ 2107 injector

Before installing a new VAZ-2107 distributor for a contact ignition system, you need to adjust the gap between the contacts of the breaker. It is more convenient to do this with the device removed from the car. We check the gap with a flat feeler gauge. The value is set from 0.35 to 0.45 mm. In this case, the protrusion of the cam should move the moving contact away from the stationary contact as much as possible. We adjust by slightly loosening the screws, and then tighten them more firmly and check the gap again. Contacts that have worked hard may have a protrusion on one and a depression on the other, which interferes with adjustment. You can get around this problem by grinding off the protrusion with a needle file. It is better not to use sandpaper, because... small particles of abrasive will definitely “eat” into the surface and interfere with the operation of the contacts.

Before removing the old distributor, mark its position relative to the cylinder block with a marker. You also need to accurately mark the position of the moving contact (slider) relative to the body. If all this is not done, the settings will be violated and the engine will not start.

Installation

Having established exactly the same position of the roller in the body on the new distributor, carefully insert it into the hole in the block, slightly turning the roller to align the splines. Having “planted” the device in place by rotating the body relative to the block, we set the approximate advance angle, as on the old distributor. Secure with a washer and nut, but not too tight. Now you need to plug in the high voltage wires. This is easy to do - each contact on the distributor cover has the number of the cylinder to which it needs to be connected. We connect the wire from the ignition coil to the central terminal. The wires should fit tightly, with a slight tension, the protective caps should be pushed all the way down. Don’t get carried away, don’t bend the petals of the wire tips too much, otherwise later, when you try to remove them, you’ll tear off the wires “with their roots”! A wire goes from the contact wire to the “K” terminal of the ignition coil, usually it is green. If your VAZ-2107 is equipped with a contactless ignition system, then you need to connect a connector with three wires. Having plugged it into the socket, check the fit of the wires; it happens that they “crawl out” from their places and the device does not work. Everything is done, the new distributor is installed and ready to go. Let's try to start the engine. Started up? Great, that means everything was done correctly, all that remains is to check and slightly adjust the ignition timing.

Lost spark on VAZ 2107, what could it be?

Hello everyone, the spark has disappeared on the VAZ 2107, what could it be?

31 comments on “The spark is missing on the VAZ 2107, what could it be”

Check the spark plugs, caps, armor wires, spool, switch and distributor cover for moisture.

Injector? Or a carburetor? What ignition? Contact? Without contact?

Pavel, what does the caps have to do with it?

Denis, they can break through, verified

Pavel, so what kind of caps?

Pavel, call the details by their proper names.

The candle doesn't work

candles from matches should then work. stearic. just be careful!

Look at the coil, is it not a coil of wires or spark plugs?

Contacts on the distributor, coil, capacitor, distributor cover, wires

How can you not find a spark on the carburetor?

look, the contacts on the distributor were pinched and there was no rupture, so the spark plug doesn’t let go with the pliers; the pliers can be very open in the reverse order. if it doesn’t help, look at the coil, but it’s best to spend money on contactless ignition and completely forget about the loss of spark

Zhenya, I can’t find a spark on the BSZ carburetor on the 2107 coil kamutator new wire for the hall sensor new what to do

Alexey, I can’t find a spark on the BSZ carburetor on the 2107 coil kamutator new wire for the hall sensor new what to do

***Wiring for hall sensor

and what kind of spark is on the carburetor? You can also look at the ignition relay, I have it above the clutch pedal under the panel, put your hand in and the wires from the ignition switch to this relay go because of it, it may also not give a spark, I suffered with it for a long time, changed everything, but it turned out the wire was oxidized and burned out

what the hell is the spark in the carburetor, you should look for it in a diesel engine

The carbure only supplies fuel through the intake manifold and already in the combustion chamber an explosion occurs with a spark. Look how a gasoline engine works.

There is a resistor in the distributor slider, most likely it has oxidized. Clean it or replace it.

Alexey, do you generally know the electronic device on a carburetor engine and what one is on the injector?

We check the ignition module of the 16-valve VAZ-2112 with a multimeter

Timing marks on a VAZ 2107 injector car

The situation is as follows: for no apparent reason the engine began to “trouble”, the thrust was lost, and the idle now does not even reach 500. I removed the high-voltage wires one by one, and so, there was no spark at all in cylinders 2 and 3. The engine is 16-valve, but without “individual coils”. The question is how to check the ignition module on a VAZ-2112 engine, and it is advisable not to remove it. Inside the module, in addition to the coils, electronics are installed. How can I check if it's working properly?

Checking the VAZ-2112 ignition module with your own hands

Inside the ignition module there is such a board

It is clear that we are talking about the 21120 engine and the ignition module 2112-3705010. By the way, there will be two more numbers in the article numbers - they indicate the manufacturer.

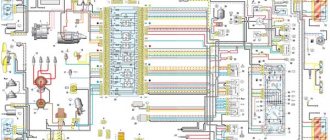

All elements of the ignition system

Four wires are connected to the module connector:

- Blue-red – nutrition +12;

- Brown – “mass”;

- White-blue – signal for candles 1 and 4;

- Gray-red – candles 2 and 3.

First check that all voltages are supplied to the module:

- Turn off the ignition, disconnect the connector;

- Turn the key to position I;

- We connect the probe voltmeter probe to the battery negative;

- Using the second probe (positive) we find the “+12V” contact in the connector;

- At each control contact the arrow will show “almost 0”;

- With the starter running, the values should increase while remaining less than 0.7 V.

The voltage on both control contacts must be the same.

Let's say that checking the connector did not reveal any errors. Next we will look for the reason in the module itself.

Tester CNT-SPMZ

According to the recommendation of the plant, on VAZ-2112 cars the ignition module should be checked for the need for repair with a tester called TsNT-SPMZ. The kit consists of a generator and a arrester module.

CNT-SPMZ, version 3

If we don’t have a tester at hand, we’ll try to make one ourselves. Only the ignition module will still have to be removed by unscrewing three nuts “10”. First, disconnect the battery, then the spark plug wires and connector. By the way, the wires have numbers corresponding to the numbers on the module (see video).

No spark, VAZ injector

Using the 2111 injection engine of VAZ 21083, 21093, 21099 cars as an example, we will understand the causes of the “no spark, injector” malfunction.

Symptoms of a “no spark, injector” malfunction

There are only three signs of a “no spark, injector” malfunction in relation to the ignition system of the 2111 engine.

— The car engine starts and stalls

— The engine “troits” or “doubles” at idle

Causes of the “no spark, injector” malfunction

Spark plugs are faulty

In rare cases, all spark plugs may fail at once. But most often one or two of them fail. The engine begins to run unsteadily at idle. The cause of spark plug malfunction is a breakdown of the insulator to ground (the spark goes not to the spark plug electrodes, but to the engine), carbon deposits on the electrodes due to the engine running on a rich fuel mixture, a malfunction of the spark plug itself (does not pass current), etc. See "Spark plug malfunctions" and "Checking the spark plugs of an injection engine."

In addition, the reasons for the disappearance of the spark on the spark plugs may be faulty high-voltage wires and the ignition module.

The ignition module (“coil”) is faulty

The ignition system of the 2111 engine uses an ignition module consisting of four coils. Most often, two of them fail, and the engine, at best, begins to “doubly” - only two cylinders work, but most likely it will not start at all. Under certain conditions, difficult starting and ghosting of a cold engine may occur; when the engine is warm, the problems disappear.

Checking the module (ignition coil) VAZ 21083, 21093, 21099

And in case of malfunction, replace it.

High voltage wires are faulty

The high voltage wires are designed to carry high voltage current from the ignition module to the spark plugs (the so-called high voltage circuit). If a “break” occurs in this circuit, then there can be no talk of any spark. The cause of the “break” may be burnout of the central core of the armored wire, oxidation, or burnout of the contacts (tips). Or a violation of the integrity of the wire insulator (“breakdown”) due to which the spark goes to the “ground” and not to the spark plug.

The signs of malfunction of high-voltage wires are the same as those of spark plugs (“triples”, “doubles”, does not start, stalls).

The ECM crankshaft position sensor is faulty

In the event of a complete failure of the DPKV sensor or a “break” in its circuit, the ECU does not receive an impulse when the pistons pass the top dead center. Accordingly, there will be no command to ignite the fuel mixture in the combustion chambers, and there will also be no spark on the spark plugs. When the DPKV fails, the “Check Engine” warning lamp (CHEK ENGINE) lights up in the instrument panel.

You can check the crankshaft position sensor yourself using the "Checking the Crankshaft Position Sensor" section.

Checking the DPKV engine crankshaft position sensor

Ignition module low voltage circuit is faulty

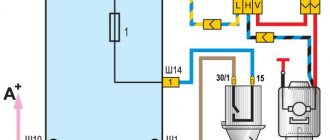

The diagram at the beginning of the article shows the electrical circuit of the 2111 engine ignition system. If there is a break in any of the system wires, the ignition system will not work.

Using the diagram, check the reliability of fastening of the wire blocks (chips) and the oxidation of the contacts in them.

The control unit (ECU) is faulty

If the test establishes that all elements of the ignition system are in working order, then the controller (ECU) of the electronic engine control system (ECM) is most likely faulty, since the ignition system of an injection engine operates on its command.

Or the main relay (position 1 in the picture) and the ignition system fuse (6) in the relay and fuse box under the instrument panel have failed.

Relays and fuses of the ECM for injection VAZ 21083, 21093, 21099

A faulty controller will have to be replaced or sent for repair. You can check the relay and fuse yourself.

Notes and additions

Similar symptoms (the engine does not start, the engine stalls) can occur not only due to a malfunction of the ignition system, but also the power system, control system, or the engine itself. For example, “Signs of a clogged fuel filter, injector.”

Source

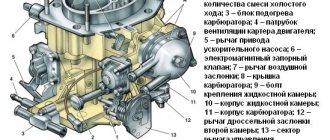

Repair of VAZ 2108 distributor (replacement of the vacuum regulator)

In distributors of VAZ 2108-09-099 cars, the VROZH quite often fails. Its performance can be checked without removing the PR from the engine - we suck in air through the hose, and if a vacuum is not created, the regulator should be changed.

The ignition timing regulator can be replaced on site without removing the distributor:

- unscrew the two screws of the distributor cover, and together with the high-voltage wires, move the cover to the side, disconnecting only the central wire;

- we pull out the slider, it can be removed by hand;

- Using a thin screwdriver, pull out the latch that secures the VROZH rod; you need to remove the fastening element carefully so as not to lose it;

- unscrew the 2 screws securing the “vacuum unit” and remove the device;

- We install the new part in place and put everything back together.

Replacing the VROZH can also be done by removing the distributor, which will even be more convenient. Remove the distributor as follows:

- disconnect the high-voltage wires from the PR cover;

- use a thin screwdriver to hook the retaining springy wire on the connector and remove the plug going to the distributor from the bottom left;

- we pull off the hose from the VROZH, make a mark on the PR body or notice how it stood;

- unscrew the three nuts that secure the distributor itself, and then remove the breaker - distributor.

It’s easy to install the distributor back - the camshaft spline has a groove shifted to one side, and therefore the PR is installed in only one position, it’s impossible to make a mistake here

During installation, you need to pay attention to the rubber O-ring - if the rubber has hardened, the part must be replaced. And in any case, the seal should be coated with an oil-resistant sealant, in which case oil leakage will be almost 100% avoided

Checking the contactless distributor

If the “six” is equipped with a contactless ignition system, then checking elements such as spark plugs, coil, and explosive wires is performed in the same way as with a contact one. The differences lie in checking the switch and the Hall sensor installed instead of the contacts.

Hall Sensor

The easiest way to diagnose a Hall sensor is to install a known working element. But since the part may not always be at hand, you have to look for other possible options.

Checking the removed sensor

During the test, the voltage at the sensor output is determined. We determine the serviceability of the element removed from the machine according to the presented diagram by applying a voltage in the range of 8–14 V.

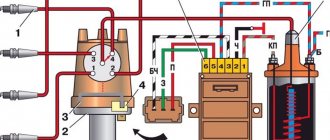

Diagram for checking the removed Hall sensor: 1 - ignition distributor; 2 - 2 kOhm resistor; 3 - voltmeter with a scale limit of at least 15 V and an internal resistance of at least 100 kOhm; 4 - plug connector connected to the ignition distributor sensor

By placing a screwdriver in the gap of the sensor, the voltage should change within 0.3–4 V. If the distributor has been completely removed, then by turning its shaft, we measure the voltage in the same way.

Checking the sensor without removing it

The performance of the Hall sensor can be assessed without removing the part from the car, using the diagram provided.

Diagram for checking the Hall sensor on a car: 1 - ignition distributor; 2 - adapter connector with a voltmeter having a scale limit of at least 15 V and an internal resistance of at least 100 kOhm; 3 — plug connector connected to the ignition distributor sensor; 4 - car wiring harness

The essence of the test comes down to connecting a voltmeter to the corresponding contacts on the sensor connector. After this, turn on the ignition and turn the crankshaft with a special key. The presence of voltage at the output, which corresponds to the above values, will indicate the serviceability of the element.

Video: Hall sensor diagnostics

Switch

Since the formation of a spark also depends on the switch, you need to know how to check this device too.

One of the reasons for the lack of spark on the spark plugs may be a faulty switch

You can purchase a new part or perform the following sequence of actions using a control light:

- Unscrew the nut and remove the brown wire from contact “K” of the coil.

- We connect a light bulb to the resulting open circuit.

- Turn on the ignition and crank the starter several times. If the switch is working properly, the light will light up. Otherwise, the element being diagnosed will need to be replaced.

Video: checking the ignition system switch

The performance of the systems and components of the VAZ “six” must be constantly monitored. The occurrence of problems with sparking will not go unnoticed. Troubleshooting and troubleshooting does not require special tools or skills. A minimal set consisting of keys, a screwdriver and a light bulb will be quite sufficient for diagnostics and repairs. The main thing is to know and understand how a spark is formed, and what elements of the ignition system can affect its absence or poor quality.

Troubleshooting the ignition system

Malfunctions of the car’s ignition system are unpleasant because any of them is always accompanied by serious interruptions in the engine’s operation or its complete stop.

The main sign of a malfunctioning ignition system is the complete absence or “weak” spark between the electrodes of the spark plugs. What to do if there is no spark, and where to look for it? Read about this and more in our material. Most often, the spark disappears precisely at the moment when you need to go somewhere. In order not to push the car to the nearest car service center, it is important to understand what the operation of the ignition system depends on, then finding the missing spark will not cause any particular difficulties.

At the end of this article, watch the video instructions for finding a spark in the ignition system of VAZ cars.

And below we propose to get acquainted with the algorithm for searching for a missing spark in a car’s ignition system.

Why is there no spark at the spark plugs?

There can be several reasons for the lack of spark at the spark plugs. Most often the culprits of the malfunction are:

- Accumulator battery;

- High voltage wires;

- Ignition coil;

- Distributor;

- Malfunctions in the low voltage circuit.

Also, in the absence of a spark, special attention should be paid to checking the quality of contacts and electrical connections of the ignition system elements. You can check the condition of the contacts simply by rubbing them with your hand.

Carefully inspect the wires and blocks of the ignition system - if dirt, oil or water is found on them, they must be wiped with a dry cloth. After that, try starting the engine, it may start this time.

Checking the battery

A clear sign of problems with the battery is a dull and quiet horn signal. Also, if there are problems with the battery, the indicator lights on the instrument panel usually go out while the starter is rotating. In this case, the reason for the lack of a spark may be poor contact at the terminals or a low battery charge.

- If the terminals are oxidized, they must be cleaned and tightened tightly. In addition, you can use graphite lubricant, which will reliably protect the contacts from oxidation in the future.

- If the battery is discharged, it must be charged using a charger.

For information on how to properly charge a car battery and maintain it, read our battery charging instructions.

Checking high voltage wires

Next, it’s worth inspecting the high-voltage wires: they must have a neat, not “tattered” appearance, without insulation damage, otherwise they will have to be replaced. If the wires are ok, then you can start looking for a spark.

We recommend starting your search for a spark with the spark plug wires. To do this, you need to remove the tip of the spark plug wire from the spark plug and bring it to the “ground” (the nearest unpainted metal part of the body or engine) at a distance of 5-8 mm, after which you need to turn on the starter for a few seconds.

The rotation of the starter should be accompanied by an uninterrupted bright spark of white color with a slight blue tint. If there is no spark, you need to check the ignition coil. A violet, red or yellow spark indicates a malfunction in the ignition system.

It is also worth noting that the spark plugs themselves rarely fail all at the same time. If there is a “spark” in the spark plug wires, you can check any spark plug by unscrewing it from the cylinder head and putting the spark plug wire on it. Touch the metal part of the spark plug to the “ground” of the car, and by rotating the starter, make sure that there is a spark at the electrodes of the spark plug.

It is necessary to change spark plugs within the time limits established by the maintenance regulations for your car (usually every 15-25 thousand km).

You can learn more about the markings and heat ratings of spark plugs from our material at this link.

Checking high voltage wires

After checking the contact spark plugs, we move further along the circuit and test the performance of the high-voltage wires. The instructions below will help you diagnose if the spark disappears on only one of the cylinders:

- swap the wires connected to the spark plugs;

- check for the presence of a spark;

- if it appears on the cylinder to which you transferred the new wire and disappears on the other, then the problem is in the cable. Therefore, the latter will need to be replaced.

In exactly the same way, the integrity of the central wire through which voltage is supplied to the ignition coil is checked. You can also try to press it harder against the transformer and distributor cap to restore contact.

High voltage wires

After the spark plugs have been checked and it turns out that they are not the problem, you need to test to see if anything has happened to the high-voltage wires. Diagnosis is carried out in four simple steps.

- If there is no spark on only one cylinder, swap the wires

- Let's check if the problem is resolved after this action

- If a spark appears on a cylinder, but it disappears on another cylinder, then the problem is definitely in the wire.

- The faulty wire must be replaced with a new one.

Likewise, it would not hurt to check whether the central wire that supplies current to the ignition coil is working properly. Sometimes a spark appears after this wire is pressed harder against the transformer, which is located on the distributor cover.

Checking the contact distributor

The need to check the distributor-breaker arises if problems arise with sparking, but during the diagnostics of the ignition system elements the problem could not be identified.

Cover and rotor

First of all, we inspect the cover and rotor of the device. The check consists of the following steps:

- We dismantle the distributor cover and inspect it inside and out. There should be no cracks, chips, or burnt contacts on it. If damage is found, the part must be replaced.

- We check the carbon contact by pressing with a finger. It should press easily.

- We check the rotor insulation for breakdown by placing the explosive wire from the coil near the rotor electrode and manually closing the contacts of the distributor, after turning on the ignition. If a spark appears between the cable and the electrode, the rotor is considered faulty.

contact Group

The main malfunctions of the ignition distributor contact group are burnt contacts and incorrect clearance between them. In case of burning, the contacts are cleaned with fine sandpaper. If they are severely damaged, it is better to replace them. As for the gap itself, to check it it is necessary to remove the cover of the distributor-breaker and turn the engine crankshaft so that the cam on the distributor shaft opens the contacts as much as possible. We check the gap with a feeler gauge and if it differs from the norm, then we adjust the contacts by unscrewing the corresponding screws and moving the contact plate.

The contacts are adjusted by unscrewing the corresponding screws and moving the contact plate

Capacitor

If a capacitor is installed on the distributor of your “six”, then sometimes the part can fail as a result of a breakdown. The malfunction appears as follows:

- problems starting the engine;

- sudden engine stop while driving.

If the distributor capacitor fails, engine operation malfunctions

You can check an element in the following ways:

- Control lamp. Disconnect the wiring coming from the coil and the capacitor wire from the distributor according to the figure. We connect a light bulb to the open circuit and turn on the ignition. If the lamp lights up, it means that the part being tested is broken and requires replacement. If not, then it's OK.

- Wire from the coil. Disconnect the wires as in the previous method. Then turn on the ignition and touch the tips of the wires to each other. When sparking occurs, the capacitor is considered faulty. If there is no sparking, then the part is working.

Why is there no spark at the spark plugs?

There can be several reasons for the lack of spark at the spark plugs. Most often the culprits of the malfunction are:

- Accumulator battery;

- High voltage wires;

- Ignition coil;

- Distributor;

- Malfunctions in the low voltage circuit.

Also, in the absence of a spark, special attention should be paid to checking the quality of contacts and electrical connections of the ignition system elements. You can check the condition of the contacts simply by rubbing them with your hand.

Carefully inspect the wires and blocks of the ignition system - if dirt, oil or water is found on them, they must be wiped with a dry cloth. After that, try starting the engine, it may start this time.

Checking the battery

A clear sign of problems with the battery is a dull and quiet horn signal. Also, if there are problems with the battery, the indicator lights on the instrument panel usually go out while the starter is rotating. In this case, the reason for the lack of a spark may be poor contact at the terminals or a low battery charge.

- If the terminals are oxidized, they must be cleaned and tightened tightly. In addition, you can use graphite lubricant, which will reliably protect the contacts from oxidation in the future.

- If the battery is discharged, it must be charged using a charger.

For information on how to properly charge a car battery and maintain it, read our battery charging instructions.

Checking high voltage wires

Next, it’s worth inspecting the high-voltage wires: they must have a neat, not “tattered” appearance, without insulation damage, otherwise they will have to be replaced. If the wires are ok, then you can start looking for a spark.

We recommend starting your search for a spark with the spark plug wires. To do this, you need to remove the tip of the spark plug wire from the spark plug and bring it to the “ground” (the nearest unpainted metal part of the body or engine) at a distance of 5-8 mm, after which you need to turn on the starter for a few seconds.

The rotation of the starter should be accompanied by an uninterrupted bright spark of white color with a slight blue tint. If there is no spark, you need to check the ignition coil. A violet, red or yellow spark indicates a malfunction in the ignition system.

It is also worth noting that the spark plugs themselves rarely fail all at the same time. If there is a “spark” in the spark plug wires, you can check any spark plug by unscrewing it from the cylinder head and putting the spark plug wire on it. Touch the metal part of the spark plug to the “ground” of the car, and by rotating the starter, make sure that there is a spark at the electrodes of the spark plug.

Troubleshooting

Troubleshooting in the ignition system of the VAZ “Six” should be carried out using the method of elimination, checking element by element sequentially. This is worth dwelling on in more detail.

Battery check

Since when starting a car, the power source is the battery, it is by checking this device that diagnostics should begin. Malfunctions with the battery appear when you try to start the engine. At this moment, the indicator lights on the instrument panel go out. The reason could be either poor contact on the terminals themselves, or simply a weak battery charge. Therefore, the condition of the terminals should be checked and, if you need to clean them, tighten the fastening. To prevent future oxidation, it is recommended to cover the contacts with a graphite coating. If the battery is discharged, it is charged using an appropriate device.

Spark plug wires

The next elements that require mandatory checking in case of problems with sparking are explosive wires. Upon external inspection, the cables should not show any damage (cracks, breaks, etc.). To assess whether a spark passes through the wire or not, you will need to remove the tip from the spark plug and place it near a ground (5–8 mm), for example, near the engine block, and crank the starter for a few seconds.

At this time, a powerful spark should jump. The absence of one will indicate the need to check the high-voltage coil. Since it is impossible to determine by ear which of the cylinders does not spark, the test should be performed one by one with all wires.

Video: diagnostics of explosive wires with a multimeter

Spark plug

Spark plugs, although infrequently, still fail. If a malfunction occurs, it is with one element, and not with all of them at once. If a spark is present on the spark plug wires, then to check the spark plugs themselves, they are unscrewed from the cylinder head of the “six” and an explosive cable is put on. The metal body of the spark plug touches the masses and turns the starter. If the spark plug element is working, then a spark will jump between the electrodes. However, it may also be absent from a working spark plug when the electrodes are filled with fuel.

In this case, the part needs to be dried, for example, on a gas stove or installed another one. In addition, it is recommended to check the gap between the electrodes with a feeler gauge. For a contact ignition system it should be 0.5–0.6 mm, for a contactless ignition system it should be 0.7–08 mm.

Ignition coil

To test the high-voltage coil, you need to remove the central cable from the distributor cover. By cranking the starter, we check for the presence of a spark in the same way as with the explosive wires. If there is a spark, then the coil is working and the problem should be looked for elsewhere. If there is no spark, the problem is possible both with the coil itself and with the low-voltage circuit. To diagnose the device in question, you can use a multimeter. For this:

- We connect the probes of the device, switched on to the resistance measurement limit, to the primary winding (to threaded contacts). If the coil is working properly, the resistance should be about 3–4 ohms. If the values deviate from the norm, this indicates a faulty part and the need to replace it.

Low voltage circuit

The high potential on the ignition coil is formed as a result of applying a low voltage to its primary winding. To check the functionality of the low voltage circuit, you can use a tester (light bulb). We connect it to the low voltage terminal of the distributor and ground. If the circuit is working, then the lamp, when the ignition is on, should light up when the distributor contacts open and go out when they close. If there is no glow at all, then this indicates a malfunction of the coil or conductors in the primary circuit. When the lamp lights up, regardless of the position of the contacts, the problem may be the following:

- damage to the conductor that goes from the distributor terminal to the lever. Eliminated by restoring damaged wiring;

- break in the conductor running from the movable disk to the housing. The malfunction can be treated as in the previous paragraph;

- oxide formation on contacts. In this case, cleaning and adjustment of the elements is required.

No spark on VAZ 2106

Sparking is an important process that ensures the startup and stable operation of the power unit, for which the ignition system is responsible. The latter can be contact or non-contact, but the essence of its work remains the same - to ensure the formation and distribution of a spark to the desired cylinder at a certain point in time. If this does not happen, the engine may either not start at all or run intermittently. Therefore, it is worth dwelling in more detail on what kind of spark there should be and what the reasons for its absence may be.

Why do you need a spark?

Since the VAZ 2106 and other “classics” are equipped with an internal combustion engine, the operation of which is ensured by the combustion of the fuel-air mixture, a spark is required to ignite the latter. To obtain it, the car is equipped with an ignition system, in which the main elements are spark plugs, high-voltage (HV) wires, a distributor-breaker and an ignition coil. Both spark formation as a whole and the quality of the spark depend on the performance of each of them. The principle of obtaining a spark is quite simple and comes down to the following steps:

- Contacts located in the distributor provide low voltage supply to the primary winding of the high-voltage coil.

- When the contacts open, a high voltage is indicated at the coil output.

- High-voltage voltage is supplied through the central wire to the ignition distributor, through which sparks are distributed to the cylinders.

- A spark plug is installed in the cylinder head for each cylinder, to which voltage is supplied via explosive wires, as a result of which a spark is formed.

- When a spark appears, the combustible mixture ignites, ensuring the operation of the engine.

What should be the spark?

Normal engine operation is possible only with a high-quality spark, which is determined by its color, which should be bright white with a blue tint. If the spark is purple, red or yellow, this indicates problems in the ignition system.

Signs of a bad spark

The spark can be either bad or completely absent. Therefore, you need to figure out what the possible symptoms are and what could be the cause of problems with sparking.

No spark

A complete lack of spark is manifested by the inability to start the engine. There can be many reasons for this phenomenon:

- wet or failed spark plugs;

- damaged explosive wires;

- break in the coil;

- problems with the distributor;

- failure of the Hall sensor or switch (on a car with a contactless distributor).

Video: searching for a spark on a “classic”

Weak spark

The power of the spark also has a significant impact on the functioning of the power unit. If the spark is weak, the combustible mixture may ignite earlier or later than necessary. As a result, power decreases, fuel consumption increases, failures occur in different modes, and the engine may also misfire.

Tripletion is a process in which one of the cylinders of the power plant works intermittently or does not work at all.

One of the reasons why the spark may be weak is the incorrect clearance of the ignition distributor contact group. For classic Zhiguli cars this parameter is 0.35–0.45 mm. A gap less than this value results in a weak spark. A higher value, at which the contacts in the distributor do not completely close, can lead to a complete absence of a spark. In addition to the contact group, other components of the ignition system should not be overlooked.

An insufficiently powerful spark is possible, for example, when spark plug wires break down, i.e., when part of the energy goes to ground. The same thing can happen with a spark plug when the insulator is pierced or a significant layer of soot forms on the electrodes, preventing the breakdown of the spark.

Spark to the wrong cylinder

Quite rarely, but it happens that there is a spark, but it is supplied to the wrong cylinder. At the same time, the engine runs unstable, troits, and shoots into the air filter. In this case, there can be no question of any normal operation of the motor. There may not be many reasons for this behavior:

- the explosive wires on the distributor cap are mixed up;

- the cover on the distributor is installed incorrectly;

- The spark plug wires are not connected correctly to the spark plugs.

The last point, although unlikely, since the length of high-voltage cables is different, is still worth considering if problems with ignition occur. The listed reasons arise, as a rule, due to inexperience. Therefore, when repairing the ignition system, you need to be careful and connect the explosive wires in accordance with the numbering on the distributor cover.

Repair of VAZ 2106 distributor

On older VAZ 2106 cars, a contact distributor is installed, but such a system is not very reliable - due to malfunctions in the contact group (CG), various problems often arise:

- due to burnt contacts, the engine may not start;

- too large a gap in the CG affects engine power - the engine stops developing speed;

- If there is a small gap in the contacts, the motor jerks and works unstably.

To repair the VAZ 2106 distributor, it must be removed and troubleshooting carried out. Removing the device on the “Classic” is very simple, but before repairing it, it is recommended to align the crankshaft to the mark - this will make it easier to install the distributor after repair. We remove the distributor as follows:

- rotate the crankshaft until the marks align;

- we pull off the tips of the high-voltage wires from the spark plugs;

- unclip the two latches of the distributor cap and see what position the slider is in. If it is directed to the fourth cylinder, we make another full turn of the crankshaft. Usually, with correctly set marks, it should be located as in the picture below;

- pull off the hose from the vacuum regulator;

- unscrew the nut number 13, which holds the distributor, and dismantle the distributor.

Now the PR should be disassembled, perform the following operations:

- unscrew the fastening screws of the runner, dismantle the rotor;

- unscrew the nut located on the body, hold the screw on the other side of the body with a screwdriver;

- dismantle the fasteners, take out the plastic insulator;

- tighten the screws holding the contact group (KG);

- dismantle the CG;

- knock out the shaft pin;

- remove the oil deflector and washer from the roller, pull the shaft out of the housing;

- to get to the bearing, remove the locking washer of the ignition timing regulator rod from the top of the housing;

- Unscrew the bolts securing the regulator, dismantle the ignition timing mechanism;

- unscrew the screws (2 pcs.) that hold the bearing fixing plates;

- dismantle the bearing, lifting it from different sides;

The disassembly is now complete, all that remains is to troubleshoot and replace worn parts.

Which distributor is suitable for the VAZ-2107

On all carburetor rear-wheel drive VAZ cars, the device has almost identical components and a similar operating principle. Distributors for engines with a volume of 1200-1300 cc differ in that: - the drive rod is 7 mm shorter; — no vacuum ignition timing regulator; — the settings of the weights and springs of the centrifugal regulator are different. For engines with a volume of 1500-1600 cc, all distributors are suitable in terms of mounting dimensions and characteristics. Only “Nivovskie” ones differ. They are tuned for stable traction at low speeds and the VAZ-2107 with such a distributor will accelerate slowly. The brands of “Nivovsky” distributors are: 3810.3706, 038.3706-10. And distributors of brands 0.3706 (contact) and 38.3706 (non-contact) are suitable for the “Seven” and other classic cars.

VAZ 2107 injector does not start

- Diagnostic scanner. There is nothing complicated here. If there is an error, then everything is much simpler than when there are no errors at all. In this case, we check the part itself, and then the reasons, if it is working.

- Ignition module. There are several methods worth trying to check, but the most reliable is to go to the store and take it with a receipt for verification. You can immediately talk about returning it if your own is in working order. Of course, not all stores will do this, but most will agree.

- The VAZ engine does not start for one reason. This is quite common among car enthusiasts. The control unit contains two transistors, each of which is responsible for a pair of cylinders. Most often they burn out at the same time, and the spark disappears completely.

- If the spark plugs are dry, then you need to see if voltage is supplied to the injectors, first. To do this, remove the connector from one, connect the tester probes to the connector and ground.

- After you are convinced of this, you need to measure the pressure in the fuel rail.

- Most likely this is the problem. Therefore, you need to check the fuel pump, first of all, the fuse that is responsible for it.

- It is easier to check the fuel pump by replacing it with a known good one, as with the ignition module.

VAZ-2107: the injector starts and immediately stalls

In this case, you should check the mass air flow sensor. It is located immediately behind the plastic filter housing.

This element receives information about air flow and transmits it to the control unit. As a result, the electronics makes a decision on the composition of the combustible mixture. The unit can intentionally adjust the concentration of fuel and air. The service life of the mass air flow sensor is 150 thousand kilometers. If the element is dirty, it may send false readings. Due to the lean mixture of the VAZ-2107, the injector does not start or works and immediately stalls. You should also check the condition of the air pipes for leaks. Replace if necessary.

Ignition system failures

The starter may turn briskly, but the engine will not start. The VAZ-2107 (carburetor or injector) most likely cannot move due to the fuel supply system or its ignition. It is better to start with the latter when diagnosing. This system in the presented model fails more often. This is especially true in wet weather.

The contact system of the “seven” can be very different. There are cars with the simplest device (classic) or with a very complex electronic contactless principle. There are also combined options.

In any case, the ignition system will consist of 4 parts. This is a low-voltage group, step-up transformer (coil). Next comes the high-voltage part and spark plugs. The check is carried out step by step (and better from the end).

Solving the problem yourself

There are quite a few reasons why the VAZ-2107 starts and stalls or does not move at all. You can easily find the problem yourself. But for this you need to be patient, the necessary tools and enough free time. If trouble catches the owner of a car when he is in a hurry about his business, it is better to take another car. It will be possible to repair this later, when there is enough time to carry out diagnostics.

It does not matter whether the carburetor or injection engine is installed on this model. Diagnostics is carried out in any case according to a single scheme.

First of all, you need to pay attention to the battery, whether it is charged. Also, the battery may fail for some reason.

Next, the spark plugs and fuel filters are inspected. You can also check the throttle valve. There may be a blockage in it. This is the simplest test, which sometimes immediately reveals a malfunction. If the cause cannot be determined, a more in-depth diagnosis will be required.

Checking the ignition module

Often the problem of the inability to start the engine lies in a failed ignition module. This part is a special device that, using special coils, generates energy to generate a spark and further start. The simplest and most reliable way to check serviceability is to install a new module purchased from a store. If the engine started, the problem lay in this part. It should be noted that this process has its own characteristics and subtleties.

If it is not possible to purchase a new module for some reason, you can carry out diagnostics yourself, on site using a tester set to the “ringing” mode. Main stages:

- the module itself is carefully detached from the tips;

- one probe must be connected to the central contact;

- the second probe is connected to ground.

If after performing these manipulations there is no signal on the device, then there is no problem. If the connection is present, the ignition module must be replaced. Since there is a breakdown.

Let's sum it up

Spark plugs play a vital role in the performance of a vehicle. If at least one spark plug fails and does not produce a spark, accordingly, one of the cylinders will not work, the car will have increased fuel consumption and will be less dynamic. Finding the reason for the disappearance of the spark is a very difficult task, since several units may be “to blame” for this. However, for normal functioning this is simply necessary.

What to do if there is no spark on a VAZ-2106 car? As is known, this phenomenon leads to the fact that the air-fuel mixture does not ignite and the engine stops starting. Therefore, you will have to look for the causes of the problem without fail.

On VAZ cars, and on the “six” in particular, the spark can disappear due to a variety of malfunctions. But in this article we will describe only the most common of them, and also give useful tips for identifying and troubleshooting problems.