The most unusual automatic transmission shift knobs.

For many decades, automotive shift knobs essentially gave us little choice in the way we shifted. Everything primarily depended on the type of transmission. That is, we were essentially choosing between an automatic and a manual transmission. It depended on this which gearbox knob was installed in the cabin.

The maximum that could have happened was that the gear shift knob could have been located not between the two front seats, but, for example, on the steering column. Also, despite the location of the gearshift knob, almost always, when switching the transmission mode, we almost always went through a strict order of gearbox modes: Park, Reverse, neutral, Drive, and in some cars, low gear.

But now with the advent of new powertrain designs and the proliferation of electronic technology in the auto industry, car designers can now experiment with transmission shifting technologies easily and freely.

Yes, many modern gearboxes are essentially the same technology, although they have more efficient gear ratios. But despite this, automatic transmission shift knobs have literally evolved before our eyes in recent years. Have you noticed that in a short period of time, many automatic transmission shift knobs have changed virtually beyond recognition, and are now presented in many car brands in various forms (sometimes strange). Let's look at all the strangest modern technologies and methods of switching automatic transmission modes.

Adjustment

After the gearbox linkage and rod have been replaced, they should be properly adjusted for the correct stroke of the handle. It is needed in order to be completely sure that in this case the drawstring will last longer. In order to adjust all replaced devices, you need to take only three steps. In fact, there are two methods, but about them in order.

- The first method is adjustment by engaging reverse gear. To do this, the gearshift knob must be in the reverse gear position. Then you need to loosen the clamp. Once the gearshift knob is in the desired position, you can proceed to the next step. The next step is to tighten the clamp. That's all, in 99 out of 100 cases, such an adjustment helps solve the problem with gears not engaging correctly.

- The second method already implies the position of the gearbox handle not at reverse speed, but at first. In order to begin the adjustment, you need to put the handle in the appropriate position. Then you need to loosen the clamp, as in the first method. After this, you need to turn the rocker drive counterclockwise until the gearshift knob rests against the plastic protection. After the gearshift knob has rested, the clamp should be tightened. This completes the adjustment.

Selecting automatic transmission switching using a button

Push-button gear shifting is becoming more and more popular in the modern auto industry. But in fact, this is not a revolutionary technology of the 21st century. The fact is that this technology was proposed by Chrysler back in the 1950s, equipping some of its car models with it as an experiment.

Also, subsequently, some American automobile companies decided to try placing the automatic transmission shift button on the steering wheel.

But, unfortunately, in those years this technology did not gain popularity. But surprisingly these days, the technology of switching automatic transmissions using buttons has returned. It all started with expensive supercars and luxury cars. Then brands such as Acura, Alfa Romeo, Ferrari, GMC and Honda joined this trend.

And the fashion for buttons instead of transmission shift knobs continues to gain popularity all over the world. So we must admit that if we are talking about automatic transmissions, then switching them using buttons is much more comfortable and convenient.

Therefore, it is quite possible that this particular automatic transmission switching technology will become the main one in the entire automotive industry.

Replacement

As already mentioned, this mechanism is rarely replaced, but it does happen. Many drivers wonder when they should change this device. Most often, the shift link of a manual transmission is replaced; this happens because the manual gearbox knob is subjected to more frequent use, which is why its resource is quickly lost. This can happen on a good foreign car.

- Firstly, the gearshift knob will start to wobble a lot, because a large amount of play in the handle will form. Handle play will manifest itself even at the initial stage of wear of the mechanism.

- Secondly, the gearshift knob will move into position with some difficulty. In this case, the handle may fly out of position, the gears may turn off, or they will not engage at all. In addition, during switching, extraneous sounds, such as crunching or grinding, may appear.

- Thirdly, the gears are engaged with great force on the gearshift knobs.

- Fourthly, when one gear is engaged, another is engaged. Even an inexperienced driver can determine this; when the wrong gear is engaged, the car’s engine will operate at high or low speeds.

- The fifth reason why the rocker is replaced is that the gears are not engaged, or are engaged, but not all. For example, out of five gears, it is possible to engage only one or two.

If at least one reason has been identified, it must be eliminated immediately. In fact, when it is faulty, you can drive, but it will become more difficult to engage gears with the handle. In order to replace this device and easily engage gears with the handle, you need to find instructions specifically for your car.

The fact is that each car is unique in its own way and the structure of some units may differ significantly. There are cars whose structure changes with progress, for example, a car of an old model is different from the same car of a new model. There are cases when even the handle is transferred.

In addition to the fact that the rocker may be faulty, the gearbox rod may also be broken. Therefore, when it is replaced, the stem should also be replaced. It often happens that after replacing the rocker the problem remains or it is not so pronounced, in which case the rod should be replaced. In order to replace the rod, you need to look for instructions for this. The rod, like the rocker, has its own special structure or features for each car.

Some drivers, mostly owners of Lada cars, trying to get rid of excess rattling of the handle, get rid of the gearbox stabilizer rods. In order to remove the traction, a serious reason is needed; some do not resort to this step by simply redoing some devices. If, nevertheless, it was decided to remove the jet thrust, you should carefully study the structure of your car and find out whether this will damage other units.

Unusual shaped gear shift knobs

Starting from the second generation of the Toyota Prius hybrid car, technology began to gain popularity in the auto industry, allowing the installation of unusually shaped transmission control elements instead of conventional automatic transmission shift levers.

For example, these days it has become fashionable to install miniature handles instead of bulky automatic transmission knobs. This became possible thanks to electronic systems, which, in fact, switch modern automatic transmissions. Here is an example of how a modern gear shift knob can look unusual. Look at the interior of the Nissan Leaf, where the round gear knob immediately catches your eye, which is very similar to a computer mouse.

Monostable shift knob

The monostable gear lever (especially in the joystick style) has been fashionable since its first appearance in BMW cars. But this automatic transmission shift knob received the most attention after the premiere of the new generation 5-Series.

As a result, the fashion for such automatic transmission shift knobs began to gain popularity all over the world. For example, General Motors decided to equip its cars with similar handles (Buick LaCrosse and Chevrolet Bolt EV).

Audi, which has long used classic knobs as gear shift knobs, also paid attention to this technology. True, for now Audi has decided to externally adhere to a more classic design of automatic transmission shift knobs, expanding only their functionality for now by additionally equipping them with buttons.

Manual transmission gearshift device type 020, rocker and everything about it

FAQ VW Audi Skoda Seat

The five-speed gearbox type 020 was installed on cars:

Volkswagen Golf 3 / Volkswagen Golf 3 (1H1, 1H5, 1E7) 1992 - 1998 Volkswagen Vento / Volkswagen Vento (1H2) 1992 - 1998

Volkswagen Golf 2 / Volkswagen Golf 2 (191, 192, 193, 194) 1984 - 1988 Volkswagen Jetta 2 / Volkswagen Jetta 2 (165, 166, 167, 168) 1984 - 1988 Volkswagen Golf 2 / Volkswagen Golf 2 (1G1) 1989 - 1992 Volkswagen Jetta 2 / Volkswagen Jetta 2 (1G2) 1989 - 1992

Volkswagen Scirocco 2 / Volkswagen Scirocco 2 (533, 534) 1981 - 1992

Volkswagen Polo Classic / Volkswagen Polo Classic (6V2) 1996 - 2002 Volkswagen Polo Variant / Volkswagen Polo Variant (6V5) 1994 - 2002

Volkswagen Caddy / Volkswagen Caddy (9K9) 1996 - 2003

SEAT Ibiza 2 / Seat Ibiza 2 (6K1) 1993 - 2002 SEAT Cordoba 1 / Seat Cordoba (6K2, 6K5) 1993 - 2002 SEAT Inka / Seat Inka (6K9) 1996 - 2003, etc.

Adjusting the gear shift mechanism (slides)

Necessary special devices, control and measuring instruments, as well as auxiliary equipment:

— Template for selector -3104-

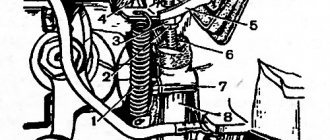

Photo:

Drawing:

Adjustment

Conditions necessary for correct adjustment:

— The ideal condition of the switching and transmission elements of the gear shift mechanism. — easy movement of the gear shift drive mechanism — The gearbox, clutch and clutch drive must be in perfect condition. — The gearshift lever is set to the neutral position. – Loosen the clamping clamp -arrow-.

– Remove trim from frame – Install selector lever template -3104-. – The template should not be clamped.

Photo:

– Align the shift rod (gearbox in idle position) and tighten the clamping clamp.

Torque

Shift rod clamp 25 Nm

Mechanism operation

— The gear shift lever in neutral should be on line 3./4. transfers. – Select all gears one after another several times. Pay special attention to the operation of the reverse gear lock. If, when switching on again, any of the gears still encounter jams, then proceed as follows: – Set 1st gear. – Increase the gap in the switching drive by carefully pressing the selector to the left.

Distance -a-

should be between 0.5 and 1.5 mm.

– If this is not the case, make fine adjustments with 1st gear engaged

Fine tuning

1st gear is set.

– Loosen the clamping screw -B-. – Create dimension -a- by turning adjusting eccentric -A-. The distance -a- should be between 0.5 and 1.5 mm. – Tighten the clamping screw -B-. – Place the lid into the frame.

Torque

Clamping screw for adjusting eccentric 2 Nm

I will continue my story about the backstage. I'll start with this element:

After 17 years of operation it looks like this:

And so on in order!

1. Support bracket. 1H0 711 083

The support bracket practically does not wear out, with the exception of rare, particularly advanced cases when the plastic bushings are broken and create wear through their rotation (see photo)

But I ignored this defect; I think that it is not significant in my situation. It is believed that the rubber bushing 191 711 208 A (see photo below) is included in the delivery package of the support bracket. The cost of the original support bracket 1H0 711 083 is 1,700 rubles, I have not found any analogues.

2. Support bracket bushing 191 711 208 A

Rubber bushing

over time (seen in the photo), and often becomes the cause of distortions and difficult movement of the gear shift rod. Analogues: Jp Group 711260005 - 23 rub. Dello 307110208191A — 24 rub. Hans Pries 107 325 755 — 30 rub. Original: VAG 191 711 208 A — 145 rub.

3. Enveloping shaft. 1H0 711 173

I have this item in a very poor condition:

The plastic ball is not fixed.

In places of friction on the part, significant significant wear is visible.

Prices for this part are as follows: Analogues: Jp Group 711280004 - 150 rubles. Hans Pries 108 839 756 — 200 rub. Meyle 100 711 0012 — 630 rub. Original: VAG 1H0 711 173 - 2500 rub.

3. Gear shift mechanism bushing. 191 711 067

There are two of these bushings, at the top and bottom, respectively:

They are most susceptible to wear and create play in the enveloping shaft both vertically and horizontally.

The bushings have a “hook” that prevents them from turning in the seat. On one of my bushings this hook was broken, and I rotated the bushing. Prices for this part are as follows: Analogues: Hans Pries 109 705 015 - 140 rubles. Original: VAG 191 711 067 - 60 rub. Required: 2 pcs.

4. Intermediate lever. 191 711 205 B

This lever is not supplied separately (without bushing), in the catalog it has the number VAG 191 711 204 A, and the delivery set includes bushing VAG 171 711 181 (see below). The lever hardly wears out, the bushing is also little subject to wear, but just in case, I’ll tell you how much this kit costs. VAG 191 711 204 A - 430 rubles, no analogues found.

5. Bushing. 171 711 181.

This bushing does not wear out significantly, but I decided to change it anyway. Prices for this part are as follows: Analogues: Jp Group 711255007 - 10 rubles. Hans Pries 109 119 466 — 10 rub. Original: VAG 171 711 181 - 120 rub.

6. Safety plate. N 90315301

I have this record in satisfactory condition, but to reassure myself, I decided to order a new one, especially since the original VAG N 90315301 costs 20 rubles. This part is simply attached:

7. Self-locking hex nut. N 90908301

M8 nut with “built-in” washer. I didn’t change it, but if someone wants, prepare 40 rubles. It winds up here:

That's all for now, to be continued. ps prices are indicated from the website www.exist.ru

We continue to sort through the scenes. Let's talk about this node:

This lever is necessary for pre-selecting a gear (see diagram below)

To replace it after long-term use, there is an original repair kit: VAG 1H0 798 201

Composition: Intermediate lever - 1 pc. Cone bolt - 1 pc. (191 711 199) Insert - 2 pcs. (191 711 590 A) O-ring - 2 pcs. (171 711 965) Self-locking nut (M8) - 1 pc. (N 90226403) The original repair kit costs 1200 rubles.

Since I still need to buy a lot of things to replace the rocker, and the budget is limited, I decided to buy a non-original Hans Pries repair kit 109 074 755

Price 186 rub.

The cone bolt (191 711 199) is most subject to wear:

The liners are also worn out (191 711 590 A) (pictured: old and two new ones)

The lever itself was not seriously damaged

...except that the hinges on which the rods fit are a little worn out.

O-rings - 2 pcs. (171 711 965) (on the left - new, on the right old)

The entire structure is assembled:

In general, if the budget allowed, I would of course take the original. The difference, although not significant, is there. 1. Bottom hole for the bolt on the lever. On the original lever, which is still in use after 16 years, the bolt is screwed into the hole; on the non-original lever, there is a gap, albeit small, (accordingly, backlash).

2. The nuts are different. The original has an oval nut on one side, which allows it to self-lock. The non-original nut has an ordinary nut, except for the teeth in the form of an engraver.

3. Non-original plastic liners (191 711 590 A) do not fit perfectly on the bolt, there is a small gap.

My Hans Pries 109 074 755

, according to quantum, not the worst “non-original”

That's all for now, to be continued.

Continuation.

1. Gear shift mechanism housing. VAG 1H0 711 061

Nothing has been done to this part after many years of use. The cost of the original is 2350 rubles, no analogues have been found.

2. Gasket. VAG 357 713 075

I decided to buy a new original gasket (160 rubles) and stick it on.

3. Repair kit for gear shift mechanism. VAG 191 798 116 A

The original repair kit costs 900 rubles, since my budget is limited, I decided to buy

SWAG 99 90 8338

, costing 210 rubles.

Insert the rubber gasket...

...next we insert a plastic “glass” in which the ball will then be placed...

4. Shift lever VAG 1H0 711 116A + Adjusting eccentric VAG 191 711 073 A

There is an eccentric on the lever for fine adjustment (see the first message in this topic)

5. Spring VAG 431 711 197

The spring is not included in the repair kit. We put the spring on the lever...

...then we put on the metal plate from the repair kit. It is important to put it on the correct side, the “smooth side” to the ball...

...then we put on the ball...

...we hold the ball tightly with our hand and hammer the bushing from the repair kit into this hole...

...it turns out something like this...

...general view of the “blank”.

6. Gear shift fork rod. VAG 1H0 711 155 A

It was this detail that became the reason for my global repair of the scenes. The link was in terrible condition, there were gaps, a lot of wear, and the rod was bent as a result of a blow from below by the previous owner.

... in the end I broke this part...

...before breaking, the rod rubbed against the car tunnel for a long time...

7. Guide bushing. VAG 191 711 190 B

I purchased the original for 600 rubles, but you can get by with 150 rubles. I decided that it was too labor-intensive to change these bushings, and did not risk the “non-original”.

...who cares what's inside...

...fill the bushing with grease and put it on the rod...

...collecting everything...

...lubricate...

...insert the bushings from the repair kit..

...insert the structure into the “box”...

...we fix the guide bushing in the seat...

...tighten the nuts from the repair kit...

For those whose gear shift knob dangles to the right/left, I would like to draw your attention to the fact that replacing the repair kit VAG 191 798 116 A will not solve the problem. This repair kit solves the problem of the handle play up/down, and another repair kit VAG 1H0 798 201 is responsible for “right/left” (see previous message in this topic)

Description of the last node:

1. Gear shift lever. VAG 1H0 711 176 A

This part costs 850 rubles. No analogues were found. The photo shows the wear on the walls, this was done by the ball of the enveloping shaft 1H0 711 173

.

2. Screen VAG 1H0 711 081

The part practically does not wear out, but just in case, the price of the original: 300 rubles, no analogues have been found. I concluded that this part has a protective function, i.e. You can do without it, but it’s better not to experiment. vw_wink.gif

We put the screen hole on the hinge...

...turn counterclockwise...

... we finish it and snap it in place...

3. Clamp VAG 1J0711603

We put the clamp on the gear shift lever. VAG 1H0 711 176 A, there is a hole in the lower part of the clamp, we match it with the protrusion on the “switch”.

Insert bolt N 0103404

(M8x40)…

... tighten the nut N 90200201

We get the following:

One of these days I intend to install the backstage. The entire assembly assembly is installed from below, from the bottom. The resonator (catalyst) is first removed and the thermal insulation protection is removed. I'll try to take a photo during installation.

ps When I previously looked at various reports about the scenes on this forum in the hope of understanding what and how it works, questions constantly arose and a desire to look at everything from different angles. I took these desires into account when creating my first report. I think I managed to explain to everyone how the backstage works, and those who have never seen it live can now imagine how it works.

Continuation and all discussions of the report here

Thanks: NickBhl

How can I find the information I need here?

Decoding the factory equipment of the car (English) Decoding the factory equipment of VAG in Russian! Diagnostics of

Volkswagen, Audi, Skoda, Seat, error codes.

If you have not found information on your car, look at the cars built on the platform of your car. Most likely, the information on repair and maintenance will be suitable for your car.

Rotary gear shift knob automatic transmission

What is now becoming fashionable in modern cars was called "Dial-A-Gear" in the 1950s. Yes Yes. Rotary gear shift knobs did not appear in the 21st century, but in the middle of the last.

For the first time, such automatic transmission knobs appeared on the classic Jaguar XF model.

But in the end, in those years this technology never became popular. But today a number of automakers, realizing that the time has come, began to equip many cars with beautiful and elegant rotary gear shift knobs.

In some exclusive luxury cars, such handles not only serve as transmission controls, but are also an expensive interior decoration.

For example, in some rare luxury cars, such handles are made of precious metals and encrusted with diamonds.

Unusual gear shift knob on the BMW i3

To be honest, when we noticed the gearshift knob in the BMW i3 electric car, we thought for a long time what to call this technology. But after rummaging through the Internet, we surprisingly did not find the official name for this type of gear shift. By the way, you will no longer see such technology for switching automatic transmissions in any car.

This unusual BMW i3 shift knob is mounted on the steering column of the electric car at a certain angle. The handle can rotate in one direction or the other at an angle. Thus, the driver can select the automatic transmission operating mode.

Most likely, this style of gearshift knob in the BMW i3 remains from the concept car, which was presented long before the production version of the car appeared. Apparently, the designers and constructors decided to leave this futuristic and unusual interior element in the production car.

Source

Manual transmission lever

On the vast majority of modern cars (both domestic and foreign models), the manual transmission lever has a floor-mounted remote location. The lever itself is connected to the gearbox using a rocker – special rods located outside the box body, as well as cables and a roller. This design provides a convenient and easily accessible lever position for the driver.

It is also worth mentioning the manual transmission stalk. In this case, it is located directly on the steering column. A similar mechanism was quite popular in the USA and Europe, starting from the late 1930s, and was also found on domestic cars (Volga GAZ-21). Many car enthusiasts rate the steering column lever as more convenient, noting that when changing gears they do not have to reach for it every time. However, the disadvantages of such a transmission are also significant: increased wear of the rods, low clarity and speed of gear selection, incomplete engagement and disengagement of gears, spontaneous “knocking out” of the gear and even complete jamming of the rods are possible.

Features of levers

Levers may vary in length. In the modern automotive industry, there is a tendency to reduce the length of the lever. If earlier on passenger cars one could find levers whose length sometimes reached thirty centimeters, today manufacturers, trying to make every detail as ergonomic as possible, use much shorter levers.

The lever knob can be round, oval or cylindrical. Thus, manufacturers are experimenting with shape to make it more comfortable for the driver to change gears. As a rule, the knob also performs an information function - it depicts the gear shift diagram for a given car.

When tuning a car, a weighted metal knob can be installed on the lever. This makes it easier to quickly change gears - you just need to push the lever slightly, and then it will continue to move by inertia, due to the weight of the knob.

Gear shift patterns

When selecting a specific gear, the gearshift lever is tilted in the longitudinal (back and forth) and transverse (left and right) planes. By swinging the lever left and right, the gear shift fork is selected. And then, pushing the lever forward or backward, the driver, using the selected fork, moves the synchronizer or clutch in the desired direction, thereby including one or another gear. In the neutral position, the lever is held in place by one or more springs.

In most cases, on cars with a four-speed manual transmission, first and second, third and fourth gears are located opposite each other, and the rear gear is engaged either by moving the lever to the right and back, or to the right and forward.

In the case of a five-speed transmission, a fifth gear is added, usually to engage it you need to tilt the lever to the right and then move it forward.

Many European cars (including front-wheel drive VAZs) use another version of this shift system, in which reverse gear is engaged by moving “left-forward”. This is where the issue of unintentionally engaging reverse gear instead of first becomes relevant. To prevent this from happening, manufacturers provide various systems for blocking such inclusion. The locking is disabled by pushing the lever inward, pressing and holding a special button, or lifting the ring located directly on the gearshift lever handle.

It is worth noting that the gear shift patterns are the same for both left- and right-hand drive vehicles.

Operational issues

Perhaps the main problems that motorists face when operating the gearshift lever are its rattling and vibration. And, of course, AVTOVAZ products often suffer from this.

Usually the lever handle itself rattles. Moreover, if you press it with your hand, the rattling stops. Such a defect can easily be eliminated by grinding down the lever mounting sleeve by 3 mm.

Lever vibration is a little more difficult to get rid of. Vibration is transmitted to the lever via rods from the power unit. As a rule, this is a design feature of a particular model, a design feature, and to permanently eliminate the problem it is necessary to change the entire gear shift drive. On cars with a cable drive mechanism, problems with vibration do not arise.

“Robot” or “automatic”, “manual” or “mechanics”: what is the correct name for gearboxes?

The reason for this material was one of our reader’s comments. He scolded us, saying that we allow inaccuracies in the names of types of gearboxes: they say, in no case should you call a “robot” an “automatic”, since these are different things. Well, on the one hand, such a reproach is not new: the average consumer is not at all obliged to know professional terminology, the main thing for him is the feeling of driving. On the other hand, we thought about it and decided to give an explanation on this issue, since a fair part of our audience does not accept garage slang and wants to know what is actually “correct”, as in science.

Let’s start with science, and not just any science, but with the “Theory of Automatic Control”, it is this that will help us understand the boxes - the basics of TAU are given to students of almost any engineering specialty. No, no, we are not at all going to burden readers with the principles of operation of the Watt regulator and a description of the proportional-integral law as one of the principles of automatic control of systems. TAU offers much simpler postulates, some of which we adapt to explain a seemingly simple question that is clear as day: what is the difference between a car with a manual transmission and a car with an automatic?

We will not rush to answer, but let us clarify that TAU defines the breakdown of all systems by type of control into the following: “manual”, “semi-automatic” and “automatic”. What does this mean when applied to a car? This means that if the driver:

. then the box according to the “type of control” criterion is classified as “manual”.

Porsche 911 gear shift lever

Let’s immediately jump to the third case – “automatic”. Simple logic suggests the opposite: if the electronics thinks for the driver in full, at the same time

. therefore, we have before us a gearbox, which, according to the “type of control” criterion, is classified as “automatic” or “automatic”.

Gearbox selector for Opel Insignia Country Tourer 2018

The “semi-automatic” option is now mostly familiar to racers - say, those driving Formula 1 cars. In this case, the driver only has the choice of gear: the driver gives a signal - closes the contact, and the electronics, following this instruction, already carries out the process of engaging the gear using a servo drive.

From all of the above, a simple conclusion suggests itself: the type of gearbox according to the criterion “type of control” does not imply absolutely any design features of the part of the box in which the torque is transformed. This is important because the same box, as we will show below, will be “automatic” according to the “control type” criterion, and “mechanical” according to the “torque transformation type” criterion. Could this be possible?

Are “mechanical” and “manual” the same thing?

Yes, how can it! Just to begin with, let’s ask ourselves whether it is correct to call “manual” boxes “mechanical” - it seems that this has long come into use. Yes, we are used to this, because in the 80s, 90s and the first half of the 2000s, the general consumer practically did not know other automatic transmissions except hydromechanical ones, which are a pair of torque converter and planetary gearbox.

Automatic transmission 9G-TRONIC Mercedes-Benz

Here we will make a reservation right away: within the framework of this material we are not considering the evolution of the design of boxes. Sometimes they produced such things in small series that people were perplexed: why? In any case, we will write a separate article about this, there will be something to talk about there. The substitution “manual means mechanical” does not bring anything bad, especially since in many ways it reflected the consumer picture of the automotive world in the three decades until the mid-2000s.

Manual transmission MT6 Opel

Meanwhile, the word “mechanical” according to the criterion “type of torque conversion” means that the torque in the box is increased or decreased without the use of pneumatic, electrical or other devices other than mechanical ones. Simply put, the torque supplied to the box changes due to the interaction of any two pieces of hardware. Please note that we say “glands” and not “gears”: this criterion for grouping gearboxes is already directly linked to the design of the unit.

The design of a manual transmission - how a manual transmission works

Most modern vehicles are equipped with the following types of gearboxes:

Each type of gearbox has its own design, different from others, its own advantages and disadvantages, based on which a car enthusiast may give preference to one or another device when buying a car. The design of a manual transmission (MT), which will be discussed in detail in this article, is distinguished by its simplicity, so it is quite easy to understand the principle of its operation.

Mechanism

Mechanical box

Before we begin to study the structure of a manual transmission (MT) and the principles of its operation, this mechanism should be described in detail. A manual transmission is an integral part of any vehicle equipped with an internal combustion engine. Its mandatory presence is due to the specific operation of modern engines, which have a fairly small speed range within which maximum power and torque values are achieved. In addition, any engine has a critical speed value, exceeding which invariably leads to premature wear of the unit, up to its failure. Before transmitting torque to the secondary shaft and to the wheel drive of the vehicle, the manual transmission changes the direction of this vector physical quantity and transforms it. The transition to each new stage in a manual transmission is carried out by mechanically moving the lever to one position or another.

The gearbox mechanism itself is located in a metal case, into which lubricants are poured, ensuring stable operation of the mechanism. The gear shift lever can be located both in the gearbox itself and outside it (in the body of the car). In the case of a remote gear shifting process, a control drive rod (yoke) is used.

Design Features

Components of manual transmission:

- input shaft;

- intermediate shaft;

- secondary shaft;

- additional shaft;

- crankcase;

- synchronizers;

- gear shift device, which includes locks and locking mechanisms;

- gear shift knob.

Operating principle

Principle of operation

Bearings located in the crankcase contribute to the rotation of the device shafts. Each shaft is equipped with sets of gears, on which special teeth are located in varying numbers.

The function of synchronizers is to balance the angular velocities of the gears that arise during their rotation. Thanks to their operation, gears shift smoothly without extraneous noise.

Locking mechanisms prevent the possibility of spontaneous disengagement of gears, while locks prevent the simultaneous engagement of several gears.

The gear lever handle is classified as follows:

By type: standard and for tuning (differ in original design.

By purpose: for cars and trucks, for certain models, universal, for automatic or manual transmission.

According to the configuration: just handles without additional decor, handles with covers (straight or corrugated), with additional equipment (buttons for automatic selectors, a stand and other elements).

Material of manufacture: handles can be metal, plastic, wood, or combined. Covers and trim are often made of leatherette or rubber. Products made from genuine leather are much less common.

The gear knob can be attached to the lever in different ways. The most common solution for manual transmissions is threading (the lever is simply screwed into the handle). The gear shift knob can be fixed with various clamps, screws, and self-clamping mechanisms. This option is most often used in automatic transmission selectors, where it is very important to fix the lever in a certain position.

Interesting, but no one ever bothered before buying a gear shift knob . Now it has become not only a functional, but also a stylish element.

If you want to buy a gear shift knob , you should first of all pay attention to the installation dimensions and recommendations of the manufacturer (whether it is universal or model). There should also be a sign on its surface indicating the location of the gears.

Replacing the handle is not difficult: if the fastening is threaded, the old model is simply unscrewed, and the new one is fixed in its place. If there are clamps, you will have to tinker: remove the retaining ring, unscrew the screws, pull out the pins. To change the cover you will have to remove the panel on the console.

WHERE CAN YOU BUY A CAR TRANSMISSION HANDLE CHEAP?

VODOOL gear knob (8.5 cm, 6 colors)

Seller's reliability: excellent!

Delivery within Russia: free!

Customer reviews:

Review #1: Excellent quality for reasonable money! I recommend it to everyone! Fits Toyota Noah/Voxy 2010 perfectly! Much more convenient than the traditional one. Practical. Doesn't get dirty like traditional ones. Satisfied.

Review #2: The order arrived quickly. I recommend. Auto Kia Cerato mechanics. The quality is good, but the universal adapters did not fit.

Review No. 3: Ordered 07/20, received training on 08/24 in Moscow Region. Long delivery for me, I was really looking forward to it. I changed it without any problems, the adapter fit on the Lanser X, the only thing was that there was a gap between the tip and the leather pad. Thin, WARNING. I'm happy with it, I'm very comfortable with thin.

Universal gear lever La MaxZa

Seller's reliability: excellent!

Delivery within Russia: free!

Customer reviews:

Review No. 1: The handle is not bad, but a little thin, it looks bigger in the picture. Overall, it's ok for the money.

Review No. 3: I installed it, of course it fits well in my hand, so far I like it. I was very pleased with the price and fast delivery. I recommend taking it.

Gearbox shift knob in Auzan car

Seller's reliability: excellent!

Delivery within Russia: free!

Customer reviews:

Review No. 1: Thanks to the seller, the order arrived very quickly, in fact, in a week to the Vologda region. Good quality. The set contains three adapters. With one of them I approached the Hyundai matrix. The item itself is convenient. I recommend.

Review No. 2: After three months of use, there are no complaints, the paint has not worn off, it’s convenient. So take it without hesitation.

Review No. 3: Excellent quality, fits on the Subaru Forester SH without any problems, just like a native one! The post office tried to deliver and not spoil the order. Special respect to her.

IZTOSS gear knob with backlight (for BMW Toyota VW Honda)

Seller's reliability: excellent!

Delivery within Russia: free!

Customer reviews:

Review #1: Everything arrived intact. Adapters and keys included, eyes glow. I didn't order for myself. It was not installed on the car. It arrived in a month.

Review #2: Very beautiful! I took it as a gift, so I won’t try it. THANK YOU! I’ll also order one for myself.. By the way, the subgrid is LED. Effective in the dark.