03/24/2021 35,581 automatic transmission

Author: Ivan Baranov

The automatic transmission, being a rather sensitive unit to improper operation, may periodically work incorrectly, in particular, it may not change gears. In such cases, the car owner has no choice but to take his car to specialists or try to solve the problem on his own. From this material you will learn why the automatic transmission does not change gears, what this may be due to and what to do in such cases.

[Hide]

Diagnostics

Shifting the automatic transmission lever

Automatic transmissions have already become popular among domestic motorists, although twenty years ago no one could have thought that this would happen. As a result of many advantages, the demand for these units is constantly growing. Of course, like any other component in a car, an automatic transmission can periodically fail or function incorrectly. In fact, there can be many problems with the unit, but if the automatic transmission does not change speeds, then the only way out is diagnostics.

But, first of all, you need to reliably make sure that this malfunction is really related to the operation of the unit. You must ensure that all vehicle systems are functioning properly if you are unable to change gears. In principle, one of the main faults due to which the automatic transmission does not change gears is often a lack of working fluid in the system. As a rule, this is usually due to a worn out oil seal of the unit, which causes fluid to leave the automatic transmission.

A lack of lubricant level in the box may be due to the following factors:

- Liquid leak. Oil can escape through the crankshaft seals, the cylinder head gasket, the oil filter seal, or through the oil reflective caps. If transmission oil (hereinafter referred to as TM) escapes through the seals, this indicates their wear, which can be caused by the use of chemicals or poor-quality lubricants. The cylinder block gasket could wear out due to overheating of the engine or incorrect tightening of the screws during disassembly and reassembly of the engine. If the problem is with the oil filter, then most likely it is due to the fact that the sealing rubber cannot stay in place. If oil leaks from the automatic transmission due to the reflective caps, then the problem is their wear caused by overheating.

- Breakdown of the vacuum corrector. Inside this device there is a special membrane that reacts to the level of vacuum in the collector. If the integrity of this element is violated, then the TM will get into the car engine. In this case, the unit can function for a long time even with a significantly reduced level of lubrication, but over time it will simply fail.

- If the TM goes into the cooling system. If the tightness of the oil cooler is broken, then the lubricant will go into the engine radiator, since the oil pressure in the automatic transmission radiator is always higher than the pressure in the cooling system. And when the engine turns off, the process of lubricant leakage into the coolant begins. As a result, an emulsion begins to appear in both the internal combustion engine and the automatic transmission. When antifreeze gets into an automatic transmission, it corrodes the clutches, as a result of which corrosion begins to form on the latter. In the event that gears have not been changed for a long time, the problem can be solved by replacing the oil cooler. It is also a good idea to rinse the automatic transmission with working fluid. Having done this, you can try to bring the unit back to life.

- If the pipe that connects the automatic transmission to the oil cooler breaks. In this case, all the lubricant will come out of the transmission in a matter of minutes, so the unit will simply stop working.

Automatic transmission disassembled

This is only a small part of the reasons why an automatic transmission may not change gears. A more complete list is presented in the table.

| Causes | Breakdowns |

| The need to replace clutches, a broken piston cuff, failure of the clutch rings, or a stuck valve body. | In this case, a car with an automatic transmission will only be able to drive in reverse; forward gears will not engage. |

| Breakage of clutches, piston cups, wear of o-rings, malfunction of the spline connection of the clutch drum or other failure associated with this unit. | In this case, the automatic transmission cannot change gears back, but the first and second gears, unlike the others, will work. |

| Malfunction of the cuff, piston rod of the brake band or its wear, problems in the operation of the braking package. | The car does not go backwards, all forward speeds engage normally. |

| Failure of the torque converter, breakage of the oil pump gear, lack of lubrication in the system, clogged filter, wear of the clutches, breakage of the cuff, sticking of the valve. | In this case, the vehicle will not be able to move either forward or backward. When trying to switch to any mode, the driver will not feel a characteristic push. |

| Failure of the torque converter, lack of lubrication in the system, clogged filter element. | The speeds don't change at all. When the parking mode or neutral speed is activated, a characteristic push to engage the gear will appear, but the car will not move. |

| Valve stuck in the valve body. | The car can go backwards or only in first and second speed. Other transmissions will not be included. |

| The turbine wheel hub splines and friction clutches are worn out, and the clutch seals are out of order. | In this case, the car will slip when starting to move, but then the gears will engage well. |

| The pistons of one of the clutches are jammed, the adjustment of the automatic control cable has been disrupted, and the clutches have become welded to other discs as a result of prolonged slipping. | The car can only be driven at neutral speed. |

| Incorrect adjustment of the throttle valve cable, the filter element is clogged, the throttle valve or centrifugal regulator valve is stuck. | In this case, gear shifting will be carried out at increased speeds, significantly higher than standard values. |

| The clutches of the automatic transmission have worn out, and excessively large gaps have appeared in the packages. | With such a breakdown, switching on a particular speed will be accompanied by shocks. In normal mode, the driver would feel the shocks. |

| During long-term operation, the splines of the turbine wheel were cut off. | The car cannot go forward or backward. In this case, the pressure in the transmission line will be normal. |

| The oil pump pulley splines are worn. Also in this case, the splines on the reactor pulley may be worn out. | The car will not be able to drive forward or backward, but there will be no pressure in the line. |

| Failure of clutches. When the clutches wear out, the transmission fluid will contain more metal dust and chips from the discs. As a result, dust clogs the filter element, and the pressure in the line begins to decrease. | The vehicle will operate normally until the lubricant warms up. After warming up, the car will begin to slip and the car will not be able to move at all, neither forward nor backward. |

| In the design of the automatic transmission, one or more gear clutch valves have become stuck or the torque converter is not functioning correctly as a result of the turbo wheel being jammed. | In this case, changing gears will be completely impossible. When any mode is activated, the car will immediately stall, the driver will not even have time to press the gas pedal. |

| Moisture somehow gets into the structure of the unit. As a result, foam begins to appear inside the automatic transmission, and the oil pump will stop creating pressure. | The gears may change normally for a while, but the car will slip. Visually assessing the oil, you will see that it has foamed and turned light brown. |

Loading …

Signs of a torque converter malfunction

- A metallic sound is heard when shifting gears. As the speed increases and load is applied, the sound disappears. This indicates a problem with the bearings. It is necessary to disassemble the torque converter and assess their condition.

- In the speed range of 60-90 km per hour, slight vibration is observed. Over time, its value increases. This is caused by the filter becoming clogged with wear products. In this case, you need to replace the oil filter and oil. Usually it is necessary to change the oil in the gearbox and engine.

- Problems with dynamics indicate a faulty overrunning clutch. It is necessary to disassemble the torque converter and replace the broken clutch.

- The car has stopped and it is impossible to continue driving. This indicates a broken spline on the turbine wheel. Repair of the unit consists of replacing the turbine wheel.

- The occurrence of a rustling noise while the engine is running indicates a malfunction of the bearings located between the torque converter cover and the turbine wheel. The rustling noise may disappear while driving. In this case, you need to contact a car repair shop and carry out repairs. Thrust needle bearings are usually replaced.

- A metallic knock is heard when changing speed. This indicates deformation of the shoulder blades. Repair is carried out by replacing the faulty wheel.

- It is necessary to periodically monitor the condition of the oil in the automatic transmission and torque converter. If aluminum powder appears on the dipstick, you need to check the freewheel, which is made of an aluminum alloy. Most often, the appearance of this powder indicates wear of the end washer.

- With the engine running and standing, there may be a smell of melted plastic near the automatic transmission. This occurs due to overheating of the torque converter and melting of the polymer parts of the assembly. Overheating occurs for a variety of reasons, but is usually due to lubrication. When the oil level decreases, signs of oil starvation of the torque converter and gearbox appear. There may be problems with automatic transmission cooling. In this case, the repair consists of changing the oil and checking the cooling.

- When switching speeds or changing the operating mode of the box, the motor may stall. This indicates a breakdown of the automatic control system that blocks the action of the torque converter. The repair consists of replacing the control unit.

There are no definite signs of a torque converter failure, so technicians sometimes cannot immediately determine the cause of the failure. This leads to increased repair costs and vehicle downtime. If such problems arise with the automatic transmission, the driver needs to contact a car service center as quickly as possible.

Malfunctions of an automatic transmission can be detected in the fact that it is impossible to switch operating modes of the transmission or it is blocked in any gear. In this case, the driver is required to transport the car using a tow truck. Driving independently in a car with a faulty gearbox is prohibited, as this will lead to serious damage to the drive and the entire transmission.

We recommend: The best spark plugs for a car – platinum or iridium

Sometimes a fault can be detected using sensors built inside the box. Such sensors signal a lack of oil pressure, overheating or malfunctions in the gearbox drive. Many signals about malfunctions with the box are vague, and in this case it is not possible to find out an accurate diagnosis even when using computer equipment. A specialist needs to inspect the transmission, remove the box and, after disassembling it, determine the fault.

Solutions to the problem

Based on the data in the table above, there can be many reasons for incorrect gear shifting on an automatic transmission. Methods for eliminating the problem will depend solely on the signs of a malfunction in the automatic transmission of your vehicle.

In any case, first of all, you need to check:

- Level and condition of transmission fluid. The level should always be normal, the same applies to the condition. If there is little oil in the system, then the cause of its leakage must be identified and solved, and fluid added to the system. If the quality of the TM is low, that is, it contains dust from wear of the friction discs, then the discs should be replaced and the lubricant should be changed. At the same time, do not forget to flush the system several times.

- Conditions of clutches. As can be understood from the table, wear of the clutches is one of the most common problems when it is impossible to change gears. Carry out diagnostics and, if necessary, replacement of clutches.

- Check the functionality of the valves. If they jam for any reason, then this must be eliminated.

- Check the operation of the rocker, transmission system wiring, and speed controller. It would be a good idea to check the brake band as well. If any of these elements are not working correctly, the problem should be corrected.

If none of this helps, then the only way out is computer diagnostics. Diagnostics of the unit is carried out individually in each case, taking into account all the requirements of the automobile manufacturer. We will look at this process in general. So, you will need a computer or laptop and a diagnostic cable.

The appropriate program must be installed on the computer:

- The computer is connected via a diagnostic cable to a special connector (diagnostic). The location of the connector will be individual in each case. Sometimes this connector is located under the hood, but most often it can be found under the steering wheel on the driver's side. It is usually hidden behind a plastic cover, so you need to open it.

- After connecting, the diagnostic utility starts on the computer. It may take several minutes for the program to synchronize with the car’s on-board computer. After that, run the diagnostics. If possible, before starting the test, select the “Gearbox” item so that only the automatic transmission is diagnosed, and not all components of the car.

- Upon completion of the diagnostics, the program will give you a list of error codes that indicate certain malfunctions. You need to decipher these codes in accordance with the documentation for your car. Some of the decoding instructions can be found on our resource. Once you understand what the problem is, you can solve the problem.

1. Find the diagnostic connector in your car, usually located on the left.

2. You must connect your laptop to this connector via a cable.

3. Carry out diagnostics in accordance with the instructions and read the codes.

Causes

Before getting acquainted with methods for eliminating breakdowns, it is necessary to consider their main causes.

Lever link

In old automatic transmissions, where the selector is mechanically connected to the transmission, the gearbox lever often breaks, making it impossible to switch the operating mode. In this case, the repair consists of replacing the faulty selector and rocker. Such malfunctions are detected by difficult movement of the automatic transmission selector. As a result, the lever does not move and the transmission must be repaired. Some brands of automatic transmissions cannot be repaired without removing them from the car, making repairs easier.

Oil leak

A popular problem with automatic transmissions is oil leaks at the seals. Therefore, it is advisable for the car owner to periodically visually inspect the box on a pit or lift. If you detect oil leaks on the gearbox, you need to contact a car repair shop. In this case, the problem is solved by simply replacing the gaskets and gear lubricant.

Control block

Electronic components can break down for various reasons. Sometimes there are problems with the functioning of the automatic transmission control unit. The unit may incorrectly select the speed for the gears, or it itself blocks the operation of the transmission. Troubleshooting the operation of this unit, as well as the electrical circuit of the box, consists of replacing control cables and faulty units.

You need to know that driving a car with a faulty unit is dangerous, so it is recommended to contact a workshop at the first sign. And if the automatic transmission does not want to work at all, then you should not start the engine, but it is better to move it to a service center using a tow truck. The causes of ECU failure may be:

- Exposure to moisture.

- Heat.

- Effect of vibration loads.

- Mechanical impact.

- Sudden voltage drop.

These reasons can lead to damage to the control unit, which requires expensive repairs or replacement. Car service centers can tell you how to check the electronic unit of an automatic transmission. Fault diagnosis is carried out using special instruments that allow us to identify the nature of the fault, which makes it possible to eliminate it at the lowest cost. In many cases, ECU repair comes down to replacing burnt out chips and boards. This work is quite complicated, since it requires desoldering microcircuits from boards and replacing failed capacitors. Sometimes it is easier to replace a faulty unit with a new one. This makes it possible to get rid of problems with the automatic transmission.

Qualified repairs should be carried out only in a certified center that has sufficient experience in automatic transmission repair. There is no need to skimp on qualified repairs and turn to garage technicians.

Valve unit malfunctions

One of the important components of an automatic transmission is the valve body, which is responsible for the gear shift process. This unit, according to the masters, is the brains of the automatic transmission. The valve body plays the role of organizer of the movement of transmission oil through the box. There are different hydraulic block designs, depending on the type of box.

During operation, the valve body takes on heavy loads, so if it is poorly maintained or used incorrectly, the valve body may break. Malfunctions of the automatic transmission valve body may occur due to improper operation of the transmission. For example, in cold weather, a driver can not wait for the oil in the box to warm up, but immediately start driving with heavy loads. In some cases, there are problems with the cooling system that arise due to infrequent oil changes and improper operation of the oil receiver. This can lead to malfunctions of the valve body and the entire box.

Failures can be determined by various signs of the valve body. You need to know that despite the progression of computer diagnostics of machines, it is difficult to determine the malfunction of this unit. Therefore, during maintenance, specialists can accurately diagnose only by removing the box from the car.

Torque converter malfunction

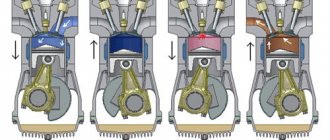

This mechanism is an element of the automatic transmission. It makes it possible to create smooth gear shifts for the gearbox. Its design is constantly being modernized and complicated. Now the torque converter on an automatic transmission works as a clutch. When changing gears, this unit disconnects the engine from the gearbox. After engaging the gear, it takes over the torque, which ensures the smoothest speed change.

If problems arise with this unit, only repair it is necessary. In general, these works cost less compared to the electronic unit and valve body. Torque converter malfunctions are identified by the symptoms we indicated above.

Recommendations for use

- Forget about slipping - you need to eliminate it by any means necessary. Automatic transmissions have a negative attitude towards slipping, especially in snowy and icy conditions.

- Always warm up the automatic transmission in winter. With an unheated automatic transmission, the likelihood of certain elements of the unit failing is very high.

- Don't use neutral speed in vain. Mode “N” is considered a service mode, so limit its activation.

- Cars with automatic transmissions should not be towed by anyone, since such transmissions are simply not designed for this. Loads have a very negative impact on the design of the unit as a whole. If you plan to drive with a trailer, then keep this factor in mind when purchasing a car.

- Cars with automatic transmission are not allowed.

- Do not tow your car with a rope. While driving, lubricant should always circulate in the transmission, but if the engine is turned off, the TM will not move through the system. Of course, this negatively affects the operation of the unit as a whole.

- Always use only high-quality transmission fluid recommended by your vehicle manufacturer. Remember that using a cheaper lubricant over time can only harm the unit of your car, if not kill it.

Why the automatic transmission does not change gears: electrics, mechanics and hydraulics Smart69

For example, automatic transmission gears do not shift if there is a breakdown of the automatic transmission electronic control system (ECS). Main malfunctions of the automatic transmission ECU: Smart69

- failure of input sensors, sensors of the internal combustion engine control system (camshaft position sensor, throttle position sensor, etc.); Smart69

- failure of the automatic transmission ECU; Smart69

- malfunction of the control system actuators (disturbance or break in the winding of the solenoid valve or increase in resistance capacitance); Smart69

- breakage of electrical wiring and connections (short circuit, oxidation, etc.); Smart69

To check the electrical part, codes are read using computer diagnostics and a special scanner, almost all faults of the automatic transmission ECU are identified.

The exception is electrical wiring, the diagnosis of which is carried out by visual inspection and “ringing”. Smart69

What's the result?

It should be understood that the automatic transmission is a complex vehicle component that requires increased attention, and servicing of such an automatic transmission should be carried out only in qualified centers by experienced specialists.

If we talk about independent repairs, in addition to checking the level and quality of transmission oil, it is not recommended to repair automatic transmissions without the proper experience and equipment, especially in makeshift conditions.

Why the automatic transmission kicks, the automatic transmission jerks when changing gears, jerks, jerks and impacts occur in the automatic transmission: the main reasons.

Automatic transmission slipping when changing gears: the main reasons why an automatic transmission slips. Box diagnostics, troubleshooting.

Is it possible to tow a car with an automatic transmission: basic rules and recommendations. What you need to consider if a car with an automatic transmission is towing another car.

The automatic transmission jerks: the main causes of jerks, kicks, and shocks in the automatic transmission. Diagnostics of faults, tips and recommendations.

How an automatic transmission works: classic hydromechanical automatic transmission, components, controls, mechanical part. Pros and cons of this type of gearbox.

Driving a car with an automatic transmission: how to use an automatic transmission, operating modes of an automatic transmission, rules for using this transmission, tips.

Actions of motorists

I’m moving on to the most anticipated part - if you are not able to figure out on your own why the gear shift on your gearbox does not engage, then you should contact a car service center, where specialists will carry out diagnostics and educate you about the breakdown, cost and repair time. Checking the functionality of automatic gearboxes is carried out only using computer diagnostics, so you should make sure that the service is available at the car service center.

If after diagnostics no faults are found, and the car continues to act up when changing gears, then you should pay attention to the speed sensors, wiring and scenes.

The backstage can be cleaned quite easily using a hole in the garage or an overpass. The gear and speed sensor is a rather capricious thing. If there is a breakdown, the sensor stops sending signals, which forces the gearbox not to respond to the signals (the gearbox simply sees that there were no signals).

It will be useful: Which CV joint to choose for Ford Focus 2? review of CV joints which one is better

If all the presented methods for eliminating the breakdown are not effective, then the car requires the intervention of a car service guru.

It is worth understanding that there are many more causes of failure, symptoms and methods for eliminating them. You should not delay resolving the issue and allow your car to “cure.”