The internal combustion engine of a car, as you know, consists of many moving parts in contact. Its work will be impossible without high-quality lubrication of all rubbing elements. Lubrication not only reduces friction by cooling metal parts, but also protects them from deposits that appear during operation. To ensure reliable engine operation, it is necessary that the oil pressure be maintained within the range specified by the designers in all modes. Insufficient or excessive oil pressure in the engine will sooner or later lead to engine failure. In order to avoid big problems associated with expensive repairs, you need to identify the problem in time and fix it immediately.

Oil pressure alarm

On the instrument panel of any car there is an emergency oil pressure indicator, in other words, a light bulb. It usually looks like an oil can. Its function is to instantly inform the driver that the oil pressure has dropped to a critical level. The indicator is connected to the oil pressure sensor, which is located on the engine. If the oil pressure alarm goes off, you must immediately stop the engine. It can be restarted only after the fault has been eliminated.

Before the light comes on, it may flash periodically, which is also a sign of low oil pressure. It is better not to delay solving this problem, but to immediately diagnose the problem.

Checking the alarm

During normal engine operation, the warning light does not light up, so the question may arise: is it working? It is very easy to check its operation. When the ignition is turned on, before the engine starts, all indicators on the instrument panel light up in test mode. If the oil pressure light is on, it means the warning light is working.

The instrument panel is in test mode when the ignition is turned on - at this moment all the lights come on to check their operation

An easy way to check oil pressure without a pressure gauge

However, a pressure gauge is not always available. Therefore, a simple express method for diagnosing engine oil pressure is often used. This will require the help of a friend and some available equipment. You need to understand that this way you can only verify the presence of pressure at which you can still drive a car. So, if you don’t have a pressure gauge, you need to do the following:

- Open the hood and check the lubricant level using the dipstick.

- Disconnect and unscrew the oil pressure sensor installed on the engine.

- De-energize the ignition coils by disconnecting the wires.

- Use the starter to turn the engine crankshaft.

- While the starter is operating, observe the mounting hole of the oil pressure sensor. You need to make sure whether a stream of oil appears from there when the engine rotates.

If there is a jet, then we can confidently conclude that the sensor is not working. Therefore, you can drive to the service center on your own. If lubricant does not flow out of the sensor seat, it means there is no oil supply to the engine. Therefore, you should refrain from further movement in this car. As you can see, this method can also check the serviceability of the oil pressure sensor.

Insufficient engine oil pressure

For a number of reasons, the oil pressure in the engine may decrease, which will lead to a condition where some engine parts receive an insufficient amount of lubricant, i.e. oil starvation. The engine will operate in a mode of increased wear of parts and will eventually fail.

Reasons for low blood pressure

Let's look at the reasons that can lead to a decrease in oil pressure.

Low oil level

Insufficient oil level in the engine leads to a decrease in its pressure and the occurrence of oil starvation. The oil level must be checked regularly, at least once a week. For this purpose, the engines are equipped with a special probe with a permissible level scale.

- Place the car on a horizontal platform so that there is no measurement error. It’s good if the car is parked in a garage with a flat floor.

- Turn off the engine and wait 3–5 minutes for the oil to drain into the oil pan.

- Take out the dipstick and wipe it with a rag.

- Insert the dipstick into place all the way down and remove it again.

- Look at the scale and determine the level by the trace of oil on the dipstick.

It is advisable to maintain the oil level in the engine so that its trace on the dipstick fills approximately 2/3 of the distance between the MIN and MAX marks

If the engine oil level is too low, it needs to be topped up, but first inspect the engine for leaks. Oil can leak from any connection of parts: from under the oil pan, crankshaft oil seal, fuel pump, oil filter, etc. The engine body must be dry. A detected leak must be repaired as soon as possible; driving the vehicle should only be done if absolutely necessary.

Oil can leak from any joint between engine parts, for example from a damaged oil pan gasket.

Old, worn-out engines often suffer from the problem of oil leakage, which is called “from all the cracks”. In this case, it is very difficult to eliminate all sources of leakage; it is easier to overhaul the engine, and this, of course, will not be cheap. Therefore, it is better to constantly monitor the oil level, add it if necessary, and fix the problem at the first symptoms of a leak.

In the author’s practice, there was a case when a driver delayed repairs until the last moment, until a worn-out 1.2-liter engine began to consume up to 1 liter of oil per 800 km. After a major overhaul, everything fell into place, but you shouldn’t expect a similar outcome every time. If the engine jams, the crankshaft under great force can damage the cylinder block and then it will only have to be replaced with a new one.

Late oil change

Motor oil has a certain service life. As a rule, it fluctuates in the range of 10–15 thousand kilometers, but there are exceptions when the oil needs to be changed more often, depending on the manufacturer’s requirements and the condition of the engine.

Modern motor oil plays a big role in the operation of the engine; it reliably protects all parts, removes heat and wear products from rubbing parts, and removes carbon deposits. The oil contains a number of additives designed to enhance certain of its properties in order to make engine protection even more reliable.

During operation, the oil loses its quality. A lubricant that has exhausted its service life contains a large amount of soot and metal filings, loses its protective properties and thickens. All this leads to the fact that oil may stop flowing through narrow channels to the rubbing parts. If the car is used little and the recommended mileage is not covered within a year, the oil should also be changed. The chemical properties of oils are such that with prolonged interaction with engine material they also become unusable.

The oil thickens in the engine as a result of prolonged use, far exceeding the permissible service life.

Deterioration of oil quality and increased engine wear are processes that contribute to the aggravation of each other. That is, bad oil, which does not lubricate parts well, leads to increased wear, and during wear, a large amount of metal shavings and deposits appear, further contaminating the oil. Engine wear increases almost exponentially.

Oil type does not comply with manufacturer's recommendations

Motor oil must exactly match the mechanical, thermal and chemical influences that the engine has on them during operation. Therefore, motor oils are divided into several types according to their purpose:

- for diesel or gasoline engines, there are also universal products;

- mineral, semi-synthetic and synthetic;

- winter, summer and all-season.

What is more dangerous for the engine, low oil level or insufficient pressure?

These two events are related to each other. Oil starvation (low level) is one of the causes of low blood pressure . The oil pump “grabs” air, which has a high compression ratio. As a result, the forces of the pump impeller (gears) are wasted on compressing air bubbles, instead of pumping up pressure.

What other reasons lead to loss of oil pressure?

- Viscosity mismatch according to SAE. Liquid that is too thick has difficulty passing through the pores of the oil filter. And increased fluidity leads to cavitation - the formation of air bubbles at normal oil levels.

Air bubbles in engine oil - Engine overheating, or more precisely, incorrect operation of the cooling system. At abnormally high temperatures (outside SAE tolerances), the oil thins out. Next: see previous paragraph.

- Physical malfunction of the oil pump: Breakage of the injection unit (impeller, gears);

Violation of the tightness of the housing: there are cases of rubbing of the pump by the timing chain inside the crankcase. - Foreign liquids getting into the engine oil: for example, antifreeze through a “broken” gasket. Consequences: liquefaction, formation of emulsion, foam, air bubbles.

- Severely dirty oil filter. Sometimes during routine maintenance, only the fluid is changed, but the filter continues to clog.

How to increase engine oil pressure

To restore the required oil pressure in the engine, you need to eliminate the reasons for its decrease - add or replace oil, repair the oil pump or replace the cylinder head gasket. After the first signs of a drop in pressure, you should immediately contact a specialist for a more accurate diagnosis. Such signs may be:

- motor overheating or unstable operation;

- loss of power;

- oil leak from the engine;

- strong smoke from the exhaust pipe of a bluish, white or black color;

- the emergency oil pressure indicator is triggered or blinking.

The reason for the drop in pressure can be very complicated, or rather, expensive. We are talking about engine wear and tear during operation. When it has already passed its service life and requires repair, unfortunately, other than carrying out a major overhaul, there is no way to solve the problem with low oil pressure in the engine. But you can take care in advance to ensure that the oil pressure in an already worn-out engine remains normal. Today, there are a number of additives on the automotive chemical market designed to eliminate minor engine wear and restore factory technological gaps between rubbing parts.

Briefly about the design of the lubrication system

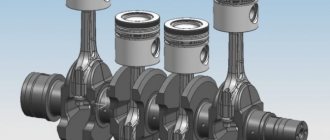

Continuing to draw parallels between the operation of the engine and the circulatory system of the human body, let’s consider what makes the oil circulate through the channels of the power unit, performing its assigned functions.

The role of the heart, which drives the life-giving fluid, in the engine is played by an oil pump. From it, lubricant is distributed through the “vessels”, which are represented by special channels in the car’s power plant, to all corners of the system.

Most modern passenger cars use a combined oil supply method. Under a certain pressure, the lubricating substance is pumped from the crankcase into the main line, bypassing the receiver and filter device.

The purified oil reaches all functionally significant parts and components of the engine, such as crankshaft bearings and camshaft bearings or piston pins. The slightest deviations in the normal operation of the system are regulated by special valves:

- reducing is designed to control pressure. Excessive excess of the standard value leads to valve activation. Through it, excess oil is discharged to the inlet;

- If the oil filter is clogged, the bypass valve is activated. His responsibilities include supplying unclean lubricant to the system.

A special sensor is placed on the cylinder block. Its functions include timely notification of the driver about an excessive drop in oil pressure in the lubrication system of the power unit.

How to measure engine oil pressure

Some vehicles are equipped with a stationary gauge that displays operating oil pressure on the instrument panel. In the absence of one, you must use a special pressure gauge. In order to measure oil pressure, the following operations must be performed.

- Warm up the engine to operating temperature 86–92 °C.

- Turn off the engine.

- Unscrew the emergency oil pressure sensor from the engine block.

The sensor is completely unscrewed from the engine housing after disconnecting the wire from it

The pressure gauge fitting is installed instead of the unscrewed emergency oil pressure sensor

Oil pressure varies in engines of different models, so the range of its operating indicators must be looked for in the technical literature for a specific car model. But if these are not at hand, you can use averaged data corresponding to the normal operation of the engines.

Table: average oil pressure in serviceable engines

| Engine characteristics | Indicators |

| Engines 1.6 l and 2.0 l | 2 atm. at idle speed (idling), 2.7–4.5 atm. at 2000 rpm. per minute |

| Engine 1.8 l | 1.3 atm. at idle speed, 3.5–4.5 atm. at 2000 rpm. per minute |

| Engine 3.0 l | 1.8 atm. at XX speed, 4.0 atm. at 2000 rpm. per minute |

| Engine 4.2 l | 2 atm. at XX speed, 3.5 atm. at 2000 rpm. per minute |

| TDI engines 1.9 l and 2.5 l | 0.8 atm. at XX speed, 2.0 atm. at 2000 rpm. per minute |

Accordingly, if the indicators go beyond those given in the table, then you should contact a specialist or take action to eliminate the malfunction yourself.

Before starting repairs, the oil pressure must be measured to make sure that the primary signs are correct.

Video: measuring oil pressure in a car engine

Motor oil can be compared to the blood in a living body - it plays a fundamental role in the functioning of all organs, just like the oil for the mechanisms in a car engine. Carefully monitor the condition of the oil in the engine, regularly check its level, monitor for chip impurities, monitor the mileage of the car, fill in oil from a trusted manufacturer and you will not experience problems with oil pressure in the engine.

In order for the car’s motor system to function properly and for a long time, all its mechanisms must be constantly lubricated. In this case, the oil should not simply “splash” at the bottom of the crankcase; it should be distributed between the components through special channels of the engine lubrication system. To “make” it flow and flow out of these channels, a special pump is provided, with the help of which the operating oil pressure is created in the engine.

The principle of operation of the system is simple: the technical fluid, under the influence of the pump, enters the filter element of the structure, is cleaned and then penetrates into the oil line and channels. Part of the protective material is distributed onto rotating parts, and part of it irrigates the elements by airborne droplets. Thus, it is the pump that creates the oil circulation rate required by the engine.

What oil pressure should be in a car engine?

There is no consensus on this matter, since the engine system of each automobile brand is designed according to specially developed engineering projects of the automaker. However, all power plants have an important feature in common: at idle speed, the oil pressure in the engine must be lower than the pressure under load. And this is quite logical: the higher the rotation speed of the parts, the more intense their lubrication.

The average working pressure has the following indicators:

- at idle – 2 bar (0.2 MPa),

- with increasing speed - 4.5-6.5 bar (0.45-0.65 MPa).

Any deviation from the norm can have serious consequences for the engine.

Checking the pressure in the power plant

Each car is equipped with an oil pressure warning lamp, which is activated when the usual “oil circulation” is disrupted. Moreover, the indicator can be constantly on or blink at idle. In any case, the problem should not be ignored.

When there is no built-in digital meter, a pressure gauge must be used to diagnose the problem.

You can check the oil pressure in the engine according to the following scheme:

- We “warm up” the car to operating temperature - not lower than 90 degrees Celsius.

- Turn off the engine and open the hood.

- We disconnect the emergency oil pressure sensor and install a pressure gauge in its place.

- We check the oil level with a special dipstick and, if necessary, add engine lubricant to the required level.

- Let's start the engine.

- We measure the pressure at idle, then at high speeds.

To more accurately diagnose the problem, you can measure the device readings two or three times, and then calculate the average value.

After disconnecting the control sensor, some of the filled oil may leak out, which is why you need to measure its level before restarting the car.

Result of checking

If the pressure gauge shows normal oil pressure in the power plant, but the control indicator continues to glow treacherously after connection, then the reason for its activity lies in its malfunction. Replace the sensor with a new one and enjoy your trips further.

High blood pressure

Causes

If you are lucky enough to encounter the problem of high blood pressure, then you need to figure out what caused it. This disease occurs for the following reasons:

- Using oil that is not suitable for the engine technical parameters. If you ignored the manufacturer's instructions and poured the first liquid with an excessively high viscosity into the engine, the problem will not be long in coming. It becomes especially relevant when using summer lubricants in winter.

- Obstruction of oil channels and filters. Oil pressure is affected by clogging of the lubrication system paths and filter elements of the structure. A large amount of soot, soot and metal shavings clog the channels through which the oil circulates. As a result, the same amount of liquid continues to move through the “cut down” system, increasing pressure inside it.

- Reducing valve malfunction. The valve does not provide the required dosage of fuel and lubricants and leaves in the system an excess amount of oil for the cycle. As a result, the free space required for effective functioning is reduced and the pressure increases.

- Malfunction of the bypass valve. Its main task is to supply working fluid from the pump to the channels of the lubrication system, bypassing the filter element if it is clogged. If there are malfunctions in its operation and it begins to leak oil while the filter is functioning, the pressure in the power plant increases.

- Exhaust valve defective. Exhaust gases must leave the structure and not accumulate in it. The pressure in the engine lubrication system may increase due to the failure of the exhaust valve: the gas-air mixture will fill the crankcase and increase the pressure of the oil lubrication.

How dangerous is excess engine oil pressure?

Every more or less experienced driver always scrupulously notes deviations from the standard performance indicators of the engine, laid down by the manufacturer during the manufacturing process of the car. This is akin to how a person controls his health. Any malfunction is identical to feeling unwell. What “diseases” of the power unit can be a sad consequence of high engine oil pressure in the engine?

It should be noted that the malfunction in question is not as dangerous for the normal operation of the car as an insufficient amount of lubricant.

The most predictable consequences are:

- First of all, excess oil pressure negatively affects the integrity of the sealing surfaces. The seals, unable to withstand excessive load, collapse, releasing excess oil from the system. Increased lubricant consumption;

- As oil pressure increases, its quantity increases. Excess oil is released through the crankcase ventilation system. This also affects the increase in consumption;

- engine malfunctions occur as a result of lubricant getting on the surface of the idle speed regulator;

- Damage to the air flow sensor, even complete failure, is possible from contact with the oily substance of the measuring element of this device. A similar problem is typical for power units with a fuel injection system;

- The increased level of lubrication generated by excess pressure leads to foaming of the oil by the crankshaft counterweights. An oil emulsion saturated with gases harms the normal functioning of the engine. Knocking may occur in valve actuators and hydraulic compensators;

- The most unpleasant consequence of excess pressure in the lubrication system of a power plant is the destruction of the piston skirts.

Of course, the listed factors are not critical for normal operation of the motor. However, dumping excess lubricant causes a decrease in the level of oil product, and an insufficient amount of oil in the system is fraught with much more tangible troubles.

This is interesting: Should I install Philips daytime running lights?