Surely every car owner has noticed markings on the windshield, side or rear windows of the vehicle. The set of letters, numbers, and other symbols contained in it carries a lot of useful information for the car enthusiast - by deciphering this inscription, you can get information about the type of glass used, the date of its manufacture, and also find out who and when it was produced. Most often, the need to use markings appears in two cases - when replacing damaged glass and in the process of purchasing a used car.

If upon inspection it turns out that one glass was replaced, most likely this was caused by its physical wear or accident, but the replacement of two or more glasses will almost certainly confirm the presence of a serious accident in the past.

What is automotive glazing?

With the development of technology, vehicle speeds have also increased, and, consequently, the requirements for the quality of visibility and the ability to see the space around the vehicle while driving have also increased significantly.

Automotive glass

Automotive glass is a body element that is designed to provide the required level of visibility and perform a protective function. The glass protects the driver and passengers from headwinds, dust and dirt, precipitation and stones flying off from under the wheels of other moving cars.

The main requirements for auto glass are:

- Safety.

- Strength.

- Reliability.

- Sufficient service life of the product.

Why are deflectors needed on a car?

50% of all drivers believe that car fairings spoil the appearance of the car and do not perform any important functions. This opinion is especially shared by new car owners who are just beginning to experience in practice all the capabilities of their Mustang.

Wind deflectors change the trajectory of air masses rotating around the car while driving and provide:

- protection of the paintwork of the car from insects, small stones, dirt and sand spinning in an air whirlpool;

- dryness and comfort in the cabin in rainy weather with the window open;

- softening ventilation in the cabin, preventing drafts;

- reduction of noise waves entering the cabin.

Types of automobile glass

Today there are two main types of automotive glass:

- Triplex.

- Stalinit (tempered glass).

They have significant differences and have completely different features.

Triplex

Auto glass produced using triplex technology consists of several layers (most often three or more), which are connected to each other by a transparent film of polymer material using high temperatures. Most often, such glass is used as windshields, and occasionally as side windows or hatches (panoramic roofs).

Triplex technology

Triplex has a number of advantages:

- It has extremely high strength.

- If the impact was strong and the glass was badly damaged, the fragments will not scatter throughout the vehicle interior, injuring drivers and passengers. The polymer film acting as a layer will hold them in place.

- The strength of the glass will also stop an intruder - it will be more difficult to break into the window by breaking such auto glass.

- Glass produced using triplex technology has a high level of noise reduction.

- Reduce thermal conductivity and are resistant to thermal effects.

- Possibility to change color.

- Environmentally friendly.

The disadvantages of laminated glass are:

- High price of products.

- Heavy weight.

- The complexity of the manufacturing process.

If laminated glass breaks while the car is moving, the fragments will not scatter throughout the cabin, which guarantees additional safety for all passengers and the driver of the vehicle.

The thickness of such a standard triplex package varies from 5 to 7 mm. They also produce reinforced ones - its thickness reaches from 8 to 17 mm.

Strained glass

Tempered glass is called stalinit, and, accordingly, is made by the tempering method. The workpiece is heated to a temperature of 350-680 degrees and then cooled. As a result, compressive stress is formed on the surface of the product, which can ensure high strength of the glass, as well as the safety and heat resistance of the product.

Strained glass

This technology is most often used to make side and rear car windows.

In the event of a strong impact, such auto glass shatters into many fragments with blunt edges. It is not recommended to install it in place of the windshield, since in the event of an accident the driver and passengers can still be injured by them.

International terminology code

"windscreen" is used to refer to a windshield.

.

Additionally, the windshield of vintage open sports cars that is less than 20 cm (8 inches to be exact) in height is sometimes referred to as an "aeroscreen"

.

American English uses the term "windshield"

, and “windscreen” usually refers to a fleece or polyurethane covering over the microphone that reduces background noise.

In British English,

everything is exactly the opposite.

What is auto glass marking?

The marking is applied to car windows in the lower or upper corner and consists of the following elements:

- Information about the glass manufacturer or trademark.

- Standards.

- The date it was made.

- Glass type.

- Encrypted code of the country that has granted regulatory approval.

- Additional parameters (information about anti-reflective coating, presence of electric heating, etc.)

Today there are two types of auto glass markings:

- American. Manufactured to FMVSS 205 standard. According to this safety standard, all vehicle parts leaving the assembly line must be marked accordingly.

- European. A single safety standard has been adopted by all countries belonging to the European Union and applies to all automobile glass sold on their territory. According to its provisions, the letter E must be inscribed in the monogram.

In Russia, in accordance with GOST 5727-88, the marking includes a code consisting of letters and numbers, which in encrypted form contains all the information regarding the type of product, the type of glass from which it was made, its thickness, as well as technical operating conditions.

Types of deflectors

On store shelves there are windshields that differ in shape, manufacturer, characteristics, color palette and other parameters. The main criterion that the driver must follow is the method of attaching the fairings to the car doors.

- Plug-in windshields are attached very simply between the rubber seal and the glass, but they perform worse in practice. On some brands of cars it causes inconvenience when opening/closing the glass.

- Overhead windshields are fixed to the door frame, but installation is a little more difficult and takes longer. However, proper installation of such overlays will not cause any interference and will last much longer.

Often, reputable manufacturing companies produce high-quality deflectors and complete them with the necessary consumables for installation.

Decoding glass markings

Automotive glass markings

Manufacturer

The logo indicated in the labeling or trademark will help you find out who the manufacturer of automotive glass is. At the same time, the specified logo may not always belong to the direct manufacturer - the specified information may concern the company that is a party to the contract for the production of auto glass. The markings can also be applied directly by the vehicle manufacturer.

Standards

The marking also contains the letter “E” and a number surrounded by a circle. This figure indicates the country code where the part was certified. The country of production and issue of the certificate often coincides, however, this is not a mandatory condition. Official codes of countries issuing certificates:

| Code | A country | Code | A country | Code | A country |

| E1 | Germany | E12 | Austria | E24 | Ireland |

| E2 | France | E13 | Luxembourg | E25 | Croatia |

| E3 | Italy | E14 | Switzerland | E26 | Slovenia |

| E4 | Netherlands | E16 | Norway | E27 | Slovakia |

| E5 | Sweden | E17 | Finland | E28 | Belarus |

| E6 | Belgium | E18 | Denmark | E29 | Estonia |

| E7 | Hungary | E19 | Romania | E31 | Bosnia and Herzegovina |

| E8 | Czech | E20 | Poland | E32 | Latvia |

| E9 | Spain | E21 | Portugal | E37 | Türkiye |

| E10 | Serbia | E22 | Russia | E42 | European Community |

| E11 | England | E23 | Greece | E43 | Japan |

DOT marking means the code of the auto glass manufacturer. In the example given, DOT-563 is indicated, it belongs to the Chinese company SHENZHEN AUTOMOTIVE GLASS MANUFACTURING. The full list of possible numbers contains more than 700 items.

Glass type

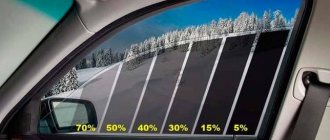

The type of glass in the marking is indicated in Roman numerals:

- I – reinforced windshield;

- II – conventional laminated windshield;

- III – frontal processed multilayer;

- IV – made of plastic;

- V – not a windshield, light transmittance less than 70%;

- VI – double-layer glass, light transmittance less than 70%.

Also, to determine the type of glass, the markings indicate the words Laminated and Lamisafe, which are used for laminated glass, and Tempered, Temperlite and Therlitw - if the glass used is tempered. The letter “M” in the marking indicates the code of the material used. From it you can find out information about the thickness of the product and its color.

Date of manufacture

The glass production date can be indicated in two ways:

- Through a fraction, indicating the month and year, for example: 5/01, that is, January 2005.

- In another case, the marking may contain several numbers that will have to be added in order to find out the date and month of production. First of all, the year is indicated - for example, “09”, therefore, the year of glass production is 2009. The line below encrypts the month of production - for example, “12 8”. This would mean that the glass was produced (1+2+8=11) in November. The next line indicates the exact production date - for example, “10 1 2 4”. These numbers will also need to be added - 10+1+2+4=17, that is, the glass production date will be November 17, 2009.

In some cases, dots may be used to indicate the year in markings instead of numbers.

Additional designations

Additional symbols in the form of pictograms in the marking will mean the following:

- The inscription iR in a circle is athermal glass, chameleon. During its production, a layer of film was added, which contains silver, the purpose of which is to dissipate and reflect thermal energy. The reflection coefficient reaches 70-75%.

- The thermometer symbol with the letters UU and an arrow is athermal glass, which is a barrier to ultraviolet radiation. The same pictogram, but without the letters UU, is applied to athermal glass with a solar reflective coating.

- Often another type of pictogram is applied to athermal glass - a mirror image of a person with an arrow. This will mean that a special coating has been applied to the surface of the product, reducing the possibility of glare. This auto glass is as comfortable as possible for the driver - it reduces the percentage of reflection by 40 points at once.

- The marking may also contain pictograms in the form of drops and arrows, which will mean the presence of a water-repellent layer and an antenna icon in a circle - the presence of a built-in antenna.

Anti-theft marking

Anti-theft marking involves applying the vehicle VIN number to the surface of the car in several ways:

- In the form of dots.

- Fully.

- Indicating the last few digits of the number.

Using a special composition containing acid, the number is etched onto the glass, mirrors or headlights of the car and acquires a matte color.

An example of applying anti-theft markings

This marking has several advantages:

- Even if such a car is stolen, it will be quite difficult to resell it, and the chances of returning it to the owner will increase.

- Using the markings you can quickly find glass, headlights or mirrors stolen by criminals.

- When applying anti-theft markings, many insurance companies provide a discount on CASCO policies.

The ability to read data encrypted in the markings applied to car glass can be useful to every car enthusiast when the need arises to change glass or buy a used car. The code, consisting of letters and numbers, contains data about the type of glass, its manufacturer, features, as well as the date of actual production.

DIY windshield replacement steps

Removing the old windshield

A string or a special knife is inserted between the glass and the groove, and the old sealant is cut. Be extremely careful when passing the area bordering the dashboard so as not to damage the plastic.

Preparing the place for gluing the windshield

Using a construction knife, cut off the remnants of the old sealant. In this case, the molding usually fails, but we didn’t forget to buy a new one, so we’re not particularly worried. We try on the new glass for its future location.

If necessary, make notes with a marker. Some car models have special stops that will prevent the windshield from being installed or replaced incorrectly. If you do not have a glass stand, then prepare a place on the hood by first covering it with something soft so as not to damage the new windshield.

Degreasing the glass groove

Either the degreaser from the kit or an anti-silicone degreaser.

Padding

It is not recommended to apply a primer to the remains of old sealant. The primer is applied in one layer either with a brush or with a swab from the kit. The primer is applied to the place of gluing on the body and to the glass at the place of intended contact with the groove.

Activator

We use it to treat the remaining remains of the old sealant that have not been removed.

Oldsmobile Cutlass 1973

Triplex finally arrived on the conveyors of the main factories in the late 1920s. Designers gradually abandoned various types of tilting, sliding and folding glass, and began to install them “tightly” on a rubber seal molding, which ensured sufficient tightness of the connection. Looking ahead, this fastening method lived for a very long time - the first cars with a glued windshield appeared only in 1973 (Audi 100 in Europe and Oldsmobile Cutlass in the USA).

We have to bend!

In the 1930s, the V-shaped concept won the world market - a windshield made of two parts, with an additional pillar in the middle. Vertical or almost vertical placement is a thing of the past - only at an angle! The era of angular “carriage-like” carriages is over. This was preceded by active development and research by “mad scientists” in the field of aerodynamics - among them it is necessary to mention Edmund Rumpler and Paul Jaray, who had a huge influence on automotive design.

Ford T Roadster 1920

Triplex and seal

Figuring out when and where the windscreen first appeared is not easy. For some reason, many sources persistently call the 1913 Ford Model T, mentioning that the glass was round, protected only the driver and was secured using a holder mounted on the steering column. This seems to be incorrect: the windshield also appears in photographs of earlier Tashkents, and in a normal rectangular configuration and in a full-fledged frame. And on other models too, for example the 1907 Rolls-Royce Silver Ghost - with a complex multi-sectional design.

Constructions

The second - the so-called. rigid ones are the same, already well-known and familiar car hatches, which have many options in terms of size and design. Today there are two types of structures that differ in the principle of opening: “lifting” and “sliding”. Hatches of the first type open with one side up (like a door or a book), and the second type move out of the landing frame and slide along the roof. Hatches of both types can be opened either automatically, by means of electric drives, or manually. Lifting hatches with manual opening can have two types of drives: lever - with pushing upward (the same system that is used in buses and other commercial vehicles) - and screw (the most modern and widespread) - using a rotating handle (like on a door), adjustment The opening value can be step-by-step or stepless.

One of the frequently used design solutions is a mesh curtain designed for shading, which is equipped with many hatch models. Manhole covers are made, as a rule, from painted metal or tinted triplex glass. However, progress in this matter is obvious, and manufacturers are using new technologies and materials, such as various plastics, polycarbonate and silk-screen printing. Automation is also constantly being improved. Many electric models have a “return motion” system: when it encounters an obstacle, the lid moves back a little and stops. Often such hatches are included in the security system, when when the car is set to alarm, the hatch automatically closes.

Aerodynamic aspects

As shown by the experiments of the American researcher V. E. Lay on models in the wind tunnel, the geometry and location of the windshield seriously affect the aerodynamics of the car.

The minimum values of the streamlining coefficient Cx (that is, the smallest aerodynamic drag), other things being equal, are obtained when the angle of inclination of the windshield is 45...50 degrees to the vertical; a further increase in the inclination does not lead to a serious improvement in streamlining. The difference between the best and worst (with a vertical windshield) values was 8...13%.

The same experiments show that the difference in the streamlining coefficients of a car with a flat windshield and with a windshield with the most advantageous shape from an aerodynamic point of view (semicircular cross-section, unattainable on a real car), other things being equal, is 7...12%.

In addition, the literature indicates that a significant role in the formation of the aerodynamic picture of a passenger car body is played by the design of transitions from the windshield to the roof, body sides and hood, which should be as smooth as possible. Today, a spoiler cutter in the form of an “upturned” rear edge of the hood is widely used, diverting the air flow from the boundary of the hood and the windshield, due to which the windshield wipers are in the aerodynamic “shadow”. Gutters must not be placed at the transition points from the windshield to the sides of the body and the roof, since at these transitions the air flow speed increases sharply

The importance of using modern glued glass is noted, which not only significantly reduces air resistance, but also increases the structural strength of the body as a whole.

Renault Type B (1899)

Therefore, historians are more credible when they point to 1899, when Marcel Renault built a fully glassed, self-propelled two-seater carriage.

All glass of that time, of course, was flat, at first - ordinary building glass, and a little later - tempered. Although back in 1909, the Frenchman Eduard Benedictus patented Triplex laminated glass. It dawned on him when, having dropped the flask with the remains of nitrocellulose, he discovered that the flask was cracked, but did not fall into fragments. It is reported that already in 1911, Benedictus created an enterprise for the production of automobile glass. Production was complex and painstaking, and the products were expensive, so orders were mainly one-time - from numerous body shops.

The adhesive layer between the two glasses was a sheet of celluloid, which quickly became cloudy and yellow during use. Therefore, the inventors spent a long time improving the compositions of the polymer layer until they achieved decent results - polyvinyl butyral film, which appeared in 1938, satisfied everyone. By the way, the modernized PVB technology is still used today.

Cadillac De Ville 1949

Then it took about ten years for the world war and the creation of technology for the mass production of curved glass. Many people have worked in this direction, and it is difficult to name who was the first. But, definitely, one of the technological leaders during this period was Cadillac, the author of many innovations and a trendsetter. It is believed that it was on the production Cadillac in 1948 that curved glass appeared - although still made up of two halves. But even here there is an alternative option - Studebaker in 1947.

It is curious that in this area the USSR auto industry kept pace with the times, not far behind the Americans and even ahead of post-war Europe. In April 1956, production of Moskvich-402 with curved windshield and rear windows began.

Choice

When choosing among various models and designs, the first thing that attracts attention is, of course, the price, which can vary significantly. Thus, all other things being equal (manufacturer, design, materials, dimensions), sliding hatches turn out to be on average 1.5-2 times more expensive than lifting hatches. But at the same time, sliding structures are considered more advanced: they provide direct air flow and their opening is not interfered with by the roof rack.

You will have to pay approximately 2 times more than a manual one for a model with an electric drive. In addition, the installation price will double or more, since the automated hatch requires additional work on laying the power wiring. Very noticeably affects the cost and overall technical performance, materials and the use of innovations, which, however, determine the quality and status of the product.

And finally, you should always remember that not every model you like can be installed on your car. The flatter the car roof is, the more options there are, as a rule; the more convex-rounded it is, the fewer models that may be suitable. In any case, before buying a sunroof, you must definitely find out from the seller or at the station which models of hatches are suitable for a particular car.

Do's and Don'ts when replacing a windshield

1. Avoid slamming doors too hard. Most cars have a sealed system, so immediately after installing new glass, try not to forcefully slam the door with the windows closed. Slamming the door will create excess air pressure on the windshield, which can easily damage the new seal. This in turn will create leaks and move your glass from its actual location.

2. It's not time to wash your car yet! After replacing the windshield on your car, do not wash it for the next 48 hours. At the same time, we would like to note that neither automatic nor manual washing is advisable at this time. Remember this vital tip and avoid any type of unnecessary water or air pressure on the vehicle for at least 48 hours or so.

If you ignore this advice, you may simply damage the new glass seal, which has not yet had time to set properly. In the meantime, while the windshield is drying, you can wash the wheels of your car yourself, naturally with your own hands.

Tasks

In addition, it is worth remembering such a practical point as driving in the heat on a dusty road. Still, less dust flies into the hatch, which is located at the top, than into windows and vents. Which certainly matters for the owner of a car without air conditioning, since in such cases you always have to solve a dilemma: either suffocate now, or vacuum the interior later.