Wheel bearing grease performs the function of protecting the rotating mechanism and its individual parts, extends their service life, and also promotes easy rotation of the wheel, which reduces the load on the engine and chassis. When choosing a lubricant, it is necessary to take into account the requirements for them. In particular, the composition must withstand high temperatures, have anti-corrosion properties, and also protect the surfaces of iron balls and cages from wear. Currently There are five main types of such lubricants - lithium-containing, high-temperature, polyurea-based, molybdenum-based and perfluoropolyether. Next, we will look at their features, as well as factors that must be taken into account when choosing a particular lubricant.

Properties of hub lubricant

The properties of lubricant for wheel bearings are determined by its operating conditions. In particular, the working pairs rotate at a high angular velocity, which causes a high temperature at the point of their contact. In addition, moisture and dirt enter the bearing surface, which can cause corrosion. Therefore, the hub lubricant should:

- Do not spread when heated . The average temperature at which a wheel bearing operates is +120°C. However, the higher the temperature the lubricant can withstand, the better.

- Maintain its performance properties at negative temperatures (down to -40°C). That is, the lubricant should not thicken and create obstacles when the wheel rotates.

- Do not lose its properties upon contact with water , and also protect metal surfaces from corrosion.

- Do not change its consistency when operating temperatures change.

- Have a chemically resistant composition . In addition, the lubricant should not have an aggressive effect on the polymers and rubber from which the anthers and seals on bearings or other components and mechanisms located nearby are made.

The frequency of lubrication of the wheel bearing is individual for each car, and you will find its value in the manual for your car.

At different times and different companies solved the problem of creating a lubricant with the listed properties in their own way. Therefore, there are currently five main types of wheel bearing lubricants.

Wheel bearing lubrication

- Lithium-containing compounds . Some of the most popular lubricants are based on lithium soap. In particular, the most common of them is “Litol 24”. The reason for the popularity of this product lies in its low price and good performance characteristics. The only drawback is that lithol lubricants mediocrely protect working surfaces from moisture.

- High temperature lubricants . Nickel and copper powder compounds added to their composition give them the appropriate properties. Phthalocyanine of copper, sodium or other metals is also sometimes added. Examples of such lubricants are Litho HT, Castrol LMX and Liqui Moly LM 50.

- Based on polyurea . They also contain silica gel and a stabilizing substance - calcium sulfonate. These are modern lubricants, popular among car enthusiasts. Examples of such compositions are AIMOL Greasetech Polyurea EP 2. Its distinctive feature is thermal stability (withstands short-term heating up to +220°C).

- Based on molybdenum . They have proven themselves well because they can withstand significant operating temperatures. However, they have one significant drawback - upon contact with water, a chemical reaction occurs, the result of which is sulfuric acid. And it reduces the resource of the parts it touches.

- Perfluoropolyether . These are the most advanced, but also the most expensive lubricants. As a rule, they are used in sports cars that travel at high speeds and experience significant mechanical loads. Sometimes Japanese and German manufacturers use such lubricants in premium cars. However, for most ordinary consumers their use does not make sense, given their high cost.

What lubricants should you be careful of?

As already mentioned, the hub bearing is a highly loaded unit. Accordingly, lubricants containing synthetic hydrocarbons cannot be used with it. Their chemical compounds decompose already at a temperature of +45°С…+65°С. Their main purpose is preservation or operation in lightly loaded mechanisms. These include silicone lubricants or Vaseline-based lubricants.

The popular domestic lubricant “Shrus-4” is not recommended for lubrication of hub bearings.

Also, do not use calcium or sodium based lubricants (in particular calcium and sodium soaps). They lubricate work surfaces quite effectively, but do not protect them well from moisture. You should not use graphite lubricant for wheel bearings. It can harm this important node. Lubricants containing zinc and iron are also not recommended for use in wheel bearings.

Two or more different lubricants cannot be mixed in one bearing, especially if they are of different types.

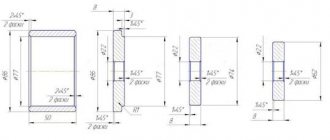

How to lubricate wheel bearings

First of all, let's ask ourselves the question of how to lubricate the wheel bearing without removing it? Of course, this is an option for those who simply do not have the opportunity to remove this part or time does not allow it. An important condition for this procedure is that the lubricant must be the same in the bearing itself and added. Usually, it is very difficult to find out for sure the previous lubrication, so you will still have to remove the hub.

So, how to lubricate the front wheel bearing without pressing it out:

- You need to install the car on the handbrake;

- Raise the car

- Remove the wheel, then the metal cap covering the hub;

- Now you should remove the locking ring using a screwdriver or thin pliers;

- After this, access to the bearing opens; here it is necessary to add lubricant, then rotate the hub.

Rating of the best lubricants for hub bearings

There is a lot of controversy on the Internet regarding the use of this or that composition. The best wheel bearing lubricant is selected based on several factors - recommendations from the manufacturer of your car, performance characteristics of the lubricant (temperature range, protective properties), personal experience and preferences of the car enthusiast, as well as price. The best hub lubricants are presented in the table below. The rating is based on reviews from car enthusiasts.

| Grease name | Price as of winter 2017/2018 | Catalog number | Description |

| Liqui Moly LM 50 | 950 rubles, 400 ml tube | 7569 | High temperature lithium grease for bearing hubs. |

| Castrol LMX Li-Complexfett | 480 rubles, 300 ml tube | 4506210098 | High performance grease consisting of a lithium complex thickener, mineral base oil and a specially selected additive package. |

| Step Up HIGH TEMPERATURE WHEEL BEARING LITHIUM GREASE | 700 rubles for a can weighing 453 grams. | SP1608 | High temperature lubricant for ball and roller bearings of all types. Contains metal conditioner SMT2, lithium additive complex, metal passivators and corrosion inhibitors. |

| MS-1000 | 44 rubles per pack of 30 grams | 1101 | Restoring multifunctional lithium plastic metal-clad grease. Contains a metal-clad complex that regenerates friction surfaces and blocks corrosion |

| "Litol 24" | 35 rubles per package weighing 100 grams | 714 | Anti-friction multi-purpose waterproof lubricant |

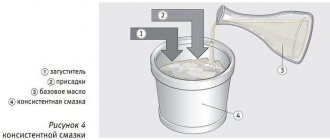

Description of bearing grease

Now let's look in more detail at each of the listed lubricants. Next, their operational characteristics, scope and some features will be given. Based on them, everyone can choose the best one for themselves.

Liqui Moly LM 50

Lithium based grease, capable of operating at high temperatures, contains extreme pressure additives. Performance characteristics:

- color - blue;

- thickener - lithium complex;

- temperature range for applications - from -30°C to +160°C (short-term up to +170°C);

- NLGI class - 2 (according to DIN 51818);

- penetration - 275-290 1/10 mm (according to DIN 51804);

- dropping point - > +220°C (according to DIN ISO 2176).

Liqui Moly LM 50 is one of the best lubricants for wheel bearings. The composition can also be used to lubricate other heavily loaded parts - plain and rolling bearings, clutch bearings.

Before applying the composition, working surfaces must be thoroughly cleaned of dirt and corrosion. It is also not recommended to mix Liqui Moly LM 50 with other types of lubricants.

Castrol LMX Li-Complexfett 2

It is an effective grease thickened with a lithium complex. It also contains a base oil and an additive package. Performance does not deteriorate over the entire operating temperature range. Their values are:

- NLGI class - 2;

- Green colour;

- resistance to water washout (according to ASTM D 1264 method) -

- adhesion to metal surfaces;

- welding load (when tested on a four-ball friction machine according to the DIN 51350-5 method) - >2600 N;

- dropping point (according to ASTM D 566 method) - >260°C;

- operating temperature range - from -35°C to +170°C.

According to reviews from some car owners, Castrol LMX Li-Komplexfett 2 lubricant is easily washed out if water gets inside the bearing. Therefore, ensure the integrity of its body and boot, if present . The lubricant must be stored only in sealed containers, preventing moisture from entering it. Also, do not allow it to be exposed to direct sunlight or ultraviolet radiation for a long time.

STEP UP High Temperature Wheel Bearling Lithium Grease

This is a high temperature lithium grease that can be used for both wheel bearings and other roller and ball bearings. Contains metal conditioner SMT2, lithium additive complex, metal passivators and corrosion inhibitors. It has high anti-friction, extreme pressure, anti-wear, and anti-corrosion properties. Does not lose its protective properties when contaminants enter the lubricant. Its operational characteristics are as follows:

- withstands speed limits - up to 10,000 rpm;

- operating temperature - from -40 to +250°C;

- drop point - +260°C;

- scuff index - 627 N;

- maximum load - 1166 H;

- wear scar diameter - 0.65 mm;

A distinctive feature of the lubricant is its wide temperature range. Therefore, it can be used both in conditions of significant frost and in the southern regions of the country . It can also be used for sports and rally vehicles, where the wheel bearings experience increased loads, including temperature.

MS-1000

It is a lithium-based multifunctional metal-clad grease. It includes a metal-clad complex, the task of which is to regenerate friction surfaces, as well as neutralize corrosion processes and increase the service life of the unit. Performance characteristics:

- penetration class NLGI - 2/3;

- compatible with lithium greases;

- significantly extends the service life of metal bearing parts;

- allows you to increase the interval between lubricant changes;

- eliminates the occurrence of scuffing and welding of rubbing parts;

- reduces noise caused by bearing wear;

- works successfully in heavily loaded friction units;

- successfully replaces all types of grease, general purpose lubricants and some other greases.

In addition to wheel bearings, MS-1000 can also be used in chassis parts of various vehicles, gears and related mechanisms, and various loaded working pairs.

There are 9 types of packaging in which the lubricant is sold, from 30 grams to 170 kg.

Litol 24

"Litol 24" is a popular lubricant among car enthusiasts. It is an anti-friction, multi-purpose, water-resistant lubricant intended for use in friction units of various vehicles. It is made by thickening a mixture of mineral oils with lithium soaps of technical 12-hydroxystearic acid with the addition of additives. Performance characteristics:

- operating temperature - from -40°С to plus +120°С (short-term up to +130°С);

- dropping temperature - not lower than +180°C;

- evaporation at +120°C - up to 6%;

- critical load - 63 kgf;

- scuffing index - 28 kgf;

- NLGI class - 3.

The disadvantage of Litol 24 is that upon contact with water it loses its properties and is washed out quite easily. Therefore, it is necessary to monitor the integrity of the wheel bearings and their anthers. At the same time, it protects metal surfaces well from corrosion and has stable mechanical, chemical and colloidal stability.

What should you not lubricate bearings with?

Not all thick compounds are suitable for use in automobile hubs. For example, traditional solid oil is not the best lubricant for such components, since it is not able to compensate for the friction of parts under conditions of large temperature differences. A number of other lubricants fall into this category:

- Graphite lubricant tolerates loads well, but contains abrasive particles that quickly destroy the metal parts of the bearing.

- Vaseline or silicone-based compounds lose their anti-friction properties due to an increase in operating temperature to 60 °C, which is clearly not enough for a bearing assembly.

- A group of lubricants, including calcium and sodium compounds, reduces friction of parts, but does not protect against corrosion.

- A popular product called “CV joint-4”, designed to work in rough articulated mechanisms.

What substances a particular material contains must be indicated on the packaging. Before lubricating the bearing rollers with new grease, please read this checklist carefully.

Other lubricants

In addition to the wheel bearing lubricants listed above, there are also a large number of other compounds. Without going into details and without describing their technical characteristics, we will simply list them below. So:

- VNIINP-261 lubricant (Sapphire lubricant);

- AIMOL Greasetech Polyurea EP 2 SLS;

- lubricant No. 158 (TU 38.101320-77);

- anti-seize grease for high loads SKF LGWA 2;

- semi-synthetic universal lubricant Total MULTIS COMPLEX S2 A;

- Scania 8371W grease;

- SLIPKOTE High-Temperature Wheel Bearing Grease #2;

- ARAL Radlagerfett;

- Mobilgrease XHP 222;

- CHEVRON DELO GREASE EP 2;

- Mobil 1 Synthetic Grease;

- "Ciatim-221";

- MOLYKOTE® LONGTERM 2/78 G;

- SLIPKOTE POLYUREA CV JOINT GREASE.

When choosing a particular lubricant, carefully read the documentation supplied with it. Pay special attention to the conditions for which the product is intended (medium, severe). It is better to choose lubricants designed to work under difficult conditions .

It is also important to know what type of brakes are installed on your car (disc or drum). This is important because they produce varying amounts of heat during operation, especially emergency braking.

Summary by choice

Before choosing a particular lubricant, check the manual for your car to see what the manufacturer recommends in this regard. It’s good if he directly indicates which specific brands. If not, then the choice must be made based on the operating conditions of the machine. For most ordinary car owners, any of the five lubricants listed above will be suitable. Their performance characteristics are approximately the same, and they differ only in price. Otherwise, carefully read the instruction manual for each product you want to buy.

Also beware of fakes. Try to make purchases in trusted stores that have the appropriate licenses and other permits. Do not buy goods in dubious places (small shops, underground passages, etc.). This minimizes the risk of purchasing counterfeit goods.