- What are silent blocks?

- How to check silent blocks yourself?

- Replacing the front arm silent block

How often do you change silent blocks?

Or how often should this be done? Even the most careful motorist regularly repairs his car. Even if there are no visible damages, there is always something to check and tweak. All mechanisms must work flawlessly. Safety during operation of the machine directly depends on this. From time to time, certain components require repair or simply diagnostics. In this case we will talk about silent blocks.

Checking and replacing silent blocks of front levers

Why do you need a suspension arm silent block?

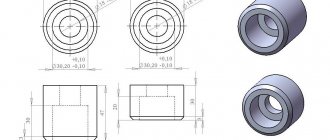

A rubber-metal hinge or silent block is a part consisting of two metal tubes, between which there is a polyurethane or bushing, which is why it is called a polyurethane silent block. The decoding of the name itself will help explain its purpose. “Silent” is translated from English as “quiet”, therefore the part is used in the mechanism to suppress vibration and noise. A silent block is used to connect the suspension parts, and a rubber insert helps soften impacts on its components. They secure the anti-roll bars and control arms.

The silent block is also used to connect the rear suspension. And also for attaching shock absorbers, gearbox or engine. This part can withstand enormous loads, so it quickly fails and requires frequent replacement. The performance of the silent block is affected by the condition of the road surface, sudden temperature changes, and the service life of the vehicle itself. In some cases, rubber begins to crack due to age.

Typically, the manufacturer of the part guarantees that it can withstand a mileage of one hundred thousand kilometers. But given the state of the roads in our country, it’s better not to risk it. Every car enthusiast should carry out a visual inspection of the silent block after 50,000 km. It is very easy to do this even at home.

What is a silent block of a suspension arm and its functions

In car structures where there are vibrations, displacements, radial and axial loads, there must be softening special rubber parts. They perform an important function, so they need to be changed frequently. Rubber parts that are subjected to compression, stretching, and displacement wear out quickly.

A silent block is a rubber-metal hinge (RMH) in the design of a car suspension. The salent block device includes:

- two metal tubes;

- rubber connection between these tubes.

This part is made by vulcanization, which is why it has excellent vibration insulation properties. Salent blocks are capable of absorbing all types of loads that appear during vehicle operation.

If the silent blocks are heavily worn, then driving the car will be uncomfortable, noise will appear and the joints of the parts will begin to wear out faster.

Silent blocks are installed on the front and rear suspensions. They are installed on levers. In addition to levers, silent blocks connect the mounting points of the gearbox, engines and shock absorbers.

To increase reliability, it is necessary to change vibration isolation pads on time.

Design features

So, two bushings with a rubber layer - it would seem that everything is elementary. But this design is simple only at first glance. How to fix the elastic element in the bushing? A fairly obvious method is strong compression (in other words, tension), however, in this case the connection will be too rigid, which will affect the smoothness of movement.

There is a second option - “gluing” rubber to metal using the vulcanization method - there is almost no compression. But in this case, the rigidity of the connection is clearly insufficient. The angle of torsion and skew increases (relative to the longitudinal axis of the silent block), which entails unfavorable changes in wheel alignment angles while the vehicle is moving. And, accordingly, accelerated uneven tire wear.

Taking these difficulties into account, in the design of modern silent blocks a combined fixation scheme is used: simultaneously by compression (of moderate force) and vulcanization.

Further, the rubber part itself can be solid, or maybe with additional slots. Let's take, for example, the Polo sedan that came to us on a turnkey basis. On it, the rear silent block of the front suspension arm (just the MacPherson type) is installed vertically and there are cutouts in its rubber part.

What are they needed for? To limit the movement of the lever in the longitudinal direction, the stiffness of the bushing should be maximum; but we do not need maximum rigidity when moving the lever in the vertical plane (when hitting an obstacle, for example). To maintain these properties, to put it simply, excess rubber was removed. The bushing provides decent smoothness and rigid fixation of the lever in the longitudinal direction at the same time.

Subsequent developments in engineering led to the creation of floating and sliding silent blocks, again to improve the smoothness of the ride.

Volkswagen Passat B5 in the late 90s “became famous” for the complexity and high cost of the suspension, including floating silent blocks. The

hinge design has become significantly more complicated, additional elements have appeared: an intermediate bushing (plastic), end washers, durable lubricant and side seals.

As always, complication has led to higher prices. Seals wear out, lubricant leaks, silent blocks creak, and new ones are expensive. Someday we will return to floating “silents” when a car with such hinges arrives at our repair shop. Today we will limit ourselves to the usual ones.

Purpose and location of the part

In a car, the wheels are attached to the power part of the body using levers. In order for the suspension to smoothly handle all road irregularities, the following conditions must be created:

- The wheel, under the influence of a spring, must move up and down on the lever, so it is screwed to a steel axle rigidly fixed to the spar.

- To absorb small potholes in the road surface at the junction of the chassis and the body, an elastic gasket is needed. Otherwise, the driver and passengers will begin to feel vibration transmitted from the wheels.

Accordingly, silent blocks are needed for a movable and at the same time springy connection between the body part and the entire suspension of the car. They are the same gasket that softens small impacts and allows the lever to work out large irregularities.

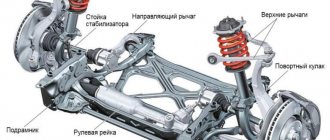

On each side, the suspension rests on body elements at 2 or 3 points. In the first case, it is mounted on a lever and a strut, in the second - on two levers and a shock absorber. As many attachment points as there are, so many pairs of silent blocks are used as softening pads.

The second name for a rubber-metal part is a dry hinge. It characterizes the ability of silent blocks to work without lubrication - only due to the elasticity of the insert between two steel bushings. At the same time, the turning radius of the lever is limited by the ability of the rubber or polymer to twist. But for the working stroke of a car suspension, this radius is quite enough.

Now about the specific points where dry hinges are located:

- The main place mentioned above is the attachment of the upper and lower arms. The strength element of the body - the spar (standing under the wheel arch) has a protrusion with a hole into which the axle is inserted in the form of a long bolt. Rubber-metal hinges, pressed into the eyelets of the lever, are placed at the edges of the axle and secured with nuts.

- The small silent block is located at the lower point of attachment of the strut to the steering knuckle.

- On shock absorbers, the hinges are placed on both eyes - top and bottom.

- Parts are also used at the support points of torque rods and anti-roll bars.

The rear suspension of modern cars most often has a multi-link or torsion bar design. In both cases, levers mounted on silent blocks are involved. So hinges are used not only in the front suspension. Even on cars with a continuous rear axle beam, rubber-metal products are used to install rear linkages and shock absorbers.

Dismantling and installation process

Installation begins after purchasing the parts. You will need a tool - wrenches for removing the beam and suspension arms, a hammer or sledgehammer.

Step by step guide:

- The car is driven into a pit or overpass. You can lift the wheel with a jack, but it is so inconvenient to work with the suspension - you have to work lying down. The jack foot should not be in the same plane as the beam bracket.

- Dismantle the suspension beam. Be sure to remove the handbrake cable when doing this.

- The brackets have special brackets that hold the brake system hoses. The staples are removed.

- The old silent block of the beam is dismantled. Garage conditions require the use of a hammer or sledgehammer. You should work carefully so as not to damage the seat, otherwise there will be problems with installing the new part.

- The seat is cleaned of dirt and graphite lubricant is placed there.

- Install a new part. Replacement of the silent block of the rear beam is done so that there are no gaps or holes. Pressing is done with careful blows of a hammer.

- Reassemble the beam in the reverse order.

The replacement is complete and you can drive the car immediately. During assembly, you should check the installation of each part and only then proceed with assembling the next one. The silent block of the front beam is changed according to the same scheme.

Dismantling the old gum is done with 3 - 4 strong blows with a sledgehammer. You should hit strictly in the center of the part, without deviating to the side from the vertical axis. The edge of the clip is bent using a chisel to facilitate dismantling.

We recommend: Engine water hammer. Causes and consequences

Experienced craftsmen use a piece of tube to press out the silent block of the rear beam. It is important that its diameter is slightly smaller than the same parameter of the seat. The tube is placed against the part and hit with a hammer. In a few blows the part will be removed without unnecessary operations.

Having removed the silent block of the rear beam, check the seat. There should be no chips or cracks on it. If there are any, the part should be replaced. Otherwise, the new silent block will not fit as it should.

How to change rear silent blocks?

You can replace the rear silent blocks yourself if you prepare properly. The most important thing when performing repair work is not to rush and act consistently.

Techniques for replacing silent blocks of the rear suspension using the example of a VAZ2109

If there is no lift, jack up the wheel by first loosening its mounting bolts. But first, place safety supports under the beam. Prepare keys for “19”, puller, hammer, WD40, new parts. At the following stages:

- Disconnect the brake pipes, unscrew the nut, which will loosen the bolt connecting the body and the beam.

- Remove the bolt using a metal rod of smaller diameter and a hammer.

- Lower the beam down.

- To remove the old part, use special tools or simply crumble the rubber.

- Clean the freed area and lubricate it with liquid soap or other similar household product.

- To install a new product, use a homemade device if you do not have special tools. Insert a long bolt into the hole in the bushing and the eye of the beam. Now place the washers and gradually tighten the nut until it is in place.

- Now you can install the beam by tightening the fasteners in the reverse order.

This is interesting: Technical inspection of Renault Logan by mileage: maintenance regulations

Installation

When installing, you should thoroughly clean the seat from dirt and dust. To do this, use white spirit or another solvent soaked in rags. Generously lubricate the area with soapy water. Next (using the same puller) we evenly press in the new silent block. When installing, try to avoid distortions. Otherwise you will damage the new item. At the next stage, we take out a wooden block from under the body and put on the bolt securing the beam, and also attach the nut. Reinstall the rear wheel and lower the car from the jack.

Next, we move to the adjacent side - all suspension elements, as well as the brakes, are changed in pairs. Then we go for a short test drive. After five to ten kilometers, we drive the car back into the garage and tighten the mounting bolts until they stop. Then you can safely begin normal use.

Replacing silent blocks on the “nine” and “ten”

So, if you decide to change the silent blocks on your car yourself, how to do it? Let's take popular cars as an example: VAZ 2109, 2110 and 2107. Let's assume you need to replace the silent blocks of the rear beam of a VAZ 2109. In this case, the procedure is as follows:

- we prepare tools and consumables - wrenches for wheel bolts, spanners for 19. Hammer, crowbar, a wooden block the size of a brick, a puller for hinges, a jack and new bushings for replacement;

- jack up the rear of the car and remove the wheel;

- to make your work easier, it is advisable to treat all bolts and fasteners with WD40;

- disconnect the brake lines and unscrew the nut that holds the bolt connecting the rear beam with the mount on the body itself;

- we take out the bolt and, using a crowbar, carefully move the rear beam down so that a wooden block fits between it and the body;

- Now the hardest part is that you need to knock out the old silent block. This can be done using a special device or a hammer. As a last resort, drill out the old rubber and pull out the bushing scraps;

- clean the hole and lubricate it with soapy water to make the new bushing easier to fit into place;

- installing a new bushing is also not an easy task - for this they use a special device or a structure consisting of a bolt, nut and two large washers. A long bolt is threaded into the bushing and eye of the beam, and the nut is slowly screwed in so that the part snaps into place;

- When everything is ready, we install the beam in place in the reverse order.

Note that replacing the silent blocks of the rear beam of a VAZ 2110 is carried out in a similar way, so we will not describe it in detail. But we’ll talk about the “seven” separately, using its example to show how to replace the bushings on the front suspension.

How to profitably exchange a used car

To guarantee the legality of the used car exchange service and its objective cost, the purchase and sale process should be carried out at a trusted auto center. Here the client will be offered:

- Diagnostics of the old model, on the basis of which its cost will be determined;

- Selection of cars for exchange, completely new or with a clean mileage history: all cars undergo forensic examination, therefore the car dealership will never sell a car with a “dark past”;

- Legal support of the transaction: the client enters into a notarized agreement and, if necessary, can use the credit services of the car dealership’s partner bank;

- Efficiency of the service: the client does not need to look for buyers for his vehicle; he does not need to settle issues with the traffic police or the bank. The listed functions are the task of the auto center.

Read here! How to make a wheel alignment

Thus, with minimal documents, it is possible to buy an improved car within one to three days. The used car exchange service makes it possible to regularly change the owner’s vehicle fleet by purchasing its best models.

Which silent blocks are better, polyurethane or regular ones?

If you are thinking about how to replace silent blocks, then you need to make an important choice about what material they will be better from. There are several options available on the domestic market.

- Rubber Rubber-based parts are inexpensive, but have many disadvantages:

- have a low resource;

- cause squeaking, even if they are new;

- quickly become unusable under the influence of harmful environmental factors.

- Polyurethane elements significantly improve the performance of the suspension and the entire vehicle. Their advantages are as follows:

- long service life (five times longer than rubber).

- improving the behavior of the car on the road, eliminating the “squeezing” effect that appears when using rubber, as well as reducing deformation in the suspension elements, therefore, the part functions in the mode in which it should;

- absorption of vibration, shock, noise reduction;

- improved handling.

The only drawback of polyurethane silent blocks is their high cost. But the miser pays twice, so it is better to initially use a more durable and effective material.

The main installation locations for pairs of silent blocks.

Why are silent blocks needed in a car?

When the car moves, the impacts from road unevenness are transmitted through the wheels and chassis system of the car to the body and then to the driver and passengers. A complex system of connections, starting from contact with the road surface of the wheel and ending with the seats of the cabin, is designed by engineers to provide maximum comfort to those in the car. In other words, to smooth out as much as possible and remove shock and vibration loads and noise from the frequency range that is unpleasant for the human body.

To solve these problems, silent blocks are used - devices that allow the connections between the parts of the vehicle's chassis system to dampen shock and vibration loads and reduce the noise level.

The latter circumstance is due to the fact that in a conventional threaded connection of parts subject to various loads (compression-tension, bending, torsion, shear), friction inevitably arises in the joint and, as a consequence, the creaking of metal on metal and noise from impact. And since metal is an excellent conductor of sound vibrations, these noises are transmitted to the body, and therefore into the interior of the car.

The name is due to the fact that the part dampens noise (silent literally means “silence”).

But the silent block performs another important task: the flexible connection in the connection allows you to reduce the requirements for the accuracy of the fit of the part, and, therefore, significantly reduce the cost of its production, which is important from an economic point of view.

Replacing the front suspension arm silent block

Regardless of the make and model of the car, the replacement process is almost the same. All you need to do is get to the part being replaced, dismantle it and install a new one. Below, the photo shows what the suspension of a Ford Focus 2 looks like.

Work order:

- We place the car in a viewing hole or on a lift.

- Raise the front side on which the silent block will be replaced with a jack.

- Remove the wheel.

- Remove the protective casing and crankcase protection.

- Remove the ball joint. You may need a ball puller to remove the ball.

- Remove the front arm. To do this, unscrew several bolts, 3-5 pieces. The lever can be easily removed.

- Remove the old silent blocks from the dismantled front arm. To do this, you need to use a puller or a chisel with a hammer.

- Clean the seat before installing a new part. Clean with sandpaper, wash and lubricate.

- Now you need to press in the new silent block using a puller. After installing it, assemble the unit in the reverse order of disassembly.

- After lowering the car, tighten the bolts.

On the other side, perform the same actions.

Advice! After installing the new silent blocks, you need to stop by the service center and get a wheel alignment done.

The cost of silent blocks of the lever

First of all, the price will depend on the material from which the silent block is made. There are two types recognized - rubber with metal bushings and polyurethane. Many drivers will say that polyurethane ones are much better, but they also cost five times more than rubber ones. The reason for this difference is quite simple: polyurethane silent blocks are easier to change, pressing is easy and does not require much effort. In terms of service life on a car, they last 5 times longer than rubber ones. In terms of pricing policy, a lot depends on the make and model of the car, and maybe also on the year of manufacture. As an example, a silent block for a Mazda 626 engine mount will cost from 1,200 rubles. On the Chevrolet Epica 2.0, for the rear upper control arm it will cost about 1,150 rubles per piece. The price is for rubber ones, polyurethane ones will be many times more expensive. There is only one conclusion: if the car model is not expensive and you do not use it often, then there is no point in installing expensive ones, but if the opposite is true, and you will change it often (considering the quality of our roads), then it is better not to skimp on the quality of the material and install only high-quality ones . This way, you can save money and time on the replacement process. As soon as the first symptoms of failure of the silent blocks of the car appear or it is clear that the wheel camber/toe is incorrect, do not rush to go to a service station to have it corrected. First, inspect the silent blocks for damage, and remember the last time they were replaced.

Sources

- https://www.kolesa.ru/article/sajlentbloki-avtomobilnoj-podveski-kak-oni-ustroeny-i-kak-ih-menyat

- https://autostuk.ru/kak-pomenyat-sajlentbloki-na-perednix-rychagax.html

- https://unit-car.com/ustroystvo/272-saylentblok-v-avtomobile.html

- https://voditelauto.ru/%D1%81%D0%B0%D0%B9%D0%BB%D0%B5%D0%BD%D1%82%D0%B1%D0%BB%D0%BE%D0 %BA%D0%B8-%D0%BF%D0%B5%D1%80%D0%B5%D0%B4%D0%BD%D0%B8%D1%85-%D1%80%D1%8B%D1 %87%D0%B0%D0%B3%D0%BE%D0%B2/

- https://KrutiMotor.ru/zamena-sajlentblokov-perednih-rychagov/

- https://saylentbloki.ru/plavayuschiy-saylentblok.html

- https://fastmb.ru/autoremont/1834-prednaznachenie-saylentblokov-v-avtomobile-i-kogda-nuzhno-ih-menyat.html

Silent blocks, what are they for?

This part is an intermediary between the rigid body structure and the suspension component (link, shock absorber, torque rod, anti-roll bar, spring, subframe, etc.).

If you screw a metal suspension element to a metal body element, the connection will be excessively rigid and every vibration of the suspension will be clearly audible, which will significantly reduce the level of comfort of the vehicle.

We recommend: How to remove and unscrew the crankshaft pulley?

POLYURETHANE OR RUBBER BUSHING BLOCKS, WHICH IS BETTER?

If the car has rubber bushings and silent blocks in the suspension, which can be replaced with polyurethane parts, then you will only improve the characteristics of the suspension and its operation. Polyurethane silent blocks will last at least 5 times longer than rubber parts. The only drawback of polyurethane is its higher cost compared to rubber products (more than 5 times), but you can save on replacement.

Polyurethane silent blocks improve the behavior of the car on the road , reducing unwanted deformations in the suspension and eliminating the “squeezing” effect typical of rubber parts. This means that the suspension always operates in the mode intended by the designers. Properly installed and sized polyurethane parts perform better at absorbing shock, vibration and reducing noise compared to rubber.

If you want to improve handling , polyurethane silent blocks are what you need. If you calmly move from one point to another, then choose ordinary silent blocks.

What are silent blocks?

Silent block is a part that dampens vibrations that occur between the suspension elements during movement. Thus, it dampens noise and vibrations that can lead to rapid wear of parts. The hinge is very important because it is responsible for the correct operation of the entire system. It consists of inner and outer metal bushings, with a rubber or polyurethane gasket placed between them.

Note that polyurethane silent blocks are considered more durable and last up to 2-3 times longer than rubber ones. Cars equipped with polyurethane hinges listen better to the driver.

It is important to monitor the serviceability of silent blocks, because their breakdown leads to difficulties in controlling the car, slowing down the response to the steering - the car will not immediately respond to the driver’s actions. In extreme cases, the car will wobble from side to side at speed.

Broken silent blocks can damage the joint seats, in which case you will have to replace the entire lever, which will not be repairable.

Therefore, it is necessary to regularly diagnose the hinges. The manufacturer claims excellent performance for 100 thousand km, but, given the quality of domestic roads, it is recommended to inspect silent blocks every 50-70 thousand km.

How to replace the front arm silent block

To carry out repair work on a silent block, you will need special equipment and professional skills, so it is not always possible to do this at home. If you have little experience, there is a high probability of damaging the new rubber-to-metal joints and suspension arms, so be careful. The procedure for replacing the silent block is as follows.

- Raise the car with a jack, or, if possible, hang it on a lift. Then remove the front wheels to gain access to replacement parts and suspension repairs at the same time.

- Remove the silent block along with the lever. To do this, remove the special bolts by unscrewing the nuts.

- Dismantle the lever by removing the bolts from it and pulling it towards you.

- Now you need to remove the rear silent blocks of the front control arms. Services use a special device for pressing out parts (mandrel), but at home you can get by with a regular sledgehammer and vice. There is no need to worry about damage to the part, it is already faulty, the main thing is to try not to break the lever itself. If the part fits tightly when pressing out, you can use a special burner to heat the hinge.

- After knocking out the hinge, inspect this place and clean it of all kinds of dust and dirt. Also make sure that there are no scratches, mechanical damage or sharp edges on its surface.

- Treat the seat with lubricant or soap solution.

- Before installing a new silent block, carefully inspect it from all sides. You need to make sure that it is completely suitable for your specific case (it often happens that on the outside it fits perfectly, but on the inside it has a different shape).

- Now you need to press in the rubber-metal hinge. This can be done using a vice. You can also use a hammer or sledgehammer, but then you will have to be more careful.

- Reinstall the lever, tighten the nuts and bolts, and then put the wheels in place and lower the car or remove it from the jack.

- Now you can finally tighten the silent blocks using the weight of the car itself.

- Don't forget to restore the wheel alignment.

When replacing silent blocks, you should pay attention to the material they are made of. For lovers of a quiet ride, a rubber product is suitable. Its service life is not so long, but the cost is much lower. For fans of extreme driving, it is better to purchase a silent block made of polyurethane. They are better able to dampen noise from shock and vibration, and can also last 3-4 times longer.

Getting started with replacement

It doesn’t matter what kind of car you have, because the technology for replacing bushings on all models is almost the same. Conventionally, this process can be divided into several stages: removing the front arms, replacing silent blocks and installing dismantled elements. Below are instructions for replacing rubber-metal joints using the example of a Hyundai Elantra J4.

Replacement of silent blocks of front levers

Removing the front control arms

Before replacing the silent blocks, you must first remove the front control arms. Below are step-by-step instructions for this process.

Step 1. Be sure to put the car on the handbrake.

Putting the car on the handbrake

Step 2. Place wheel chocks under the rear wheels of the car or, if you don’t have them in the garage, a regular brick.

Installing a brick under a wheel

Step 3. Jack up the front of the car and place it on secure supports.

Installing a support under the front of the car

Step 4: Remove the front wheels. The bushings need to be replaced as a set, so do the same manipulations on the other side.

Front wheel removed

Step 5. Unscrew the two bolts securing the ball joint to the steering knuckle using a 17mm socket. Do this on both sides of the car.

Unscrewing the ball joint mounting bolts

Step 6. Unscrew the bolt securing the rear arm to the subframe with a 17mm wrench. Hold the bolt with a second wrench or ratchet.

Unscrewing the rear lever mounting bolt

Step 7. Lifting the lever with a mounting tool, remove the mounting bolt.

Removing the Mounting Bolt

Step 8. Unscrew the front suspension arm mounting bolt with a 19mm socket. Hold the bolt itself with a 22mm wrench.

Unscrewing the front arm mounting bolt

Step 9: Carefully remove the bolt. If you can’t remove it, then screw a nut onto the bolt and lightly hit it. After this, the bolt will come out smoothly.

Removing the Mounting Bolt

Step 10. Using a mounting tool, remove the arm mount from the subframe and remove it from the car. Carry out all the same operations on the opposite side.

Removing the front suspension arm

Replacing silent blocks

So, the levers are removed. Now you need to remove the old silent blocks and install new ones in their place. Detailed instructions will help with this.

Step 1. If you have a bench and hydraulics for body repairs, then you can use them to remove the bushings or levers.

Jib and hydraulics for body repair

Step 2. Fix the suspension arm as in the photo, and using a special puller, press the rear hinge out of its socket. It requires 10-ton hydraulics to operate.

Squeezing the rear hinge out of its socket

Step 3. This is what the part looks like after dismantling.

Front lever silent block after dismantling

Step 4. There is another way to remove old parts. Not everyone has hydraulics in their garage. Cut out the rubber bushing using an electric jigsaw. You can use a hacksaw, but it will take a little longer.

Cutting out a rubber bushing with a jigsaw

Step 5. Remove the outer joint races from the arms. To do this, use a regular hacksaw to cut through the rings in several places to loosen them.

Sawing out the silent block clip

Step 6. Follow the procedure for both front and rear bushings. Just don't saw through the lever itself, otherwise you'll have to replace it.

Sawing grooves in the metal part of the hinge

Step 7. Carefully knock out the outer joint races with a chisel, being careful not to damage the seats. Otherwise, some problems may arise with the installation of new bushings.

Knocking out the outer ring of the silent block

Step 8. This is what the outer ring looks like after knocking it out with a chisel.

The outer ring of the silent block after pressing out

Step 9. Clean the seats in the levers from corrosion, and then lubricate them.

Cleaning the lever seat

Step 10: Also lubricate the metal part of the new hinges. Be careful not to get any grease on the rubber.

Applying lubricant to the metal part of the hinge

Step 11: Hydraulically press in the new joints. As practice shows, pressing requires a small force, 2-2.5 times less than for removing the part. But this is provided that the seat is lubricated.

Pressing in the silent block using hydraulics

Step 12: Alternatively, the bushings can be pressed in using spacers and rings that were used for the hydraulics. Tighten them with a bolt.

Installing hinges by tightening the bolt

Step 13. The silent block is installed and the lever is ready for installation. Choose the method of removing and installing hinges yourself, based on your capabilities. In the absence of hydraulics, all parts (both front and rear) can be replaced manually.

Lever with replaced silent blocks

Step 14: Pay attention to the front bushings. They have a small arrow on them. The repair manual states that this arrow should be directed along the car. But on the factory bushings it was directed towards the ball joint, and equally on both sides. Therefore, it is recommended to install new parts in the same way.

Arrow on the front silent block of the lever

Installing the front control arms

The hardest part is behind us. Now you need to install the finished levers in their places. As usual, below are step-by-step instructions with photos.

Step 1. Place the arm into the front mount on the subframe.

Inserting the lever into the front mount

Step 2. Now hit the rear mount with the suspension arm.

Installing the lever in the rear mount

Step 3. Insert the bolt into the rear mount.

Bolt installed in rear mount

Step 4. When straightening the front silent block with a mounting tool, hit it with a bolt.

Installing a bolt in the front silent block

Step 5: Screw in the front hinge. For now, just attach the fasteners. Repeat all these manipulations with the other lever.

Screwing the front hinge

Step 6. Tighten the two bolts securing the ball joint to the steering knuckle on both the left and right sides of the vehicle.

Screwing in the ball joint bolt

Step 7. Using a jack under the ball joints, compress the suspension into working condition.

Compressing the suspension to working condition

Step 8. Finally tighten the front and rear silent block mounting bolts. You can try to tighten the bolts by putting the car on its wheels, but this is unlikely to work on this model due to lack of free space.

Tightening the silent block bolts

Note! Tightening the bolts is necessary so that the hinges are clamped in their working position, without unnecessary stress on the rubber element.

Step 9. Reinstall the removed wheels.

Putting the wheels in place

Step 10. After jacking up the front of the car a little, remove the previously installed supports from under it. This is the end of replacing the arm joints.

Removing stands from under the car

What is a silent block?

The part is made in the form of a small cylinder consisting of three elements:

- the outer part is made of thin-walled steel and equipped with seating elements - shell and stiffeners;

- core – solid metal sleeve;

- the gap between the outer and inner elements is filled with an elastic composition - rubber or polyurethane.

Reference. Manufacturers began using polymer as a filler relatively recently; previously only natural technical rubber was used.

The operation of any silent block is based on the fact that the inner sleeve, compressed on all sides by the elastomer, should not rotate. The outer shell “sits” just as tightly; it does not rotate relative to the rubber insert. But if sufficient torsional force occurs, the steel bushings can move relative to each other - due to the elasticity of the filler.

Right choice

The choice is made after diagnosing the malfunction or during a planned replacement. It is necessary to understand what role the part plays in the suspension. Its task is to dampen vibrations that inevitably arise due to unevenness on the road.

Vibrations during movement are transmitted to the suspension springs, where they are partially damped by shock absorbers. The vibration then spreads to the frame through the connecting nodes. It is partially damped by silent blocks due to the presence of a soft base between the bushings. Therefore, the quality of the base must be of a high level. The factory version of the suspension is equipped with rubber-based silent blocks. This is a proven material, but there are better ones - for example, polyurethane.

Advantages of polyurethane:

- The service life is increased by 5 times. This allows replacements to be made after long mileage intervals and the suspension to be loaded more aggressively.

- Increased thermal stability. Polyurethane tolerates temperature changes well. The material works just as well in cold weather as at high temperatures.

- Thanks to the dense structure of the material, vehicle handling is improved.

Rubber and polyurethane are equally popular. Drivers themselves choose what to focus on. With rubber spacers you can get increased riding comfort, but improved handling can only be achieved with polyurethane. But in the latter case, comfort decreases, which is especially felt by passengers.

Recommended: Engine Duty Cycle

When purchasing a part, it is better to consult a specialist in the store. The fact is that vibration isolators are difficult to distinguish from each other in appearance - they are almost similar. But their outer diameter is sometimes slightly different, which will cause installation difficulties.

How do you know when it's time to change silent blocks?

What signs and symptoms indicate that the front suspension arm bushings or rear beam bushings need to be replaced?

Failures can manifest themselves as follows:

- the car begins to react poorly to steering turns;

- extraneous sounds, tapping, etc. are heard;

- at high speeds the car pulls to the side is noticeable;

- Uneven tire wear is noticeable.

If you feel any of the above, then replacing the silent blocks is already necessary. To do this, you can visit a car service center, where specialists will do everything, or you can deal with the problem yourself. Let's look at how to do this below.

Replacement timing

The average resource of silent blocks of the front levers is 100-150 thousand km. But the service life of parts can be increased if you operate the car more carefully (drive on smooth roads, and crush all potholes and bumps or drive slowly enough).

Timing for replacing the front arm silent block

Unfortunately, domestic roads cannot boast of high quality, so it is recommended to regularly check silent blocks for wear. It is advisable to carry out diagnostics every 20 thousand km, and replace elements every 60-70 thousand km. The frequency of replacement may vary slightly depending on the quality of the product used.

Recommended timing for replacing front arm bushings

What is a silent block in a car?

Silent block (rubber-metal hinge) is a device responsible for reducing the transmission of vibration and noise from the suspension to the car body. It consists of a pair of metal bushings, between which there is an elastic insert made, as a rule, of rubber or polyurethane. This is a kind of intermediary that is inserted between the rigid body and the suspension part (shock absorber, subframe, spring, lever). To fully understand why silent blocks are needed, try attaching a metal element to the body. In this case, all the noise and vibrations caused by the vibration of the suspension will be perfectly audible, which will cause a decrease in the comfort of the entire car and its passengers.

The shape, weight and dimensions of silent blocks differ depending on their location in the car.

Many manufacturers claim that the silent block is designed for 100,000 km. But the condition of our roads leaves much to be desired, and climatic conditions also have a significant impact. In connection with the described harmful factors, the service life can be divided into two, or even three.

Untimely replacement of a part provokes a number of problems:

- Reduced comfort while driving. Among the most visible signs are loss of vehicle stability, a feeling of roll, and the appearance of play. All this is caused by the fact that the car misses all the bumps - both large and small.

- Uneven tire wear. That is why you need to monitor the condition of the parts, because replacing tires is a very expensive pleasure.

- Damage to the lever mounts.

An image that clearly shows the location of a silent block that is already in use.

Replacing suspension silent blocks

Silent blocks have the function of damping vibrations, softening loads and attaching levers and stabilizer rods to the body brackets. Thanks to silent blocks, the suspension operates smoothly and silently. The car manufacturer estimates the service life of silent blocks to be up to 100,000 km. However, experience shows that it is difficult for standard silent blocks to withstand the peculiarities of our climatic conditions, plus driving style may interfere, which affects the reduction of the resource.

The car owner may notice the need for diagnostics and, with a high degree of probability, replacement of silent blocks for the following manifestations:

— knocking in the suspension, — deterioration in response to turning the steering wheel, — deterioration in handling, — uneven/rapid tire wear, — frequent violation of wheel alignment angles (wheel alignment).

Diagnosis of silent blocks is carried out mainly by visual inspection after cleaning them. They should not have cracks, tears or any other damage. The silent block is at the limit of its wear - if play in the suspension arms is felt when the silent block twitches.

We recommend diagnosing silent blocks as part of diagnosing the entire vehicle suspension, because Some of the manifestations of malfunction may indicate inspection of other suspension elements. The cost of diagnosing the entire suspension is low, but the result will be an understanding of the condition of the arms, tie rod ends, CV joint boots, wheel bearings, wheel bearing seals, stabilizer bushings, brake hoses, etc.

Because The load on the suspension is generally symmetrical; it is recommended to change the left and right silent blocks in pairs. The silent blocks of one lever are always replaced in pairs.

Consequences of untimely replacement of silent blocks:

- rapid wear of silent blocks, - squeaks and knocks when driving on uneven roads, - instability of the car, especially at speed, - destruction of the mounting holes of the lever bolts, in which the suspension repair will not end with the replacement of silent blocks.

We often suggest that clients use reinforced silent blocks when replacing.

For popular VAG car models - Audi, Volkswagen, Skoda, Seat, Porsche, silent blocks are always available in our warehouse. For less popular ones, delivery usually takes 1-3 days. The prices for spare parts in our technical center are not higher than the prices of the most popular spare parts store.

Cost of the most common works (current for 2020):

1. Replacement of four silent blocks in the lower support arms of the front suspension on a VW Touareg - 2,850 rubles. for the lever., plus wheel alignment.

2. Replacing the silent blocks of the support brackets of the lower load-bearing parts of the front suspension on Tiguan, Octavia, Passat, Seat - 1,500 rubles. per piece

3. Replacing the front silent blocks in the lower support arms of the front suspension on Tiguan. Seat, Octavia, Passat — 2,550 rub. per piece

4. Replacement of subframe silent blocks (4 pieces) for Touareg, Q7 - 10,000 rubles, plus wheel alignment.

We calculate the cost of spare parts and consumables upon request.

After replacing the silent blocks of the subframe or the work from point 1, you need to adjust the wheel alignment angles.

To make an appointment with VRS for diagnostics and replacement of silent blocks on your car, call or fill out the form below:

See you at the hospitable VRS service!

Design features of silent blocks

What is a silent block? The classic definition of this structural element is a rubber-metal hinge, made, as a rule, in the form of two metal bushings inserted concentrically into one another with a rubber or polyurethane filler between them.

According to the installation location, silent blocks are divided into three groups:

- Front suspension (with predominant torsional deformations): mounting of shock absorbers, stabilizers, levers;

- Rear suspension (torsional deformations also predominate): shock absorbers, stabilizers, rear beam fastening elements;

- Elastic mounting elements for the engine and gearbox (prevalence of compression and bending deformations - use as vibration isolators).

Schematic examples of installing silent blocks in various places of the car are presented in the following figure:

Of course, the specific dimensions and additional structural elements (for example, collars) of silent blocks, their number and specific installation locations are determined by the design of the vehicle's chassis system, but the operating principle and basic design are the same.

During operation, the elastic element of the silent block experiences high cyclic loads and therefore the requirements for the material are also quite stringent: as a rule, these are elastomers based on natural rubber. Modern materials are also used as an elastic element: polyurethane and polyurethane with natural rubber additives.

Polyurethane silent blocks are somewhat stiffer than rubber ones, but at the same time they are significantly (4 - 5 times) more durable (and more expensive).

What is a silent block and what is it for?

This part is made in the form of two steel bushings. Between them there is a rubberized polyurethane insert. Therefore, the adjective “polyurethane” often appears in the name of a silent block.

As for the insert, it plays one of the important roles in the performance of the vehicle. Thanks to the presence of this part, the gearbox, engine or shock absorbers are mounted.

Many car owners know very well what the silent block is used for, and therefore understand that the condition of the part must be carefully monitored. Despite the fact that most manufacturers guarantee a long service life of the silent block, the part wears out quite quickly, and among the reasons for possible failure are:

- road condition;

- quality of the part;

- negligent attitude towards the driver's vehicle.

To avoid unexpected breakdowns, it is recommended to carry out regular inspection of the silent block serviceability approximately every 50 thousand kilometers traveled by the car. In addition, the inspection can be performed at home, so there should not be any difficulties with this.

Selecting new parts

Before replacing worn silent blocks, you need to select new ones and buy them. Today there are many choices of these parts.

Types of silent blocks of front levers:

- rubber;

- polyurethane.

Before buying new ones, the following question arises: which silent blocks to take, rubber (rubber) or polyurethone.

Polyurethane ones have a longer service life, they last 3-5 times longer. But, they are more expensive. The polished tan vibration isolator is less likely to be deformed and squeezed out of the grooves of the seat.

Advice! In case of increased vehicle operation, it is better to install polyurethane ones. For low mileage mode, ordinary rubber silent blocks will be sufficient. Both types of these parts are produced by many manufacturers. The main thing is not to take the cheapest ones.

Before purchasing, you should check whether they are suitable for your particular make and model of car.

What do you need for work?

Before you begin the repair, you need to prepare everything you need. Tools and materials for replacing silent blocks:

- bushing remover;

- vice;

- a set of open-end and socket wrenches;

- jack;

- hacksaw for metal;

- car stands;

- hammer and chisel;

- work gloves and glasses;

- lubricant;

- sandpaper;

- new silent blocks.

Diagnostics of silent blocks of front levers

As noted earlier, everything at the replacement site must be cleaned of accumulated dirt and, if possible, washed. Once everything you need is at hand, you can begin the work process.

Tool for removing silent blocks

WHERE ARE THE BUSHING BLOCKS LOCATED?

FRONT ARM BUSHING BLOCKS

In the front suspension, silent blocks are used in the levers; through them, a movable and elastic connection of the levers with the wheel hub and with the car body is carried out. Silent blocks are often used at the junction of the anti-roll bar with the lever, if this is structurally provided for. It can also be used at the bottom of the shock absorber strut, where it is attached to the hub.

In the rear suspension, silent blocks can be installed on levers (longitudinal and transverse), at the point where the torsion beam is attached to the car body, and in shock absorbers.

In general, the number and location of installation of these rubber elements depends on the design of the car's chassis. For example, consider the location of silent blocks on a VAZ-2110 car. And let's start with the front suspension where these joints are used:

- in the transverse arms (at the place of their attachment to the body);

- at the ends of the anti-roll bar (its attachment to the wishbone);

- in the shock absorber struts at the bottom (the place where they are attached to the wishbone);

- in the extension of the transverse lever (at both ends - at the point of its connection with the lever and with the cross member);

In total, there are 5 silent blocks installed in the front suspension on one side only, and the same number in the other part of the suspension.

Features of replacing front silent blocks on a VAZ “classic”

First, the silent blocks of the upper arm are changed. It is better to do all operations in the inspection pit. To do this, jack up the car and remove the wheel, loosening the wheel nuts in advance. Then:

- turn the steering wheel in a convenient direction to unscrew the ball joint nut using an open-end wrench set to “22”;

- the support must be dismantled with a puller;

- remove the long bolt securing the lever to the body;

- pull out the lever and remove the old bushings from it: this can be done using special tools or simply by breaking the worn parts;

- You can install new silent blocks using a socket of a suitable size and a hammer.

As for the lower lever, everything is more complicated. First you will have to remove the shock absorber. Then you need to tighten the spring with a special device. Then:

- remove the shock absorber;

- Unscrew the nut securing the ball joint and pull it out using a puller;

- unscrew the mount (a couple of nuts) of the anti-roll bar: be careful not to break the studs;

- remove the spring;

- now an important point: you need to unscrew the two nuts securing the lever to the body: the most important thing here is not to confuse or lose the gaskets by which the camber of the front wheels is adjusted;

- pull out the lower arm.

If you do not have a special puller to press out old silent blocks, it is better to burn out the old parts using a can of gas (they are inexpensive and are sold in hardware stores). It is better to insert new parts using a special tool or using crimping in the form of the same head of the required diameter and a hammer.