Reading time: 5 minute(s)

The shock absorber's name suggests that the component will absorb shock. This sounds logical, but it is incorrect because it is actually a vibration damper. Irregularities that convert impact energy into vibrations. Shock absorbers help convert vibration energy into heat so that the initiated rocking movements die out as quickly as possible. Thus, they not only contribute to driving comfort, but above all have a bearing on the driving safety of the vehicle.

Shock absorbers help prevent the vehicle from rocking, especially during sudden load changes. They also provide improved road contact between the wheels, which means higher braking forces are transmitted. The result is a shorter braking distance. Of course, shock absorbers also prevent premature tire wear. In this article we will talk about how to recognize a broken shock absorber and which shock absorbers are better to install on a VAZ 2110?

How to choose?

To understand which racks to install on a VAZ 2110, you need to find out the characteristics of each model and understand which one suits you best.

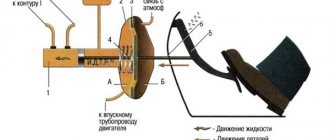

There are different types of shock absorbers to suit every need, such as mono-tube and twin-tube shock absorbers, spacers, spring mounts (with spring plate) and spring cylinders (with hydraulic leveler). Let's look at the most basic ones - single-pipe and double-pipe.

Monotube damper

In monotube gas shock absorbers, the working cylinder is filled with oil and gas, which is under an excess pressure of approximately 25 to 30 bar. Oil and gas are precisely separated from each other by a movable separating piston.

The monotube damper can be installed in any position. It has a higher pressure than a two-pipe damper. Advantages: Good response characteristics of the reed valves in the piston and prevents foam or bubbles in the hydraulic oil.

Double pipe damper

Twin-tube shock absorbers have two spaces filled with oil: the working space in which the piston and piston rod move, and the compensation space.

The compensation chamber is located between the working cylinder and the container tube and is 2/3 filled with oil, and 1/3 with air or gas. This means that a double-tube damper has a shorter overall length than a single-tube damper.

The damping force characteristics of the twin-tube damper are specifically designed for each vehicle type, that is, matched to the vehicle weight, structure and chassis springs.

When a vehicle is equipped with an oil shock absorber as a sequential damper, switching from oil to gas shock absorbers optimizes driving stability, road holding, comfort and safety for every production vehicle. Cars with standard gas shock absorbers retain their driving behavior only if the gas shock absorbers are installed again when the shock absorber is replaced.

Switching to a monotube shock absorber (eg BILSTEIN B6) improves the overall driving behavior and provides more damping power for greater safety and driving pleasure even under high loads.

Analogs of rear shock absorbers Lada 2110-2112

When buying a car, many car owners change the rear struts to higher quality foreign parts, this allows them to increase the reliability of the car, the softness of the suspension and the stability of the ride. The most popular spare parts from foreign manufacturers are presented in the table.

| Manufacturer | vendor code | price, rub. |

| Rear gas shock absorbers for Lada 2110, 2111, 2112 | ||

| Hola | S434 | 1500 |

| OAT | 21100291540220 | 1500 |

| KYB | 341824 | 2900 |

| Rear oil shock absorbers for Lada 2110, 2111, 2112 | ||

| Fenox | A12291C3 | 1200 |

| BelMag | BM9500 | 1200 |

| KYB | 441824 | 2600 |

Shock absorber KYB 441824

Shock absorber OAT 21100291540220

How to recognize faulty shock absorbers, and what are the reasons?

The first sign of a bad shock absorber is usually unusual tire wear. Because the vehicle loses contact with the road more frequently and has brief sliding moments, the tread wears out much faster than with active shock absorbers. The next step usually leads to the workshop. There the wheel is removed so you can look at the axle suspension as well as the suspension and damping. The seal on the piston rod often leaks, causing some oil to leak out of the piston with each movement. Repair is not possible, so the damper must be replaced.

A specialist workshop can also place the car on a vibration machine and measure the body's sway using a sensor. In a home workshop, you can try to simulate this by rocking the car and seeing how long it takes for it to stand still. Of course, such observations are quite inaccurate. While driving, defective shock absorbers can often be felt, changes in steering behavior and unusual swaying of the car occur, which can also cause nausea.

The danger of worn struts

Some car owners believe that failure of the front shock absorbers is not a problem, especially if the car does not even tilt to one side. In fact, problems with the front suspension can lead to the following troubles:

- The support bearings will fall apart , which can lead to an accident.

- The tires will begin to wear unevenly , and you can forget about wheel alignment. In addition, so-called “bumps” may appear on the tires.

- Wheel bearings won't last long either.

- Brake performance will become unsatisfactory because the pads will wear unevenly.

It turns out that one problem that is not corrected in time can lead to serious damage to the car.

When are shock absorbers replaced?

Shock absorbers are always replaced if there is a defect. Depending on the style and quality of driving, the lifespan of the best struts on a VAZ 2110 ranges from 100,000 to 120,000 kilometers. In addition to replacement for wear reasons, it is also recommended to adapt the shock absorbers when making modifications to the chassis.

Piston rods are often too long to lower, meaning without replacing the shock absorbers there is a risk of the piston rod becoming caught in the piston while driving. So-called stroke stops solve the problem by limiting the freedom of movement of the piston rod during the compression phase, but this should only be considered as a temporary measure.

Knock and replacement of rear elements

The appearance of a knocking sound from the rear pillars of a VAZ 2110 is a kind of signal that indicates the need to replace them. The cause of the knocking noise may not only be a breakdown of the rear suspension. The possible cause can be determined professionally or experimentally. The possible causes of knocking noises from the rear may be the following.

When driving a car on an uneven road surface, the most likely cause of knocking will be a malfunction of the shock absorbers, which require replacement with new ones. If the wear of the rubber bushings of the suspension arms is clearly visible visually, then the cause will be the suspensions themselves, and the solution will be to replace them. It is also necessary to change the spring if it settles.

The appearance of a knock may be the result of a weak shock absorber. The rubber bushings on the lugs may be worn and need to be replaced. After replacing worn parts, carefully tighten the nuts and bolts. Due to overload or breakdown of the rear suspension, if the compression stroke buffer is destroyed, a knock may also occur.

The displacement of the rear axle, if the suspension arm bushing is damaged, can also be the cause of the knocking noise. If the reason for the knocking is the suspension arms, then they need to be replaced with new ones. You can determine the cause of the noise if there are no passengers in the back seat, then the most likely are shock absorbers or springs. When replacing the rear struts of a VAZ 2110, proceed in a certain sequence.

- Remove the backrest from the rear seat.

- Fold back the edges of the upholstery and unscrew the nut that secures the rack.

- Unscrew the lower mounting nut and remove the bolt; for this operation you need to crawl under the car.

- Remove the stand by pulling the lower end out of the bracket.

- Remove the spring insulating gasket located in the wheel well, then remove the upper cushion and support washer located in the hole on the support.

- Install the new rear strut in reverse order.

In general, replacing VAZ 2110 struts seems simple. But if you have any doubts, it is recommended that you contact a car service specialist. In order to perform such an operation yourself in the future, you need to carefully observe the actions of the mechanics.

Rating of the best racks for the VAZ 2110

SACHS

A company whose products are of very high quality, but at the same time cheap. In addition to the production of spare parts, it specializes in the production of portable components.

The constant development of new generations of cars places increased demands on vibration reduction and damping systems. SACHS shock absorbers are also pioneers in many areas, for example with modular shock absorbers or innovative products such as the SACHS CDC shock absorber for cars.

BOGE

German mid-range shock absorbers, often used in BMW, Volvo, Audi and Volkswagen cars. Enjoy stability and comfort, mainly thanks to the optimal price-quality ratio.

The same suspension elements can be found on Korean cars such as the premium Kia Quoris. Overall, users are happy with what they get, and this is a reliable indicator of a good manufacturer.

If you are tormented by the question of which rear struts are best to install on a VAZ2110, take BOGE.

Bilstein

Currently, Bilstein shock absorbers are a symbol of quality and reliability. They are famous all over the world. They are installed on such brands of cars as Jaguar, Lamborghini, Ferrari.

Bilstein has firmly established itself in the global market as the premier supplier of shock absorbers for luxury vehicles. They are so famous in the world that Japanese automakers Subaru install the company's products on their cars.

In the range you can find both gas and oil struts, which are aimed at different driving styles.

The company produces a separate “Sport” series; in fact, it is not about sports, but about fast driving on highways or city roads.

But the Sprint and Rally series are exactly the same dampers as those found in racing cars and, one might say, the company’s calling card. Of course, it is unreasonable to hope for any comfort with shock absorbers of this series, but stability on the road will be ensured. As a result, the products of this company are expensive, but such a high price is fully justified by the excellent quality in all respects, without exception.

Krosno

Which rear struts are best installed on a VAZ 2110 so that they are inexpensive, durable and provide driving comfort? Pay attention to Krosno, a Polish brand specializing in the production of suspension elements, including shock absorbers.

As a rule, most models are oil-based, so they are not expensive. Among the design features, we can highlight the presence of special rod seals on all rear struts without exception, which prevents dirt, dust and ice debris from entering the assembly.

SAAZ

In fact, the manufacturer's model series is limited to only twin-tube shock absorbers. They are cheap but have some interesting features. Firstly, unlike foreign analogues, there is a reflective shock absorber, which works great when driving on remote, uneven roads (of which, unfortunately, there are plenty of them in Russia).

In addition to such a very useful component, another vulnerability has appeared on the racks - they do not work well at road junctions, which is why the smoothness of the ride suffers. Another feature of Russian shock absorbers is that they are durable. The plant's marketing has gone even further: now every customer can order shock absorbers at their own request (SAAZ-Eng series). SAAZ provides a cheap and inexpensive option for replacing struts for the entire line of “young” and “old” VAZ and Niva cars.

Replacing front struts

The car is placed on a viewing ditch or lift. The parking brake must be on and the ignition must be off. There are two replacement options. In the first case, remove the struts and steering knuckle. This method is more labor-intensive, but after the replacement process there is no need to adjust the wheel alignment angles.

- Remove the cap on the top support.

- Loosen connections.

- Disconnect the steering rod.

- Remove the brake pad guide with the brake disc and caliper.

- Remove the outer spool.

- Unscrew the 3 nuts securing the upper support and body.

- Remove at the same time as the steering knuckle.

In the second method, the first operation, as in the previous one, will be to remove the rubber plug from the upper support. Subsequently, before disconnecting the steering rod, mark the location of the adjusting bolt so that the wheel alignment angle is fixed at its original value. Remove the nuts from the lower and upper adjusting bolts holding the steering knuckle and strut together. Knock them out using a punch.

To avoid strain on the brake hose, move the steering knuckle away from the strut. Unscrew the nuts holding the upper support and remove them. Installing new front struts is done in the reverse order. It is important not to forget that with the second method it is necessary to adjust the wheel alignment angles.

How much does it cost to change shock absorbers?

Shock absorbers are relatively cheap and even with additional parts, such as a dust protection kit and a new dome bearing, cost only about 1000 - 2000 rubles apiece. However, drivers of heavy SUVs can expect slightly higher costs. Shop labor time is the second largest cost factor and varies greatly by region, vehicle and axle.

I believe that we have given a comprehensive answer to the question of which struts to install on a VAZ 2110. Choose dampers according to your driving style and keep in mind that more and more fakes appear on the spare parts market every year. We hope that the shock absorbers from our rating will never let you down and you will ride in comfort.

Petr Alekseev

Regular author of articles for the magazine rating cars.

We determine that the element has failed

There are several signs by which a malfunction can be identified:

- The body vibrates intensely on the comb on the side of the damaged shock absorber;

- There is a beating sensation in the steering wheel;

- The braking distance becomes longer;

- When turning, the car skids;

- Traces of oil leaks;

- When driving in a straight line, the car drifts to the side;

- There are knocks and extraneous noises in the rack.

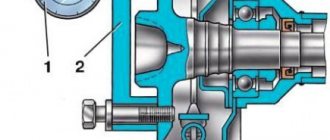

Device diagram

If you do not repair the front struts in a timely manner at a service station or with your own hands, this can lead to dire consequences:

- The support bearings will be destroyed;

- Tires will wear unevenly, jump, and form bumps on the rubber surface;

- The wheel bearings will fail;

- The braking distance will become longer, which is dangerous on any section of the road;

- The brake pads will malfunction and their service life will be significantly reduced.

There are two main ways to check elements for malfunction. One is professional, the other is artisanal, but also quite effective.

- Special vibration stand. A car is driven onto it, and the computer calculates the efficiency of the shock absorbers. It should be noted that new racks may show a result of about 75%, but this is quite normal. If the percentage is less than 50, then it’s time to change the part.

- Manual rocking. You need to grab the front of the car, its wing, and start swinging. Try to achieve the maximum amplitude that your body weight allows. If anything, ask a friend to help. The point is to suddenly remove your hands after swinging and look at the car. If it immediately returns to its original position and does not fluctuate anymore, then everything is fine. If even a slight vibration is detected, you can assume that it is advisable to replace the racks in the near future.

DELPHI

Toughest oil rack Country: UK

The largest manufacturer of auto parts in the world is the British company Delphi Corporation. It is the main supplier of components to the General Motors assembly line. The British made hard oil shock absorbers for domestic VAZ cars. They allow you to experience the pleasant emotions of sporty driving, without the fear of flying into a ditch. Front and rear pillars are offered to owners of the VAZ-2110 model range. Products are manufactured on modern high-precision equipment, using innovative technologies and high-quality materials.

Consumers who managed to install British shock absorbers note the excellent stability of the car on the road. Severe operating conditions in Russia significantly reduce the service life of DELPHI racks. On average, motorists manage to drive about 200 thousand km, but knocking noises appear in the components after driving 150-170 thousand km.