Useful tips

Author: Anastasia Safonova12/27/201612/27/2016

The VAZ 2110 ignition switch cannot be called a reliable part, especially when you compare its service life with the same devices on cars of foreign origin. Therefore, owners of the tenth - twelfth model, who use the car for a long time, sooner or later encounter problems with the lock and its repair. On the other hand, the element can be easily removed from the car and every skilled motorist can replace it. But first you should figure out whether the entire part needs to be replaced, since in most cases it can be repaired.

- Instructions for removing the element

Dismantling the VAZ 2110 lock in the photo - Training video on replacing the ignition switch

Replacing the ignition switch for VAZ 2110, 2111, 2112

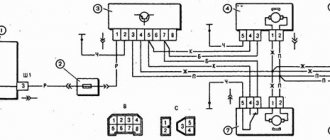

One of the most common reasons for the inability to start a VAZ 2110, 2111 or 2112 may be a failure of the ignition switch. This node switches or disconnects groups of electrical circuit contacts, activating or switching off the engine. If there is a problem with it, the driver simply will not be able to operate the car. Replacing the ignition switch of VAZ 2110, 2111 and 2112 is a simple operation; it is quite possible to do the repair yourself. But before you repair the unit, it is advisable to familiarize yourself with its diagram. It is similar on all of the above VAZ models.

VAZ-2114, ignition switch: troubleshooting methods and installation of a new device

Starting the engine, its systems, as well as other important devices and mechanisms in cars of the Samara family is impossible without the ignition switch. Car owners who have encountered a malfunction of this device know what an unexpected malfunction can lead to. Especially if this happens on the road.

Further in the article we will talk about what the VAZ-2114 ignition switch is, consider its main malfunctions and how to eliminate them. We’ll also try to find out how to replace it with your own hands and connect it correctly.

Tools you will need for your work

To perform the work you may need the following tools:

- chisel;

- hammer

- socket wrench 10;

- a set of standard screwdrivers and wrenches;

- pliers or round nose pliers;

- sandpaper.

An experienced master will spend about an hour on the job, a beginner will have to tinker twice as long. But this is a completely justified time investment, since it allows you to save money - as of January 10, 2019, the average price for replacing the ignition switch of VAZ 2112, 2110 and 2111 in car services costs 800 rubles. In addition, the car owner will be charged another 500 rubles for adjusting the system. While the complete unit itself costs about 1 thousand rubles. Replacing a contact group will cost the car owner about the same money, when the element itself costs an average of 300 rubles.

Disassembly and replacement procedure

When the source of the malfunction is identified, the question immediately arises: how to disassemble the ignition switch on a VAZ 2110.

To do this, first it is removed. Since the preparatory work has already been done, the following actions remain:

- The housing mounting bolts are unscrewed.

- The lid made of plastic material is removed. The lock is removed.

Replacing the larva

Before changing the ignition switch on a VAZ, sometimes it is enough to replace the cylinder.

The process consists of several steps:

- A small diameter pin holding the cylinder is removed from the side. The work is carried out using a thin screwdriver and a hammer.

- The old larva is removed and the new one is installed.

- To check, the steering wheel is turned and the reliability of the jamming is checked.

- Sometimes the blocking is adjusted.

Order of Operations

It is worth immediately noting that independently replacing the ignition switch cylinder of VAZ 2110, 2111 and 2112 is problematic. This part is difficult to find on sale, and working with it requires special skills. An incorrectly performed operation will result in unstable operation of the ignition system. In this case, you need to purchase the assembly and change it completely:

- Since there is work to be done on the on-board electrical system, you need to disconnect the battery; to do this, disconnect the negative terminal of the battery. In addition, it is rational to provide good lighting in the work area, so you will spend less time performing operations.

- Now you need to lower the steering column all the way and remove the plastic casing, after unscrewing the screws.

Using a chisel, unscrew the bolts with cut heads and pull them out with pliers. Hammer blows should be directed clockwise.

Now you can remove the bracket and the lock itself from the steering column by disconnecting the electrical connector.

If the backlight lamp needs to be replaced, the contact is disconnected and its socket is removed with pliers. Installing a new device.

To replace the contact group of the ignition switch of a VAZ 2110, 2111 or 2112, the clamps are released.

If the microswitch stops working, unscrew the screws, remove the rod, and pull out the latch. We install a working device.

- We replace the contact group of the ignition switch of VAZ 2110, 2111 or 2112.

- Now the operations are performed in reverse order. We install the assembled unit on the steering shaft, clamp it with a strap and tighten it with bolts. They need to be screwed in all the way; for this you can use a 10mm spanner or a socket with a knob. IMG8

- Without breaking off the heads from the fasteners, we begin to adjust the steering wheel: the key is located opposite the I icon, and the steering shaft is in the same position. If the shaft does not lock and the steering wheel continues to rotate freely, you need to find the correct location of the lock so that its latch engages the groove in the shaft.

- Now you can break off the heads from the bolts.

- Once again we test the functionality of the mechanism. If everything is in order, you can connect the contacts.

- We connect the lock with the battery by replacing the negative terminal. And again we test the performance of the node. If the results are positive, the decorative plastic casing is mounted in its original place.

Failure of the lock may be due to normal oxidation of the contacts in the group. In this case, you only need to clean with fine sandpaper. This malfunction can be determined using a multimeter in ohmmeter mode. Each pair must be tested for short circuits.

Is it possible to check the contact group with your own hands?

Diagnostics of a contact group consists of measuring the resistance value between certain terminals on the device's wiring harness.

To check you will need:

- Remove the plastic cover of the steering column (you need to unscrew three screws).

- Disconnect the wires of the VAZ-2114 ignition switch (disconnect the unit).

- Turn on the ohmmeter (if you have a multimeter, switch it to resistance mode).

- Connect the device probes (polarity does not matter) to pins 4 (top right) and 7 (second bottom right), which correspond to pins 15 and 30.

- Turn the ignition key to the first position.

- Take an ohmmeter.

- Turn off the ignition

, connect the device probes to pins 3 (second from the top right) and 7, corresponding to pins 50 and 30. - Turn the lock to the second position.

- Measure the resistance between the terminals.

If the ignition switch (injector) of the VAZ-2114 is working properly, the resistance between the contacts will be zero. Otherwise, most likely, the contact group of the device has become unusable.

Tuning VAZ 2109

The VAZ 2110 ignition switch cannot be called a reliable part, especially when you compare its service life with the same devices on cars of foreign origin. Therefore, owners of the tenth - twelfth model, who use the car for a long time, sooner or later encounter problems with the lock and its repair. On the other hand, the element can be easily removed from the car and every skilled motorist can replace it. But first you should figure out whether the entire part needs to be replaced, since in most cases it can be repaired.

Symptoms of a problem

What are the symptoms of a bad ignition switch? Let's start with the fact that its malfunction can be either mechanical or electrical. In the first case it is:

- lock jamming in one of the positions;

- inability to unlock the steering shaft;

- turning on the ignition with a key or other object other than yours.

If the lock is electric, you may notice the following symptoms:

- indicator lamps on the instrument panel do not light up or do not light up and periodically go out;

- the starter does not start;

- Some or all of the electrical appliances whose circuits are powered by the ignition switch (cigarette lighter, headlights, washer, wipers, etc.) do not work.

Reasons for replacing the ignition switch

There are 3 main reasons leading to breakdowns of this device:

Reference. The first troubles associated with turning on the ignition and starting the engine may appear after three years of operation of the VAZ 2110-2112.

Appearance of the ignition switch VAZ 2110—2112

Not every one of the listed reasons leads to a complete replacement of the element; sometimes you can get by with “little loss” by changing one of its parts. To determine this issue, you need to diagnose the signs of a malfunction:

- Contacts are burnt or oxidized. In this case, the mechanical part works, but the electrical part does not. The problem is solved by cleaning or replacing the contact group.

- The key gets stuck in the slot, after starting the engine it is not thrown back and you have to turn it by hand. These are malfunctions of the core (larvae) and the ejection spring, which can be completely repaired.

- Obvious mechanical failures of the locking tongue (the steering wheel is very difficult to rotate), jamming or cracks in the housing are a reason to replace the entire ignition switch.

In the event of a mechanical failure, the key may not turn or may not be released by the spring.

A separate issue is the loss of all keys by the owners. It can be solved in two ways - by replacing the entire device or the key turning mechanism - the cylinder. For obvious reasons, the second option will be cheaper, especially if you do the work yourself.

Reference. As practice shows, the mechanical insides of an element can be broken by an ignorant driver who has lost his keys and is trying to unlock the steering wheel in order to start the engine by shorting the wires. There is a more elegant way - to remove the lock, and only then connect the wires of certain colors, as described below.

Checking the lock contact group with a multimeter

A faulty contact group can be easily diagnosed if you have a multimeter or other device with a resistance measurement function in your household. To do this, you need to get to the connector located under the plastic frame of the steering column and disconnect it. Then use a multimeter to measure the resistance between all contacts in the block, turning the key to different positions. Depending on the result, the following conclusions are drawn:

- the device shows infinity - the contact group is out of order and needs to be replaced;

- some resistance value indicates burnt or oxidized contacts, try to clean them;

- zero readings on the device indicate that the electrical part is fully operational.

VAZ 2110 ignition switch diagram

Important! You need to measure the resistance in the block whose wires come from the ignition switch (male connector), do not confuse it with other contacts connected to the car’s on-board network.

Actually a replacement.

The first thing that is necessary before changing the ignition switch of a VAZ 2110 is to turn off the power to the car. To do this, disconnect the negative terminal on the battery, then remove the steering column cover. In order to facilitate the procedure for replacing the cylinder, it is necessary to remove the ignition switch, then replace the faulty cylinder with a working one and put the lock back.

If we talk from a financial point of view, we can say that replacing the contact group is the most profitable. The disassembly principle is somewhat similar to the previous one; you will also have to remove the casing and lock. In order to avoid any unpleasant moments, I advise you to mark all the wires being removed when disconnecting the contact group; this will allow you to avoid confusion and save your time. Some cars have a retaining ring in the contact group, which you will need an awl to remove. After replacing the contact group, do not forget to return the retaining ring to its place.

To replace the ignition switch of a VAZ 2110 you also won’t need any super abilities, but if you don’t know some of the nuances, you can tinker a lot and get tired.

Instructions for removing the element

For disassembly you need to prepare a simple set of tools:

- 10 mm head and ratchet drive;

- Phillips screwdriver;

- narrow chisel (width 5-8 mm);

- hammer;

- round nose pliers with tapered, curved ends.

Ignition switch replacement tool

To successfully install a new or repaired lock in place, it is advisable to purchase 4 special fastening bolts with M6 threads with a head size of 10 mm and a length of 20 mm. Their feature is the heads that come off with a key at a certain tightening torque. After tearing off the heads, semicircular caps remain on the surface, which are much more difficult to unscrew for an untrained person. But you will have to do this during disassembly.

The battery must be disconnected before starting work.

Like any event related to tampering with the electrical part of the car, dismantling the ignition switch begins with disconnecting the negative terminal of the battery. Then proceed in this order:

- Using a Phillips screwdriver, remove the screws holding the two halves of the plastic frame of the steering column together.

- Lower the handle that fixes the position of the steering wheel during adjustment all the way down and remove the plastic panels. Disconnect the ignition switch block and carefully cut the tape connecting your bundle of wires to the common harness. In order not to cling to the steering column switch during operation, it can also be pulled out of the connector.

- On the metal casing of the steering column you will see a lock mount consisting of two clamps. They are held together by 4 bolts with the heads torn off (visible on the left side). Pointing the chisel at the semicircular caps, use a hammer to loosen the tightening of these bolts one by one.

- Using pliers and then your hands, unscrew all 4 bolts and remove the ignition switch.

Unscrewing the plastic steering column cover

Note. There are “dozens” in which not all the bolt heads are torn off during assembly. This simplifies the matter; the fasteners can be easily unscrewed with a 10 mm socket.

Bolts with intact heads can be unscrewed with a wrench

At the stage of disconnecting the connectors, it becomes possible to check the functionality of the contact group by measuring resistance, as described in the previous section. If you remove the lock due to the loss of the keys and want to move on, then after dismantling you need to do the following:

- On the “mother” block, which remains hanging after the lock is turned off, find contacts with thick wires of purple and blue color (the latter with a black stripe).

- Connect these terminals with any conductor, after which the ignition will turn on.

- The thick red wire leads to the starter. To start, its contact must be temporarily connected to the installed jumper. When the engine starts, the red wire must be disconnected.

How to properly connect the ignition switch

If the wires are collected into one chip, then connecting the lock is not difficult, you just need to install it on the contacts.

If the wires are connected separately, you need to pay attention to the diagram:

- Cream 50 red wire, the starter works with it;

- clema 15 blue with a black stripe, responsible for interior heating, ignition and other devices;

- Terminal 30 pink wire;

- Terminal 30/1 brown wire;

- The black INT wire is responsible for the dimensions and headlights.

Connection diagram

If the wiring is done, then everything needs to be assembled and connected to the terminal to the battery and check the operation. First you need to check whether all electrical appliances are powered from the lock, after the starter itself operates. If any malfunctions are detected, it is necessary to once again check that the wires are connected correctly, since the operation of all devices in the car will depend on this after turning the key. Next, you can familiarize yourself with the electrical ignition circuit.

Today there are two types of ignition systems:

- The battery is usually self-powered; it can be used to turn on electrical appliances without starting the engine.

- During generation, electrical appliances can only be used after the engine has been started, i.e. after starting the electric current.

Replacing the contact group

In the event that, as a result of diagnostics, a malfunction of the contact group is detected, you will still have to remove the ignition switch, since it will not be possible to get to it in any other way. After removing the element, disassemble it using the following algorithm:

- Disconnect the connectors with the backlight power wires.

- Remove the decorative plastic cover by releasing the 4 latches. Work carefully because these clips are easy to break off, and buying a cover separately is quite a task. It is not advisable to change the entire lock because of it.

- By bending the 2 clamps holding the contact group, remove it from the ignition switch.

The plastic cover can be removed using a screwdriver

Note. You will additionally need a small flat-head screwdriver as a tool to bend the latches.

The contact group is located immediately under the cover

First of all, examine the status of the contacts. If they have darkened (oxidized), then clean the current-carrying surfaces with fine sandpaper P1000. Then put the group in place and, without installing the lock, connect it to the vehicle's on-board electrical system to check its functionality. If unsuccessful, the part must be replaced. The same will have to be done if the contacts are burnt or the group does not work without any external signs of malfunction.

The part is removed after bending two latches

Do we replace the entire lock, or just the contact group?

The issue is purely economic in nature. It is clear that replacing the complete lock will cost three times more , so before replacing the ignition switch completely, it is worth understanding the causes of the malfunction. It is possible that it will be enough to simply replace the contact group if everything is in order with the cylinder and the mechanical part of the lock.

Appearance of the contact group

A startup problem may occur when the contacts on the contact group are burnt or oxidized.

Ideally, it is better to replace oxidized, and even more so burnt, contacts, however, they can simply be cleaned with very fine sandpaper. Diagnostics of the contact group is carried out using a multimeter in ohmmeter mode . Each pair of contacts on the terminal block is checked using the probes of a multimeter - we turn the key in the ignition switch and test each pair of contacts on the terminal block for a short circuit; if the multimeter shows zero resistance, everything is in order with the contacts.

We check each pair of contacts on the terminal block

There may be problems with the mechanical part of the lock, and in this case, experts do not recommend changing the cylinder yourself - firstly, it is quite difficult to find it on sale, and secondly, replacing the cylinder may be carried out incorrectly and, as a result, the entire lock will not work incorrect. In this case, it is more rational to buy a complete lock and replace it completely. It's more reliable and safer. Good luck to everyone and good travels!

Installation of a new larva

To replace the lock core due to mechanical failure, remove it from the vehicle as described above. Then follow this algorithm:

- Insert the key into the slot and use a Phillips screwdriver to unscrew the 3 screws holding the 2 halves of the lock body together.

- Separate the housing while holding it with the key facing up. If you hold the lock in a different position during disassembly and do not insert the key, the insides will spill out and you will not understand how to put them back together. In this case, the ball with springs may get lost.

- Remove the locking mechanism, which consists of two spring-loaded parts, and pull out the spring itself.

- After removing the key, carefully remove the core so that the ball with the spring (located on the side of the cylinder) is not lost.

To disassemble the case, you need to unscrew 3 screws

Before replacing, it is necessary to remove the return spring from the old cylinder, since it is not sold complete with a new core. The spring is inside the part on the back side in a cocked state; it must be installed in the same form on the new cylinder. Also, do not forget to remove the thin spring from the hole where the ball is inserted.

The locking mechanism tongue peeks out from the bottom of the case

Important point. Remember that if you replace the core because it is broken, the new key will no longer fit the door lock. There are 2 options: use two separate keys or simultaneously change the cylinder in the door. The last method becomes the only applicable one when all the keys are lost.

The larva must be pulled out so as not to lose the details

When installing the core, you need to move the spring for the ball into the hole and insert the part into the body. Then push the larva all the way, while simultaneously inserting the ball into the socket. After that, all that remains is to assemble the locking mechanism and tighten the housing with screws. When finished, check the operation of the ignition switch by turning the key to different positions.

The ejection spring from the old core needs to be moved to the new one

How the larva changes - video

The video demonstrates how to disassemble the mechanical part of the ignition switch of a VAZ 2170 (Lada Priora), but in design it does not differ from the elements installed on VAZ 2110-2112 cars.

As a rule, there is no need to change the entire ignition switch, although car enthusiasts often resort to this option to save time. The operation will take the technician at the service station no more than 20 minutes. Replacing it yourself will require more time, but you will be able to replace only the broken part (cylinder or contact group), thereby saving personal funds.

Source

Replacing the ignition switch on a VAZ-2112

Replacing the entire assembly will take at most an hour and a half , and the price of a new ignition switch on a VAZ-2112 is within 1,000 rubles .

The ignition switch on the VAZ-2112 is a very capricious thing! We have already changed it on our editorial machine

Sometimes you can save money and change only the contact group. Then replacing it yourself and purchasing a separate contact group will cost three hundred rubles at most.

Removal

Ignition switch assembly

We can talk about the reasons for the lock breakdown and possible malfunctions for a long time, but if the task is to remove the lock, then this can be done in half an hour if you follow a fairly simple algorithm of actions, but first you should listen to simple advice :

Any work with electricity requires disconnecting the battery. The first safety rule is to remove the negative terminal from the battery or turn off the ground switch, if there is one.

Only after this can you start working. And yet, it wouldn’t hurt to organize decent lighting. Working in the area of the steering column is always associated with cramped conditions and lack of light. By spending a few minutes organizing good lighting, we will save a lot of time and nerves during work.

In addition to the standard set of keys and screwdrivers, a hammer and chisel will be useful. It’s better to find two hammers to compensate for the impact force, but for now we remove the lock in this order:

- To access the ignition switch, it will be necessary to remove the decorative plastic casing, and it is more convenient to do this with the steering column lowered all the way. The adjustment mechanism lever is located directly under the steering wheel.

- Now you can remove the casing, and for this you need a Phillips screwdriver. We unscrew all the screws and carefully remove the plastic casing.

Unscrew the screws securing the casing

Disconnect the contact block of the ignition switch contact group

These are the factory bolts

Unscrew the ignition switch bolts with a chisel

Unscrew the bolts with pliers

Installing a new ignition switch

Regardless of whether we install a new lock or a repaired old one, we will have to buy four tricky bolts with heads that break off.

Of course, you can install simple bolts, but this way we will make life much easier for the thief if he sets his sights on our car. If we install the correct disposable bolts, then it will not be possible to unscrew the lock just like that, remember how much noise we made while knocking out the bolts.

Otherwise, the process of installing a new ignition switch on VAZ cars of the tenth family is quite simple:

- We install the lock body with the contact group assembly on the steering shaft and press it with a bar. We tighten the bolts.

- Use a spanner wrench or a socket wrench to tighten the bolts until they stop.

- Before breaking off the heads, it is necessary to adjust the position of the steering wheel so that the steering shaft is fixed in the position of the key in the lock against the “I” mark. If this does not happen, the steering wheel rotates freely and the shaft is not blocked, it is necessary to set the lock so that the latch fits into the groove on the shaft.

- After final fastening to the shaft, the heads should break off. At the very least, this is what needs to be achieved from them.

Tighten the bolts until their heads come off

The ignition switch consists of two parts:

- A mechanical cylindrical lock (cylinder) consists of a cylinder with an ignition key inserted into it.

- The electrical contact assembly consists of a group of contacts that close according to a certain algorithm when the key is turned.

Typically, a cylinder lock is installed in the ignition key, which simultaneously copes with several tasks, such as turning the contact assembly and locking the steering wheel. To lock, he uses a special locking rod, which, when the key is turned, is removed from the lock body and falls into a special groove on the steering column. The ignition switch device itself has a simple design, now let's try to disassemble all its components. For clarity, let's look at how the ignition switch works:

Ignition switch parts

- a) type KZ813;

- b) type 2108-3704005-40;

- Clip.

- Housing.

- Contact part.

- Facing.

- Lock.

- Hole for locking pin.

- A locking pin is used.

The larva is connected to a wire and installed inside a wide cylindrical spring, one end is attached to the larva and the other. directly to the lock body. Using a spring, the lock can automatically return to its original position after turning on the ignition or after an unsuccessful attempt to start the power supply.

The lock driver can not only rotate the contact unit disk, but also fix the lock in the desired position. Especially for this purpose, the leash is made in the form of a wide cylinder in which a radial channel passes. There are balls on both sides of the channel; between them there is a spring, with the help of which the balls fall into the holes on the inside of the lock body, thereby ensuring their fixation.

Contact group during analysis

The contact block consists of two main parts, such as a contact disk that can be actuated, and a fixed block with visible contacts. The plates are installed on the disk itself; it is through them that current passes after turning the key in the ignition switch. Basically, the block accommodates up to 6 or more contacts, their terminals are usually located at the back. Today, modern locks use flat contacts with a single connector.

The contact group is mainly responsible for starting the starter, ignition system, instrumentation, and is located in the depths of the lock. You can check its effectiveness using a special test lamp. But first, before doing this, experts recommend checking the cables leading to the lock for damage; if any, the damage will need to be insulated with electrical tape.

Wiring diagram for the ignition switch VAZ 2109