The internal combustion engine of a modern vehicle is a rather complex device, and various malfunctions may periodically occur in its operation.

Diagnostics of a car's ignition system allows you to identify faults and determine which parts need repair, replacement or maintenance.

Main problems in the ignition system

Since the middle of the last century, the ignition system (IS) has been constantly improved, and if in the seventies of the 20th century the circuit with contact distributors was mainly widespread, then in the 80s a non-contact system with a switch was already used for better sparking on spark plugs. At the turn of the millennium, fully electronically controlled SZs began to be used, and they are still used in gasoline-powered vehicles today.

If various malfunctions occur in the ignition system, various problems arise in the engine:

- the engine starts to stall - one or more cylinders are not working;

- The internal combustion engine does not start (the spark on the spark plugs disappears);

- popping sounds appear in the intake manifold or in the muffler pipe;

- the engine begins to detonate, “piston pins knock”;

- fuel consumption increases, and black smoke comes out of the muffler pipe;

- The engine gets very hot.

The cause of the malfunction can be any parts and components of the SZ:

- spark plugs;

- ignition coil or module;

- high-voltage wires or lugs;

- breaker-distributor (in systems with distributor);

- switch (if it is installed in the system);

- egnition lock;

- wiring;

- various sensors or the control unit itself (in electronic systems).

Order of electrical connections

The most common problem for car owners is the question, what is the procedure for connecting spark plugs on a VAZ 2109? And this happens because, often removing and checking electrical wires, no one remembers the order of their connection, I admit this, So I do. sinned:

The order of the cylinders of an in-line engine in front-wheel drive VAZs is determined simply - the first is considered to be the one closest to the belt, by default. Then the timing belt, if you look at the engine from the front, then the first cylinder you will have is the one on the left. And then they all go in order - 1, 2 , 3, 4

counting to the right from the left And besides this, it is important to know the order of connections on the distributor cover and the electronic unit, about the ignition just below

Diagnostic devices

To determine a malfunction in the ignition system, various types of diagnostics are used, and you can check the serviceability of the SZ parts using various devices; you can also diagnose the engine manually, for example, using spark plugs. Computer diagnostics are used to check the functionality of electronic engine control systems (ECM) - by connecting a scanner or a computer device (laptop, desktop computer) to the diagnostic connector of the internal combustion engine, errors in sensors and fuel injectors are detected, and general parameters are checked.

Diagnostic devices also include voltmeters, ohmmeters; in some car repair shops, faults in the electrical system are determined using an oscilloscope - this device allows you to accurately determine the parameters of many elements of the electronic system.

Spark plug diagnostics

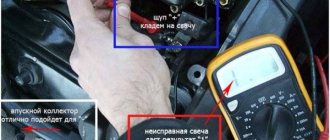

Diagnostics using spark plugs is carried out if it is necessary to find out which of the cylinders in the engine is not working. On the ECM, the shutdown is performed using a diagnostic tool, for example, on a scanner - the diagnostic stand turns off the power supply to the cylinder. With a working spark plug, the nature of the engine’s operation changes - it slows down and begins to operate even more unstable.

On a simple carburetor engine, the serviceability of the spark plugs is checked by pulling out the spark plug tips, and here the principle of determining the performance of the cylinder is the same as in computer diagnostics - if the nature of the engine operation does not change, you should look for the fault in this cylinder.

There can be many reasons for the unstable operation of an internal combustion engine, and spark plugs may not always be to blame for engine misalignment. To check the spark plugs, they are unscrewed from the cylinder head and first inspected. On a working spark plug:

- the gap between the electrodes is 0.7-1.0 mm, the electrodes themselves are not burnt, they are of sufficient thickness;

- there is no black carbon deposits or chips of the insulator around the central electrode;

- There are no cracks or burn marks on the outer insulator.

The performance of the spark plug is checked on a special stand under pressure - they wrap it in a chamber, create a working pressure (9-12 atmospheres) and apply high voltage - if a good working spark slips between the electrodes, then the spark plug is in order.

What should be the gap

Drawing diagram of gap measurement

Since the Samara-2 engine is an injection engine, we will talk about the gap and settings specifically for the electronic fuel injection system.

Spark plug gap standards for VAZ-2114 (8 valves)

We set the gap between the electrodes of the spark plug, the tap is 1 mm, everything is according to Feng Shui!

The normal indicator of the spark plug gap for an engine installed on a VAZ-2114 is the distance between the electrodes in the aisles - 1.0-1.13 mm.

Consequences of an incorrect value

Therefore, if the spark plug exceeds these parameters, this can cause problems in the operation of the engine, namely:

- Fuel consumption will change upward.

- The car will start to stall and stall.

- The revolutions may fluctuate.

- An oil trace will appear in the spark plug well.

- And others.

Ignition coil diagnostics

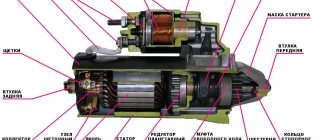

Ignition coils (IC) on cars fail quite often; due to the malfunction of these parts, the engine may not start at all or may stall and not gain speed. It should be immediately noted that short circuits can be different in design - on older models there was one round cylindrical coil, on modern internal combustion engines the following are installed:

- double (two short circuits each) or monolithic modules with high-voltage wires and lugs;

- coils for each cylinder - such ignition modules are installed directly on the spark plugs, and they do not have I/O wires or tips.

Short circuits are checked in various ways:

- external inspection;

- ohmmeter;

- oscilloscope.

Often the coils fail due to overheating, and on older engines (for example, VAZ “Classic”), as a result of a break or short circuit of the winding turns, the engine stops starting, since the short circuit is installed on these engines alone. On newer cars, if the winding is faulty, only one or two cylinders stop working, and the engine starts to misfire.

The coil should be inspected very carefully - there should be no burn marks on its current-insulating parts, and there should also be no cracks. If external defects are detected, the part must be replaced - in any case, it will not last long.

You can check the integrity of the short-circuit windings using an ohmmeter:

- on the primary winding the device should show within one Ohm;

- on the secondary winding the resistance ranges from 5 to 20 KiloOhms.

Indicators for different KZ models may differ; each brand has its own parameters. But it is not always possible to determine the serviceability of a part by its resistance; this can be more accurately determined using an oscilloscope or by replacing it with a known-good spare part.

Setting up a VAZ-2109 with a carburetor engine

First, prepare the car for this work:

- Start the engine, warm it up to 90 degrees and, under the control of the tachometer, bring the number of revolutions of the power plant to 800.

- Remove the tube through which the vacuum occurs from the fitting. Pinch the end of this tube with your finger and raise the speed until the vacuum disappears.

- At this point, turn off the motor and bend the tube so that there is no gap. Loosen the distributor cap. Remove the plug and clean the inspection hatch with the scale located on the gearbox housing.

Next you will need to set the ignition angle. This work is done according to the instructions:

- using a screwdriver, turn the flywheel so that a long division appears in the window (cylinders 1 and 4 will be in the TDC position at this time);

- check how correctly the flywheel is aligned with the timing gear - to do this, remove the casing from the mechanism;

- if everything is done correctly, the mark on the gear will coincide with the one on the belt.

Confirm the adjustment result using a strobe light. For this:

- the ignition coil is connected to the red strobe probe;

- a black probe is installed on the body;

- The fastening wire is fixed to the 4th cylinder.

Distributor diagnostics

Many older vehicle ignition systems had a distributor installed, and it was often the cause of engine malfunctions. In contact breakers-distributors, the elements of the contact group often burn out, and for this reason the motor may be difficult to start or may not start at all. In non-contact distributors, the Hall sensor may fail, but this is not a typical “disease” of distributors - sensors do not break so often.

The most common distributor malfunctions:

- burnout of the resistor on the slider;

- the appearance of cracks and burnout in the distributor cover;

- breakage of the Hall sensor wiring (this is often noted in VAZ 2108-09, GAZ 31029-3110 distributors with a ZMZ 402 engine);

- wear of the shaft bearings.

The distributor cap on Russian cars is very inexpensive, can be changed within a few minutes, and therefore it is better to always have such a part in stock. The easiest way to check the cover is to replace it - if the motor starts working properly, it’s all about it.

Other breakdowns and their elimination

If the engine does not start when the ignition is turned on, then, first of all, you need to turn off the ignition system and try to start the engine again after a few seconds. If all this does not give any results, perhaps it makes sense to check the correct installation of the spark plugs - it could very well turn out to be incorrect. If all these actions do not produce any results, then the entire system will have to be thoroughly checked. It may also turn out that the cause of the malfunction is in the distributor cap.

It must be carefully dismantled and both sides thoroughly checked.

In addition, it is necessary to examine the graphite coal - it could well have been worn off. If the cover is worn out, when its surface is cracked or covered with soot, it is better to replace the cover; it cannot be repaired. The same should be done with graphite coal. Attention! All wiring must be well fixed, because if it comes into contact with other components, its insulation will wear out very quickly. A short circuit can occur due to working fluids getting into the wiring. Therefore, when diagnosing the condition of the ignition system, you should pay special attention to the condition of the wiring. If you find moisture on them, you should definitely wipe it off, because this may well be the reason for poor engine starting. If scratches or other mechanical damage are found on the wiring, it must be replaced. If this is not possible yet, you should wrap problem areas with electrical tape. The ignition coil is checked with an ohmmeter. The resistance must be within the specified range, otherwise the coil will have to be replaced. It is highly not recommended to repair the ignition switch on your own. You can only check the contacts and clean them if oxidation is detected. It is worth thinking about the switch

, because breakdowns in this unit quite often cause incorrect operation of the ignition coils.

The switch is checked with a portable lamp. This is done as follows: the wire that comes from the switch terminal is disconnected from the coil, and then its end is connected to the carrier. The other carrying wire is connected to the coil terminal. Then the ignition is turned on and the car starts using the starter. To do this, the crankshaft will have to be rotated a couple of times. If the light in the carrier lights up continuously, it means that the switch is indeed faulty. Then the problem can only be solved by replacing it. It may also happen that all the wiring is working properly, but the pulses still do not arrive at the switch. Most likely, the contactless sensor is faulty

.

It is checked with a voltmeter. This is done as follows: with the ignition off, they begin to carefully turn the crankshaft. In this case, you need to monitor the devices. If the sensor is working properly, then their readings will change sharply. If this does not happen, it can be stated that the sensor is faulty, then it must be replaced. Spark plugs are checked with a “spark”. To do this, you need to remove the wire from the spark plug and bring its end to the ground at a distance of 5-6 mm. After this, you should rotate the crankshaft and look at the gap. If a spark is visible, it means that the system itself is working, and all that remains is to change or clean the spark plugs. During this procedure, it will not be possible to do without an assistant who will have to turn the crankshaft. In this way, the distribution system covers can also be checked. The central wire is disconnected from it, and its end is brought to ground, leaving a gap of 5-6 mm. In this case, you also need to rotate the crankshaft. When a strong spark appears, it can be stated that the circuit is operating normally, and the problem may be in the cover or rotor. It is no longer possible to repair the rotor; it can only be replaced.

But if the resistor burns out, the problem can be completely solved with a piece of wire.

You can use aluminum and copper wire. A jumper is made from it, which is inserted between the contacts of the router. Of course, this measure is temporary, and you should resort to it only when it is not possible to resolve the issue by installing a full-fledged resistor. For example, this can happen while driving. Do not forget also that a piece of inserted wire causes radio interference, which can spread not only in the cabin, but also near it. The reason for the lack of a spark may also be poor contact of the breaker. Poor contact is quite often the cause of cylinder failure. When checking the contacts, you need to ensure that they are in close contact with each other. Any contamination of the contacts with rust or carbon deposits will certainly reduce the tangent area, and this will certainly cause a complete loss of contact. Sometimes the contacts need to be cleaned non-aggressively. A needle file is used for this. You can clean the contacts with a rag. After cleaning the contacts, rotate the crankshaft until they are completely closed. If any contact does not fit tightly, you need to bend its stand. As you can see, a variety of breakdowns in the ignition system can be eliminated on your own. But if you do not feel completely confident in yourself, then it is better to seek help from specialists who will do everything professionally. Video about checking the ignition system:

Sources

- https://topmekhanik.ru/printsip-raboty-sistemy-zazhiganiya/

- https://opuske.ru/zazhiganie/diagnostika-osnovnyx-elementov-sistemy-zazhiganiya-avtomobilya.html

- https://diagnozbibike.ru/avtomobilnyj-osczillograf/

- https://autostuk.ru/diagnostiruem-sistemu-zazhiganiya-ne-dozhidayas-polomki-avtomobilya.html

- https://avtobrands.ru/diagnostika-neispravnostej-voznikayushhih-v-sisteme-zazhiganiya-dvigatelya/

- https://VipWash.ru/toplivnaya-sistema/diagnostika-inzhektora

- https://fastmb.ru/autoremont/2451-kak-nayti-i-ustranit-neispravnosti-v-sisteme-zazhiganiya.html

[collapse]

ECM diagnostics

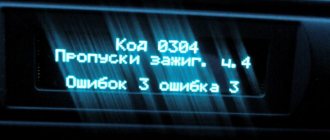

The serviceability of the electronic engine control system is checked using a special scanner or computer; programs are installed in ignition diagnostic devices, and each engine model uses its own software.

There are various sensors in the electronic system, and they can fail. If malfunctions appear in the ECM, they are recorded electronically, and the presence of an error is indicated by the Check Engine diagnostic lamp on the instrument panel in the car interior. Each error is assigned its own code, for example, for VAZ cars, misfire of the fourth cylinder is indicated by code P0304. Any of the sensors in the system may be faulty:

- throttle position (TPP);

- detonation (DD);

- camshaft position (CPRV);

- crankshaft position (CPCV);

- air flow rate (MAF) or absolute pressure (DBP), different sensors are installed depending on the type of ECM;

- temperature (DTOZH);

- ambient air (DTOV).

In all electronic systems, an idle speed regulator and the control unit itself are installed. Often the cause of ignition failures is electrical wiring, for example, power is not supplied to one of the coils. If the ECU refuses to work, the engine may not start, in which case the unit must be repaired or replaced.

Ignition switch malfunctions

In non-contact ignition systems with a distributor, a switch is installed; it is designed to ensure uninterrupted sparking at the spark plugs, and also serves to form a stable spark at all engine speeds, including idle. If the switched device fails, the engine begins to start poorly, and in many cases does not start at all.

The main sign of a faulty switch is that it is very hot; overheating can be determined by touching the body of the device with your hand. As a rule, along with the commutator, the coil also gets very hot. Often these parts heat up and fail on old Gazelle and Volga GAZ 31029-3110 cars with a ZMZ 402 engine. The reason for such frequent breakdowns is the low quality of spare parts supplied by various manufacturers.

Related articles:

- Repairing internal combustion engines (ICE) with your own hands Most often, major repairs of internal combustion engines are carried out in specialized car services, but it is not so rare that car owners repair engines with their own hands - much depends on the complexity of the power […]

- The benefits and harms of chip tuning The main task of tuning a car engine is to improve its technical characteristics: increasing power, increasing torque, improving dynamic and […]

- What are the most reliable engines in the world? This article will consider both the most reliable engines in the world, which do not break down for a long time, have a very good service life in terms of mileage and hours worked, and not the best power […]