Last week I drove the car on business and didn’t like the fact that the idle was floating - it either dropped to 500, then jumped to 1500, the engine shook at idle. But at the same time it drags normally, without failures. Checking the ignition by ear” using the well-known method - giving full throttle in 4th gear at a speed of 60 showed that the ignition is set correctly. So you need to look at the carburetor. And today, Sunday morning, the weather turned out to be good, sunny, I decided to see what was wrong with him. (By the way, it’s snowing outside now!).

To begin with, I studied on the Internet the description of the carburetor, its design, what is connected where. In principle, the K-151 is very similar to the Zhiguli “ozone”, it also has an autonomous idle system, an EPHH economizer controlled by almost the same control unit (externally the same) and the same solenoid valve. In general, I figured it out, nothing too complicated.

So I remove the “pan” and see... well, to put it mildly, the carburetor needs to be removed and cleaned - it’s overgrown with carbon deposits and dirt, but that’s for later. And now, for preventive purposes, we need to replace the fuel hoses, which are all cracked from old age, and we’ll try to adjust them.

The first thing that surprised me was that there is no vacuum tube on the economizer. It’s strange, because then there shouldn’t be any idling at all. Or rather, it is there, dangling nearby and plugged with a screw inserted into the tube. Oh, here it is - the former owner decided to simplify the system - instead of the throttle stop plug, he inserted a long pin, screwed two nuts onto it and made an idle speed regulator screw out of it, regulating the degree of opening of the throttle valve. Here I am just twisting it with my hand.

In fact, the idle system did not work at all, and the engine idled because the throttle valve did not close completely. The previous owner was probably a Solex fan, but the transition system of this carburetor is not designed to maintain even and stable speeds, so the speeds float. And the motor was shaking because the quality screw was screwed in all the way, but there was no o-ring on it, so the motor responded poorly to attempts to adjust due to the lack of a rubber ring on the quantity needle. There was an EPH system here, but it was eliminated - there is an electronic valve, but there is no microswitch on the carburetor. If desired, the system can be restored, but for now we will assemble and adjust as necessary at least what we have. To begin with, I put a vacuum tube on the economizer (in the photo it is already put on, but not the one in the foreground, but below, take a closer look. The one in the foreground is part of the USR system, and then...

I went to my nearest parts store. Yes, among the spare parts for the Volga there is only an air filter, but the fuel hoses and the rubber ring of the propeller are quality ones that can be supplied from a Lada, and the clamps are a universal thing. I bought 2 quality sealing rings for the needle (one in reserve just in case), a long fuel hose, the “return” hose from 2108 was perfect for the “return” and on the Volga, and clamps for them.

First, I removed all the old fuel hoses and pulled out the fittings. This is how tired they are:

On the Volga, the fuel supply hose is very serious, not just on clamps, but also on metal fittings, tightened with a wrench “14” (hello Volga, in Lada cars everything was mostly “13”, I read somewhere that the fasteners “13” actually came to the USSR with Zhiguli cars, before that there were no such sizes, they somehow managed with “12” and “14” sizes). I tried on the long fuel hose in place and cut it into two parts, put it on the fittings, tightened the clamps and installed it.

For a long time I thought about leaving this authentic “glass” - a fine filter or installing a regular plastic filter. Then I decided not to violate the authenticity - let it be, then I’ll replace the actual filter element in it and okay. Next I set the return line. A good system, the fuel pump does not pump “against the wall”, but works constantly, dumping excess fuel back into the tank. This eliminates the possibility of the fuel pump overheating and failure due to a vapor lock, which often happened on Zhiguli cars.

Now we remove this collective farm with the idle regulator using the throttle stop. Instead of this stud I put a screw with a lock nut. I tighten the screw so that the throttle valve stop is only slightly supported, so that the valve closes completely against this screw, and in this state I fix it with a lock nut.

And now the engine is already purring at idle, steam and water are coming out of the pipe. In general, anyone who has ever seen “live” how a normally adjusted 402 engine works at idle will understand what kind of song this is. The impression is that the revolutions are generally low, the crankshaft seems to barely rotate, but according to the instrument everything is correct - 700 revolutions (approximately). That is, the tachometer needle is slightly below 1000.

Now we turn on the headlights, the heater fan to full and the heated rear window and see how the engine will work under the load of the generator and how much the speed will drop. If they sag a lot, then add the quantity with a screw; if the engine also shakes, there are interruptions, then you can add not by quantity, but by quality. That's basically all science is.

Despite the apparently terrible condition of the carburetor, it was adjusted normally. The engine “whispers” at idle and picks up speed without any dips. In general, it’ll do, I’ll put the “saucepan” in place.

Another thing that was noted along the way is that there is a new pump on the engine; it stands out sharply due to its novelty against the background of other parts. It looks like the previous owner forked out money for it to get from the Lipetsk region to Moscow without problems. The old one seemed to pump very poorly, so there is an additional pump in front of the stove faucet, the same one I once installed on the Omega when I froze in it in the winter. True, I couldn’t find where it turns on, but the stove heats normally even with it not working. Moreover, there is also a faucet to expel air pockets (part of this can be seen in the photo where I unscrew the throttle stop). Most likely, then I’ll remove this whole collective farm, replace the standard Zhiguli faucet with a ceramic one, which I liked on the Zhiguli, and the air temperature in the car can be adjusted using the regulator handle, and not just by lowering the window.

This is interesting: Video of repairing a trimmer carburetor with your own hands

The radiator commands respect with its appearance. When making repairs under the hood, it is convenient to place screwdrivers on it; there are various fasteners - it will not fall anywhere, just like the shelf is wide and has sides. The upper fitting seems to be soldered, but with the cooling hoses there is generally some kind of collective farm - tubes, adapters, clamps, the hoses themselves are already made of oak, they are all cracked, one hose is pinched too much at a bend. In general, I will order new hoses and then replace them along with the antifreeze. The fact that the former owner only changed the pump and screwed such terrible old hoses onto it also indicates that he was already taking the car for sale.

Design and principle of operation, diagram

The carburetor is designed for high-precision dosing of the air-fuel mixture and its subsequent delivery to the engine cylinders.

The K-151 carburetor has 2 parallel channels through which purified air from the filter passes. Each of them has a rotary throttle (damper). Due to this design, the carburetor is called a two-chamber carburetor. And the throttle drive is designed in such a way that, depending on the force of pressing the gas pedal (i.e. changing the operating modes of the internal combustion engine), the first damper is opened alternately, and then the second.

In the middle of each air channel there are cone-shaped constrictions (diffusers). Air flows pass through them, due to which fuel is sucked through jets from the float chamber.

In addition, the carburetor contains the following components:

Below is a detailed diagram of the K-151 carburetor with symbols:

Device design

To ensure that the engine can operate at any speed, the carburetor prepares the fuel-air mixture. Despite the fact that the individual systems of the K-151 carburetor are made according to standard designs, all three modifications differ from other devices in their layout. The advantage of the K-151 is the shut-off needle located in the body, which greatly simplifies the adjustment of the gasoline level. In general, the entire assembly can be divided into three parts with a base in the form of a float chamber.

Other important design elements are:

- Locking mechanism located in the top cover of the float chamber;

- Dosing system consisting of air and fuel jets;

- Adjusting screws and economizer valve of the XX system;

- Eliminates dips during vehicle acceleration using a special accelerator pump with a fuel sprayer;

- At high speeds, the fuel assembly enriches the econostat;

- A transition system is necessary to gradually increase the number of revolutions at the moment the secondary chamber opens.

The K-151 received two chambers, which guarantees continuous movement of fuel in the event of any breakdown. The fuel level is adjusted automatically due to the ability to close the valve opening with a shut-off needle. The operating principle is as follows: if there is not enough gasoline in the chamber, the float lowers and releases the needle. As the chamber fills, the float rises, followed by the needle closing the valve cross-section. The lower compartment houses the primary and secondary throttle valves with control actuators. During operation, they open alternately, fuel passes through a mesh filter mounted in the fitting, due to which gasoline enters the system without impurities and inclusions.

How to set it up yourself?

To adjust the K-151 carburetor you will need the following minimum set of tools:

To dismantle the carburetor you will need open-end or ring wrenches for 7,8,10 and 13.

Before tuning, remove the top part of the carburetor and clean it of dirt and carbon deposits. At this stage, you can check the fuel level in the float chamber. This will be discussed in detail below.

The carburetor should only be removed if absolutely necessary! When blowing with compressed air and washing do not eliminate the consequences of jamming of dampers and contamination of jets (channels).

It is important to understand that a carburetor that is not too dirty works the same as a perfectly clean one. The moving parts in it clean themselves, and it is not easy for dirt to get inside. Therefore, it is often necessary to clean the carburetor from the outside, in places where large pieces of dirt stick to mutually moving parts (on the lever mechanism and in the starting system).

We will consider partial disassembly of the device with all adjustments and subsequent assembly.

Removal and disassembly algorithm

Step-by-step algorithm for removing and disassembling the K-151 carburetor:

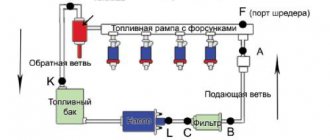

If you suddenly forget which hose to plug into where, we suggest using the following diagram (for the ZMZ-402 engine):

Connection diagram for carburetor hoses for ZMZ 402 engine

4- fitting for vacuum selection into the vacuum ignition timing regulator (VROZ); 5-vacuum sampling fitting to the EPHH valve; 6 – crankcase gas intake fitting; 9-vacuum sampling fitting to the exhaust gas recirculation valve; 13- fitting for supplying vacuum to the EPH system; 30- channel for fuel removal; 32 - fuel supply channel.

For the ZMZ 406 engine, a special K-151D carburetor is provided, in which there is no fitting number 4. The distributor function in it is performed by an electronic automatic pressure sensor (APS), which is connected by a hose to the intake manifold pipe, where it reads the vacuum parameters coming from the carburetor. Otherwise, connecting the hoses on the 406 engine is no different from the diagram presented above.

How to adjust the fuel level of the float chamber?

The normal fuel level for K-151 carburetors should be 215 mm. Before measuring, pump the required amount of gasoline into the chamber using the hand pump lever.

Fuel level control using the communicating vessel method

The level can be checked without disassembling the top of the carburetor (see figure above). A fitting with an M10×1 thread is screwed into place in place of the drain plug of the float chamber. A transparent hose with a diameter of at least 9 mm is put on it.

If the level is not correct, then unscrew the carburetor cap to access the float chamber. As soon as you remove the top, immediately measure the level using a caliper depth gauge (from the top of the carburetor to the fuel line). The fact is that gasoline quickly evaporates when exposed to the atmosphere, especially in hot weather.

An alternative option for level control is to measure the distance from the top plane of the chamber connector to the float itself. It should be within 10.75-11.25 mm. In cases where this parameter deviates, you need to carefully bend the tongue (4) in one direction or another. After each bending of the tongue, gasoline should be drained from the chamber and then refilled. In this way, fuel level measurements will be the most accurate.

Functions and design of the carburetor

Design and adjustment of the OZONE VAZ 2107 carburetor

In modern engines, an electronic system working in tandem with an injector is responsible for the preparation of fuel assemblies. The predecessor of this circuit is a carburetor, which is able to prepare a high-quality combustible mixture without any participation of electronic brains. And since the proportions of the mixture change depending on the operating mode of the engine, the carburetor must be able to prepare the optimal composition under any load, from idle to maximum crankshaft speed. And, I must say, he copes with this task well. Even today, K-151 can be found on such domestic cars as the Gazelle with all its modifications, IZH, Volga, and, of course, UAZ.

Although there are many models in the assortment of the Pekar brand, the “one hundred and fifty-first” is given pride of place, and there are many modifications of this carburetor, differing in the name by the letter after the numerical designation of the model. In particular, GAZ-3302 (or simply “Gazelle”), as well as GAZ-3102 (“Volga”) cars are equipped with a K-151S modification carburetor. The differences between the modifications consist of jets of different diameters, designed to prepare fuel assemblies for specific power units.

Composition of the Pekar-151 carburetor:

- body with a float chamber;

- a secondary upper housing in which throttle valves are installed, controlled by a drive cable connected to the accelerator pedal;

- PC cover, which serves as a platform for installing a locking mechanism that prevents the chamber from overflowing with fuel. An air damper is also located here, used when starting and warming up a cold engine;

- a dosing system, which is responsible for the formation of the air-fuel mixture and includes channels of a certain diameter, two air and the same number of fuel nozzles;

- idle subsystem used when the power unit operates in idle speed mode. Includes a bypass channel, one fuel and air nozzle each, screws for adjusting the quantity/quality of the combustible mixture, a membrane-type economizer valve;

- accelerator pump, responsible for uniform engine dynamics, without failures with a sharp increase in speed. Includes additional channels passing through the housing with a float chamber, a membrane device, a ball valve and a gasoline sprayer;

- econostat is a part that enriches the mixture when the engine operates at high speeds. Includes a system of additional channels designed to supply an unscheduled portion of fuel to the intake manifold with the throttle valves fully open;

- a transition system, which is activated at the initial stage of opening the remote control, located in the secondary chamber and serves for a smooth increase in speed. Includes a pair of jets of both types.

Thus, the K-151 belongs to the category of two-chamber carburetors, in which the throttle body opens sequentially. A strainer is integrated into the inlet fitting. It also has a fuel line designed to drain excess gasoline back into the tank and to protect against excess pressure in the chamber. As you can see, this device cannot be called simple, so setting it up requires considerable experience.

Malfunctions and their elimination

Freezing of the economizer housing

The K-151 carburetor on some engines has one unpleasant feature. In humid subzero weather, the fuel mixture in the carburetor actively condenses on its walls. This occurs due to the high vacuum in the channels at idle (the mixture moves very quickly, which leads to a decrease in temperature and the formation of ice). The economizer body freezes first, since air enters the carburetor from here, and the flow cross-section of the channels here is the narrowest.

In this case, only drawing warm air into the air filter can help.

The trunk of the air intake hose can be thrown directly to the manifold. Or make a so-called “brazier” - a heat shield made of a metal plate, which rests on the exhaust pipes and to which the air vent hose is connected (see figure).

"Brazier"

Also, in order to reduce the risk of the economizer freezing problem, before the trip we warm up the engine to an operating temperature of 60 degrees . Despite the thermal insulation gasket from the engine, the carburetor still receives some heat.

Flange straightening

With frequent disassembly and removal of the carburetor, as well as with excessive force when tightening the flange to the engine, its plane may be deformed.

Working with a damaged flange leads to air leaks, fuel leakage and other serious consequences.

There are many ways to solve this problem. But the simplest and most accessible method is the following:

Useful video

For more information about the method of straightening a flange, we recommend watching this interesting video:

To prevent further bending of the flange, simply tighten it evenly once to the engine and do not remove it again. As we saw above, the carburetor can be cleaned and adjusted without removing it from the engine.

GAZ Gazelle ZMZ Stroitel › Logbook › Installing spare parts, adjusting the K-151D carburetor

The morning greeted us with an oak, fortunately nothing fell from the sky. I took my friend Mikhanik and headed to the garage. in order to redeem everything purchased. We started by warming up the car and also simultaneously pouring all parts with liquid moth liquid, but it’s better to do such things in advance. Carburetor - After warming up the engine, I decided to rebuild the carburetor since the last trip of 200 km showed some unstable conditions. after which I finally dug up instructions for setting up a carburetor, and decided to try it in action (if necessary, I can send you the file to someone). After half an hour of dancing with a tambourine, it was still possible; when I pressed the pedal sharply, there was no failure. Then they went to change the muffler and at the same time I inspected the pants for integrity while the car was rattling, the clamp on the muffler of course tore when unscrewing it, and so did the clamp on the leaky muffler, so after running around a bit and tapping the place of fastening with a hammer, I managed to remove the muffler by loosening it thoroughly with my hands, then We tried on the new fasteners, it was immediately decided to modernize them, we welded long 13mm bolts to both upper parts of the muffler clamps so that they did not need to be held with a wrench, then we hung the muffler, leveled it, and hammered it into the old place using a boss and a hammer. and I found a branch from an old water pipe, such a one will burn out for a long time. ))) I think that the muffler-resonator should be in good condition because it affects traction. I remember at 99 my muffler fell off right after the manifold, there was no traction at all, you farted alone.

Adjusting and tuning the K 151 carburetor on a UAZ

UAZ is a legendary car that has become famous not only among the military, but also among the civilian population. The plant really spared no effort and time on it. It is reliable, easy to maintain and repair, but requires constant attention, as it is a breeding ground for problems. One of the sore spots is the food system. Adjusting such a complex unit as the K151 carburetor on the UAZ Bukhanka is not a complicated procedure. However, it requires the correct technique. Today you will learn how to clean and tune, as well as adjust the carburetor to 151 on the UAZ.

Carburetor design K 151

The K 151 Pekar carburetor works according to the same scheme as similar carburetors. The task of preparing the air-fuel mixture and then feeding it into the engine cylinders always remains unchanged.

Structurally, the carburetor consists of the following elements:

In the event of a malfunction, the carburetor begins to work incorrectly. This means that the UAZ in our case “Bukhanka” begins to consume too much fuel or does not develop full power. There are times when the engine may not start at all. To fix this problem, the carburetor must be removed, inspected and adjusted.

Carburetor diagram K 151

Connecting hoses to the carburetor

Several hoses of two diameters are connected to the K-151 carburetor - if they are mixed up, the engine will not work properly. We connect the hoses in the following order:

- the main fuel pipe - to the fitting, which is located under the float chamber closer to the engine (in the picture it is held in the hand);

- “return” - to the lower outlet (it is directed on the opposite side of the engine, and is located below the main fitting);

- two thin hoses go from the solenoid valve, one of them goes to the XX economizer valve;

- the second - to the lower fitting on the other side of the throttle body (below in the picture, number 2)

- output number 3 – with the vacuum ignition advance hose on the distributor;

- fitting on the carburetor number 5 (picture below) - with a forced crankcase ventilation hose, which on many engines is located on the top of the valve cover;

- outlet 1 (figure below) - to a thermal vacuum switch, which is not installed on engines without an exhaust gas recirculation system. In the absence of a sensor, pin No. 1 is often plugged, but this is not at all necessary - no air leaks through the fitting;

How to remove the K 151 Pekar carburetor on an UAZ?

To do this, you need to go into the car's interior in the driver's or passenger's seat in the front and open the engine compartment hatch. The next step is to remove the air filter. To do this, first unscrew the upper fastening nuts, after which the filter element itself is removed. Be careful not to drop the nuts into the diffuser!

Now unscrew the nuts securing the filter housing. Lift it up, disconnect the thin hose and set the housing aside. Now disconnect all the linkages associated with the throttle valve. To avoid breaking the plastic elements, it is recommended to use a flat-head screwdriver.

Cleaning the UAZ carburetor

Before setting up, the unit must be cleaned. To do this, completely disassemble the carburetor: remove the top cover and separate the throttle part from the diffuser.

Cleaning is carried out using special means for cleaning throttle valves or any other liquid intended for these purposes. You can also use gasoline or kerosene.

Cleaning is 100% necessary. This will save you from the problems associated with contamination and remove the need to do it in the near future. Therefore, it is necessary to perform it in order to prevent malfunctions.

How to adjust the fuel level in the float chamber

After assembling the carburetor, you need to adjust the level in the float chamber. This is the very place on which the fuel consumption of the UAZ Bukhanka vehicle depends. You can adjust it yourself in the garage. To do this, the carburetor is installed in its regular place, tightened with nuts, and the top cover is unscrewed and simply pressed by hand. Insert the fuel hose and pump up gasoline using the manual fuel pump.

Fuel level in the float chamber

Now you need to lift the lid and put it aside, and use a ruler to measure the level in the chamber. It should be 21 millimeters. If the parameter differs from the nominal value, then you need to set the float position at which the level will always be maintained at the specified level and the needle valve will be in the closed position.

To do this, you need:

The cycle is performed until the level in the float chamber is normal. By the way, you can see in detail how to do this in the video. After the level becomes nominal, you need to reassemble the carburetor. All attachments are installed on it, except for the air filter and its housing. It will interfere with adjusting the air damper drive. Installation is carried out in reverse order.

Carburetor adjustment process

If you troubleshoot problems with your own hands, it will be very difficult for a motorist to do this. It will be much easier to understand the principle of work in setting up and carry out everything according to the existing manual.

Types of adjustments and settings:

- Idle/running mode;

- setting up an air valve;

- adjusting the fuel value in the float chamber;

- adjusting the location of the throttle valve.

Changing the fuel level in the float chamber is best left to specialists with extensive experience. But every car owner will be able to normalize idle speed with his own hands.

Detailed instructions:

- It is advisable to warm up the engine well;

- the engine must be in operating mode at idle speed, at which time the air valve must be open;

- the bolts with the spring are turned out, the engine needs to reach the maximum number of revolutions;

- 2 screws are gradually tightened until the internal combustion engine begins to operate intermittently.

You need to increase the speed with the screw, and while making adjustments, feel the smooth operation of the motor. Considering that the correct position of the screw has a bearing on fuel consumption. And only because of this it is necessary to wrap it as tightly as possible.

By tightening the screw you need to achieve the engine running at 700-800 rpm without interruption. If the screw is tightened much more, failures may occur when pressing the accelerator pedal with your foot. It is worth remembering that the regular operation of an internal combustion engine largely depends on the appropriate adjustment of the ignition system.

Increased engine speed can be lowered using a bolt; it adjusts the position of the throttle valves. Sometimes it gets seriously stuck, so much so that there is no way to unscrew it. One cunning and effective method can help in this matter, which will help you unscrew the stuck element.

What is needed for this:

You need to take a screwdriver made of good hard metal, first insert it into the slot and carefully hit it with a hammer 2-3 times. At the same time, carefully calculating your strength, if you strike too hard, you can end up breaking part of the carburetor. After such actions, the screw should begin to be unscrewed. But if it doesn’t work out the first time, you need to repeat the procedure.

Repair:

During operation of the machine, various problems may occur in the carburetor system.

This is interesting: Repair and replacement of common rail diesel injectors

How to adjust the air damper of a K-151 carburetor?

To start the UAZ in cold weather, you need to use a starting device, which is a manual air damper drive. The bottom line is that during a cold start, you need to pull the handle towards you, thereby closing the damper, and start the engine. As the handle warms up, it should be gradually returned to its original position.

Now you need to adjust the position of the cable so that the damper opens completely and closes without jamming. To do this, completely pull out the handle on the carburetor car and close the choke manually. Fix the position of the cable as in the video and tighten the nut. Try opening and closing the damper. The system must operate accurately without jamming. After this, you can begin adjusting the idle speed.