03.07.2019

| (Votes: 5, Rating: 4.2) |

Issues discussed in the material:

- What is an engine mount or mount?

- For what reason can an engine mount break?

- How to understand that the engine mount has become unusable

- How to change an engine mount

An engine mount is a support structure that maximally softens vibrations of the engine in the engine compartment of the car. An ideally functioning cushion should completely dampen any engine vibrations, preventing vibration from spreading throughout the body.

What are engine mounts

A car engine weighs quite a lot, and due to the vibrations it creates during operation, the engine must be securely fastened. When rigidly attached to load-bearing body elements, the fasteners will be subject to significant variable loads while driving over uneven surfaces. In this case, they will fail very quickly.

The vibration will also be transmitted to the entire body. On the one hand, this will create discomfort for the driver and passengers, on the other hand, it will negatively affect the durability of all components of the car.

Special supports called pillows are designed to cope with this problem. They dampen the vibrations created by the engine and at the same time reliably fix it from displacement.

The motor can rest on 3-5 supports, depending on the specific car model. Mounts located front and rear control idle vibration when the engine reaches peak loads.

On Soviet cars, these cushions were ordinary rubber inserts of sufficient strength with fastening points. Modern products can have different appearances. Among them, rubber-metal and hydraulic supports stand out. On front-wheel drive cars, engines and gearboxes rest on 4-5 supports, two of which are located under the gearbox.

The rubber-metal product, in turn, can also be made in different ways. Often this is a steel or aluminum cylinder with a rubber silent block inside. Sometimes cars are equipped with a “lamp” made of aluminum alloys with a rubber insert.

As standard, the supports are arranged as follows:

- The right airbag is located on top and attached to the body side member.

- The front support is usually located on the engine beam and is visible from below.

- The rear support is fixed to the underbody or front body subframe. Some engine modifications do not have this support.

- Under the gearbox, closer to the rear of the engine, there is a common cushion.

The modern design of an electrical hydraulic cushion looks like this:

Pillows of this type are able to adapt to any engine operating mode, maximally damping the resulting vibrations and making driving the car more comfortable.

The greatest loads on the supports occur at the moments of starting, moving and stopping the vehicle. A malfunction of the support leads to an increase in the load on the motor and transmission units and, as a result, to an increased risk of their breakdown.

We recommend

“Parking brake malfunction: causes and solutions” Read more

How to change it yourself?

To do this, you will need a set of tools (sockets and open-end wrenches), a jack and repair stands (since the engine will be suspended). So, jack up the car on the right side. We hang the motor on a chain. We unscrew the bolts (there are 3 in total) that secure the support to the engine and body. Next, remove the brackets and take the element out. We install the new part in place.

To replace the rear support, jack up the body on the left side. However, unlike the previous case, we will also have to suspend the gearbox. We use a wooden backing to avoid damaging the pallet. We unscrew the bolts securing the pillow and take it out. We install a new one in place of the old one and perform the assembly in the reverse order.

Motorists recommend replacing the support in warm weather. In winter, the pillow becomes very dull, and can only be removed after preheating (using a hairdryer or blowtorch). If the support does not come out, it is recommended to use VD-40 type lubricant or its equivalent from. Regular lubricant will not work for this.

Often dust and moisture enter the cavity of the old cushion, resulting in corrosion processes occurring on the cylinder. It is not possible to remove the pillow. If you are replacing the rear support, pay attention to the direction indicated by the arrow on the part. It must be installed in the direction of travel of the vehicle. Otherwise, there is a risk that the element will not withstand the load and will break.

Causes of engine mount malfunction

The failure of airbags is not caused by any specific reasons. And yet, experts pay attention to certain indirect factors that ultimately lead to the malfunction of these elements.

- Insufficient suspension performance

To improve handling and improve the appearance of their foreign cars, owners often install low-profile wheels and high-stiffness shock absorbers. Indeed, a positive effect is achieved, but only until the moment when the car drives a wheel into a hole. As a result, vibrations are not completely damped and are transmitted to other suspension components: ball joints, levers, and including engine mounts. The car body also experiences stress. Therefore, when changing the suspension parameters, you need to be extremely careful on uneven surfaces. - V-shaped engine

A motor with such a cylinder arrangement, as a rule, begins to vibrate earlier at idle compared to an in-line engine. Four-cylinder in-line units have the lowest risk of malfunction because they have optimal balance and better weight distribution. The operation of the crank mechanism of such an engine creates a minimum of vibrations and almost does not load the support. - Driving style

The driver's driving directly affects the condition of many automotive components, including engine mounts. For example, the supports experience significant loads during sudden acceleration and braking. The loads are explained by the ordinary laws of physics due to a shift in the center of gravity. Accordingly, the service life of the airbags decreases in direct proportion to acceleration during braking and acceleration. - Condition of the roadway

Even the most careful driving style cannot eliminate the occurrence of faults in the airbags if the road surface leaves much to be desired. And in this case, the entire suspension suffers. If possible, it is better to avoid sections of bad road - this is the only way to protect the engine mounts and suspension as much as possible. - Natural wear

Rubber-metal support is a fairly wear-resistant element, and the first signs of its malfunction may appear only after reaching 200 thousand km under normal operation. For particularly careful car owners, engine mounts last for decades without replacement. However, in addition to mechanical wear, supports are subject to negative thermal effects. As a result of repeated temperature changes, the rubber cushion loses its elasticity over time. It is this malfunction that occurs most often, which is why the product usually fails and must be replaced. In this case, cracking and delamination of the material occurs, and the support ceases to effectively dampen vibrations and extraneous noise.

There is also another, less illuminated, but nevertheless influencing the durability of the product factor. It turns out that regular engine washing can extend the life of the pillow. It's all about the oil layer, which gradually covers during operation all the external surfaces of the engine components, including its supports.

The negative impact of oil on rubber is obvious. Oil that gets on the rubber surface of the supports reduces the elasticity of the cushions and, accordingly, reduces their service life.

Antifreeze, gasoline fuel and brake fluid affect rubber in a similar way. It is recommended to avoid contact of these liquids with the surface of the supports. And regular engine washing will not only extend the life of the airbags, but will also help to promptly identify their malfunction, as well as problems in other attached parts.

Wear of the bearings manifests itself in the form of a distinct engine vibration felt from the passenger compartment. In addition, when you press the accelerator pedal, you can feel a single blow, repeated after releasing the pedal.

You will see a faulty engine mount when you open the hood. If, when you press the gas pedal all the way, the engine seems to rise a little, this may indicate wear on the support under the gearbox. Critical wear of one of the remaining pillows warps the engine in the corresponding direction.

At the initial stage, such a malfunction as natural wear and tear of engine mounts does not pose a serious danger. In the future, any vibration gradually destroys every mechanism on which it acts. Also, an advanced case of wear on the cushions can lead to the engine breaking off its mounts, and this is already a dangerous consequence.

If you stop monitoring the integrity of the engine mounts, at one point these cushions will come off, and the engine itself will break off its mounts. But for this to happen, you need to endure a noticeable knock from the engine for a long time while driving and not pay any attention to this knock.

Moreover, even after only one support is torn off, there is no guarantee that the car will move on without problems. There are known cases of support separation, in which the engine tilted and the lower pulley clung to the beam, resulting in damage to the timing belt.

We recommend

“How to charge a car battery: methods, tips, features” Read more

Design features

A rigid engine mount contributes to the transmission of noise into the car interior and increases the load on the internal combustion engine parts, since the body inevitably “plays” when driving over uneven surfaces. Therefore, vibration-damping materials are used in the design of the pillows. In modern automotive industry, several types of support designs are used:

- rubber-metal cushion. The units are fastened to metal elements, between which there is a layer of rubber. The silent blocks used in car suspensions have an identical design. This type of pillow is the most common because it has a long resource and low production cost. Some types of rubber-metal supports use springs to increase rigidity, as well as buffer elements to reduce shock loads. Rubber alloy or polyurethane is used as a damping material;

- hydraulic cushion. The operating principle is close to the operation of shock absorbers. The design of hydraulic mounts is more progressive, since it allows vibration damping to be adapted to the changing amplitude of engine and gearbox vibrations. The device assumes the presence of a working fluid, a membrane, upper (working) and lower (expansion) chambers, as well as a throttling channel. At idle speed, vibrations of the internal combustion engine are dampened by a membrane. As the speed increases, the rigidity of the membrane is not enough, so vibration damping begins to be carried out by hydraulic fluid. Thanks to this principle of operation, the cushion remains soft at idle, changing hardness only as engine speed increases.

We will not consider the design of electromagnetic and electrovacuum engine mounts, since they are found only on luxury cars, where replacing an engine mount with your own hands is a phenomenon bordering on science fiction.

Where is the engine mount located and what does it look like?

Mounts can mount the engine to a subframe, frame, or directly to the car body. The photo shows the main types of supports, so even a novice car enthusiast can find an internal combustion engine support on his car by analogy. To securely fix the motor, at least 3 pillows are used. The most commonly used scheme is with three lower and two upper supports.

Symptoms of a problem

When, when crossing obstacles in the area of the gearbox, a characteristic knock is observed that disrupts the sound insulation in the cabin, most likely, attention should be paid to replacing the engine mount. In addition, a defect in such a gasket is indicated by strong vibration transmitted to the car body. If a running motor begins to knock on the frame, it means that an urgent replacement of the engine mount is necessary.

You should pay attention to the condition of the airbags when clicks and other extraneous sounds appear in the front when braking and when the car starts to move. You should be concerned if there is a roar in the cabin when overcoming holes and potholes on the road. If driving over rough terrain is accompanied by kickback on the gear shift lever, the support must be replaced immediately.

And also evidence of signs of malfunction of the engine mounts is a significant increase in the level of vibration when starting or turning off the mechanism. It is strictly not recommended to ignore such symptoms. The consequences can be very unpleasant, ultimately resulting in deformation of the suspension and body, and premature wear of the transmission.

This is interesting: OBD2 error code P0500: speed sensor malfunction

Therefore, if the car shows signs of malfunction of the engine mounts, then the failed gaskets must be replaced.

What are the types of engine mount malfunctions?

The reasons for failure of engine mounts can be different. The most common of all support malfunctions is the separation of their rubber part. Despite the declared long service life of the product, the increased load on the support tears its rubber part. For fans of high-speed driving who accelerate sharply at the start, the airbags under the engine quickly fail.

Under certain conditions, rubber tends to dry out and lose elasticity. Sometimes hitting an obstacle causes the aluminum bracket to come off. Drops of oil falling from the engine or gearbox onto the rubber surface inevitably corrode it, and the service life of the support is sharply reduced. In short, a malfunction of the engine mounts, the symptoms of which are listed below, at a minimum causes discomfort when driving, and in some cases can lead to dangerous situations.

The main signs of broken supports are:

- The engine runs quite smoothly, but strong vibration is felt throughout the body.

- Pulling away and braking is accompanied by dull knocks and clicks under the hood.

- When driving over uneven surfaces, impacts occur in the front of the car, which are transmitted to the gearshift lever. Changing gears in a car with a manual transmission during impacts becomes difficult.

We recommend

“Brake fluid pressure: maximum value, fault diagnosis” Read more

Replacing the rear engine mount

The rear cushion is collapsible. Therefore, it is possible to purchase the product without a bracket. It will be much cheaper this way. But it is extremely important to inspect the condition of the old bracket. If it has cracks and other signs of critical wear, then you need to buy the support assembled. In general, replacing the rear engine mount is carried out similarly to the previous ones. To do this, we need to unscrew the nuts securing the support to the body and gearbox.

We dismantle the pillow and inspect the condition of the bracket. If everything is normal, then we buy a support without fastening.

How to identify a faulty engine mount

An initial check of the supports can be carried out independently, without contacting service center specialists. It is usually not difficult for even a driver who is not very experienced in repairs to identify a malfunction.

The simplest diagnostic method is to manually rock the engine under the hood, pay attention to the knocking noises that arise and use their source to find the damaged cushion.

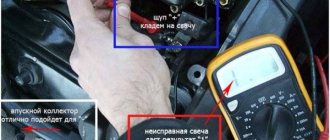

Another method requires an assistant. The driver sits behind the wheel of a car with the hood open and fixed, starts the engine, shifts the lever to first gear and begins to move forward in small jerks. Then it moves backwards in a similar manner when reverse gear is engaged. At this time, the assistant visually evaluates engine vibrations.

For a more precise diagnosis, you must first accurately determine the location of the engine mounts. If possible, the supports are first inspected for any noticeable damage or defects. For the most complete inspection, it is recommended to have an inspection pit, overpass or suitable lift.

If nothing is found during a visual inspection, you need to move on to the next stage, where you will need the help of a partner. Armed with a pry bar, one person moves one of the pillows under study. At this time, another person carefully observes the appearance of cracks or tears on the rubber element when the support moves. Sometimes it is when rocking or moving that damage to the pillow appears that is not visible when it is stationary.

A pillow with a detected malfunction must be completely replaced. Replacing just one rubber part pressed out of the cylinder in order to save on spare parts most often does not give the required result.

We recommend

“How they deceive you at a car service center and what you can do to protect yourself” Read more

Replacing the engine mount if a malfunction is detected

If you need to replace the engine mounts, the signs of malfunction described above will usually allow you to get to the nearest car service center or your own garage on your own. But you should drive carefully, if possible at a speed no higher than 60 km/h. The rear or left cushion is usually subject to wear. A detected malfunction of one support will most likely entail the replacement of the second pillow. At the end of the inspection, you need to purchase the necessary spare parts in advance - you won’t be able to go get them by car while replacing the airbags.

- Preparing to replace the engine mount It is recommended to carry out work on replacing supports in a warm place, since the rubber used at low temperatures hardens and loses elasticity. This will significantly complicate the process.

It is also advisable to drive the car into an inspection hole and carry out the replacement from there, having first disconnected the battery terminals. They often begin to inspect the left front side of the engine, where the airbag malfunction appears in most cases and access to which is most convenient.A torn mount can be repaired, since the price of a new mount for a foreign car engine is about 2,000 rubles (and for an SUV it is twice as high). If the rubber element is damaged, the support will have to be changed in any case.

- Engine mount replacement process

First of all, protective elements are removed from the motor to facilitate access to the necessary parts. A jack is then placed under the engine to provide support while the mounts are removed. If the process takes place in a viewing hole, you can lay a wide, fairly strong board across it and install a jack on it.Next, the unit is raised with a jack until it is possible to freely unscrew the support being replaced. After unscrewing the mounting screws and removing the old support, a new one is installed in its place, and the operation is repeated in the reverse order.

Replacing a rear airbag is usually associated with certain difficulties. This support experiences the greatest loads during engine operation. As a result, all fasteners are deformed, including bolts. The shape of the fastener differs from other supports.

Here a jack will no longer be enough. To free the support, it is best to hang the motor from the upper beam. If this is not possible, you can build a crossbar on two glasses, lifting the engine with a jack in advance. In some car models, external components may interfere with troubleshooting and will have to be removed. It is more efficient to cut off a severely deformed pillow fastening bolt with a cutting wheel. Sometimes they try to align and unscrew such a bolt, but after a while it will still have to be replaced.

The old support often sticks to the frame and forms rust due to the accumulation of dirt. Oil or a product like WD-40 can help remove it. It is important to install the new rear support correctly. The arrow on the support should point forward, in the direction of travel of the machine. The rest of the assembly is carried out in reverse order.

After replacing the rear support, you can proceed to the right one. Here, too, there is a possibility of encountering deformed bolts, but a more serious problem lies in the generator or car air conditioning compressor located here. It is known that removing the compressor can lead to depressurization of the circuit and leakage of refrigerant.

If the repair takes place at a service station, it is better to subsequently check the air conditioner for possible malfunctions. Short-sighted car service employees sometimes remove the compressor themselves to save time, without warning the car owner about it.

In foreign cars, in most cases, the right engine mount is located closer to the front. Therefore, to access this cushion, the right headlight and radiator grille are often removed.

Some of the deformed bolts cannot be cut off even with a grinder, since access to them is limited by other neighboring elements or simply cannot be reached. In this case, it is better to use a regular hacksaw, cutting off the damaged bolt by hand.

This procedure will take much longer, but at least this way you will not damage adjacent parts and components. The new support is placed in place of the old one as usual, in reverse order. When installing the radiator grille, you need to be careful - the radiator honeycombs are sharp enough to cut yourself.

- Safety during operation

The most important thing is to fix the motor securely and safely. A second assistant is desirable for assistance and backup.

We recommend

“How to fill brake fluid: choose a brand and follow the rules” Read more

Preparation for repair work

The presence of rubber elements in the structure of the racks implies a “positive” temperature at which their repair can be carried out. Otherwise, the rubber hardens, making it impossible to properly adjust the position of the power unit. The sequence of preparatory actions looks like this:

- entry to the inspection pit;

- battery disconnection;

- inspection of the front left pillar (it is the one that most often fails);

- inspect all the pillows one by one.

If the fastening is broken, the rack itself can be repaired. This is economically justified, since replacing engine mounts, which are quite expensive, will cost much more.

What is needed for repairs

First, you need to determine which support on the VAZ 2110 engine should be changed (if you do not want to change all the damper mounts at once). To do this, you need to do an independent inspection of these parts. Sometimes, the power plant seems to be tilted horizontally on one side or tilted along the central axis of the car. This is the first sign to replace the damper mounts.

| Locksmith kit | Rolling jack |

| A couple of short boards | Angle grinder (grinder) |

Two cushions (side) secure the engine to the left and right side members in the engine compartment. And one (rear) fixes the motor to the bottom. Therefore, it is necessary to lift the machine on a lift or install it on a viewing hole. The wear is immediately visible. The rubber has tears and core failure. Depending on the result of visual diagnostics, you should purchase the required number of parts for installation.

You will need a tool. In most cases, a standard locksmith set consisting of open-end and box-end wrenches with heads will be sufficient. In addition, to replace engine mounts on a VAZ 2110 you will need a rolling jack and a pair of short boards. It is advisable to have electricity and a cutting machine with a disc, since you may have to cut off the mounting bolts.

Helpful information! A couple of hours before repairs, it is strongly recommended to apply universal lubricant “Liquid Key” to the threaded connections. Damper supports are changed very rarely, therefore, unscrewing them without prior preparation is quite difficult.

This is interesting: What are the best means to blacken rubber yourself?

DIY repair tool

To install the engine mount, you will need:

- a set of keys and sockets (the exact number depends on the size of the bolts used on the old and new cushions, as well as the number of parts that will have to be removed to gain access to the supports. All this information is in the operation and repair manual for your car model);

- a jack that will be used to support the engine while the replacement takes place;

Additional tools may require a brush to clean dirt from bolts, as well as WD-40 or its equivalent to remove stuck nuts.