Gear shift lever design, problems and repairs

The gear shift lever in a car with a manual transmission is a relatively simple and at the same time important element. The fact is that the driver constantly interacts with the specified lever while driving the car.

At the same time, like any other device, the gearshift lever can fail, resulting in the gearshift knob dangling, grinding, knocking or squeaking when the lever is moved, etc. Taking into account the fact that force is constantly applied to the lever, in certain situations breakdowns can occur even on cars with low mileage.

Next, we will look at how the manual gearbox lever is designed, what the structure of the gear lever is, as well as what malfunctions of this element are most common and what you need to pay attention to in order to eliminate them.

Adjusting the brakes.

Incorrect brake adjustment is a direct path to losing control of the bike and increasing the likelihood of an accident. To set up the brakes on a bicycle, you must first determine their type - disc or rim. The next step is to check the functionality of the braking system while idling. Usually, after such a check, you have to tighten the cable so that when you press the brake lever it does not touch the steering wheel. For disc brakes, this is usually sufficient. Adjusting rim brakes may include adjusting the pads: they are installed symmetrically, parallel to the rim and at a distance of 1 mm from it.

Manual transmission lever: how it works, types and features

So, the usual gear knob (gearbox lever, gear knob) at first glance may seem like an extremely simple element in terms of design. However, the overall design of the system is actually somewhat more complex. Let's figure it out.

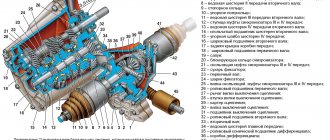

First of all, on all manual transmissions (manual gearboxes), you must manually operate the lever. In fact, through the lever, the driver transmits force to the gear selection and on/off mechanism.

Thanks to the ability to move longitudinally and transversely relative to the axis of the car, it is possible to select and engage gears. Transverse movement allows for selection, and longitudinal movement is responsible for turning on/off speeds.

To put it simply, the gear shift lever handle is connected through a rod system to the synchronizer using a fork. The gearbox synchronizer forces the necessary gears to engage, which allows the selected gearbox stage (gear) to engage. As a rule, the gear shift pattern is usually displayed on the lever head (gearbox knob).

The fact is that the steering column location of the gearshift lever is characterized by reduced speed and worse clarity, there is a risk of not fully engaging the gear, wear of the rods occurs faster, the rods themselves jam, knock out gears, etc.

It is noteworthy that the design of the lever (both floor and steering column) is almost the same. The difference is the length. So, in practice, the longer the lever, the worse. If previously a lever could be 20, 25 or even 30 cm in length, now all levers on modern cars are as short as possible.

This allows you to get rid of the long travel of the gear lever. At the same time, a floor location is best suited for installing a short lever, which allows improving the quality of operation of the mechanism without changing the design.

Basic faults of the gear shift lever and repairs

As a rule, drivers are faced with the fact that during operation the lever can:

Please note that if any problems occur with the gearbox lever, you must immediately stop using the vehicle and restore functionality.

As a rule, the lever stops working normally for two reasons:

You can check the gearbox lever, as well as, in some cases, repair it yourself. First of all, normally the gear shift knob should move freely. Jamming is not allowed. If the lever moves with obvious difficulty, there is a high probability of failure of the spherical washer or ball joint. These elements need to be changed.

Another temporary measure is sometimes to apply a thick lubricant, which manages to neutralize the squeaking of the gear shift lever. By the way, creaking also often indicates wear of the above elements. Let's add that if the gears switch off on their own, you will need to check the spring, which may jump off. To solve the problem, the spring is simply put in place.

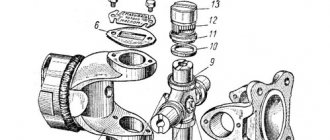

To remove the lever, the plastic protective plate is dismantled, then the hinge cage is released. Next, you will need to move the jet rod to the side, after which the entire lever is completely removed.

You will also need to check how the axle moves. If the movement of the axle is not hampered in any way, the bushings will need to be replaced (before installation, all replaced elements must be lubricated with grease).

To replace the spring, this element must be pulled out. To do this, the locking ring is removed, as well as the hinge with the lever. If it is necessary to replace the ball joint, carefully move the spherical washer apart with your fingers, after which you can remove the worn element. When installing a new support, the part must be lubricated in advance.

After replacing all elements and lubrication, the lever should move smoothly and clearly, without dangling, which allows you to comfortably and quickly select and engage gears. Also, if necessary, it is periodically necessary to lubricate and adjust the gearshift lever, linkage and other elements during vehicle operation.

Rear derailleur

The gear shifter is an important part of a multi-speed bicycle. Thanks to this component, it becomes possible to move in extreme conditions, which include moving against the wind, climbs, and poor road quality

The transmission unit must cope with all these problems. The quality of the ride and the safety of the cyclist depend on the smooth operation of the speed switch. This skill is very useful, and every bike owner should learn how to adjust the gear shift themselves. Every cyclist can adjust bicycle gear shifters independently. You need to study the theory in detail by reading the instructions, or using the advice of experienced bike owners.

Before adjusting the derailleur, you need to adjust the rear derailleur. The entire adjustment process will be greatly facilitated by placing the bicycle in the correct position (wheels up). This way, all the necessary details will be visible, and getting to them will be much easier.

Reasons for poor gear shifting:

- physical defects of switch parts;

- contamination of parts. To prevent this from happening, the components of the transmission unit must be periodically cleaned of dirt, dust and old grease;

- worn cable with elements of damage. This part requires replacement;

- rooster damage.

If you observe damage, deformation and wear of the component parts, they must be replaced as they are practically irreparable.

If all parts are in good condition, begin adjusting the switch. What does the speed switch consist of? The components of the speed switch are as follows:

- Gear shift knob located on the steering wheel;

- A shifter that is mounted on the steering wheel near the handles. Handles and a cable are attached to the shifter. It is with the participation of the cable that the impulse is transferred from the shifter to the stars;

- A cassette that includes different-sized sprockets;

- front fixing mount;

- rear derailleur, whose main function is to transfer the chain to the necessary sprockets.

What's the result?

As you can see, the gear lever is an important element, since the driver interacts with this part constantly and directly. It is not allowed to operate the vehicle if there is excessive play in the lever, vibration is noticeable, movement of the gearbox lever is difficult, etc.

As a result, the driver is able to quickly and clearly change gears, which affects the comfort and safety of operating a car with a manual transmission.

What is a gearbox rocker: the design of the gearbox rocker, signs of malfunctions. Adjusting the gear shift link. Recommendations.

Why gears on a manual transmission are difficult to engage: the main reasons for difficulty engaging manual transmission gears. Clutch and transmission failures.

The reverse gear does not engage, the reverse gear is engaged every other time: the main reasons for the failure of the reverse gear in manual and automatic transmissions, diagnostics.

Reasons for difficulty shifting gears with the engine running. Transmission oil and level in the gearbox, wear of synchronizers and gearbox gears, clutch.

Manual transmission gears (speeds) do not engage after replacing the clutch: main reasons, settings and adjustments. Diagnosis of problems, useful tips.

The clutch pedal has fallen: why does this happen? The main reasons why the clutch pedal fails, what should the driver do if the clutch fails.

Source

Rear derailleur

The gear shifter is an important part of a multi-speed bicycle. Thanks to this component, it becomes possible to move in extreme conditions, which include moving against the wind, climbs, and poor road quality

The transmission unit must cope with all these problems. The quality of the ride and the safety of the cyclist depend on the smooth operation of the speed switch. This skill is very useful, and every bike owner should learn how to adjust the gear shift themselves. Every cyclist can adjust bicycle gear shifters independently. You need to study the theory in detail by reading the instructions, or using the advice of experienced bike owners.

Before adjusting the derailleur, you need to adjust the rear derailleur. The entire adjustment process will be greatly facilitated by placing the bicycle in the correct position (wheels up). This way, all the necessary details will be visible, and getting to them will be much easier.

Reasons for poor gear shifting:

- physical defects of switch parts;

- contamination of parts. To prevent this from happening, the components of the transmission unit must be periodically cleaned of dirt, dust and old grease;

- worn cable with elements of damage. This part requires replacement;

- rooster damage.

If you observe damage, deformation and wear of the component parts, they must be replaced as they are practically irreparable.

If all parts are in good condition, begin adjusting the switch. What does the speed switch consist of? The components of the speed switch are as follows:

- Gear shift knob located on the steering wheel;

- A shifter that is mounted on the steering wheel near the handles. Handles and a cable are attached to the shifter. It is with the participation of the cable that the impulse is transferred from the shifter to the stars;

- A cassette that includes different-sized sprockets;

- front fixing mount;

- rear derailleur, whose main function is to transfer the chain to the necessary sprockets.

The manual transmission lever jerks when starting - what could it be?

Despite the rather terrible manifestations of a breakdown, often the cause is hidden in one small part that simply requires replacement. The repair may take 20-30 minutes and cost you a couple of hundred rubles. Therefore, it is better to immediately drive the car to the station, carry out diagnostics and fix the problem. Of course, the consequences may be completely different. For example, a failed clutch will have to be replaced in this case as an assembly. It is unlikely to last too long if it has already begun to show such symptoms. It is the clutch that is considered first of all in such a situation, but there is no need to rush. It is quite possible that the problems are hidden in completely different planes that do not initially come to mind. Let's take a closer look at these features so that you can more accurately and efficiently diagnose the car before going to the station.

Content

It is very likely that the culprit of the chatter will be the lever itself or the system that is used to transmit the translational movements of the lever to the shift mechanism in the transmission. If the rattling occurs only on the lever, but is not transmitted to the entire body, most likely the problem is hidden in this module. If the car does not have a large engine crankcase protection, you can put the car on a lift or drive into a pit and inspect the elements yourself.

The following parts may break:

These are common causes of lever rattling, but in such a situation the unpleasant sensations will be noticeable not only when driving in first gear. Each touch of the lever will bring unpleasant emotions; you will not recognize the behavior of your car. It will be difficult to find the moment to change gear and find out the correct amplitude of movement of the handle during the trip. Therefore, problems with these nodes need to be eliminated as quickly as possible, without expecting that something else serious and expensive will break.

The main element of vibration under the hood is always the power unit and gearbox cushions. Typically, the rear cushion, which holds both the gearbox and the engine, is responsible for lever rattling, but this greatly depends on the design of the car. It is impossible to find a definite answer to the question of how to check pillows yourself. You can watch videos of masters and craftsmen and use their advice, but the fastest way to do this is with the help of specialists at a service station. This is an accurate and quick diagnosis on a lift.

You can check these details yourself like this:

If at least one of these symptoms is present, you need to start replacing the engine mounts. Doing it yourself is also not advisable unless you have experience. An incorrectly positioned power unit on the cushions will rattle and cause even more problems. It is important to find a specialist who can properly adjust the cushions, set the motor perfectly and test its operation in all modes. This is the only way to hope to fix problems in your car. Otherwise, repairs will only make the situation worse.

The CV joint is more difficult to check, but you can do the following:

At the station, with a superficial diagnosis, the hinges may be sentenced to replacement along with the clutch, rocker and other parts. This suggests that the specialist does not want to understand the problem, but wants to make money from you. It is extremely unlikely that all the elements responsible for the possible jerking of the lever in first gear simultaneously fail. If the service station presents a huge list of problems, you will have to find another station and re-diagnosis. In general, this is very important to understand when choosing a specialist to service your car.

If you read the opinions of forums on this issue, you will find that it is the clutch that is most often condemned by “armchair experts” in this situation. This is indeed very similar to a broken clutch, but you should check all the above options before repairing or replacing it. You may be able to avoid significant financial investments by eliminating minor problems and eliminating the unpleasant effect of jerking the gearshift knob when starting off. If all else fails, move on to the clutch issue.

Operation No. 1: how to adjust rear speeds on any type of bicycle

When starting the process of setting up the rear derailleur, you should familiarize yourself with its configuration. The standard module has five adjustment elements:

- nut securing the cable;

- cable tension drum;

- limit screw for the lowest gear (Low);

- limit screw for the highest gear (High);

- screw that regulates chain tension.

The method “how to adjust the rear speed on a bicycle” consists of three stages.

Setting the limiters

This is usually done once - when installing a new switch and in order to prevent the chain from jumping off on the outer sprockets of the cassette. The sequence of actions is as follows:

- the largest star is installed in front, the smallest in the back;

- the cable is released;

- adjustment is performed by rotating screw H clockwise or counterclockwise (the derailleur frame moves towards the spokes or the frame stay, respectively) until the rollers with the smallest cassette sprocket lie in the same plane;

- then the cable is tensioned and secured, the switch is moved to the largest sprocket at the rear and the smallest at the front;

- by rotating the screw L, a similar position of the rollers is achieved in relation to the sprocket.

Adjusting the transfer quality

It is a key operation in the process of how to adjust the rear speed range on both a road and mountain bike. The process technology is simple: the smallest sprockets are installed at the front and rear; by rotating the adjusting drum, ensure that the transfer is triggered clearly and instantly:

- if the cable tension is insufficient, the switch moves poorly (slowly) to lower gears (large sprockets) - you need to turn the drum counterclockwise;

- if there is excessive tension, the derailer lingers in its previous position (does not shift well to upper gears - small sprockets), making a clattering sound (metallic clanging) during operation (the drum must be turned clockwise).

Best articles: What is a fatbike and what are its advantages

Adjusting the tensioner (height of the guide roller or chain angle)

In the technology “how to adjust rear speed on a bicycle,” this adjustment is aimed, all other things being equal, to improve the quality of gear shifting.

The smallest sprocket is installed at the front, and the largest at the rear. By rotating the screw, the guide roller approaches or moves away from the sprocket. The task is to achieve a gap between the roller and the sprocket of 3-5 mm.

Let's sum it up

Modern cars rarely provide the owner with surprises in the form of unexpected problems. But domestic budget transport, as well as old foreign cars, very often demonstrate such unpleasant consequences. This may be a consequence of the failure of a small part in the gear shift system, or it may be a consequence of the failure of some complex mechanisms that will cost a lot of money during repairs. In any case, this problem needs to be eliminated. If the lever shakes when starting, other components of the car also receive increased loads. This can cause serious damage that can be expensive to fix.

If you don't know where to start diagnosing, use the four points presented above. The reason for the twitching of the lever when starting to move is usually hidden precisely in them. If this does not help, most likely the problem is hidden in the box itself. This could be a broken tooth on one of the gears or failed fastenings of important parts. It is best to contact a specialist and carry out repairs, but you need a reliable specialist who accurately understands the design of your car. Ask around on forums or with other owners of the same cars if you don’t have a good specialist in mind. Have you encountered such problems on your car?

Source

Synchronizers or clutch?

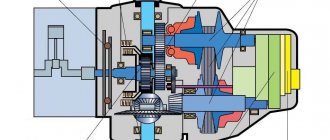

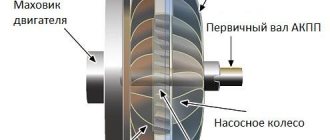

In the design of a manual transmission, synchronizers are necessary to equalize the rotation speed of the input shaft and the selectable gear mounted on the secondary shaft.

The hub is rigidly connected to the gearbox output shaft, while the helical gear of each gear rotates freely on the shaft. When changing gears, the sliding clutch moves, locking together a pair of hub and helical gear corresponding to the desired gear. Since the speed of rotation of the hub and gear will be different when moving to a higher/lower stage, synchronizers are needed for smooth and silent shifting.

In the design of a synchronized manual transmission, the clutch, when moving, presses the locking ring against the synchronizer cone. Due to the high friction force between the cone and ring, the speed of the output shaft and the helical gear are equalized. The sliding clutch then seamlessly engages the gear with the output shaft hub.

If the synchronizer malfunctions, due to different rotation speeds of the input shaft and gear on the secondary shaft, rigid engagement occurs, accompanied by a characteristic roar/crunch.

You can distinguish a synchronizer malfunction from a clutch failure by the frequency of sounds. If the problem is in the release drive or the clutch basket itself, then the gearbox crunches with every shift. In the case of burnt or worn synchronizers, the sound appears when changing to a specific gear. For example, on front-wheel drive VAZ cars, due to a design flaw in the domestic manual transmission, a characteristic roar most often occurs when switching from 1st to 2nd gear.

After disengaging the gear, release and then depress the clutch again before engaging the next gear. If after double squeezing the gears shift softer, the problem is clearly in the synchronizer.

What to do if you can’t adjust the rear derailleur of your bike

There are several methods to solve this issue. But if the standard setting instructions did not work, to set up the rear speed derailleur you need to:

- dismantle the chain, remove the cable;

- move the switch to the chain position on the smallest star;

- use adjusting bolts (this way you can tighten the cable);

- set the adjusting bolt H to the extreme position;

- move the piece called the parallelogram to the large star and adjust the position of the bolt L.

The regulator is fixed with bolts. It must be set to its extreme position. After which, the chain must be shifted in this order: the front cassette is the largest sprocket in diameter, the rear, on the contrary, is the smallest.

The gearshift lever of the VAZ 2110 dangles and plays - we eliminate the reasons

Even ardent supporters of the Russian automobile industry cannot help but be annoyed when the gearshift lever on a VAZ 2110 dangles; moreover, it also produces the most unpleasant rattling sound. Those with stronger nerves put up with it as an inevitable “side effect”; some even got used to constantly holding the gear shift knob with their own hand.

However, this cannot continue forever, especially if the vibration gets to the point that the lever begins to miss when shifting gears, confusing second with fourth and third with fifth. But in order not to take the situation to an extreme, let's talk about what to do to avoid rattling the gearbox handle.