Under normal conditions, the air-fuel mixture burns evenly, without creating shock loads on the piston group, cylinder walls and parts of the gas distribution mechanism. Car engine detonation is the consequence of an incorrect setting of the ignition system or the use of fuel with a low octane number, which negatively affects the efficiency, power and service life of the power plant.

Car engine detonation can occur due to incorrect settings of the ignition system.

Concept of car engine detonation

During normal operation, the fuel mixture ignites when the piston approaches top dead center and burns at a speed of up to 50 m/s. Pre-ignition causes combustion problems as the expanding gases try to compress the upward piston. An increase in the rate of oxidation to the speed of sound and an avalanche-like increase in pressure form a shock wave that reaches the walls of the engine cylinders and produces a metallic knock (sometimes the phenomenon is mistakenly called the knock of piston pins).

Signs of engine detonation

The main symptoms of detonation combustion: 1. A high-pitched metallic knock when pressing the accelerator pedal. Short-term detonation is allowed in the speed range from 40 to 60 km/h when accelerating on a straight section of the highway. 2. An increase in coolant temperature with a normal level and a working fan and radiator. 3. A drop in the power of the power plant, which negatively affects the dynamic capabilities of the car. 4. The appearance of extraneous vibrations transmitted to the body or felt on the steering wheel, pedals or transmission selector.

Varieties

Car engine detonation is divided into categories:

- Short-term, occurring with a sharp increase in speed and lasting 1-2 seconds. The effect occurs on forced engines and units with large cylinder volumes. The process does not cause damage to parts and is normal.

- Long-term, manifested with increasing load and increasing crankshaft speed (regardless of the selected gear and speed). The process is uncontrollable and can destroy combustion chambers, piston crowns or partitions between rings.

Can a car engine detonate when turned off: let’s understand the aspects

It is wrong to classify uneven engine operation or any other knocking as a sign of detonation. To avoid mistakes, the best option would be to find out what the detonation mode sounds like in practice. For example, watch thematic video files.

Dieseling

As already noted, an undesirable phenomenon can appear exclusively on a functioning motor. How then to qualify the operation of the power plant with the ignition off? The mechanics' answer is short - dieseling. Its nature is different: self-ignition of gasoline, identical to the working process of a diesel engine.

Beginners who have caught up on their knowledge base on gasoline internal combustion engines will immediately object, citing a couple of arguments “against”: high-octane fuel has poor self-ignition ability, and the compression ratio in a gasoline engine is lower. All this is true, but when the unit is stopped, favorable conditions are created for dieseling.

- Fuel supply to the cylinders.

- Low crankshaft speed.

In reality the process looks like this. The power plant is turned off, the crankshaft rotation speed drops, fuel is supplied. The time allotted for ignition of the mixture increases.

Under such conditions, a spark from a spark plug is not needed to ignite the fuel - a gradual increase in pressure and temperature is sufficient. After completing the power stroke, the crankshaft speed increases, and self-ignition does not occur. Then the frequency drops again and dieseling occurs again. And so on for several cycles of “twitching”.

Harm or benefit

Unlike knocking when rocking the steering wheel, there is nothing dangerous about the engine running unstably after being de-energized. On the contrary, the presence of this effect indirectly confirms the good tightness of the combustion chamber, which indicates the general serviceability of the internal combustion engine. This phenomenon can only occur on carburetor engines, because on injection power plants the fuel supply stops when the ignition is turned off.

Hence the conclusion - the absence of twitching after stopping the unit is not at all a sign of poor condition. By the way, a properly tuned and well-maintained carburetor protects the engine from diesel build-up. This is realized using the electromagnetic valve of the EPH system, which, in good condition, shuts off the supply of fuel to the cylinders when the internal combustion engine is turned off.

Main causes of engine detonation

Detonation processes in internal combustion engines can be caused by:

- filling the tank with gasoline with a reduced octane number;

- incorrect operation of the power plant;

- incorrectly set ignition (early or late ignition) or incorrect software in the control unit;

- worn spark plugs or incorrectly selected spark plugs;

- impaired mixture formation;

- sedimentation of carbon deposits on the walls of the combustion chamber and valve plates;

- local overheating due to a faulty cooling system.

Detonation occurs not only in spark-ignition engines, but also in diesel engines.

The reason is incorrect adjustment of the timing of diesel injection and the use of low-quality fuel.

Diesel has a reduced thermal regime, but under increased load and a faulty cooling system, hot elements (for example, the edges of exhaust valves) can prematurely ignite atomized fuel.

Wrong choice of fuel for a car

Engines with a compression ratio of more than 10 units and supercharged units are designed for fuel with an octane rating of at least 95. When using low-grade gasoline or evaporating additives (used by some oil refining companies to increase detonation resistance), premature ignition of the explosive mixture occurs. The injection engine controller is able to reduce the likelihood of detonation by adjusting the ignition timing and valve timing (if there is a camshaft rotation system).

One of the reasons for engine detonation is incorrectly selected fuel.

Features of engine operation

Detonation occurs when the engine is overloaded (for example, while driving at low speed on a long climb in high gear). To eliminate the defect, it is necessary to switch to a lower speed, which will increase the rotation speed and normalize the combustion process.

Detonation of a car engine when starting a cold power unit indicates a lean mixture due to clogged injector nozzles. As it warms up, the problem disappears (the performance of the injection system corresponds to the required composition of the air-fuel mixture).

Incorrectly configured ignition

On engines with mechanically controlled ignition systems, detonation occurs due to pre-ignition caused by improper timing - early or late ignition. The expanding gases compress the upward piston, which leads to detonation. Power units with contactless ignition and electronic timing control automatically adapt to operating conditions and load and do not require manual adjustment of the ignition system.

Firmware

Detonation can be caused by incorrect firmware installed in the engine control unit (for example, after removing the catalytic converter, owners load a program with a modified operating algorithm). If problems are detected, it is necessary to install firmware that matches the characteristics of the power unit. Spontaneous changes to the specified settings during engine operation are impossible.

Faulty spark plugs

When choosing spark plugs, it is necessary to take into account not only the dimensions of the threaded bushing, but also the heat rating (information on tolerances is indicated in the service instructions and specialized catalogs). The use of products with a reduced or increased number leads to difficult starting and disruption of the spark formation process. The engine loses power and torque, normal fuel combustion is disrupted and the car's acceleration dynamics drop.

Lean air/fuel mixture

Owners of cars with a carburetor strive to reduce gasoline consumption by leaning the fuel mixture, which leads to incorrect combustion. Electronically controlled technology automatically maintains the stoichiometric composition of the mixture, focusing on information from temperature, air flow or oxygen concentration sensors in the exhaust gases (located before and after the catalytic converter housing). If the catalyst breaks down or the sensors fail, the working mixture may become depleted, causing detonation processes during combustion.

Carbon deposits on the cylinder walls

The carbon deposits formed on the walls of the working chamber and the exhaust valve plates worsen the cooling conditions of the parts. During the compression process, the mixture of air and fuel ignites before the permissible moment, which leads to detonation combustion. The problem often occurs on power units with high mileage; engine oil enters the combustion chambers and forms a layer of dense carbon deposits.

The result of engine detonation is carbon deposits on the cylinders in the engine.

ICE design features

Passenger car engines with a compression ratio of 10 or more are prone to detonation when using gasoline with an octane rating of less than 95. Some engines have sharp edges on the pistons and surfaces of the combustion chambers, which disrupt the normal combustion process. In this case, the problem is solved by using high-quality fuel, but short-term detonation remains during transient operating conditions.

Power units with increased liter power (for example, with a supercharger) are characterized by increased pressure of the working mixture at the inlet to the cylinder. When using low-quality fuel or violating cooling conditions, the risk of detonation increases.

The design includes a sensor that detects the moment the explosive combustion of the fuel mixture begins and regulates the operation of the systems (for example, it reduces the pressure in the boost system using a special valve in the turbine or adjusts the ignition timing).

Cooling system malfunction

An insufficient level of antifreeze leads to the formation of vapor locks in the jacket and an increase in the temperature of the cylinder head and block. The problem often occurs in hot weather, when accelerating a car, or when driving at low speed in off-road conditions. Hot parts cause premature ignition and detonation. Irreversible temperature deformations lead to a violation of the tightness of the line of contact between the head and the block and penetration of the gasket.

How does detonation manifest itself?

The occurrence of detonation in the cylinders is accompanied by a metallic ringing. At the same time, the engine itself vibrates, which is transmitted to the body, as well as a delay in stopping work (after turning off the ignition, the engine still runs for some time). If these symptoms appear, detonation combustion occurs in the engine cylinders.

In a gasoline engine, the air-fuel mixture, which is pumped into the cylinders, is pre-compressed by a piston, which ensures mixture formation and an increase in temperature, which affects flammability. The pressurized mixture is ignited by a spark from the spark plug. In this case, a flame front is formed, which spreads throughout the entire volume from the ignition point to the edges. The propagation process is slow - 20-30 meters per second. The combustion of fuel is accompanied by an increase in temperature inside the cylinder and pressure, which acts as energy converted into mechanical action.

Detonation combustion is a process in which an increase in pressure and temperature leads to the appearance of oxidation processes of the components of the mixture, which causes the appearance of an additional source of ignition. As a result, the flame front spreads faster than during normal combustion (flame propagation speed exceeds 1500 m/sec). Instead of one source (from a candle), there are two (the second is spontaneous), while the front of the flame of each of them goes towards each other.

Video: DETONATION VISUALLY

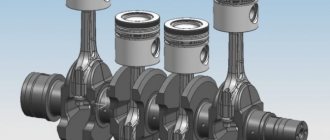

In the cylinder, this process causes an explosion of the mixture, rather than a gradual spread of flame. The collision of two flame fronts leads to an increase in pressure and temperature. And this leads to increased shock loads on the cylinder-piston group and the crank mechanism, and the engine overheats due to temperature.

Causes that are often confused with detonation

Internal combustion engines with spark ignition are capable of operating for some time after the ignition is turned off. The cause of ignition of the mixture is heated elements in the combustion chamber or an increased compression ratio. Running the engine at idle for 1-2 minutes after stopping the trip will help to reduce the temperature of the head and pistons evenly.

Glow ignition

Glow ignition is observed when the ignition of carburetor engines is turned off. Hot carbon particles ignite the working mixture, and the engine can run for 5-10 seconds after trying to stop it. The problem does not occur on vehicles with engines equipped with a distributed injection system, since when the key is turned in the lock, the injectors and the pump supplying fuel from the tank are turned off.

Dieseling

Carburetor engines with spark ignition and a high compression ratio can continue to operate due to the auto-ignition of the mixture. The problem occurs when using fuel with insufficient octane number. The air-fuel mass ignites as a result of compression caused by the inertial movement of the pistons after the voltage supply to the spark plugs is stopped. The unit operates unstably for 2-3 seconds at idle, and then stops due to a drop in the temperature of the cylinder walls.

Dieseling is one of the causes that is often confused with detonation.

Signs of detonation

There are a number of signs by which you can indirectly determine that detonation is occurring in the engine of a particular car. It’s worth mentioning right away that some of them may indicate other breakdowns in the car, but it still makes sense to check for knocking in the engine. So, the signs include:

- The appearance of a metallic sound from the engine when it is running . This is especially true when the engine is running under load and/or at high speeds. The sound is very similar to what happens when two iron structures hit each other. This sound is precisely caused by the blast wave.

- Decrease in engine power . Usually, in this case, the engine does not operate stably, it may stall when idling (this is important for carburetor cars), it takes a long time to gain speed, and the car’s dynamic characteristics drop (it does not accelerate, especially if the car is loaded).

Diagnostic scanner Rokodil ScanX for connecting to the car ECU

It also makes sense to give signs of failure of the knock sensor. As in the previous list, signs may indicate other breakdowns, but for injection machines it is better to check the error using an electronic scanner (the most convenient way to do this is with a multi-brand Rokodil ScanX , which is compatible with all cars from 1993 onwards and allows you to connect to a smartphone on iOS and Android via Bluetooth). Such a device will make it possible to see the indicators of the knock sensor and others in real time.

So, signs of a knock sensor failure:

- Unstable engine operation at idle speed;

- a drop in engine power and in general the dynamic characteristics of the car (accelerates poorly, does not pull);

- increased fuel consumption;

- Difficulty starting the engine, this is especially noticeable at low temperatures.

In general, the symptoms are identical to those that occur with late ignition.

Consequences of car engine detonation

Consequences of operating a motor with a detonation process of combustion of the working mixture:

- the appearance of cracks on cylinder liners or mirrors, the roof of the combustion chamber;

- destruction of valve seats and plates or spark plug insulators;

- deformation of connecting rods;

- burnout of the piston bottom or destruction of the bridges between the piston rings;

- breakage of rings with debris falling into the engine sump;

- destruction of the gasket between the head and the block, leading to the passage of gases between the cylinders or the entry of antifreeze into the combustion chambers;

- the entry of piston debris under the valve plates and into the crankshaft supports leads to irreversible damage to parts and major engine repairs.

What is detonation

Detonation is a disruption of the combustion process of the fuel mixture in the combustion chamber, when combustion does not occur smoothly, but explosively. At the same time, the speed of propagation of the blast wave increases from standard 30...45 m/s to supersonic 2000 m/s (exceeding the speed of sound by the blast wave is also the cause of the pop). In this case, the air-fuel mixture explodes not from a spark coming from a spark plug, but spontaneously, from high pressure in the combustion chamber.

Naturally, a powerful blast wave is very harmful to the cylinder walls, which overheat, the pistons, and the cylinder head gasket. The latter suffers the most and during the detonation process the explosion and high pressure simply burn it out (in slang it is called “blowing out”).

Detonation is typical for engines running on gasoline (carburetor and injection), including those equipped with gas-cylinder equipment (LPG), that is, running on methane or propane. However, most often it occurs in carburetor cars. Diesel engines operate according to a different scheme, and there are other reasons for this phenomenon.

Methods for preventing car engine detonation

Ways to prevent detonation:

- use fuel with an octane number that meets the manufacturer’s technical requirements;

- install spark plugs with a heat rating that meets the standards;

- in the case of using a mechanical pulse distributor, set the ignition timing correctly;

- Before programming the control unit, check the power unit model and software version for compatibility.

To reduce the risk of car engine detonation, a prechamber-torch ignition system was developed with the spark plug electrodes located in a separate cavity connected to the main chamber by a narrow channel. Similar engines were produced in small batches at the GAZ plant and installed on GAZ-3102 vehicles. The head had an additional valve through which an enriched mixture was supplied from a separate section of the carburetor to the prechamber. As electronic fuel injection systems developed, work on such units ceased.

Scheme of prechamber-torch ignition.

There are 4-stroke gasoline engines that operate according to the Miller cycle, which involves premature closing of the intake valve at the stage of filling the cylinder or late closing at the start of compression. By supplying a smaller volume of working mixture, it is possible to increase the geometric compression ratio to 12-14 units without the risk of detonation combustion. The cycle provides an increased degree of expansion and increases the efficiency of the power unit, but there is a drop in power and torque due to insufficient filling of the cylinders.

Causes

Factors provoking detonation:

- mismatch of fuel octane number;

- compression ratio mismatch. If, as a result of repair work, the compression ratio has been increased, then refueling with the same brand of gasoline can lead to detonation. It is very easy to make such an oversight if you grind the cylinder head or the block itself, and then install the cylinder head gasket of the same thickness. If you do not want to “kill” the engine, the issue of compression ratio should be taken very seriously. Please note that engine knock may occur in hot weather or in a certain rpm range;

- UOZ. Too early an angle can result in "stray" pressure in some areas of the combustion chamber, leading to spontaneous explosions;

- Incorrect fuel/air ratio. Engine detonation can occur both in the case of a lean mixture and in case of over-enrichment;

- carbon deposits in the combustion chamber. The formation of deposits promotes the fixation of particles that do not leave the combustion chamber after the exhaust stroke. By maintaining a high temperature, they contribute to the appearance of detonation in the cylinder. A large amount of carbon deposits leads to the filling of the useful volume of the combustion chamber, which can lead to detonation.

Prevention methods

Basic methods to reduce the risk of detonation combustion:

- Periodically check the condition of the ignition system components on carburetor engines. Failures or malfunction of sensors that correct the advance angle lead to disruption of spark formation and a drop in power simultaneously with an increase in fuel consumption.

- When the Check Engine light turns on, diagnose the vehicle's electronics; the detected codes allow you to identify faulty sensors or damaged wiring harnesses.

- Use motor oils with appropriate base stocks and viscosity indices, which prevents the formation of carbon deposits on the surface of the combustion chamber.

- Change worn valve stem seals in a timely manner and carry out chemical or mechanical decoking of the engine (to remove a layer of carbon deposits).

- Maintain the cooling system in accordance with the manufacturer's recommendations. During operation, antifreeze degrades, which leads to a drop in performance and local overheating of the cooling jacket.

- Do not drive at low speeds in low gears. Some manual cars are equipped with an electronic prompt that indicates when to shift up or down. The computer operating algorithm is designed to reduce fuel consumption; short-term detonation is allowed during acceleration.

Consequences

The main breakdowns include:

- burnout or partial melting of the piston due to abnormally high temperature. Breakage of the partitions between the rings may also occur. Expensive capital will help fix the problem;

- accelerated wear of the CPG. Detonation destroys the oil film on the cylinder walls, which leads to dry friction of the pistons;

- burnout of exhaust valves;

- engine overheating;

- an increase in the temperature of the turbine, which can lead to its breakdown;

- the high temperature of the cylinder walls and piston requires the rings to conduct more heat through themselves. Too high a temperature has a detrimental effect on the elasticity of the rings;

- melting of the electrode. The situation is rare and only happens in extremely advanced conditions.

For those who like to save money

If you fill a modern car with 92 gasoline in the hope of saving money, then you will be pleasantly surprised by the information about the ignition system of an injection engine. Detecting the occurrence of detonation, the ECU “pushes back” the OZ. Such measures help eliminate detonation, but lead to a loss of dynamic characteristics of the car. Accordingly, consumption increases, which negates all attempts at saving.

Tuners

Also be careful with calculations when boosting the engine. Incorrectly built turbocharged engines are especially susceptible to detonation. But this problem does not bypass atmospheric internal combustion engines. In our country, there are fans of installing 16-valve cylinder heads in engines with piston and 8-valve engines. Many people don’t even suspect that 16-valve VAZ engines have oil-cooled pistons. Therefore, installing the cylinder head alone is fraught with an increase in the temperature in the cylinder.

Riding tight

Pull-up movement - driving under load in high gear. This happens when the driver sharply adds gas, being in a higher gear, when the engine speed does not exceed 2500 thousand. This situation can be provoked by a long climb, during which the driver does not slow down, but presses the pedal harder.

Driving under tension, especially on a turbocharged internal combustion engine with a small volume, creates favorable conditions for detonation to occur. That is why it is better to abandon this method of driving.

Knock sensor

It is this sensor that registers extraneous resonant frequencies in the cylinder. Based on the readings of the knock sensor, the ECU makes a decision to adjust the SOP. If the engine is in good condition and the tank has the correct type of fuel, then a sensor failure will not lead to detonation. It’s just that now the ECU will not be able to adequately respond to the appearance of such a negative phenomenon.

Using a knock sensor

To determine detonation processes, a knock sensor installed on a special plane on the cylinder block is used. When recording shock loads, the sensor's accelerometer generates electrical signals and transmits information that is processed by the control unit.

The strength of the impulse depends on the intensity of explosive combustion in the cylinders. The controller adjusts the ignition timing, the composition of the fuel mixture, or changes the position of the camshafts, which reduces the duration and completely eliminates detonation.

The sensor is equipped with a housing made of impact-resistant plastic that can withstand prolonged heating up to +150°C and above; a bolt is used for fastening. The threaded connection allows you to press the sensitive element to the surface of the block. On the side of the case there is a connector for connecting the wiring harness. If a sensor in the instrument cluster breaks down, the Check Engine indicator turns on, and an error is recorded in the control unit’s memory. Some injection engines (for example, for classic VAZ models) are not equipped with a sensor due to their design.

avtoexperts.ru

Drivers of the old school, who began their driving journey 15-20 years ago or earlier, hardly need to be told what detonation is. They absorbed this information literally from the first lessons of the driving school, and it was one of the points of proper driving and car maintenance. Everyone memorized the characteristic sound of detonation, which was popularly called “knock of fingers,” literally from the first kilometers. However, novice motorists who have only recently joined the ranks of drivers may not be aware of this phenomenon at all. Modern cars have at least learned to deal with detonation, and it has ceased to be so common. But this is the danger - detonation itself, as a physical phenomenon, has not gone away in modern engines; when it occurs, it still causes severe harm to the engine, especially when the driver does not know what it is and how to deal with it.

What is detonation?

In scientific terms, detonation is the random spontaneous ignition of a mixture in the engine cylinders, which has the character of an explosive wave. It is the last parameter that distinguishes detonation from other cases of spontaneous combustion of the mixture in cylinders (for example, glow ignition). The main problem of detonation is not that the fuel-air mixture ignited at the wrong time, but that the speed of spread of this fire is 500-1000 times greater than in the case of a conventional “ignition” from a spark plug. It is the shock wave that leads to all the negative consequences of detonation.

To make it clear what kind of misfortune we are talking about, we will list the negative aspects that detonation has on the engine.

1. All motor elements are overloaded, which significantly reduces their service life. The pistons and crankshaft are especially .

2. Due to rising temperatures, the risk of burning out valves and head gaskets increases.

3. The detonation wave washes away the oil film from the cylinder walls, which can lead to scoring .

By the way, the characteristic sound when detonation occurs is not the knocking of fingers, as is commonly believed, but the impact of the blast wave from detonation on the cylinder walls. If the engine fingers were so worn out that they made such sounds, then the owner of this engine would have to think not about detonation, but about overhaul.

Causes of detonation

It is clear that detonation is primarily self-ignition. But why does the mixture spontaneously ignite at all? Under ideal conditions this does not happen, but as soon as several additional factors appear, the thermal operation of the engine is disrupted. And then immediately expect detonation.

Useful tips and recommendations from experienced motorists

The shock wave formed during explosive combustion changes the tone of the engine. The driver needs to learn to detect the appearance of extraneous sounds indicating incorrect operation of the power unit. It should be taken into account that the sound of the motor is not allowed to change while driving. Any extraneous noise indirectly indicates a malfunction of the unit.

If detonation appears after refueling the car, then it is necessary to add gasoline with a higher octane number to the tank. If the engine is designed for fuel type A-98 or higher, topping up will not help. It is necessary to drain the fuel and wash the ramp and injectors. During long-term operation of the machine in city traffic jams, carbon deposits on the piston group parts. To remove deposits, it is necessary to travel 50-70 km along a country highway at the maximum permissible speed.

Consequences of detonation

As mentioned above, the consequences of detonation in a car engine are very serious, and under no circumstances should repair work be delayed, because the longer you drive with this phenomenon, the more damage the engine and its individual elements are susceptible to. So, the consequences of detonation include:

- Cylinder head gasket combustion . The material from which it is made (even the most modern ones) is not designed to work under conditions of elevated temperature and elevated pressure that arise during the detonation process. Therefore, it will fail very quickly. A broken cylinder head gasket will lead to other problems.

- Accelerated wear of elements of the cylinder-piston group . This applies to all its elements. And if the engine is no longer new or has not undergone a major overhaul for a long time, then this can end very badly, up to its complete failure.

- Cylinder head breakdown . This case is one of the most difficult and dangerous, but if you drive for a long time with detonation, then its implementation is quite possible.

- Burnout of piston/pistons . In particular, its bottom, lower part. However, it is often impossible to repair it and will only need to be completely replaced.

- Destruction of jumpers between rings . Under the influence of high temperatures and pressure, they can be one of the first to break down among other engine parts.

- Connecting rod bend . Here, similarly, in conditions of an explosion, its body can change its shape.

- Burning valve plates .

This process happens very quickly and has unpleasant consequences. As can be seen from the list, the consequences of the detonation process are the most serious, therefore the engine should not be allowed to operate under its conditions; accordingly, repairs must be performed as quickly as possible.

Why does detonation occur after turning off the ignition?

Detonation with the ignition off is characterized by the fact that the engine continues to operate even when the driver has already removed the key from the ignition. Usually, this happens within 2-3 seconds, although in some cases there are breakdowns that force the engine to work even 15 seconds after the ignition has been turned off. Despite the different extent, detonation itself is not a normal operating mode, so it is necessary to take the right measures in a timely manner.

- The first reason for detonation is the use of the wrong grade of fuel as prescribed by the manufacturer. Different brands of gasoline have their own octane number, which characterizes the degree of compression of the fuel. So, low-octane gasoline must be used for engines with the appropriate compression ratio. That is, if the plant ordered A-95 gasoline to be poured into the gas tank, then this gasoline should enter the engine cylinders.

- The second reason is characterized by engine malfunction, namely, too early ignition. Typically, such adjustment is carried out in order to increase the sensitivity of the engine to pressing the gas pedal. But it is worth remembering that with the appropriate ignition timing, the moment comes too early when the fuel begins to ignite. It turns out that the piston moves to top dead center, and at this moment ignition already occurs.

We recommend: How to replace the air filter on a Ford Fusion?

The last causes of engine detonation are the use of spark plugs of the wrong brand and characteristics, as well as engine overheating, when the fuel ignites due to the combustion chamber temperature being too high.

Consequences in the photo

Below is a selection of photographs showing the effects of spontaneous combustion in gasoline and diesel engines. Most often, the bottom of the piston and valves burn out.

Engine detonation can burn spark plugs Spontaneous ignition burns out the intake and exhaust valves Detonation kills the internal combustion engine Detonation primarily affects the piston group

Detonation is dangerous for all types of engines. Bad fuel is the main culprit behind its appearance. At the first signs, try to quickly eliminate the reasons causing the uncontrolled ignition of the combustible mixture. Ignoring the problem will lead to expensive repairs to the power unit.

Detonation during acceleration

Now we need to consider how to determine detonation on an engine and the signs of its manifestation. When this process occurs, a chaotic, ringing metallic knock occurs, hence the expression “knock fingers” common among motorists (meaning piston pins, another stable expression is “rattling valves”). When accelerating the car, a knocking noise can be clearly noticeable when you sharply press the gas pedal, and the greater the load, the more clearly the detonation of the engine can be heard. In general, in practice there are not many reasons why a clattering noise appears in the engine when the load increases, and the main ones are:

- refueling a car with low-octane gasoline or low-quality fuel;

- deposition of a large amount of carbon deposits in the combustion chambers (coke often forms on the piston heads as a result of increased oil consumption);

- overheating, there are many different factors that influence the increased temperature of the internal combustion engine;

- incorrect ECU system, mainly associated with failures in the program, errors during flashing.

Also, the sound of detonation appears if the engine brake fails; in this case, the ignition adjustment no longer occurs during sudden acceleration. The configuration of the electronic unit may be incorrect; for example, the flashing was carried out in the cold season without taking into account temperature changes in the weather, so in the heat the possibility of detonation occurring on a warm engine is quite likely.

Detonation of gas and diesel engines

There is a belief that there is no detonation process in engines running on propane-butane or methane, but this is a completely erroneous opinion. Quite often, diesel leakage occurs on cars that use gas as fuel; the phenomenon is mainly due to the following factors:

- the gas reducer is not adjusted (lean mixture);

- ignition is delayed;

- coke formed in the combustion chambers;

- Spark plugs with a low heat rating are installed.

Most often, detonation here appears when the engine is turned off on gas, and on gasoline it is often completely absent. If there is no detonation on gasoline fuel, but there is detonation on gas, most likely, you need to deal with the settings of the gas system, which also significantly affects the operation of the gas engine spark plugs, because a more powerful spark is required to ignite gas fuel.

There is no detonation of a diesel engine in the usual sense: in diesel engines, the air-fuel mixture is not ignited by a spark, the energy is converted into movement, and not into heat, which means the temperature inside the cylinders is lower. But a diesel internal combustion engine can work “hard” due to an incorrectly set fuel injection angle, poor combustion of diesel fuel, and the combined mixture; such work is similar to detonation. On modern cars, a knock sensor is installed on diesel engines with an electronic high-pressure fuel pump; it adjusts the injection angle, and if the engine fails or there is a break in the wires, the engine starts to knock and the speed increases.

How to fight

Every driver should understand that the main cause of detonation is fuel, or rather, low-quality fuel. Therefore, when this problem occurs, the first thing you need to do is check the gasoline. If necessary, refuel your car from trusted suppliers. Know that the cheaper the fuel, the greater the chance that it is absolutely of poor quality. Sometimes it is better to overpay a symbolic amount so as not to face a problem tomorrow.

You also need to adjust the ignition if necessary. If nothing changes with early ignition, try adjusting it again, put it in neutral. It can also occur under light loads, but during prolonged use. In this case, a layer of carbon deposits forms on the cylinder walls, which increases compression and reduces heat dissipation. To prevent this from happening, it is advisable to carry out diagnostics: give the engine a load at least once a month (accelerate the car to high speed for several minutes). It is advisable to do this outside the city.

You should also check the spark plugs. But here you need to remember that the spark plugs for your car were recommended by the car manufacturer, so here you need to listen to their opinion. Otherwise, you will soon have to return to car repairs again.

Sometimes detonation may be accompanied by a green or black stream of smoke from the exhaust pipe. This indicates that the pistons are being destroyed or have already collapsed and parts of aluminum are being released through this pipe. In this case, adjustment will not help. Here you need to start replacing the entire piston group.

So you've checked every possibility and still can't figure out where the legs come from? Sometimes it happens that the cause may be engine overheating. You need to check the coolant and find out the status of the thermostat. In the event that everything is in order here, the best advice would be to go to the nearest service station.

I would like to think that in this article everyone learned something new and useful for themselves. In order to never encounter such a problem, take care of your horse, do not refuel it at unverified gas stations and sometimes do diagnostics of all its systems and components. Good luck!