A brake control element such as the brake pedal has several states of its position.

The first, which should be normal, is when the pedal is pressed without noticeable changes, without dips, jerks, without applying much effort, etc. The following two states of the pedal position are unpleasant for the driver and cause some concern.

We are talking about when your brake pedal becomes tight or, conversely, your brakes are too soft. In this state of affairs, when the brake pedal stops working in the normal, familiar mode, the driver’s concern is justified. This means that some malfunction has arisen and the brake system needs to be repaired. Without delay.

Why is your brake pedal tight?

There may be several reasons why the brake pedal suddenly becomes tight, and they may not necessarily be traditional and typical for all types and models of brakes. However, let's look at the main, most typical causes and methods for eliminating them.

In most faults that cause a soft brake pedal, either the vacuum booster or the brake master cylinder are to blame.

So, an increase in force when pressing the brake pedal occurs due to:

- The vacuum booster air filter is clogged. In this case, it is necessary to replace the air filter;

- The valve body in the vacuum booster is stuck. The solution is to replace the vacuum booster;

- The vacuum booster diaphragm is damaged. Change the vacuum booster;

- The tip of the vacuum booster is faulty - the tip needs to be replaced;

- the check valve in the vacuum booster is stuck or does not work, the check valve needs to be replaced;

- The check valve of the vacuum booster is faulty (leaky), which allows fuel to enter the cavity of the vacuum booster. It is necessary to change the vacuum booster assembly with the check valve;

- The hose connecting the vacuum booster to the intake manifold is damaged, or the hose fastening on the fitting is loosened. We change the hose or tighten the fastening clamp. Learn more about the brake booster hose. His condition must be monitored systematically. Especially during the cold season. As long as the hose is not warmed up, it remains quite rigid and the brakes work normally. After a short period of engine operation, the hose heats up, becomes more elastic, and if you do not notice its delamination, for example, its throughput decreases. There may be a problem with the brake pedal.

- The sealing rings in the working (wheel) cylinders are swollen. This can happen due to the ingress of fuel and lubricants into them, or the use of poor-quality brake fluid. Repair of working brake cylinders, replacement of brake fluid with that recommended by the manufacturer.

A couple of ways to check the performance of the vacuum booster

Start the engine. A vacuum is created in the system. Now press the brake. A hard brake pedal means a faulty booster or hose. After turning off the engine, wait about 5 minutes without pressing the brake.

Let's specify the problem. Step on the pedal. If the pedal is still hard, the vacuum booster valve is most likely faulty.

One more test. With the engine off, press the brake pedal several times to relieve the vacuum in the brake system. Without releasing the brake pedal, start the engine. If the pedal goes down slightly, then everything is fine with the amplifier.

Why are my brakes soft?

A soft brake pedal can indicate several problems. More precisely, there are several reasons why the brake pedal suddenly became soft. This effect can also be called: brake pedal failure.

Soft brakes have traditional causes:

- “airing” of the brake system. Naturally, air removal is required, i.e. bleeding the brake system. The cause of “airing” may be: depressurization of the system or low level of brake fluid in the expansion tank;

- Master brake cylinder malfunction:

- malfunction of the working cylinder, for example, as a result of jamming of the piston or boiling of the brake fluid. It is necessary to repair the brake cylinders or replace the brake fluid with new one.

Good luck to you in carrying out correct diagnostics and timely maintenance of the car’s brake system. After all, the brakes are our safety.

We recommend: How to properly tighten the handbrake on a Lada Priora

When the brake pedal is released, one of the wheels slows down

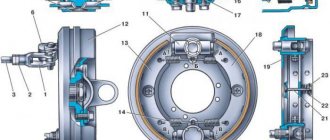

The following reasons are suspected: jamming of the wheel cylinder piston, swelling of the brake cups, deformation of the brake pipe, jamming of the pads due to contamination of the guide, peeling of the brake pad lining of the drum brake. It happens that the tension spring of the drum brake shoes is weakened or broken, the parking brake is overtightened, or the cable is stuck in the sheath.

- Do you know which faults you can drive with and which ones you cannot? Take the test and check your driving skill level.

- To increase the life of your car, use additives from SUPROTEC. Original SUPROTEC products can be purchased at.

Tools for leveling

Let's consider the pumping process using the example of Volga-made cars. So, for this we need:

- Transparent silicone tube (its diameter should be identical to the fitting on the caliper or drum).

- Keys for 8 and 10.

- Ballonnik.

- Jack, anti-rollbacks.

- Container for draining old fluid. An empty mineral water bottle will do.

By the way, recently special wrenches for unscrewing brake fittings have begun to appear in stores. How are they useful? Unlike horn-type tools, they use more edges. But the fitting tends to turn sour (it is located in a very dirty place). Therefore, there is a risk of “licking” the edges of the bolt.

Procedure

Success and high-quality pumping of the brake system lies in following the entire technology of action:

- The first step is to replace the fluid in the GTZ tank or check its quantity and, if necessary, top it up to the maximum level.

- For more comfortable work, it is necessary to clean all air release valves on each wheel from dirt, dust and deposits.

- According to the correct sequence provided in the instructions, it is necessary to unscrew the fitting plug on the desired wheel and attach the prepared hose over the valve.

- The second end of the tube is placed in a previously prepared container with brake fluid.

- The partner progressively presses the brake pedal from 3 to 5 times and at the last movement fixes the pedal in the pressed position.

- At this time, you need to unscrew the air valve halfway. After opening the valve, liquid along with air bubbles will begin to flow through the tube into the container. When the pressure of the liquid escaping into the container disappears, the valve can be screwed back firmly, and your partner can release the brake pedal.

- The process may have to be repeated several times on each node. The main thing is to maintain the wheel sequence and control the amount of fluid in the master cylinder reservoir.

After pumping is completed, you need to make sure that the fitting plugs are tight and that the brakes are operating. After the test, if successful, the brake operation will return to normal. If the driver still feels problems in operation, then perhaps attempts to bleed the brakes with their own hands were unsuccessful, or there is a problem with the wear of the pads or discs.

content .. 141 142 143 144 ..Lada VAZ-2110 (2111, 2112). Increased brake pedal travel (brake pedal falls through)

Reasons for increased brake pedal travel

| Inspect all lines, their threaded connections and cylinders, and eliminate leaks. Restore the normal fluid level in the brake reservoir and bleed the system. If you find damage to the brake hoses (cracks, swelling or traces of brake fluid), replace the hoses. If you suspect defects in the master brake cylinder, replace it with a good one. | |

| The rubber cuffs of the cylinders are swollen due to oil, gasoline, etc. getting into the brake fluid. | Replace cylinders, hoses, completely drain the brake fluid, flush the system with fresh fluid and bleed |

| Overheating of brake mechanisms | Allow the brakes to cool. Use only DOT-4 brake fluids in the system. Replace brake fluid promptly |

| The gap between the pads and the drum has been increased (the automatic gap adjustment device does not work) | Replace the wheel cylinder, bleed the system |

| One of the circuits of the service brake system does not work | Eliminate fluid leakage from the brake system, bleed the system |

| Leak in the brake master cylinder | Fix the leak |

| Loss of elasticity of the internal rubber bands of the brake master cylinder | If you suspect defects in the master brake cylinder, replace it with a good one. |

| Increased (more than 0.15 mm) runout of the brake disc | Replace both drives |

The brake pedal falls off after starting the engine

There may be several reasons for such a malfunction. Quite often, diagnostics must begin with checking the brake fluid level in the reservoir. Any hydraulic system has the specified compensation tank. The tank has “min” and “max” marks, which determine the normal amount of fluid in the system.

The fact is that although the brake fluid is incompressible, the volume of fluid in the system changes. This occurs due to the fact that brake pads tend to wear out during use. As a result, the RTC pistons extend further to move the pads, which requires more fluid in the system. For this reason, the minimum level of working fluid in the tank is determined. When the amount of fuel fluid drops below the minimum, then air enters the brake system circuit, that is, airing occurs.

If the brake pedal fails, the causes of such a malfunction can often be a critical decrease in the fluid level or air ingress. When pressed, the brake pedal goes to the floor all the way, the brakes do not work completely or barely work. To prevent possible consequences, the level of brake fluid in the expansion tank must be checked visually, without waiting for the moment when the emergency lamp lights up on the instrument panel in the cabin.

If the ABS brake pedal suddenly fails or the pedal falls to the floor on cars without an anti-lock braking system, and checking the fluid level in the reservoir does not give anything (the level is normal), then overheating of the brakes may be the culprit. Brakes overheat in cases where there is intense and frequent braking at high speeds, constant and prolonged driving at low speed with the brake pedal pressed (for example, descents on mountain serpentines). More often, deterioration of the system in such modes occurs in conjunction with high outside ambient temperatures.

After replacing the brake pads, the brake pedal fails

New brake discs and brake pads should be worn in. While the grinding is not completed, the car may jerk after pressing the brake, the brake pedal begins to vibrate, and when braking, light vibrations can be transmitted to the steering wheel. Let us add that the general grinding in of new pads and discs takes from 250 to 400 km. mileage If the symptoms do not stop, then you should check the quality of the parts and the correct installation of the elements.

A common cause of brake problems, where the brake pedal slowly sinks, is a damaged or misaligned brake caliper that is present in the design of the brake system. The displacement of the vertical axis of the caliper relative to the axis of the brake disc does not allow the system to work normally. Also, the caliper may be in good working order, but poorly secured. In such cases, the brake pads are simply not able to properly rub into the disc.

When the engine is running, the brake pedal falls down

The most common reasons for the brake pedal to fail when the car is running are air in the system, problems with the turbocharger, low fuel fluid level, critical wear of the pads/discs, overheating of the brakes, etc.

When the brake pedal does not fall, but remains very stiff after starting and the effectiveness of the brakes is greatly reduced, then the brake booster should be checked. Additionally, its malfunction is indicated by the fact that the engine speed fluctuates when you press the brake, although the fluid does not leave the brake system reservoir, and also when the engine is turned off, the brake pedal always remains elastic, and not after several presses.

The brake pedal fails: the brake fluid does not drain

If there is a leak, the brake system inevitably becomes airy. It turns out that if the brake pedal sinks, but the fluid does not leave, this does not mean that the system is sealed. Two or three drops of fuel oil will not affect the level in the reservoir, the leak itself may be difficult to detect, but the brakes will not work properly.

Brake fluid may be leaking through the master cylinder, but the leak can only be detected by disconnecting the master cylinder from the brake booster. It often happens that the cylinder is not completely filled.

After changing the brake fluid, the brake pedal fails

First of all, this may mean that air remains in the system.

If the brake pedal fails after repair, then there is a high probability that errors were made during assembly, the system is not pumped well enough, there are brake fluid leaks, etc.

Brakes lost after heavy braking

The reason may be a break in the brake hoses, tubes, or breakdown of the brake cylinders (main or working). The brake pedal also drops sharply when there is severe wear on the discs or brake drums or brake pads. In this case, the piston of the working cylinder is pushed out.

Another reason may be overheating of the brake fluid during very active braking (brake overheating).

content .. 141 142 143 144 ..

Now in more detail about the reasons for the failure of the brake pedal

Brake fluid. Poor quality brake fluid or partial dilution with condensate, which occurs over time, affects the properties of the brake fluid. Condensation, or, more simply, water, is subject to compression, and as a result, when you press the pedal, it may fail.

In addition, due to the non-compliance of the brake fluid with quality requirements, the brake system, or rather its lines, can be gradually destroyed by the aggressive composition of such a “brake fluid”. As a result, fluid leaks (when pressed) or air leaks (when the pedal returns to its original position), and when the brake pedal is pressed, it fails.

Air leak. Air leaks can not only worsen the characteristics of a turbocharger, but also, on top of everything else, it can form air plugs in the brake lines. These plugs can compress under pressure, unlike liquid, which, as I said above, does not compress under pressure. As a result, it turns out that when you press the brake pedal, it fails because the air is compressed. Despite the failure of the brake pedal, the pads practically do not move and braking does not occur, since the necessary pressure is not generated in the system for the movement of the brake piston. Therefore, no matter how much the driver presses the brake pedal to the floor, effective braking will not occur.

By the way, it should be noted that air in the brake system is not always a sign of a leaky system; air often occurs during the replacement of the brake fluid when the brakes are not pumped correctly.

Malfunctions of the main brake cylinder (GTC). One of the most common failures of the GTZ is deformation (swelling or destruction) of rubber seals. This phenomenon occurs due to a number of reasons, including the influence of the aggressive composition of low-quality fuel fluid and, of course, natural wear (aging, tanning, swelling) of rubber parts. Any leakage results in a gap appearing in the system, through which air can easily enter the brake system, as well as leakage of the brake fluid itself.

The solution to this problem is quite simple, at first glance - it is necessary to replace all rubber seals, thereby eliminating the possibility of further leakage of fuel fluid or air leaks. However, this is only at first glance; in fact, this work is quite unpleasant from a technical point of view and requires certain skills and patience. That is, you will have to not only replace all the rubber bands and seals, but also make a full replacement of the brake fluid, and then bleed the entire system in order to remove air from the system.

Vacuum brake booster (VUT). Malfunctions of this unit, as a rule, manifest themselves in the form of hissing when the brake pedal is pressed; this phenomenon indicates a leak in the VUT. Depressurization occurs for various reasons; this may be a malfunction of the valve or diaphragm, as well as the seals of the vacuum booster.

Solving the problem of a faulty vacuum booster involves replacing failed elements. Rubber seals and oil seals, as I said above, can become unusable over time for the reasons described above. As a result, a malfunction of the VUT occurs, which requires immediate intervention. Also, pipes often fail, and cracks appear on the amplifier diaphragm, after which the unit stops functioning properly.

Violation of clearances in the brake system. Due to incorrectly adjusted gaps between the brake pedal and the brake pedal, the brake pedal may fail or operate ineffectively. With the correct clearance, after pressing the pedal, it first moves smoothly, and then resistance gradually begins to appear. The increased gap manifests itself in the form of a sharp dip already in the first seconds of pressing the pedal, and only at the end of the pedal movement does some resistance begin to arise, and not always. In this state of affairs, as you understand, effective braking is out of the question.

If you experience failures in the brake pedal when pressed, and you are unable to detect the breakdown or your searches have not yielded results, seek help from specialists. Please note that if the brake system malfunctions, driving to the service station under your own power is PROHIBITED! Call specialists to your home or use the services of a tow truck

Remember, your life, as well as the lives of other road users, depends on the proper and effective operation of the brakes! That's all I have, thanks for your attention! I look forward to your comments on the topic of brake pedal failure, and I would also be grateful if you share your story of solving this problem

Stiff and soft brake pedal (problems and solutions)

Details Published: 06/13/2012 05:26 Author: Admin SuccessfulAuto.ru

Stiff and soft brake pedal (problems and solutions)

The study of the most classic defects in the brake system of a car, which are determined using a brake testing stand, continues. Such a component of brake control, such as a stiff and soft brake pedal (problems and solutions ), includes a couple of states of its position. The first is normal, when the pedal is pressed without noticeable changes, without dips, jumps, without special efforts, and so on. The next two circumstances of the pedal position are unpleasant for the driver, and which cause specific anxiety.

It is said that when the brake pedal becomes stiff or, on the contrary, the brakes are very soft. In this situation, when the brake pedal stops working normally, the driver’s anxiety is justified. This indicates that some defects have arisen and the brake system needs to be repaired. At the same time, without putting it off for a long time.

There may be a couple of reasons why the brake pedal has suddenly become tight, and they are not necessarily traditional and typical for all types and brands of brakes. Despite this, the key, most common causes and ways to eliminate them are considered.

Most of the defects that cause a stiff and soft brake pedal are “to blame”: either the cryogenic booster or the main brake cylinder. Increased effort when pressing the brake pedal is due to the fact that the air filter of the cryogenic booster has become dirty.

In this case, you need to change the air filter; jams the valve body in the cryogenic amplifier. The solution is to change the cryogenic amplifier; The partition of the cryogenic amplifier is broken.

Change the cryogenic amplifier; faulty tip of the cryogenic amplifier - the tip needs to be changed; the opposite valve in the cryogenic amplifier is jammed or does not work, the opposite valve needs to be replaced; The check valve of the cryogenic amplifier is faulty (leaky), which allows fuel to enter the cavity of the cryogenic amplifier.

It is necessary to replace the cryogenic amplifier complete with the opposite valve; the hose that connects the cryogenic amplifier to the intake manifold is broken, or the hose is loosened on the fitting. The hose is changed or the fastening clamp is tightened. Learn more about the cryogenic brake booster hose.

Its condition must be monitored regularly. Especially in the cool season. As long as the hose is not steamed, it remains somewhat stiff, and the brakes work normally. After running the engine for a short time, the hose heats up, becomes more elastic, and its throughput decreases. There may be a problem with the brake pedal.

The sealing rings in the working cylinders are swollen. This can happen due to the penetration of fuels and lubricants into them, or the use of low-quality brake fluid. Repair of working brake cylinders, change of brake fluid to the one recommended by the manufacturer.

Several methods for checking the performance of a cryogenic amplifier:

Start the engine. A vacuum occurs in the system. Then he presses the brake. A hard brake pedal indicates a defect in the amplifier or hose. After stopping the engine, wait about five minutes without pressing the brake.

Specification of the defect. Pressing the pedal. If the pedal remains hard as before, then it is most likely a faulty cryogenic booster valve. With the engine turned off, it is worth pressing the brake pedal a couple of times to remove the discharge in the braking system. Without releasing the brake pedal, you need to start the engine. If the stiff and soft brake pedal (problems and solutions) goes down a little, then everything is fine with the booster.

A soft brake pedal can indicate several defects. Namely, there are a couple of reasons why the brake pedal has suddenly become soft. This effect can also be called: failure of the brake pedal.

A stiff and soft brake pedal (problems and solutions) have traditional causes: “airing” of the brake system. Of course, air must be removed, namely in the form of bleeding the brake system.

The reason for “airing” is possible: once the system is sealed or the brake fluid level in the wide reservoir is too low; defect of the main brake cylinder: defect of the working cylinder, for example, as a result of a stuck piston or boiling of the brake fluid. The brake cylinders need to be repaired or the brake fluid needs to be replaced with new one.

How to properly charge a car battery, Adjusting the handbrake with your own hands, Changing the front and rear dampers with your own hands, How to insulate the engine

Comments:

- In contact with

- Back

- Forward

The brake failed at full speed: what to do?

First, try pressing the pedal sharply several times: perhaps its functionality will be partially restored. Next, assess the situation and identify a place where you can gradually turn. Then tighten the handbrake (don't do it too hard) and start shifting (if you have a manual transmission) to a lower gear. At the same time, when the lever is in “neutral”, press the accelerator (perform “re-throw”) to “prepare” the gearbox gears for emergency operation. As a last resort, choose the lesser of two “evils” - it is better to run into some obstacle near the road (roadside bushes are a good option) than to collide with a car.

Strong vibration/beating

You should contact your mechanic immediately if you experience vibration or squealing on your newly installed brake rotors. He will be able to find the cause of the beating and check whether the disks are installed correctly

It is very important to fix this problem before the parts wear out, otherwise they will need to be completely replaced. Strong vibrations and beating can be due to the following reasons:

- due to improper balancing,

- due to severe tire wear,

- if the brake caliper cylinders are jammed,

- the suspension may be badly worn,

- when the surface of the brake disc is severely worn.

To fix the problem, first check that the brake disc is installed correctly. This is best done by a mechanic who checks the brake rotor using a digital axial and radial runout indicator. If runout and vibration occurs at low speeds, it is most likely from worn brake discs. If at high speeds (from 100 km/h) this is already the so-called hot vibration, and it occurs from overheating of the brake discs. Overheating in brake discs may be due to a mismatch in the friction material of the pads used in the vehicle, or if the manufacturer uses low-quality material for the workpieces.

Modern developments make it possible to improve thermal conductivity thanks to new components for the manufacture of the brake disc. Now the brake pad material contains moderate abrasive, which allows the surface of the brake disc to wear out carefully and the pad will be operational for a longer period.

Other reasons why front brakes stick

The front wheels do not always jam the same way; this can manifest itself in different ways. Both front wheels can “stick” at once, and you simply won’t be able to move. It happens that they seem to be spinning, but with great difficulty, making a creaking sound. This is a dangerous situation, especially if you ignore the problem and continue driving. Only one front wheel can jam, while the other spins freely. Let's look at the possible reasons.

The brake pedal is poorly adjusted or has no free play at all.

There must be sufficient clearance between the master cylinder piston and the pusher for the pedal to move normally. This is adjustable.

The brake pad tension spring is faulty.

This does not mean that it is cracked or completely torn, perhaps just stretched. There is such a thing as metal fatigue, and a weakened spring will no longer function normally; it is better to replace it.

Another reason why the front brakes stick is that the vacuum booster is not in order.

It can jam for several reasons. Perhaps the diaphragm is swollen, or the protective cap or lid seal is pinched.

Pay attention to the amplifier adjusting bolt

It should not be too tight. It is important that it protrudes slightly above the surface of the master cylinder.

There is something wrong with the brake pad friction lining.

The problems can be different: the gasket wears out, breaks, or becomes too thin. This usually leads to damage to the pad itself, so in this case it is necessary to change both it and the lining

Important: if you are changing a worn gasket, then the pair to it should also be replaced; they must be the same in thickness, otherwise the car will be pulled off the line of movement to the side.

The reason that the front brakes are sticking may be a stuck piston in the wheel brake cylinder.

This kind of trouble can happen in any car, so you need to be able to deal with it. The reasons for this situation are different: low-quality brake fluid, uneven position of the cylinder body in the caliper, rust and corrosion on the working surfaces of the piston. Disassemble the problematic cylinder, clean all components, rinse with brake fluid, reassemble the system and bleed. Fill with good quality brake fluid.

The cuffs on the wheel cylinder have lost their shape or are swollen - this is also one of the reasons why the front brakes stick.

The cuffs of the master cylinder or wheel cylinders swell from fluids such as oil, gasoline and others that have entered the brake system. This jams the cylinders, which results in a problem with the brakes. But you just have to replace the cuff, and everything will work out. It is recommended to at least occasionally check the condition of the cuffs, and when disassembling the car (no matter for what reasons), replace them, even if these elements appear to be completely intact.

Oxidation stains on the guides.

They need to be cleaned, lubricated, and you will no longer have to think about why the front brakes are sticking.

The compensation hole on the brake master cylinder is dirty.

This is a labor-intensive process, a large and messy piece of work, but no spare parts will be needed, meaning repair costs will be minimal. It is necessary to clean the hole and bleed the brake hydraulics.

The pistons of the master cylinder as well as the wheel brake cylinders are stuck.

In this case, only experienced car owners who have already disassembled and reassembled various systems of their car more than once will be able to figure out why the front brakes are jamming. It is better to entrust the diagnostics to specialists: they will find the cause of the malfunction and immediately begin repairs.

It often happens that it is enough to just thoroughly clean and lubricate the necessary parts. Check the hoses to see if they are in order. It often happens that the hose is pinched by the clamp holding it, especially if it is corroded. This can also cause the front brakes to jam. The best thing in this case, of course, is to replace the clamp with a new one. But you can just loosen it slightly and blow out the hose well.

It is perhaps not so easy to immediately determine why the front brakes are jamming. This can happen for many reasons, and if you yourself are not very versed in the operation of car systems, then it is better to entrust the inspection and repair of the car to service station specialists. After all, a properly functioning braking system is the key to both your safety and that of other road users.

The front brakes are sticking. Causes, elimination. Watch the video:

https://youtube.com/watch?v=qZ70UPly3kc

Malfunctions of the "vacuum"

A vacuum brake booster (VUT), or simply a “vacuum booster,” creates in the vehicle’s vehicle the pressure necessary for their proper operation.

If the amplifier is not working well, the pedal simply won't push through. Since the vacuum booster is a rather complex part consisting of many components, a malfunction of any of them can lead to this situation. And since a breakdown of an amplifier component, as a rule, requires its replacement, correct diagnostics will help save the car owner not only time, but also money.

If the filter element of the “vacuum tank” is clogged, it is enough to replace it so that the amplifier begins to function normally again. This also applies to a damaged vacuum booster diaphragm, and problems with the tip or check valve. It is enough to replace one damaged component, and the vehicle will act like new again. It is important to accurately diagnose what exactly needs to be changed.

Sometimes no major replacements are required at all. For example, in a situation where the vehicle is depressurized. The seal can be broken in two cases: either the hose between the “vacuum reservoir” and the intake manifold is damaged, or the clamps are loose. And if in the first case replacing the hose is still necessary, then in the second it is enough to tighten the clamps. This can also be done at a car service center, but the car owner is quite capable of dealing with such a problem on his own.

But it happens that the unsuitability of only one component completely renders the VUT unusable. This most likely occurs in a situation where vehicle malfunctions are ignored for a long time. As a result, a badly damaged valve moves to such a position that it disables the entire “vacuum tank”. An example is damage when a valve jams in the amplifier, and the latter has to be completely replaced. This is one of the most expensive types of vehicle repair.

We recommend: The starter on the “Nine” does not turn: we are looking for the cause and a way to eliminate it

The brake pedal is too soft

If pressing the pedal has become too soft, it means there are air bubbles in the hydraulics and then the system should be pumped, or there is a loss of working fluid. The first thing you need to do is check the brake fluid level. If it is below the permissible level, the hydraulic system must be carefully checked for leaks. A leak may occur at the connection points between the tubes and fittings due to poorly clamped clamps, and the hoses themselves may be damaged. Working fluid can also be lost in wheel brake cylinders if the seals are damaged. After eliminating the leak, you will also need to bleed the brake system hydraulics to remove air from it.

If the brake fluid is of poor quality, contaminated, or has not been changed for a long time and has lost its properties, then heating during sudden braking can quite easily lead to its boiling, and then the brakes will become “wobbly” and the car itself will be difficult to control. An old, dirty, or inadequate brake fluid can cause seized brake cylinders, damaged seals, and other problems.

The conclusion is obvious - pay attention to the condition of the brake fluid and change it in a timely manner

Another reason for a soft brake pedal is the hoses, which are made of rubber and wear out over time, becoming loose. When hydraulic pressure builds up during braking, they simply inflate. As a result, the brakes become too soft and braking becomes less effective.

An extreme and very dangerous manifestation of soft brakes is pedal failure. This occurs due to significant leakage of fuel fluid or damage to the sealing rings in the gas turbine engine.

An excessively soft brake pedal, and even more so if it fails, requires an urgent solution to the problem. You need to stop immediately, braking with the engine or handbrake, and then find and correct the problems.

Soft brake pedal: reasons

Once you've figured out why your brake pedal may be hard, pay attention to the equally common problem of the brake pedal becoming soft. Then the brakes may be weak and faulty, which is just as dangerous as a hard pedal.

In extreme cases, when the brake pedal is depressed, it may not rise or drop to the floor during braking. Of course, if the pedal is “wrapped” into the bushing, owners wonder what is the cause of the breakdown, why the pedal is soft after pumping the brakes, and how to make the brake pedal harder.

If bleeding has already been done, there is a high probability that mistakes were made, there are undetected faults, brake fluid leaks, etc. For example, drivers often encounter the problem of a soft pedal after replacing the brake pads, a damaged brake pedal after replacing the brake fluid, a damaged brake pedal after bleeding, but the fluid does not drain, etc.

One way or another, the main reason is that the pressure in the brake system is low. Lines are chipped and cracked, brake cylinders may also have problems, and contaminated brake fluid can damage the brake cylinder surface. It is possible that the brake pistons may jam.

It is necessary to check connections, fittings and other elements in parallel, since even a few drops of brake fluid leakage will not affect the level in the reservoir, and air enters the system, which is caused by soft pressing of the pedal.

It should also be taken into account that if some elements of the brake system have been replaced (discs, pads, drums, brake cylinders, etc.), then the braking efficiency in this case will be slightly lower until you get used to the parts. . In this case, the brake pedal may also be softer than usual for several tens of kilometers, or the brake pedal will be soft at first and then too tight.

If the brake fluid is dirty, old and worn out, it may boil when heated. This can cause the brake pedal to break or become too soft (“cotton-wound”). This situation is so dangerous that the so-called “floating” character can be a problem. If you notice these symptoms, you should start with a complete brake fluid change.

If the brake pedal is pressed hard: diagnostics

As you can see, a tight brake pedal is often due to problems with the vacuum booster. At the same time, its operation can be quickly checked on the spot.

To diagnose VUT, you can use two methods. In the first case, you need to start the engine for the vacuum booster to start working. Normally, the pedal is soft; after two or three strong presses on the brake, the engine speed will briefly increase.

If, after starting the engine, the brake pedal is hard, then you need to check the hose or the booster itself. Also, a lack of pedal softness may be associated with the brake booster valve. Problems are indicated by hissing and extraneous sounds when you press the brake.

Another test involves pressing the brake several times with the engine off. Normally, the pedal should be soft for 2-3 presses, then it becomes hard. After this, you should press the brake and start the engine without releasing the pedal. The pedal should go down after the engine starts. If this does not happen, then you also need to look for a problem with the VUT.

The brake pedal has gone to the floor - what to do?

If the brake pedal becomes soft, that is, it begins to sink significantly, you should immediately check the entire brake system of the car. Most likely, diagnostics will be required at a service center and further repairs.

The main thing is to contact the service center in time

It is important to remember that all malfunctions of this kind are fraught with consequences. Brakes with a defect can fail while driving; this can probably happen on a busy avenue; such a car can only be stopped even at an average speed by colliding with some other vehicle or structure. If the brake pedal is easy to press, there may be several reasons:

- the brake cylinder is not able to hold fluid and the corresponding pressure; there may be significant wear on the cuffs and rubber gaskets;

- the wrong fluid has been filled into the brake tank;

- there are problems with the pads or discs;

- there are defects in the operation of the vacuum pump;

- The traction pedals may exhibit rust.

Problems with the brake system are clearly indicated by the presence of vibration, hissing and tapping in the pedal when it is pressed.

Swelling of rings in cylinders

The condition of the brakes largely depends on what kind of brake fluid is used during operation. If it is a product of a well-established company, the vehicle is rarely damaged or disabled. But if the fluid is of poor quality, one or more cylinders may not function well due to their O-rings swelling. The same thing happens when fuel and lubricant gets on the ring.

Previously, especially in the era of the Soviet automobile industry, the car owner sooner or later had to sort out the working cylinders. Such an activity was long and burdensome even for professionals. But now hardly anyone will do this if the vehicle is faulty. From the point of view of saving time, it is much easier to change them, and at the same time the brake fluid. However, you can avoid unnecessary financial costs if you use high-quality, albeit expensive, liquid from the very beginning, since repair costs are always higher.

Taking into account the above, it becomes clear that any deviations from the norm in the operation of the brake system (either a soft brake pedal, a hard brake pedal, or a combination of problems) require immediate diagnosis. After identifying the malfunction, it is necessary to properly eliminate the problem.

Let's sum it up

Taking into account the above, it becomes clear that any deviations from the norm in the operation of the brake system (either a soft brake pedal, a hard brake pedal, or a combination of problems) require immediate diagnosis. After identifying the malfunction, it is necessary to properly eliminate the problem.

You also need to promptly change the fluid, bleed the brakes, inspect the brake hoses for defects and leaks, install new brake pads, discs or drums in a timely manner, lubricate the brake caliper guides, etc. This approach will allow you to safely operate the car and achieve high-quality performance of the braking system in any conditions.

The brake pedal falls to the floor, the brakes disappear unexpectedly, after replacing the brake fluid, pads, brake discs: the main causes of the malfunction.

Reasons why the engine may stall when you press the brake. The power unit stalls during sudden braking, when the clutch and brake are depressed, etc.

What is engine braking? How to perform this technique correctly. Pros and cons, sleep recommendations. Engine braking on cars with automatic transmission.

How to brake correctly in a car with a manual transmission: types of standard braking on a manual transmission, emergency and emergency braking, tips.

The clutch pedal has fallen: why does this happen? The main reasons why the clutch pedal fails, what should the driver do if the clutch fails.

Driving a vehicle always involves various risks. A high-quality braking system can avoid most of them. Thus, if you find a hard or soft brake pedal, you need to immediately address this problem. If such problems arise, you should not delay; it is better to conduct a thorough diagnosis to find out what exactly is the cause of the problem.

Attention: brake fluid

It is most often to blame for the failure of the corresponding pedal.

Low level

Filling brake fluid in the expansion tank. There is a mark on it indicating the minimum volume required for normal brake operation. If the fluid drops below the line, air enters the system, the pedal stops feeling resistance, and the car stops braking.

It is advisable that the brake fluid does not drop to a minimum, since as the pads wear, the pistons push them deeper and deeper, therefore, more fluid is consumed. That is, at any moment it can fall below the required level. You need to check the amount of liquid regularly, even if the corresponding light bulb does not give a signal.

The next type of trouble that brake fluid can cause is the result of the negligence of the car owner himself. Filling brake fluid of the wrong class (for example, DOT3 instead of DOT 4) or mixing fluids from different manufacturers leads to corrosion of the seals and seals, clogging the entire brake line or a section thereof.

Boiling of the brake fluid leads to the fact that, if it corresponds to the class and the normal level in the reservoir, the pedal stops being caught right on the move. Everyone knows that overheating your brakes is unsafe. If it is not possible to avoid aggressive driving, especially in the summer heat, it is worth replacing the brake fluid with high-temperature fluid, and the brake discs with cooled and ventilated ones.

When checking the level and condition of the brake fluid in the event of a pedal failure, all hoses, cuffs, gaskets and seals are inspected in parallel: loss of tightness by the system is the second most likely reason for air from the atmosphere entering it.

Mono: how to change car brake fluid for one person without assistance

There is only one way to solve the question of how to replace brake fluid for one person. His goal is to update the composition in the tank and lines without using the help of a partner. The features of this method are similar to bleeding the brakes:

- To speed up the process, it is recommended to immediately remove the working emulsion from the expansion tank using a bulb or a syringe with a tube attached.

- The preparatory stage consists of purchasing 1 liter of brake fluid and a 1 meter long tube, suitable in diameter to the outlet fittings on the brake cylinders. You will also need a cut-off bottle with a certain amount of working fluid so that air does not pass through the fitting into the system.

- During the process of replacement/pumping, the composition gradually leaves the tank. The level must be replenished regularly, otherwise the system will become airy.

Process technology

The essence of the replacement is the flow of the working fluid under the influence of gravity. After all, the tank is at the highest point. In fact, the operation is no more difficult than checking the injectors of a diesel or gasoline engine. As a result, the set of actions is as follows:

- Empty the expansion tank and fill it with new fluid up to the MAX limit mark.

- Clean all 4 drain fittings and install tubes on them. Place the latter in plastic containers with “brake fluid”.

- Unscrew all the drain fitting nuts one by one:

- right rear;

- left rear;

- right front;

- left front.

- While watching how the composition drains, do not forget to add a new drug to the tank.

- When the volume of liquid poured from the left front wheel reaches approximately 200 ml, tighten the fittings on it and on all other cylinders in the reverse order:

- front left;

- front right;

- rear left;

- rear right.

- Restore the fluid level in the tank.

- Clean the fitting and put a tube on it, lowered into the brake fluid.

- Create pressure in the retarding system.

- Unscrew the union nut and wait until the liquid pressure decreases to low.

- Close the fitting.

- Repeat until liquid comes out without bubbles.

Leveling up

The method is relevant if there is no air in the deceleration system. If there are air bubbles in the unit, the emulsion will not drain under the influence of gravity. Excessive pressure is required to bleed it off - just like in production. In this case, replacing the composition comes down to bleeding the brakes:

Excessive pressure in the system can be created in several ways:

- Find an assistant or pump the brake pedal yourself and press it with a gas stop from the hood/trunk installed between it and the seat.

- Insert the syringe with the emulsion into the lid of the tank and seal it. Having opened the fitting, press the syringe pusher.

- Install the car nipple into the cover. Seal with sealant or superglue. Remove the nipple and install the tube. Install the opposite end of the hose onto the quick-release tip of the pump. Take excess pressure from the spare tire. You can do it even simpler - apply pressure from the compressor to the spool.

What to do if the brake pedal becomes hard

If the pedal becomes hard, it is necessary to determine the cause and eliminate it. A dirty air filter must be cleaned, and faulty limit switches, valves and hoses must be replaced. Usually this is enough for the system to work. If during diagnostics it turns out that the diaphragm is damaged, the entire amplifier will have to be replaced.

If the problem lies in the brake cylinders, they are repaired, including replacing seals and cuffs. In some cases, old parts are removed and new ones are installed in their place.

Is it possible to do something right away?

The best thing to do if you suspect a vacuum booster is broken or its elements are worn out is to go to the nearest car service center or replace the damaged parts yourself.

If there is an assumption that poor-quality brake fluid is to blame, it needs to be replaced. In this case, it is necessary to completely pump out the old one, and pour in a new one in its place. Otherwise, the situation will improve only slightly.

To regularly check the brake fluid, it is better to buy an electronic tester that measures the boiling point. If it exceeds +175°C, it means the fluid has recently been changed. If it varies from +165 to +175°C, the properties have deteriorated, but it can still be used. The fluid needs to be changed if it was filled more than 2 years ago or its boiling point has dropped below +165°C.

Video: Replacing brake fluid

Hard pedal - failure of the vacuum pump or vacuum booster or leaking vacuum hose. Or the master cylinder wedge.

avgor123

https://www.bmwclub.ru/threads/propadajut-tormoza-tverdaja-pedal.896947/

I had the same problem, if I let someone drive my car, they complained that the brake pedal was hard. They were sent with the statement that normal, well, there is strength - the mind... As a result, during the next maintenance, it turned out that the CH was a little high (gasoline). When I started looking into it, it turned out that air was being sucked into the vacuum brake booster through a worn-out gasket. At high speeds there is sufficient vacuum, but at low speeds the pressure gradually drops. Replacing the gasket solved the problem...

Mirage

https://audi-belarus.by/forum/viewtopic.php?t=44405

I also struggled with this pedal for a long time. I'll pump it up for a couple of days. Then again. The vacuum operator with the main brake also made a mistake. Then I replaced the pads at the rear and the problem disappeared.

aleks-tol

https://www.drive2.ru/c/2425257/

In order for the brake pedal to work well, you need to regularly change the fluid, lubricate the caliper guides, and inspect the VUT elements for damage.

The brake pedal fails (the brakes are too soft)

It is worth noting that if you feel weak braking when pressing the brake of a VAZ 2109 or any other model, you need to think about the fact that these may be features of a particular vehicle. Perhaps you just moved from another car, so you feel some discomfort while driving a new car.

On the other hand, such a symptom can also occur when air enters the system. It should be noted that in the event of depressurization of the system, the pipeline may completely burst and completely fail. This can be corrected by bleeding the brakes. At the same time, you should diagnose the cylinders, check the level of the brake fluid, as well as its quality (often air gets into the brake system simply because there is too little fluid) and perform a full check of the vehicle (the latter will help determine the presence of hidden problems) ;

If the pedal becomes soft after replacing the brake fluid, then, as a rule, the problem lies in the use of a low-quality mixture. Alternatively, it is possible that air got into the system during replacement - this is also worth paying attention to.

It is also quite common for the pedal to feel soft after bleeding the brakes. First of all, you should bleed the master cylinder. As a rule, this solves a similar problem. Alternatively, there may be problems with the anti-lock braking system (if equipped). In any case, if the brakes are soft after bleeding, you should approach this task responsibly. Perhaps you should contact specialists who can quickly and effectively fix the problem.

It will also be interesting: The starter takes over the current: what to do?

Video about the operating principle of the brake master cylinder:

Soft brake pedal after replacing pads: reasons

As you know, brake pads are a part with a limited service life. Moreover, on powerful cars and cars that are used aggressively, the pads can be considered a “consumable” item. Moreover, this simple part is the most important element of the brake system, since it is the brake pad that comes into direct contact with the brake disc or drum, stopping the wheel.

One way or another, during the operation of a car, the pads are changed quite often. The procedure is not complicated, but drivers often notice that after replacing the pads, the car does not brake well, the brake pedal sinks, the brakes feel weak after replacing the pads, etc. Let's look at what to do in such a situation and how to solve the problem.

Read in this article

The brake pedal has become hard: the reason

Thus, during operation, you can determine that the brake pedal has become hard, medium or too soft. The reasons for a tight pedal, that is, a situation where a car has a too hard brake pedal, can be either the design of the car or a malfunction. In other words, a hard brake pedal may be normal for some car models. However, if the brakes become hard for another reason, repairs are necessary.

To transfer pressure, brake fluid is poured into the system. The fluid is carried through steel pipes and rubber hoses from the main brake cylinder to the brake wheel cylinders. The brake pump with its pistons exerts pressure on the brake terminals, pushing the brake pads onto the disc or brake drum.

If the brake pedal is too hard or not depressed, it could indicate a problem with the vacuum assist system. Please note the following faults:

- Failure limit switch for vacuum brake support. Replacing the limit switch solves the problem;

- The vacuum assist system also has a special check valve. If the valve sticks or does not work, a specific element must be replaced;

- The VFT may also be equipped with a clogged air filter, which prevents contaminants from entering the layout. If the filter is clogged, it will also cause the brake pedal to become clogged;

- The auxiliary device also has a special check valve. If the header is clogged, replace the element;

- Often the cause of a stiff brake pedal after a few presses or a stiff brake pedal after parking is the brake support membrane. The VFT membrane is torn or cracked and will replace the entire amplifier;

- At the same time, what can happen is that fuel gets into the support chamber (often due to a damaged corner), which also immediately affects the brake pedal;

- One of the common causes of a hard brake pedal that won't press down is the cable that connects the intake manifold to the mounting assembly. Said hose consumes and deforms, meaning it may need to be replaced over time. It could also be that it is loose on the connector. In this case, the problem can be solved by tightening;

- The list is complemented by the use of contaminated brake fluid, which has lost its properties, introducing other fluids to the brake cylinders, as well as swelling of the seal. To fix the problem, replace the gaskets and flanges (brake cylinder repair) and replace the brake fluid. In some cases, it is necessary to replace all brake cylinders.

Air in the brakes how to fix the problem

Brake vacuum is the most common cause. It’s another matter if the texture of the sound differs significantly from the ear. That is, the hissing turns out to be quite loud and, as it were, choking.

At the same time, when pressing on the brake pedal when it is cold, we feel its movement being excessively stiff. And also - the buoyancy of the engine speed (and sometimes it can stall)

In such cases, you should pay close attention to the vacuum booster as a possible cause of the problem.

Well, a tight pedal, of course, could also be due to frost, for example, until the main one warms up. But the revs and a fairly strong hiss are already direct indicators that you need to look under the hood! How to check it?

The car's braking system is subjected to constant loads, and with the so-called sporty style of city driving, it is also subject to overloads. This happens regularly even with a measured and leisurely rhythm - there is no escape from this problem. Therefore, this unit must be regularly tested to ensure maximum driving safety for the driver and passengers. So it is with the brake vacuum story. As a rule, problems with its operation occur due to the failure of a special diaphragm located inside the device.

It bursts, cracks, and ceases to perform its duties—to create a vacuum. Sometimes the exhaust valve also malfunctions. Checking the functionality of the vacuum on their own, available to every driver, is carried out in the following way. We start the engine and let it idle for a while until it reaches ;

- We turn off the engine;

- Press the brake;

- The first press will be no different from the normal one when the unit is running.

- The pedal must be pressed as much as possible: at the same time, the diaphragm in the amplifier is extended and a vacuum is created;

Release the pedal and press it again. If there is something wrong with the system, then during the second approach a vacuum will not be able to be created, and you will tactilely observe an uncharacteristic small stroke of the pedal itself. These changes indicate a breakdown in the brake booster.

Practical tips and nuances when bleeding brakes

Even if you follow all the points of the detailed instructions, you cannot be completely sure of the correctness of your actions and a reliable result. Experienced motorists know that the secrets of any independent manipulations in the car lie in the details.

While working with each wheel, it is worth tilting the car slightly in the appropriate direction. In this case, the air inside the system will rise up and flow faster to the threaded valve. Additionally, the process is activated by a slight vibration if you tap on the caliper.

In addition to the main method, you can bleed the brakes by gravity. It is necessary to unscrew the valves and add the necessary brake fluid to the supply tank in time. The procedure is quite lengthy and is only available to experienced car enthusiasts. Moreover, it is not suitable for vehicles equipped with return pressure control valves.

Bleeding the brakes, relying solely on your own experience, is fraught with breakdowns in the brake system. Incorrect actions can lead to large accumulations of air in the lines. Before you start working, you should familiarize yourself with the experiences of other people or watch training videos on the Internet:

Each vehicle system deserves special attention. Not only the proper operation of the vehicle, but also the safety of people depends on the correct operation of the internal mechanisms. Timely pumping of the brakes will ensure high-quality operation of the car in emergency situations.

What types of speakers are there?

It must be said right away that it doesn’t matter what shape the car speakers are installed in the car - round or oval - the quality is determined only by their dimensions. Device sizes are a standard that determines their dimensions

Basically, on modern cars the sizes of loudspeakers that can be installed are standard - 10 cm, 13 cm or 16 cm. The rear shelves of cars are usually equipped with connectors for installing oval speakers measuring 15x23 cm.

Four columns with different diameters

If the speaker diagonal is higher, it will be able to reproduce low frequencies better. In general, the size of the system largely depends on the size of the woofer, since it, as stated earlier, is the largest in the entire system.

- If the front speakers are 10 cm in size, then they will be able to reproduce sounds with a frequency of 120 hertz;

- with speaker dimensions of 13 cm, there will be good quality sound reproduction from 100 Hz;

- with dimensions of 16 cm, the device will be able to reproduce sounds from 80 Hz.