Due to rising gasoline prices, many car owners began to equip their “iron horses” with gas equipment (LPG) in order to somehow save their finances. However, along with the new equipment, new troubles also appeared - its maintenance and configuration. Therefore, today we decided to address the problem of adjusting the gas reducer. After all, this must be done not only immediately after installing the LPG on the car, but also during the operation of this system.

- 1. Gearbox adjustment: what is needed for adjustment?

- 2. Gearbox adjustment methods

The longer the mileage of the LPG and the period of its operation, the more necessary this adjustment becomes. The fact is that over time, the rubber elements of gas equipment - valves and membranes - can change their properties, which, in turn, leads to excessive gas consumption. Of course, such consequences can occur only after 3-4 years of operation (this is approximately 100,000 km), but you should prepare for this in advance.

Gearbox adjustment: what is needed for adjustment?

Before you begin to get acquainted with the basic methods by which the gearbox is configured, you need to become more familiar with this device and its main characteristics. After all, it is the gas reducer that plays the most important role in the normal functioning of gas equipment. What is its main task? It is thanks to this unit that the driver of a car with gas equipment can reduce the gas pressure that comes from the cylinder. At its core, this is a rather primitive pressure regulator, which allows you to autonomously maintain the same pressure indicator.

But, since nothing in this world is perfect, the pressure may still fluctuate slightly during operation of the gas reducer. In practice, it looks like this: when gas consumption is stable, the pressure also remains at a given level, and when it begins to be consumed more intensively, the pressure may drop slightly.

Although in general this process does not pose any danger, it is still necessary to be aware of it.

As we already noted in our introduction, gearbox adjustment is necessary during the installation of a new gas equipment on a car, as well as after its long-term operation. But in addition to these factors, the need for the frequency of adjustment and the specifics of performing this task is also associated with:

– generation of gas-cylinder equipment and, accordingly, the gas reducer itself;

– the number of regulators that are on the gas reducer;

– the fuel system on which the car engine runs – gasoline or diesel.

The gas reducer contains membranes that can freeze at low temperatures. For this reason, the gearbox must be connected to the automotive cooling system. If we talk about the operation of this gas equipment element in general, it is important to note the following point: it is impossible to start the gearbox simultaneously with the engine. First you need to wait until the engine temperature rises to 30-50°C, and after that you can put the gas reducer into operation.

The design of a conventional gas reducer is also simple. In particular, this device consists of the following parts:

– separate chambers, the number of which may vary depending on the type of gearbox (from 1 to 3);

– idle channel;

– evaporator;

– a regulatory system that controls the supply of gas from cylinders to the combustion chamber of the engine.

But on modern gas equipment you can find two types of gearboxes. They have a number of very important differences between themselves, which, in particular, has a significant impact on the process of setting them up. Let's look at the features of each of them:

1. Vacuum reducer. To put such a gearbox into operation, you must perform a number of mandatory actions:

– put the switch in the “Gas-Petrol” position;

– turn the key in the ignition;

– warm up the engine.

When the first two instructions are followed, the required amount of gas is pumped into the intake manifold, which will then allow you to start the engine without any problems and hit the road. The same is ensured by the operation of the starter.

2. Electronic device of the gas reducer. It turns on only when the switch is in the “Gas” position. Similar to the vacuum reducer, we turn on the ignition and give the starter the opportunity to work a little until the required amount of gas collects in the intake manifold and the device itself warms up to the desired temperature.

To properly configure the gas reducer, you need to understand absolutely everything about its settings. Thus, a large number of propane-type reducers are characterized by two regulators, although there are a small number of models with one. But methane analogues, on the contrary, almost always have only one regulator. It is the correct setting of the gas reducer regulator that is the main problem for car owners.

We recommend: Design and principle of operation of an internal combustion engine

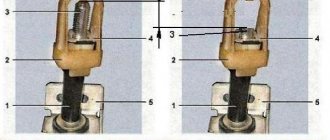

Why are two regulators installed on gearboxes? The first of these is the idle air control. In the process of setting up the device, we will need to screw it all the way. But the bottom one is the sensitivity regulator . It is he who presses the gearbox membrane. Having become familiar with this device in more detail, you can proceed directly to the setup procedure.

And to the question of what is needed to set up a gas reducer, the answer will be very simple - you need patience and strict adherence to the instructions below. You should also remember that you will have to work with gas equipment, so all your manipulations must be extremely careful. If you do not feel sufficiently confident in your own abilities, it is best to seek help from a specialized car service.

Gearbox adjustment methods

As we have already noted, there are electronic gas reducers and vacuum ones. Setting up each of them has its own characteristics and differences, for which reason we will consider methods for adjusting each of them separately.

Electronic gas reducer - which setting method to choose?

On this type of device, two types of settings must be used:

1. Adjusting sensitivity, or adjusting pressure in the second stage.

2. Adjustment according to the amount of gas that moves through the idle channel.

But before you begin both, you need to take a few more mandatory steps. First of all, we start the car engine on gasoline so that it can first warm up to operating temperature. In this case, the idle speed is set between 950 and 1000 rpm.

When the engine temperature reaches the required level, turn off the gasoline supply and allow it to burn out the remainder.

After this, we prepare the car for direct adjustment of the gas reducer:

– turn the power register to maximum (if a two-chamber dispenser is installed, then open the first chamber completely, and the second to minimum);

– turn the idle screw completely, then turn it back exactly 5 turns;

– set the sensitivity regulator to the middle position.

Well, first of all, let's start adjusting the idle speed. To do this, we start the car, but on gas. Use the choke and bring the engine to 1700-2000 rpm. Next, you need to simultaneously perform two actions at once: remove the choke a little at a time and rotate the idle speed control until you can find the position in which the largest number of starter revolutions occurs. At the end of this procedure, the choke must be completely removed, and the car must begin to idle stably.

Having set the maximum number of starter revolutions using the idle speed regulator, gradually tighten the sensitivity regulator of the gas reducer. If during this procedure the number of revolutions begins to change, again try to bring them to the maximum using the idle speed control. If you can’t do anything with this regulator, try tightening the sensitivity screw two turns and repeat the whole procedure again from the very beginning.

The goal you need to achieve is the maximum number of starter revolutions at idle (approximately 1100-1200 rpm) , with the sensitivity regulator screwed almost all the way. But driving at such speeds is not recommended, since their value should be below the nominal norm. Therefore, we again tighten the idle speed control until the speed drops to 950-1100 rpm.

Now let's move on to setting the sensitivity of our gas reducer. We also slowly turn off the sensitivity control and monitor how our actions affect the starter speed, which it performs at idle. When we felt that the number of revolutions began to change, we twist the regulator back a little - about ¾-5/4 turns. Do not forget to also check the engine operation by sharply pressing the gas pedal. If you did everything well, he will respond immediately and without jerking.

When adjusting the gearbox, it is very important not to forget to adjust the power register. To do this, it is necessary to bring the starter of the working engine to 3-3.5 thousand revolutions per minute, while simultaneously tightening the power register regulator. This must be done until the starter speed begins to decrease. To make sure you achieve what you want, try moving the gas metering screw from place to place and unscrewing it about ½-3/4 turn from the found position.

We recommend: Mass air flow sensor: what is it

But don’t worry about the fact that there are dispensers that consist of two sections. In this case, all the above steps must be applied only to the first camera, and the second one must be adjusted to only 25-30% of the first.

Some gas reducers also have the ability to adjust the pressure in the 1st stage.

To make the adjustment, you need to completely turn off the engine, shut off the line through which the gas flows, and connect a pressure gauge to the cavity of the first stage (it is advisable to use a pressure gauge with a scale of 1.5 kgf/cm2, and it is connected through a control hole, which is turned off using a regulator). After this, we open the gas line again, start the engine idling and bring the pressure of the first stage to 0.38-0.42 kgf/cm2.

Ideally, after adjusting the power register, you need to once again adjust the idle speed and sensitivity of the gas reducer. Only after this can you proceed to the final setup stage, which consists of several steps:

1. We press the gas pedal very sharply.

2. We turn the sensitivity control 0.25 turns until the intensity of the revolutions begins to decrease very much.

3. We turn the regulator back 0.5 turns and let the engine run a little, carefully monitoring the stability of this process.

What do you need to know about setting up a vacuum gas reducer?

Setting up vacuum type gas reducers can also be done in two ways:

1. The sensitivity and idle speed of the gas reducer can be adjusted separately.

2. The sensitivity and idle speed of the gas reducer can be adjusted simultaneously.

As for the first setting method, it is no different from the process of adjusting the electronic gas reducer, which we have already described above. For this reason, we will look at how to combine these processes.

First of all, we tackle the idle speed. To do this, we start the car, but immediately on gas, not gasoline. Again, using a choke, we level the engine speed to 1700-2000 per minute. We slowly remove the choke and, using the idle speed regulator, achieve the maximum value for the number of starter revolutions (at the end the choke must be completely removed). Using the regulator, we achieve the speed intensity within the range of 1000-1100 rpm and at the end we set the norm - 950-1100 rpm, by tightening the regulator a little more.

Setting the vacuum gear power register is almost the same as setting it on an electronic prototype. In particular, you need to do the following:

– start the engine at idle speed;

– set the intensity to 3000-3500 rpm;

– turn the regulator until the speed starts to drop;

– we try to adjust the register regulator, trying all the values;

– unscrew the register regulator by 0.5-0.75 turns, and also slightly adjust the idle speed.

Subscribe to our feeds on social networks such as Facebook, Vkontakte, Instagram, Pinterest, Yandex Zen, Twitter and Telegram: all the most interesting automotive events collected in one place.

What is gas equipment

GBO is gas-cylinder equipment. It is a gas installation that powers the engine instead of conventional fuel. Gas can be of two types - propane or methane. In practice, they differ little (except for the state of aggregation), but in terms of price and storage they still have slight differences.

LPG for a passenger car

There are several types of HBO:

- First;

- Second;

- Third;

- Fourth;

- Fifth generation.

The higher the generation, the more advanced the system (more sensors and electronics are used, everything is calculated more accurately and the operating efficiency is higher). But the generation of HBO is selected depending on the type of engine and it is not always possible to use the 5th generation installation on an old engine.

Adjusting the LPG gearbox

© Andrey Zelin (YMBR)

To begin with, we will divide all gearboxes of the 2nd (2+) generation into 3 groups.

- Old “Dutch” models from the late 1980s, early-mid 1990s, VIALLE type. Very reliable devices (resource under 200 thousand). There are few of them in Belarus and, as a rule, they are already “dead”.

- Gearboxes made in Italy, Poland or Turkey. For example, LONGAS, BRC, VOLTRAN. In general, they are similar to each other and have 2 adjusting screws.

- Gearboxes made in Italy or licensed with one adjusting screw. For example, LOVATO.

Setting up HBO

The HBO setting is also carried out on a warm engine. There are several ways to adjust equipment, they are all similar and choosing a specific method depends on the type of engine, its technical condition, age and similar indicators. Adjustment is carried out using only 3 screws:

- Idle screw;

- Sensitivity screw;

- Screw of greed.

The first 2 screws are located close to each other on the gearbox.

We recommend: external and internal CV joints - how they differ, design and purpose

First way

The carburetor must be adjusted. This method is suitable for most gearboxes of different brands. To begin with, with the engine not running, tighten the idle speed screw all the way, while unscrewing the plastic screw by about 5-7 turns, and also completely unscrew the greed screw. We start the car. You can start on gasoline, then switch to gas, or directly on gas. Start tightening the plastic screw until the engine stalls. Without starting the engine, turn it back 0.5-0.75rpm and start the engine. Unscrew the idle speed screw a few turns and try to catch the most stable speed. During setup, try accelerating a few times. The engine should respond immediately and show no signs of instability. Next, start adjusting the dispenser. Tighten it until it starts to knock down the idle speed. Be guided by the sound of the engine; as soon as it becomes rhythmic and immediately responds to pressing the gas pedal, stop adjusting. It is worth doing everything slowly, without rushing anywhere, so that the engine has time to start working at new settings, that is, after each turn of the screw, otherwise you simply will not hear anything.

Setting up HBO

Second way

The carburetor doesn't really matter. Adjusting the Lovato gearbox has a slightly different character. Before starting the adjustment, raise the speed to approximately 3000-3100 rpm. Next, find the dispenser. This is a metal screw located on the hose between the reducer and the gas mixer. Start turning the dispenser until the speed begins to drop and lose its stability. As soon as you notice this, turn the screw back about a quarter of a turn to set the speed to the ideal position. The first stage is completed.

Find the idle speed screw on the gearbox and begin adjusting the idle speed. Try to ensure that the engine runs smoothly at speeds of about 950-1000 rpm, while trying to constantly maintain gas thrust at a normal level. Based on the tachometer readings and the sound, adjust the diaphragm, then slightly weaken the throttle thrust. On some Lovato gearboxes there is another screw - a forced gas supply screw. Adjustment is usually not required, and the screw itself is tightened until it stops.

Stages

Adjusting the 2nd generation HBO consists of several simple steps:

- Adjusting the sensitivity of the gearbox.

- Adjusting the propane-butane mixture dispenser.

- Adjusting the idle speed when operating on a propane-butane mixture.

- Delay in the operation of the automatic shutdown when switching the operation of the car engine from gasoline to a gas mixture for carburetor cars. Or the number of revolutions at which the engine will switch from running on gasoline to running on a propane-butane mixture, provided that the fuel type switch button is set to the “automatic” position.

Before starting the adjustment, check:

- There is a sufficient level of coolant in the vehicle's expansion tank. If necessary, liquid must be added.

- Check and, if necessary, adjust the operation of a car engine on gasoline.

- Since the engine, when running on a propane-butane mixture, is very sensitive to air filter contamination, the air filter is replaced with a new one or blown out.

- No gas leaks. It is checked mainly by applying soap foam - by washing all gas compounds. If leaks are detected (in such places soap bubbles form from the foam), the connection is disassembled and the leak is eliminated. Then the reassembled connection must be checked again.

- Reliability of fastening of all clamps and nuts.

- Reliability and correct connection and absence of short circuits of all electrical appliances of HBO2 (electric valves, buttons).

- Check the presence of gasoline in the gas tank.

- Fill the cylinder with a propane-butane mixture.

HBO adjustment 4th generation

The fourth generation operates using electronics, which detect engine heating, the number of revolutions, sends impulses to the gearbox, controls the movement of the injectors and the performance of the fuel supply system. Correct setting of gas equipment allows you to synchronize the functioning of the fuel system components and not interfere with the operation of the gasoline ECU (electronic control unit).

There are no universal tuning indicators, since the operation of the gas system is influenced by:

- gas quality;

- intensity of fuel consumption;

- filtration efficiency;

- carbon deposits on pipe walls.

It is important to set the correct HBO parameters. It is not possible to do this yourself without special knowledge and skills. Therefore, it is recommended to contact a professional specialized car service for tuning.

In the process of setting up the 4th generation HBO, the following actions are performed:

- The outgoing reduction pressure is adjusted because the standard level of 1 atmosphere is not suitable for every car. Therefore, adjustments are made on an individual basis. To increase engine power at high speed (from 150 km/h), it is necessary to increase the pressure by 0.1-0.3 atm.

- Parameterization of the fuel map is carried out together with calibration. Suitable parameters are determined based on the quality of the combustible mixture. Low-quality fuel has a negative impact on consumption.

- Nozzles of a certain diameter are selected for injectors. Poorly fitted parts may not function effectively.

- The float of the cylinder is adjusted to the optimal level of gas pressure. It is important to choose the right place to install the cylinder. As a rule, it is mounted instead of a spare wheel in the luggage compartment of a car.

In most cases, it is enough to correctly configure the main system nodes. Complete rules for adjusting HBO can consist of 50-page instructions.

How to set up a gearbox in an LPG on your car?

Is your car already on gas?

With current gasoline prices, this is a sufficient reason to be happy, or at least glad that you don’t have to overpay for fuel. But here’s the problem: lately you have become frustrated with the operation of your gas equipment. Either the engine “sneezes” or does not want to start on the first try. Apparently there is something wrong with the gas equipment. What to do? If you have never adjusted and configured the mechanisms of your car, then it is better to immediately contact the HBO service , that is, where it was installed for you. Serious installation companies like the company Vremya Gas provide guarantees, offer service and repair of gas equipment installed at their gas station. Well, if you are friendly with technology and have already adjusted at least the carburetor on your car many times, then there is a chance to cope with the problem yourself.

As practice shows, many minor problems associated with the operation of gas equipment can be eliminated by simply adjusting the evaporator reducer. Before you begin self-adjustment, find out how many adjusting screws are on your gearbox - one or two, and which is responsible for what (you can look in the instructions). It depends on what exactly and in which direction you have to turn. There is a lot more there - a gas filter, a gas valve, and so on. So don't get confused!

The specialists of the Time Gas company recommend that before starting the adjustment, make sure that there are no other faults. That is, the cylinders must have normal compression (6.5 kgf/cm2), the intake tract must be sealed, and the wires and spark plugs must have good contacts. If something is wrong, it is better to immediately go for diagnostics and repair of gas equipment . If everything is normal, let’s move on to adjustments!

The stages of adjustment and maintenance of gas equipment are given on the page https://gaz-time.ua/services/servis-gbo.

Adjusting the gearbox with two screws

Let's start with the more common option - adjusting the gearbox, equipped with two adjusting screws. It is these gearboxes that are installed in most gas equipment - from the inexpensive Turkish Atiker to the elite Dutch Prins. There is an idle screw and a so-called “sensitivity screw” that compresses and decompresses the spring and senses when there is “enough” gas.

Adjusting the dispenser

The final step is setting up the dispenser. To do this, you need to start the car on gas fuel and set the speed to about three thousand per minute. There is no need to use suction, it is better to involve a partner. Then the screw that regulates the dispenser is tightened until the speed begins to change.

You need to fully verify the presence of this boundary by playing with the screw in one direction or the other. From this threshold, the adjusting screw is unscrewed by half to three-quarters of a turn. After a slight adjustment of the idle speed, the gas injection system for the carburetor can be considered configured.

You might be interested >> Gas gearboxes for 4th generation cars

It is also recommended to check the correct settings of gas equipment for a carburetor engine based on the concentration of oxygen and carbon monoxide in the exhaust. The CO level should not exceed 0.45%. Adjustment is carried out using screws that supply air to the carburetor and regulate the idle speed of the gearbox. If the indicator is underestimated, you need to add it to the second of the specified settings; in the opposite situation, vice versa.

Checking the oxygen content in domestic conditions poses a certain problem. To do this, configure the HBO as follows:

- an oxygen sensor intended for injection modifications of the Lada is installed in the muffler behind the “pants”, this is done using a pre-welded adapter nut;

- contacts for heating are connected in the same way as a gas valve; for signaling, a shielded wire is used, connected to the dashboard and connected to the tester.

As a result, HBO adjustment occurs under your constant control. If the tester shows a voltage level of 0.2-0.8 V, then everything is normal, a lower level means there is not enough oxygen, a higher level means there is too much oxygen. However, depending on the load and operating mode of the engine, these parameters may change, so fine tuning is still necessary.

Note! The ability to adjust the oxygen level is achieved only after installing additional equipment.

An even more interesting option is to use a lambda probe emulator, which provides the possibility of color indication. Three LEDs, similar to a traffic light, indicate optimal operation. A microprocessor unit can be connected to this device, which allows you to control the adjustment of the electronic dispenser, but such work cannot be handled independently, and you need to contact a service station. Moreover, this pleasure is not cheap.

Fine tuning(Online tuning)

After successful completion of self-tuning, you can proceed to the precise configuration of the fuel map.

Fuel correction:

Install the ODB adapter in the car's diagnostic socket, connect to it via Bluetooth from your phone using Torque (or a similar program). Display graph information about long-term and short-term correction. The essence of these parameters is to adjust the fuel. If any situation arises when the engine is supplied with a mixture that is too lean or too rich, then the opening time of the injectors is compensated by this coefficient. For example, clogged injectors will make the mixture leaner and the correction factor will increase. As a rule, this parameter cannot go beyond ± 25%. If a mixture problem persists for too long, the short-term correction is included in the long-term correction.

When setting up LPG, we will need to check the fuel correction coefficients for gasoline and gas and “press” the gas correction to the gasoline one in different operating modes.

Setting algorithm:

Setting up is best done with two people. Driver and adjuster. A more or less flat section of the road is selected, on which the same engine speed can be maintained for a long time.

Each cell in the fuel map corresponds to an injector opening time of 20 ms. Each injector is 8-bit, which means it has 256 time levels. 0-minimum value means that the injector is closed, 255 maximum value means that the injector is open full time.

It makes sense to make adjustments only in operating modes; say, if you do not “turn” the engine more than 4500, then there is no point in adjusting the map higher. The setting is carried out in stages, at each stage the engine speed increases by 500 rpm. The car moves for a long time at an adjustable speed.

Let's start setting up:

In the Lovato Easy Fast program, go to the “Configuration” section in the “Map” tab.

- Gasoline supply is turned on (using a button in the program)

- The driver sets a constant engine speed and precisely maintains it during tuning.

- At these revolutions, correction factors are read out via ODB.

- The gas is turned on (by button in the program)

- The correction factors are read again.

- The cell under the point on the fuel map is configured. If the correction factor is too large, the cell value is reduced, if small it is increased. I recommend selecting the entire column and changing it by several units at once. (After highlighting, press the Enter key.)

HBO lovato fuel correction map

After setup, the card is inspected for sudden changes in modes. A well-tuned map is smooth, i.e. neighboring cells do not differ much in value. If there are uneven lunges, I recommend manually “straightening” the area around them.

If everything is configured correctly, you will get minimal gas consumption and maximum thrust.