When a decision is made to install gas cylinder equipment on a car, it is primarily guided by considerations of economy. To really feel the reduction in transportation costs, you need to take care of the quality of the main gas equipment components responsible for fuel consumption.

Correctly selected components of the system, in particular gas injectors, will reduce the cost of vehicle maintenance. Valtek gas injectors meet these parameters.

Successful products Valtek Spa Unipersonale

The Italian company Valtek Spa Unipersonale, created in the 90s of the last century, produces high-quality gas equipment sets that have a long service life. Valtec injectors meet quality standards of the European Union and America.

Having its own research laboratory allows the company to produce safe, high-tech products, which are mainly exported.

The basis of Valtek gas injectors is a rod made of durable metal with a rubber tip. This design eliminates gas leakage. The electromagnetic coil is secured with a retaining ring. Special screws allow you to adjust the fuel supply; they have nothing to do with fixing.

Ramps are available that include 2, 3, 4 nozzles. You can choose products that match the number of engine cylinders.

The ramp includes a set of nozzles for the manifold, but calibration fittings, the diameter of which can be from 0.75 to 3.0, must be purchased separately. The diameter can be selected according to the table or drilled according to the power of the car’s power plant.

Calibration of Valtek injectors is carried out on your own and at a stand in a car service center.

With a cylinder power of about 40 hp, the diameter of the nozzles for gas injectors should be from 2.7 to 2.9 mm.

Valtek gas injector repair kit is affordable.

The second stage is adjusting the stroke of the injector rod

1. Unscrew the jets from the ramp.

2. We take out the corresponding power plug.

3. Instead of the jet, we install a special adapter into which the micrometer will be installed.

4. Next, install the micrometer, look at the arrow, if it starts to move, it means the armature has come into contact with the micrometer rod.

5. Install the plug into the gas injector coil.

6. We bring down the micrometer readings to zero.

7. Apply 12V power to the coil for 1 second or less.

8. Write down the value that the device shows.

| Nozzle | Nozzle stroke (in mm) |

| 1 | 0,37 |

| 2 | 0,47 |

| 3 | 0,45 |

| 4 | 0,51 |

9. Now we actually begin to adjust the gas injectors. To do this, you need to turn the hex bolt, which is the armature stroke adjusting screw.

By twisting (clockwise) we reduce the stroke of the nozzle armature.

By unscrewing (counterclockwise) we increase the stroke of the injector armature.

10. We again supply power to the gas injector coil and take control measurements. Using the same principle, it is necessary to check all injectors . The maximum permissible stroke of the Valtek injector armature should not exceed 0.7 mm.

What is needed to adjust the injectors?

Adjustment and subsequent calibration of injectors is required when they have undergone cleaning, installation or replacement.

In order to calibrate 4th generation LPG injectors (for example, valtek type 30) yourself, you need to have the necessary set of tools and devices:

- dial micrometer with an accuracy of 0.01;

- extension to the rod;

- sleeve for fixing the micrometer;

- detachable element for power supply;

- Allen key.

Adjusting and calibrating gas injectors with your own hands is not a difficult process if you have all the necessary tools and an idea of what result you need at the output.

Cleaning gas injectors - step-by-step photo report

1. First of all, you need to turn off the gas supply; to do this, tighten one or two valves on the gas cylinder.

2. Start the car and let it run in order to relieve pressure in the gas lines and exhaust the remaining gas.

3. We dismantle the gas rail with nozzles. This process will happen differently for everyone, it all depends on the brand of injectors and the type of engine.

4. Next, using a screwdriver, unscrew the screws and remove the gas injectors.

5. Remove the rods from the injector body. The photo shows the cause of all my troubles - tar deposits, which did not allow the injectors to function fully. When the engine is cold and the injectors are not warmed up, the viscous resin prevents the normal movement of the gas injector rod.

6. Using cotton swabs and alcohol (you can also use solvent), wipe the stems, as well as what’s inside the housings.

7. Assembly is performed in reverse order.

Checking the tightness of the system

Next you need to check the tightness of the system:

- All gas lines are connected.

- All connections are washed.

- The flow valve on the gas cylinder opens.

- The car ignition is turned on.

- If bottled gas leaks are detected, they must be repaired immediately.

The leak test procedure must be carried out to avoid accidents on the road and ensure the safe operation of gas equipment.

Operating principle of injectors

Before moving directly to a review of the technical characteristics of products manufactured under the Lovato brand, let's understand the general principle of its operation. This is necessary in order to better understand the big picture and be able to make the right choice at the right time.

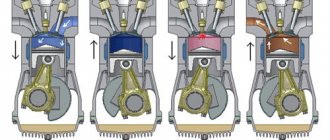

The essence of the operation of all nozzles is quite simple, and is as follows. An electromagnetic valve located in the product regulates the flow of the gas mixture from the vehicle’s gearbox to the intake manifold. The main difference in the operation of injectors from different companies is the period of time required to open and close the valve, as well as the resistance of the electromagnetic coils installed in them.

The difference between high-speed injectors and regular injectors

When choosing an HBO gas injector, you should pay attention to the speed of operation of these devices. Because injectors differ in the speed of closing and opening of the rod. They also differ in electric valve coil resistance, stem types, appearance and connector. Namely, it will depend on the engine and its volume which injector is needed for the car: high-speed or regular.

It is worth noting that the power characteristics of LPG, as well as propane or methane savings, will depend on the response speed of the LPG injectors and on how accurate the gas injection into the engine system will be. For example, on a car that has a powerful engine, high-speed injectors (for example, AEB or Hana) should be installed. And if the engine volume is 1.5 liters, then install regular injectors (for example, RAIL).

For high-speed injectors, the coil resistance is 1.9 Ohm, the injector response speed is 2ms, the maximum pressure is 4.5 bar.

At the same time, for conventional injectors, the coil resistance is 3 Ohms, productivity is 15-35 hp/cyl., maximum pressure is 3.0 bar, operating pressure is from 0.5 bar to 2.0 bar.

Installation of Lovato injectors

The installation of injectors and other systems included in the LPG system is best left to specialists. This will significantly improve the quality of work performed and the safety of the installation. However, not all drivers can afford to have their cars serviced at expensive services and use the services of specialists. In this case, during installation it is advisable to be guided by the following generally accepted requirements:

- One of the most important factors affecting the performance of products is their location. For example, it is better not to install injectors with gas supply on the side of their rod with the coils facing down. This arrangement will quickly lead to their breakdown.

- Don't forget to install a vapor phase filter. It will allow your equipment to work much longer and keep you out of trouble.

- They need to be fixed in such a position that they are subject to vibration and contact with other parts of your vehicle as little as possible.

Advantages and disadvantages of Lovato injectors

Lovato is a company located in Italy, which is one of the largest manufacturers in the automotive gas equipment market. Its products have been in great demand for 60 years and have positive reviews from both specialists and consumers.

Note! The company, when creating its equipment, uses advanced technologies and high-quality materials, which is reflected in the high reliability of the equipment produced.

Below are the advantages of Lovato products, which are typical for all models and set them apart from their competitors:

- Increased service life. This characteristic is very important for any equipment, and the greater its value, the better for consumers. The products of this company have a huge margin of safety and can withstand up to 500 thousand kilometers without replacement or repair. Also, in new generations of Lovato Kp nozzles, the ability to carry out maintenance has been implemented, which allows you to further increase the service life.

- Another, no less important property that distinguishes the products of this brand is the modularity of the design. This allows you to implement different combinations of the same nozzles when configuring and installing to achieve the best result. For example, for sports cars it is best to use a combination that involves installing four separate injectors, and for cars used for everyday life, it is best to use one ramp with injectors installed on it. Other, more exotic combinations are also possible.

- The Lovato company combines in its products not only high-quality assembly and materials, but also uses the latest technologies to create them. For example, all products use electronics that help recognize the equipment with which it will work, and based on this information, improve the interaction between the nozzles and the gas reducer.

- The company has one of the largest service networks in Russia among companies engaged in the production of gas equipment for cars. Thus, in almost any region you will be able to use the services of specialists when installing and configuring any necessary LPG system.

You might be interested >> Gas injectors aeb

Read about the main malfunctions of Lovato gas equipment and how to eliminate them.

The disadvantages include not the lowest price that the company asks for its equipment. Disadvantages also include an increased noise level, compared to other competitors, which is noted by drivers who use the products of this brand.