Every car sooner or later needs a good powertrain overhaul. Engine repair may be necessary after high mileage, too active use, as well as the use of low-quality oils or overheating. There are dozens of conditions under which a car owner condemns himself to major repairs. Sometimes it's just a matter of excessive mileage. Often the culprit for the need for major intervention in the engine design is a twist in mileage. Let's say you bought a car on the market with a mileage of 105,000 km, which, according to the owner, has just been serviced. But the actual mileage of the car is 235,000 km, and after 5,000 kilometers one of the most important comprehensive services in the life of the car needs to be done. By skipping it, you doom the engine and gearbox to great suffering, which will inevitably lead to the need for major repairs.

In general, the very combination of the words overhaul and repair causes terrible discomfort to the car owner. Not all car owners have encountered this process, but many have heard about the high cost of parts and the difficulty of finding adequate technicians. All this is true. When performing work on an official service, you will have to pay exorbitant sums. And when servicing a car in a garage station, there are no guarantees of the quality of the work performed. Therefore, it is important to find a middle ground and find a service station that provides such services at a high level of quality. Today we will talk about when you need to think about a major overhaul of the unit. However, sometimes it is better to replace the engine instead of this procedure. Often this procedure will be cheaper than a complex repair involving disassembling the entire unit.

Signs you need a motor overhaul in your car

There are more than 10 signs that indicate the need for intervention in the power unit system. Of course, not all signs lead to the need for major repairs, but in many cases this is the only normal way out of the situation. Let's list the main types of machine behavior in which you should contact a good mechanic:

- Oil consumption has increased

. This is possible if, with increased friction, serious heating of the parts occurs. - The car has great mileage

. Each type of engine has its own resource; on average, an engine travels 200-300 thousand kilometers to the capital. - Rich smoky exhaust

. Grey, black or brown smoke in copious amounts indicates a number of problems. - Black candles, excessive burnout

. This also indicates incomplete combustion of fuel and a number of problems. - Increased fuel consumption

. This problem is associated with troubles in the combustion chambers (but there may be other reasons). - Rated power drop

. Often this problem indicates a change in compression and other problems. - Knocks when the engine is running

. Constant rhythmic or chaotic sounds indicate serious problems with technology. - Floating idle speed, interruptions

. If the engine stalls on its own or runs poorly, it’s time to contact a service station. - Rattling noise on the body when idling

. This indicates that some parts of the unit have failed.

This unpleasant list can be continued. Not a single malfunction means 100% that you will need a major engine repair. Sometimes we are talking about faults in the firmware; often it is worth working with the fuel supply or exhaust system. But with a fairly high degree of confidence we can say that in such cases a major overhaul of the unit will be required. Problems can only be fixed by a good technician after an excellent diagnosis.

For what reasons does the engine wear out quickly?

If we exclude unforeseen breakdowns (engine overheating, jamming due to oil leakage, etc.), then we can identify a certain set of factors and causes that contribute to accelerated wear.

- As mentioned above, engine oil and its quality, lubrication level and compliance with the type of internal combustion engine, as well as the condition of the filters play a paramount role. The oil must be correctly selected and its replacement must be carried out strictly taking into account the operating characteristics of the vehicle.

You cannot try to replace the recommended semi-synthetic or synthetic with cheap mineral oil, save on an oil filter, etc. If the engine is under load, then oil change intervals should be shortened. The oil level should be checked regularly and lubricant topped up if necessary, avoiding mixing different types of lubricants.

Ignoring these rules significantly increases the wear of the internal combustion engine and brings the time of major repairs closer. By the way, the air filter also needs to be changed regularly, since its contamination leads to abrasive particles entering the cylinders. These particles can cause scoring and damage.

The operating conditions of the car engine also affect the timing of the overhaul, since engine wear can be quite accelerated in cases where the engine:

- often operates at maximum speed;

- a car with a running internal combustion engine sits idle for hours in traffic jams (idling mode);

- the driver is used to driving at low speeds in high gears (driving tight);

- cold engine starts occur constantly;

For example, many experts claim that one cold start at -25 degrees is equal to wear over a run of about 150 km. Also, when driving on the highway, the engine wears out much less than when driving around the city with frequent accelerations and stops. It turns out that habitual city use negatively affects the condition of the engine and its service life before overhaul is reduced.

What do specialists do when overhauling an engine?

It is impossible to repair a motor without extensive experience and high-quality equipment. By disassembling the unit yourself, you will simply throw away most of the spare parts and will be forced to turn to a specialist for more expensive services. Even though capital is not a cheap pleasure, it is better to immediately contact a specialist and get professional services. There are several important stages of engine overhaul that should not be forgotten:

- diagnostics and identification of possible problems based on the testimony of the car owner, diagnostic systems, as well as visible signs of unit failure;

- disassembling the upper part of the engine, examining and diagnosing the cylinder head system, valves and various consumables, removing the head and troubleshooting it if necessary;

- measuring the parameters of cylinders and pistons, searching for defects in the piston group and carrying out troubleshooting of this unit with the replacement of all necessary parts with new ones;

- inspection and diagnostics of the crankshaft with its subsequent repair or replacement, great attention to small parts and connections in the engine that can cause knocking during operation;

- application of modern methods of major restoration of the piston group, if necessary, professional boring of cylinders and installation of new pistons;

- assembling the power unit, carrying out professional diagnostics, identifying all minor inaccuracies in operation and their subsequent elimination, handing over the car to the owner.

As you can see, the overhaul process is quite complicated. Especially great difficulties arise if the engine is jammed, there are specific complaints about knocking and extraneous sounds in the operation of the engine. The more breakdowns, the more money you will have to spend on restoring the power unit. Sometimes the financial component of renovation work is so surprising that it makes the owner think about alternatives.

Cracked cylinder head

Overheating of the engine can cause the cylinder head or cylinder block to crack. Often, the above problems arise on aluminum engines, which also suffer from tearing of liners from the block and are susceptible to corrosion. Installation of additional attachments, including turbochargers, entails excessive loads. And due to an insufficiently efficient cooling system, the motor overheats, which leads to its rapid demise, including during the warranty period.

How much does a high-quality engine overhaul cost?

The cost of major repairs cannot be determined until you bring the car in for diagnostics. Otherwise, it is difficult to understand which parts need to be changed, what model and brand of car we are talking about. The fact is that overhaul for a VAZ and restoration of a Mazda engine are completely different cost options. We are talking about a set of costs that cannot be calculated in general for a specific machine. Individual diagnostics and addition of the following types of costs are needed:

- payment for the services of the workshop where your car is repaired, this amount depends on the complexity of the work performed, as well as on the type of service station chosen;

- purchase of spare parts - there may also be differences here, you can buy original and analog parts, you often purchase used spare parts from disassembly at a low cost;

- speed and urgency of repair work - often services are provided for enterprises where the machine is constantly needed, so urgency has to be paid additionally;

- car model - the design of the engine and the complexity of working with the unit also add or reduce the cost of disassembling, diagnosing and troubleshooting the engine at the station;

- the volume and dimensions of the engine, as well as the features of its design - the larger the engine, the more difficult it is to work with it, and the more expensive the services of repair specialists will cost.

In general, the cost can only be determined when visiting the station. And even in this case, they will not tell you right away how much it costs to repair the car. After disassembling the engine and detailed diagnostics of the unit, it will be possible to give an exact figure. Sometimes the cost of engine overhaul turns out to be so high that owners are simply not ready to pay such costs. But there is nowhere to go if half the work is already done. However, you should immediately pay attention to alternative work options.

Volume of disasters

Capital can be partial or full. To determine what kind of repair the engine needs, it is necessary to carry out control measurements and troubleshooting - start with the condition of the cylinders and the piston play in them, inspect the liners and measure the diameter of the crankshaft journals, evaluate the gaps in the piston pins. With partial capitalization, they are usually limited to replacing piston rings, liners, seals, and gaskets. With a complete overhaul, the list turns out to be much longer, and the amount of work is significantly greater. The cost of repairs is correspondingly higher.

Full capital

The sequence of actions with full capital is as follows. First, the engine is removed from the car. This operation is most expensive on all-wheel drive vehicles with automatic transmissions.

Next - disassembly, washing, troubleshooting and micrometering. Only at this stage can a more or less accurate cost of repairs be determined. If the verdict is rendered earlier, there is reason to be wary. Most likely, you ended up with incompetent specialists, or they will try to deceive you.

After measurements and troubleshooting, the main parts are sent for machining - many workshops do not maintain expensive equipment for boring blocks and grinding crankshafts and send the parts to related suppliers. The cost of work greatly depends on the volume of machining. Then the engine is assembled, installed on the car and filled with working fluids.

Now about spare parts - in the overall calculation they usually make up half of all capital costs. All gaskets, rubber and rubber-metal seals are replaced. Timing drive elements are always replaced if it is a belt drive, and almost always if it is a chain drive. During any overhaul, new piston rings and crankshaft liners are installed. The pistons of modern engines are very loaded and most often also need to be replaced.

Parts that are replaced based on diagnostic results include valves, oil pumps and even crankshafts if it is not possible to grind to a repair size. They are trying to repair the main parts - the cylinder block and heads. In this case, the cylinders are either bored to the repair size or relined to fit standard pistons. In the head, sometimes it is necessary to restore the camshaft beds and change the valve bushings, mill the mating plane and almost always machine the valve seats.

Alternative to overhaul

Many people prefer not to repair a worn-out engine, but to take a so-called contract (used) engine. Not a bad option, you can even save a lot of money - a complete overhaul sometimes costs twice as much. For example, the price of a “live” engine for Granta is 25–30 thousand rubles, for Logan – 45 thousand rubles. For more complex multi-cylinder engines they ask from 80 to 200 thousand rubles or more.

But the euphoria is inappropriate: still, you must not forget that you are not buying a new, but a used unit! And this is a lottery that you can lose. Therefore, before making a final decision, we advise you to scour the Internet. Read reviews about sellers of used units and about the design advantages and disadvantages of your motor. For example, you should not buy used 2-liter G4KD aluminum engines installed on many Hyundai and Kia models. Typically, these units do not survive up to 150,000 km - scuffs appear on the cylinder walls, which causes a sharp increase in oil appetite. Such motors are restored by re-lining.

And further. The engine number does not appear in the registration documents, but a replacement engine still needs to be registered with the traffic police.

To minimize the risk of overpayment, it would be good to understand at least the basic principles of motor capital.

What alternatives to engine overhaul exist?

The issue of alternative methods of car restoration is incredibly relevant. People do not want to spend huge amounts of money and carry out major repairs to the unit. Even good capital does not guarantee that the engine will operate for another 100,000 km without problems. The search for alternative options is especially relevant for owners of foreign cars in which the cost of repairs is off the charts. You can pay attention to the following options for your situation:

- Purchasing an assembled engine part and performing a complete replacement. In this case, you will not have to pay for diagnostics, repair work, or troubleshooting. It is enough to pay for a replacement unit, which will cost less.

- Search for a contract engine. For Japanese and American cars, the search for engines imported from other countries is relevant. You can buy a practically new engine for little money.

- Selling a car or exchanging for another car. If there is no money for repairs, you can sell the car by explaining the engine problems to the new owner. For the money you earn, you can buy a simpler car.

- Exchange a faulty engine for a working one at a showroom that deals with your brand of car. Here you can often find quite decent engine options with a small surcharge.

- Purchasing parts for repairs at disassembly. This is not the best option, but if there are no other options, it is worth using it. The savings will be noticeable.

As you can see, there are many workarounds that can often save money on repair work. But they are not always suitable in a given situation. Often there is no cheaper and more correct way out than capital. It’s worth checking out prices at various service stations to make sure the amount calculated is adequate. Also make sure that the technicians to whom you entrust the work have sufficient experience and good knowledge of cars.

We invite you to watch a video about overhauling a car engine:

A little about contract engines

Recently, capital has acquired a worthy alternative in the form of contract engines. But not everyone knows what it is. To be honest, just a few years ago I didn’t really understand what was going on. But everything changes, new knowledge and good friends appear who can give advice.

If you look at the problem of engine wear from the perspective of money, then a contract engine costs about the same or can cost a little less than capital. But remember that a contract power unit means a used engine, that is, a used one. When contacting dubious organizations, you may be offered an engine whose condition, to put it mildly, is not very good. Plus, problems may arise with the legality of purchasing a contract engine. After all, it will have to be registered again later.

That is, I believe that choosing a contract engine rather than a major overhaul is relevant only in a few cases:

- the engine in your car can no longer be restored due to serious breakdowns and major damage to its integrity;

- it is required to change the power unit as quickly as possible, and major repairs take a very long time;

- It is difficult to find suitable parts to restore the motor.

And if you are suddenly offered a supposedly excellent contract engine, and at an attractive price, I strongly advise you to refuse. The same g16a Escudo from Suzuki cannot be cheap if it is in good condition.

Source

Let's sum it up

High-quality engine performance is one of the most important aspects of car operation. The use of certain car functions, confidence in travel, and the possibility of unlimited use of transport depend on this factor. If the engine begins to behave inappropriately, it is quite possible that it will require major repairs. In this case, you can use various options for restoring the power unit, including a complete replacement of the unit. But often it is repair that turns out to be the most democratic and reasonable solution that is worth considering. It is interesting that many car owners, after realizing the need for repairs, continue to operate the vehicle.

There is no need to shelve your capital. If you have already realized that your car needs to be repaired, you should carry out this procedure immediately. Otherwise, more serious problems are possible. For example, the motor may jam while driving, which will cause an extremely unpleasant and emergency situation. The engine can be completely worn out if a major restoration is not carried out in time. In this case, the situation can become catastrophic, and not only the engine, but also many other parts of the car will suffer. Have you ever faced the need to overhaul your engine?

Engine disassembly, DIY repair and diagnostic manual, step-by-step instructions

There are no standard instructions on how to overhaul an engine. It all depends on the specific make and model of your vehicle and the wear and tear of various engine components.

In any case, for major repairs it is necessary to completely disassemble the engine. This process is long and labor-intensive, which cannot always be done at home.

Removing the power unit

For those who are not afraid of difficulties, we have prepared a short guide to engine overhaul:

- First, we remove the engine from the vehicle. To make your car's engine a little lighter, you need to dismantle some units - we start with the carburetor, then remove the cylinder head cover, dismantle the generator, disconnect the gearbox, dismantle the manifold, and then remove the flywheel and clutch. Now you can unscrew the cushions and remove the engine.

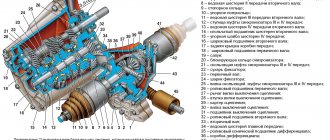

- To gain access to the crankshaft and pistons, you need to remove the crankcase cover. Then we unscrew the connecting rods. We take out the pistons and remove the pins from them. Now you need to remove the crankshaft and its bearings.

- Pay special attention to wear on the crankshaft liner and journal. If necessary, bore them. In addition, do not forget to purchase piston rings, pins and new liners.

The first start of the engine should be done like this

- The car battery must be charged 100%, otherwise the first crankshaft start will not be able to handle. The starter must also be in good working order.

- Use only high-quality motor oil, fill to the top mark of the dipstick, do not forget the oil - it is a thick liquid and requires time to drain into the pan. Do not fill the oil filter with oil to avoid air lock created by the oil-soaked filter element.

- If the engine is either carburetor diesel, i.e. There is no electric fuel pump, pump the fuel manually until the chamber or carburetor is filled with a diesel engine until it reaches the high pressure pump.

- We adjust the air damper with the ambient temperature.

- We start the engine

with the starter, monitoring the appearance of oil pressure in the line, guided by the instrument panel indicators. If after 3-4 seconds of idling the pressure does not appear, we urgently turn off the car unless we want to do another major repair and try to eliminate the defect. Pressing the accelerator pedal is useless and harmful - the load and lack of oil in the connections will quickly and irrevocably lead to failure. - If the oil pressure is in order, then we warm up the idle speed of the engine to a temperature of 85–93 °C. At the same time, the occurrence of leaks of technical fluids is controlled. After cooling the radiator with a fan, we turn off the engine. Don't be alarmed by the appearance of smoke from under the hood, this layer burns off the oil, it will disappear on its own within a short time and will not appear again. As soon as the coolant temperature rises, the oil pressure should drop; due to heating, the oil becomes more liquid. The permissible oil pressure value is 0.4–0.8 kg/cm2. If this is not the case, then errors were made during assembly (the gaps are not correct, the pump is not working correctly) or the oil was of low quality. After the engine temperature reaches 30–40 °C, we start it again. We repeat the procedure every 15–20, this will be enough for higher speeds during break-in.

- Next, keep the rpm at 1000 for 3 minutes, 1500 rpm for 4 minutes and 2000 rpm for 5 minutes.

- moving on Next, we carry out the running-in without exceeding the speed of 60–70 km/h in direct gear. It’s better not to stick the fifth into the program this period. The first 500–300 km are the most “break-in”, the appearance of a bluish muffler from smoke is a normal situation, especially if a new set of rings is installed. Also, instability of idle speed does not provide a reason for precise, panic adjustment should be done after 1000–500 km. mileage

- After 2500–3000 km. increase You can speed up to 80–90 km/h.

- After all these simple operations, the engine of your car will “thank you very much” and it will be possible to return to normal operation with a mileage of 10–15 thousand km up to the maximum time. During a load of 2500–3000 km, it is advisable to change the filter and oil several times. This oil system contains a large number of wear products and the filter does not always pass 100% of the oil through it. Most new imported cars have instructions that prohibit changing the oil during break-in, since the manufacturers themselves fill in break-in oils, i.e. containing a package of special additives that accelerates the grinding-in of repaired elements. engine engine.

Stages of engine repair

Rebuilding the engine involves performing the following actions:

- Removing the motor.

- Complete disassembly and removal of accumulated dirt by washing and cleaning.

- Identification of defective spare parts of the block that need to be replaced: inspection of the engine block for cracks, measurement of possible gaps formed, assessment of the condition of the crankshaft, identification of worn parts.

- Overhaul of the cylinder head.

- Restoration of the cylinder block.

- Assembly of the unit and installation on the car.

Disassembly and dismantling of the engine

The process of removing the unit from the car may vary depending on the car model. Dismantling a carburetor engine is much simpler than an injection engine. There are fewer electronics that have to be removed first. Also, the disassembly process will be different for brands with front and rear wheel drive.

The preparatory stage preceding dismantling will be the removal of interfering mechanisms and unscrewing the retaining bolts. The removal of a heavy unit from the car body occurs using a special lift or winch. If there is no such device, then to reduce weight, all possible parts and spare parts of the engine are removed, and it is pulled out manually. This will require the help of several people.

Disassembly follows. The work should be done sequentially, carefully inspecting the parts for wear and placing them in order.

It is worth knowing that a VAZ engine can be disassembled in about 3 hours; disassembling a foreign-made engine takes more time: about 10 hours.

Washing engine parts

Washing is an important step that many people skip.

It is not right. Each detail has a specific meaning. If the spare parts are not washed and deposits are not removed, then the degree of wear can be incorrectly determined, which can cause rapid failure of the entire motor. You should also wash the block and cylinder head with special care to examine for possible cracks.

Cold running - engine

Cold running of engines is extremely important. It allows you to significantly reduce gas breakthroughs from the combustion chambers into the crankcase and the penetration of oil from the crankcase into the combustion chambers during hot running.

| Electric braking stand for running in and testing engines. 1 - stand. 2 - electric motor. 3 — control panel with instruments. 4 - tachometer. 5 - connecting shaft. 6 - run-in engine. 7 - racks with adjustable supports. |

Cold running of the engine is carried out from the electric motor of the stand. During cold running-in, the spark plugs must be turned out (for diesel engines, the injectors are removed or the decompressor is turned off), the power and ignition devices are turned off, the cooling system is connected to the appropriate water supply system, 20 - 30 g of the appropriate oil is poured into each cylinder of both carburetor and diesel engines; The crankcase is filled with low-viscosity oil (for example, industrial grade 20) with which the running-in is carried out.

Cold running of the engine lasts 1 - 2 hours at. During cold running, oil temperature and pressure are maintained in accordance with standard test conditions. On the IT9 - 1 and IT9 - 3 installations, fuel is supplied to the fuel pumps (since without fuel the pumps can fail), while the injectors operate as a bypass.

Cold running-in of the engine is carried out on a special stand from a foreign engine, first at low speeds, then the speed is gradually increased to nominal and the engine is allowed to run for 15 - 20 hours, while it is generously lubricated with cooled lubricant. During running-in, carefully monitor the heating of the rubbing parts of the engine.

Cold running of the engine is carried out in three stages: at an engine crankshaft speed of 40 5%, 60 5 and 80 5% of the rated engine crankshaft speed. At each stage, with a centralized lubrication system, run in for 5 minutes, and with a crankcase lubrication system, for 10 minutes.

Cold running of engines on this stand can be performed at 600 - 1450 rpm, and hot running at 1600 - 3000 rpm.

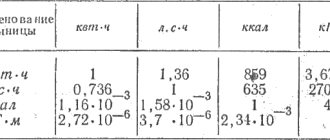

Engine cold running modes are listed in table. 7.17, where the following designations are adopted: n - crankshaft rotation speed; t is the duration of the run-in; N—load; L1cr - torque.

Engine cold running mode: without compression at 700 - 800 min 1 - 5 min, at 1500 - 2000 min 1 - 5 min; with compression at 700 - 800 min 1 - 5 min, at 1500 - 2000 min 1 - 5 min.

During cold running-in of engines, the meter takes into account the consumption of electricity from the network, and during hot running-in, the output of electricity to the network. In the first case, the counter disk rotates in the forward direction and the counter readings will increase, and in the second, the counter disk rotates in the opposite direction and the counter readings will decrease.

What is the difference between cold running-in of engines and hot running-in?

During cold running of the engine, the operation of the lubrication system and cooling system must satisfy the following requirements. The oil pressure in the heated diesel line should not be less than 0 1 MPa (A-41, A-01 M engines), 0 15 MPa (SMD-60, SMD-62 engines), 0 2 MPa (D-240 engine), 0 13 MPa (YaMZ-238NB engine), 0 8 MPa (D-37, D-21 engines) at minimum crankshaft speed at idle; oil temperature at the engine outlet is 70 - 95 C, at the inlet - at least 30 C; the water temperature at the engine inlet is not less than 50 C, at the outlet - no more than 80 C. Leakage of fuel, water and oil at the joints of parts is not allowed.

Before starting the electric motor of the stand for cold running of the YaMZ-240B engine, the diesel lubrication system is pumped with oil using an oil pump under a pressure of at least 0 15 MPa; in this case, the time of continuous operation of the pump electric motor is allowed no more than 3 minutes, and the oil temperature is not lower than 40 - 50 C.

This indicator is used to monitor the running-in during cold running of engines, since it is not necessary to interrupt the running-in process to monitor it.

In order not to use special power equipment during cold running-in of engines, a number of factories use so-called duplex installations. In this case, two engines are running simultaneously on the stand, and one of them is running in the running-in mode under load, consuming the developed power for cold running of the other engine connected to it.