You can contact the site administrator by email: [email protected]

All texts were written by me, are authored by Google, included in the original Yandex texts and notarized. For any borrowing, we immediately write an official letter on company letterhead in support of search networks, your hosting and domain registrar.

Next we go to court. Don’t try your luck, we have more than thirty successful Internet projects and have already won a dozen lawsuits.

Source

Mono injection, monomotronic versions of VW Passat B3

Subscribe here to receive announcements of new articles directly to your email!

Mono-injection Volkswagen Passat B3 is divided into two types: MonoJetronic and MonoMotronic.

MonoJetronic is a central fuel injection system with a separate ignition system and a vacuum ignition angle corrector.

MonoMotronic is a central fuel injection system with an integrated ignition system and electronic ignition angle correction.

As is clear from the definition, mono-injection systems are different and what distinguishes them from each other is the presence of additional sensors and a vacuum hose to the ignition distributor (distributor).

MonoMotronic was installed on later models of the Volkswagen Passat B3 B4 and also differs in its versions.

Different versions were installed on the Volkswagen Passat B3; in order to determine which version is installed on a particular car, it is not enough to know the year of manufacture of the car or engine, you need to know the engine ECU number.

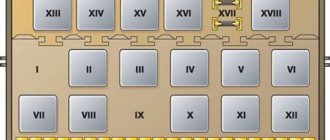

To do this, look at the BOSCH catalog number on the ECU, it looks like - 0 261 200 xxx, 0 261 203 xxx, then, depending on the number, look at the table and based on the table we calculate the MonoMotronic version:

MonoMotronic MA1.2.1 (35 legs). Numbers 0 261 200 xxx, where xxx is 251, 252, 253, 254, 259, 260, 261, 262, 263, 264, 265, 266, 271, 272, 273, 274, 277, 278, 703, 704, 705 , 706, 745, 746, 748, 749.

Monomotronic MA1.2.2 (45 legs) numbers 0 261 200 XXX 257, 258, 275, 276, 701, 702, 710, 711, 714, 715, 741, 742, 743, 744, 750, 751, 752, 753, 754 , 755, 760, 761, 774, 775, 776, 777, 784, 785, 786, 787, 788, 789. And also 0 261 203 xxx 316, 317, 318, 319, 320, 321.

MonoMotronic MA1.2.3 (45 legs). this is if you did not find your block number in the list of 45-legged blocks.

The diagram and device of the mono-injection, the catalog numbers of the components that make up the mono-injection, can be seen and read in the article on this website “Volkswagen Passat B3 Mono-injection” .

I can express the opinion of many owners of the Volkswagen Passat B3 B4 that mono-injection is the simplest, most reliable and unpretentious type of injection on internal combustion engines, since it has only one mono-injection nozzle and a minimum number of sensors.

If you have any questions or additions, please do not hesitate to write in the comments.

Source

Repair and adjustment of single injection

Information applicable to car repairs:

Volkswagen Passat B4 / Volkswagen Passat B4 (3A2) 1994 - 1997 Volkswagen Passat Variant B4 / Volkswagen Passat Variant B4 (3A5) 1994 - 1997

Volkswagen Passat B3 / Volkswagen Passat B3 (312) 1988 - 1994 Volkswagen Passat Variant B3 / Volkswagen Passat Variant B3 (315) 1988 - 1994

Volkswagen Golf 3 / Volkswagen Golf 3 (1H1, 1H5) 1992 - 1998 Volkswagen Vento / Volkswagen Vento (1H2) 1992 - 1998

Volkswagen Golf 2 / Volkswagen Golf 2 (191, 192, 193, 194) 1984 - 1988 Volkswagen Jetta 2 / Volkswagen Jetta 2 (165, 166, 167, 168) 1984 - 1988 Volkswagen Golf 2 / Volkswagen Golf 2 (1G1) 1989 - 1992 Volkswagen Jetta 2 / Volkswagen Jetta 2 (1G2) 1989 - 1992

SEAT Toledo / Seat Toledo (1L)

The procedure is also suitable for other vehicles with Mono motronic injection system

There have already been many similar topics, but questions continue to arise. Since I’ve already worked on my own, I’ll share it and let there be another one with pictures, like instructions. I started having periodic problems with idle, either it would stall in wet weather, or it would rev the next day after it froze. Yes, in fact, it’s time to work on injection because I haven’t touched it for several years... We start with the coolant temperature sensor (DTOZ), remove it and put it in a “saucepan”, for example, a tin can, you will also need a thermometer, a multimeter, snow from the street or ice from refrigerator, small stove. My thermometer “shook off” and I used the temperature sensor of the multimeter. Let's take the sensor, I have one, it's 10 years old:

We put snow or ice in the jar so that the temperature is about 0 and take the first measurement, then turn on the stove and take measurements approximately every 10 degrees until it boils at 100*C. There should be about a centimeter of snow so that the metal part of the sensor is immersed and water does not get on the contacts. My measurements: 0*C 7.25 kOhm 12*C 4 kOhm 20*C 2.75 kOhm 30*C 1.89 kOhm 40*C 1.34 kOhm 50*C 1 kOhm 60*C 665 Ohm 70*C 500 Ohm 80*С 360 Ohm 90*С 276 Ohm 100*С 188 Ohm And compare with the graph from the forum:

My readings are quite close and what is called “will work”.

Let's move on to the intake air temperature sensor (IATV), first you should check the wiring from the connector to the element ("crystal", "tablet" ...). Unfortunately, I didn’t take any photos... Both wires showed too high resistance, one was about 5 ohms, the other was almost 200 ohms, which means that the conductors in the injector cover have become acidic and need to be duplicated. To do this, I cut out the grooves with a drill, laid out new wires and soldered them to the connector pins and the element itself. Then I covered it with poxypol, or maybe epoxy, etc. Drill:

Mono-Motronic (Jetronic) Bosch

Bosch Mono-Jetronic control system - mono injection system. This means that, like carburetor engines, fuel is injected from a single injector ahead of the throttle valve.

Engines: 1F, RP.

The Mono-Motronic injection system is similar to the Mono-Jetronic system. The difference is that the Mono-Motronic system does not have a switch and a vacuum corrector of the UOZ; their functions are performed by the engine control unit, which improves the operation of the ignition system in all engine modes. The system has a self-diagnosis function. The electronics registers malfunctions in the injection system and, after the first occurrence of a malfunction, writes its code into memory.

Engines: 1F, RP, AAM, ABS, ADZ.

Signs and causes of malfunction

On the Volkswagen Passat B3, the mono-injection always starts to work poorly according to approximately the same pattern. All owners of this vehicle should pay attention to it. At first, the driver may notice that the engine speed begins to “float”, after which the engine reacts poorly to pressing the gas pedal. A similar problem occurs both when starting the engine and during the trip. Repairing the system in this case is quite short. Much more work needs to be spent on finding out the reason why the malfunction occurred.

Read also: Fuses in Volkswagen Polo cars: where they are located and how they change

As you can see from various videos on repairing the Volkswagen Passat B3, the car does not have a computer connection model. As a result, it is not possible to quickly diagnose the vehicle.

Among the most popular causes of malfunctions with a single injection system are the following:

- Loss of tightness of the gasket located directly under the assembly.

- Departure of contacts of wires located directly under the sensor.

- Replacing old spark plugs with new ones with their rapid failure after engine operation.

- Reduced sealing of the distributor cap (the problem may even relate to a microcrack invisible to the naked eye).

- The compression level is too high or low, which is created by the fuel pump.

- Clogged or dirty throttle valve.

- Damage to the wires that extend from the sensor, which are responsible for monitoring the throttle position.

Thus, the above problems are the main signs of a malfunction. Before you begin, you need to pay attention to the Volkswagen Passat B3 repair videos available on the Internet.

Setting up mono injection in garage conditions

The correct operation of the mono-injection system depends on the crankshaft rotation speed, on the ratio of the volume of incoming air and its mass, on the angle at which the throttle valve is open, on the absolute pressure in the intake, etc. There is also a connection with the oxygen sensor (lambda probe). The signal from the oxygen sensor is sent to the adaptation system, which adjusts the operation of the single injection, making the necessary changes in different operating modes of the internal combustion engine. It is quite obvious that during the operation of the vehicle, malfunctions occur in this system.

Taking into account the fact that the scanner cannot detect the error, it is necessary to check individual elements one by one that may affect the operation of the monoinjector. The following breakdowns are noted in the list of faults:

- The tightness of the gasket installed under the monoinjector is broken. Loss of tightness leads to uneven distribution of fuel. In this case, the gasket should be replaced with a new one.

- problems with the contact group or wiring to individual electrical elements of the mono-injection unit. Possible damage, breakage, loss of insulation integrity, etc. To check, each element and its wiring must be “ringed” with a multimeter.

- The operation of single injection is affected by the type of spark plugs installed. If, after replacing the spark plugs, the engine begins to malfunction, then to check, you can screw in the old spark plugs and evaluate the stability of the internal combustion engine.

- The dependence of the monoinjector and ignition suggests the need to inspect the distributor and its cover. Minor defects or a breakdown of the cover is a reason for replacement.

- Additionally, you should check the TPS sensor, which determines the throttle position. Checking is carried out with a multimeter.

- You should also pay attention to the pressure that the fuel pump produces. If the device is faulty or malfunctioning, then repair or replacement of the fuel pump is necessary. Don't forget about fuel filters, which can become clogged.

- carbon deposits and deposits on the throttle valve must be removed (cleaning the throttle valve), since contamination can have a significant impact on the performance of the single injection.

The most common problems associated with the monoinjector were discussed above. If self-checking does not yield anything, it is better to visit a car service center. Also, the mono-injection system after repair, cleaning or as a result of failures needs to be adjusted and further diagnosed. Let's look at how this is done using the example of a Volkswagen B3 with a monoinjector.

- The first step is to check the resistance of the incoming air temperature sensor. The measurement is made using a multimeter, after which the obtained values are compared with the nominal values in a special table. If the air temperature is between 20 and 25 degrees Celsius, then the resistance should be between 1800 and 1900 ohms. Heating of the sensor means that the resistance should decrease, cooling will lead to an increase in resistance. This must be checked by heating and cooling the sensor yourself.

- Also, using a multimeter, the resistance at the monoinjector injector is measured. A normal operating indicator is a resistance in the range from 1.2 to 1.6. Slight deviations are acceptable as the multimeter may have inaccuracies.

- The next step is to adjust the idle speed on single injection. For this setting, voltage is supplied from the battery to the regulator contacts (12 V). At the same time, the accelerator is set to its extreme position. Next, use a multimeter to check for a short circuit. To do this, you will need to place the multimeter probe in the gap that exists between the accelerator limit switch and the rod. If the gap is too large, then the short circuit will not be visible on the multimeter. This means that the specified gap needs to be adjusted. This is done using a screw made for this purpose, which is located at the bottom of the monoinjector. The screw changes the position of the limit switch.

- After cleaning or carrying out other work on the monoinjector, it is necessary to adjust the position of the monoinjector throttle valve. To set this up, the mono-injector must be installed on the car, after which the injection nozzle connector, the throttle position sensor connector, the incoming air temperature sensor connector, etc. are connected. Next, you should connect the fuel lines. Now the terminals are disconnected from the battery, after which you should turn the key in the ignition switch. These steps allow you to reset the monoinjector settings. Then the battery can be connected, after which the mono-injection will begin to work with the original factory parameters.

To solve the problem, you will need to slightly unscrew screw 4 on the throttle cover, after which the multimeter will be connected to contacts 1 and 2. Then the cover is slowly turned in different directions, recording the voltage changes on the multimeter at each offset. With these actions it is necessary to achieve the recommended voltage readings. As a result, a serviceable single injection with all functional and connected sensors will function normally after tuning and cleaning the throttle.

Design, purpose and principle of operation of the throttle position sensor. Types of TPS, common faults and methods for checking the sensor.

Why do you need to clean the throttle valve periodically? How to clean the throttle valve, training and adaptation of the throttle valve after cleaning, useful tips.

What does water injection into an engine provide, the principle of operation, the main advantages and disadvantages. How to inject water into the engine yourself, available methods.

Refinement and modernization of the carburetor. The main disadvantages of the carburetor injection system and how to eliminate them, settings. Intake manifold tuning.

Design and operating diagram of the injector. Pros and cons of an injector compared to a carburetor. Malfunctions of injection power systems are common. Useful tips.

Computer diagnostics of a car engine and other units: why it is necessary and what malfunctions it identifies. How to check the car yourself.