Tuning and repairing single injection on Volkswagen Passat B3

A common problem for a common German car: how to set up and repair mono-injection on a Volkswagen Passat B3. This model is very common among the entire Volkswagen model range.

It is characterized by the following positive qualities: reliability, spaciousness, durability, ease of maintenance. In general, this car contains many characteristics that make it a truly people's car. It can also be noted that the interior is large and spacious, the car starts at very low temperatures, the body is made of high quality, the car is very playful for its age.

Thanks to these advantages , many people use the Passat B3 as a workhorse; it can be found everywhere: in the city, in the country, in the middle of a field, in the forest, in swamps, and while fishing. Although the car is very reliable, breakdowns and stability in engine operation are also common. So, one of the problems may be a floating engine speed, which is why the car begins to behave poorly, as people say - the car “stumbles”.

Even if the car starts up well, after a while while driving the speed may drop and the gas pedal seems to sink. These problems are associated with the mono-injection engine.

Setting up and repairing single injection on a Volkswagen Passat B3 is not a difficult task; the most important thing is to discover the cause of this problem. The complexity of computer diagnostics in this model is complicated by the lack of a computer connection module.

The problem with uneven mono-injection, as a rule, can be as follows:

- there is a gasket under the single injection, if the seal is broken, uneven distribution of fuel begins (replace the gasket);

- The device itself has a yellow sensor, under which the wires are hidden. You need to remove the sensor and check the integrity of the wire connection;

- the malfunction may be related to them (selection of the optimal type of spark plugs);

- The trampler cover may be broken (in this case it needs to be replaced). The hole may be small, not even visible to the naked eye;

- on the sensor that regulates the throttle position, the resistance should change without significant dips in the values (checking the integrity of the wiring);

- improper compression of the fuel pump (repair or replacement of the fuel element);

- clogged fuel filter (replace with a new one);

- carbon deposits and clogged throttle valve (just disassemble and clean it).

The above are the main problems that play an important role in the operation of a single injection. If these troubleshooting options do not help, you should consult with specialists. After the mono-injection has been repaired, it is also necessary to adjust it correctly.

Setting up the single injection on the Volkswagen Passat B3 is carried out in the following order:

- you need to measure the resistance on the intake air temperature sensor with a multimeter and compare it with the table value (if work is carried out at room temperature 20-25°C, then the resistance value is at the level of 1.8-1.9 kOhm);

- when the intake air sensor heats up, the resistance drops; when cooled, it grows. If everything is exactly like this, then the sensor is working;

- we measure the resistance of the nozzle itself (resistance values range from 1.2 to 1.6 Ohms). If you get values above, check the error of the multimeter, it can be significant. This is described in more detail in the article “How to check injectors”;

- then we set the single injection idle clearance. By supplying 12 V voltage from the battery to the contacts of the regulator, we set the accelerator to its extreme position. We set the multimeter to “short circuit” mode and connect the contacts to the accelerator regulator. The following situation should arise: there should be a gap between the rod and the accelerator limit switch, insert the probe into this gap (ideally 0.45-0.5 mm), if the multimeter does not register a short circuit, then the distance is too large. It should be noted that during this procedure the adjusting bolt must be set according to the instructions. So, if the gap is too large, then we adjust the position of the accelerator limit switch with a screw located at the bottom of the mono-injection;

- adjust the throttle position. To do this, you need to install the mono-injection on the engine and connect the connector to the injector, throttle position sensor and intake air sensor. We connect the fuel hoses and remove the terminal from the battery, and turn the ignition key. This resets all on-board device settings. After that, connect the battery in place.

We measure the voltage on the first and fifth contacts of the throttle connector (with the ignition on), it should be 5-6 V. Then between contacts 1 and 2 the value is 0.186 V, if not, then we carry out the adjustment. To do this, loosen the 4 screws of the damper cover, connect the multimeter to contacts 1 and 2 and turn the cover in one or the other direction, changing the voltage.

At this point, the setup is complete, we assemble the mono-injection to the end and start the car. Thus, the single injection system on the Volkswagen Passat B3 is configured and repaired. If they are not afraid to get their hands dirty, and they grow from the right place, then there is nothing difficult about it. Doing everything yourself is much more pleasant than paying someone else a lot of money for it.

What you need to know about single injection in the Passat B3

Volkswagen Passat B3 is one of the most popular models in this line of company vehicles. Significant demand for it was due to a number of different factors. The machine is not only quite convenient and ergonomic, but also very reliable. It starts without problems at low temperatures and holds the road well at high speeds. Despite this, the Passat B3 still has one significant drawback. It concerns the stability of the mono-injection system. That is why vehicle owners often have to pay attention to it, repair the unit and try to configure it correctly.

Reliability of the 1.8 AAM single-injection engine

Mechanically, the 1.8 AAM engine is very reliable. Many examples with a mileage of half a million kilometers or more are still in use without major repairs. A broken timing belt is not capable of killing this engine, because... pistons and valves do not collide here - the low compression ratio of 9:1 for AI-92 gasoline insured it from such a nuisance.

The mono-injection system itself causes some trouble during operation, but it has already been well studied. True, some of its parts are extremely expensive - the prices for a number of components are comparable to the cost of cars with this single-injection engine.

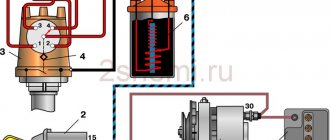

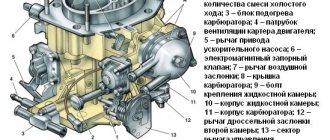

Single injection device for Volkswagen Passat

In order for the Passat B3 mono-injection setup to be done correctly, you first need to understand the structure of this important unit for the car. This device is not a carburetor, but it is significantly different from modern injectors.

The main feature of the Passat B3 mono injection is that it works through one injection nozzle, which delivers fuel. That is why this system is more reliable than using conventional carburetors. Single injection has the following advantages:

- ensuring ease of starting the internal combustion engine;

- reduction in fuel consumption;

- eliminating the need for complex setup.

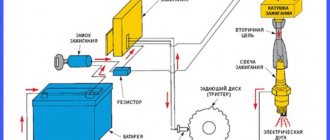

Many drivers of cars equipped with a mono-injection system note much better engine performance with noticeable fuel savings. This is achieved through single-point, electrically controlled, low-pressure mixture delivery. It is used on gasoline internal combustion engines vehicles. The installed injector can be controlled via a solenoid valve. Air dosage occurs through the throttle valve.

Parallel to how injection occurs, an ignition pulse occurs. These processes are synchronized with each other. For optimization, the device is equipped with appropriate sensors. They allow you to adjust the injection in accordance with the operating mode of the internal combustion engine at a particular moment. This is important to obtain the most optimal fuel-air mixture. It is at the inlet that gasoline is distributed among the cylinders of the internal combustion engine.

Advantages of the system

Advantages of mono injection over carburetor:

- simplified engine starting;

- fuel consumption is reduced while maintaining the same driving style;

- the mono-injection device eliminated the need to manually adjust the mixture supplied to the engine;

- reducing the amount of harmful substances in the exhaust as a result of a more optimal ratio of gasoline and air supplied to the combustion chamber;

- control by ECU.

One of the main advantages of cars with single injection was the absence of dependence of fuel consumption on the level of qualification and experience of the carburetor. The classic system, if the quality and quantity screws were incorrectly set, could burn gasoline several times more than normal, due to the low professionalism of the person who made the adjustment. In mono-injection, no intervention is provided during normal operation. Incorrect adjustment of a single-point injection system when troubleshooting does not have such a critical effect on fuel consumption.

Signs and causes of malfunction

On the Volkswagen Passat B3, the mono-injection always starts to work poorly according to approximately the same pattern. All owners of this vehicle should pay attention to it. At first, the driver may notice that the engine speed begins to “float”, after which the engine reacts poorly to pressing the gas pedal. A similar problem occurs both when starting the engine and during the trip. Repairing the system in this case is quite short. Much more work needs to be spent on finding out the reason why the malfunction occurred.

As you can see from various videos on repairing the Volkswagen Passat B3, the car does not have a computer connection model. As a result, it is not possible to quickly diagnose the vehicle.

Among the most popular causes of malfunctions with a single injection system are the following:

- Loss of tightness of the gasket located directly under the assembly.

- Departure of contacts of wires located directly under the sensor.

- Replacing old spark plugs with new ones with their rapid failure after engine operation.

- Reduced sealing of the distributor cap (the problem may even relate to a microcrack invisible to the naked eye).

- The compression level is too high or low, which is created by the fuel pump.

- Clogged or dirty throttle valve.

- Damage to the wires that extend from the sensor, which are responsible for monitoring the throttle position.

Thus, the above problems are the main signs of a malfunction. Before you begin, you need to pay attention to the Volkswagen Passat B3 repair videos available on the Internet.

Setting up mono injection in garage conditions

Adjustment or adjustment of the injection device on (VW) Volkswagen can be done independently in a garage. This does not require any experience or special skills. The main thing is to strictly follow the algorithm of actions indicated below and focus on all the advice of professionals.

Required Tools

Before repairing the Passat B3 mono-injection unit, you must first prepare the necessary tools and additional accessories. Among them, in the process of work you may need the following:

- screwdriver;

- open-end wrenches;

- new spark plugs of the appropriate type;

- socket heads with collar;

- multimeter for taking measurements;

- sandpaper for cleaning contacts;

- electrical tape for working with wires;

- flat tongs;

- gasket for single injection (if it is damaged);

- distributor cover (if there are cracks).

It is worth paying attention to the fact that not all additional devices indicated in the list may be needed. This directly depends on what exactly caused the malfunction.

Step by step guide

The repair process must occur in several stages:

- It is necessary to check the resistance of the air temperature sensor that enters the system. To do this you need to use a multimeter. The values obtained with its help should be compared with the normal values that are indicated in the manual for using the car. If the temperature range is from 20 to 25 degrees, then the resistance should be in the range of 1800-1900 Ohms. As the sensor heats up, you should see a decrease in resistance. By cooling it increases. This needs to be checked using a multimeter, independently raising and lowering the temperature.

- The next stage of repair is checking the resistance on the mono injector nozzle. In the working position it can range from 1.2 to 1.6 Ohms. Due to the fact that the multimeter does not measure very accurately, small errors in these indicators are still allowed.

- Next you need to adjust the idle speed. To do this, it is necessary to send a voltage of 12 V from the battery to the contacts of the regulator. At the same time, the accelerator should be set to its extreme position. Then we check for the presence of a short circuit (SC). To do this, the probe must be placed in the gap formed between the accelerator end and the rod itself. It is worth understanding if the gap is too significant. the multimeter will not be able to show the presence of a short circuit. In such a situation, adjustment or adjustment of the injection device on (VW) Volkswagen Pasat B three is required. To do this, you need to use a special screw located at the bottom of the assembly. With its help you can control the position of the limit switch.

- Once the driver has successfully adjusted the mono-injection, he needs to clean it and carry out other work of the same kind. Only after this can you begin to adjust the position of the throttle valve of the unit. In order to do this, you need to connect a monoinjector. The injector connector should be connected to it. Then you need to connect the position and temperature sensor connector. Next, you need to move on to installing the fuel lines in their correct position. The driver should disconnect the terminals from the battery. Once this is done, the key must be turned in the ignition. This way you can reset all previous settings. In the end, all that remains is to connect the battery.

Disadvantages of using one nozzle

The current lack of serial production of single injection is due to a number of shortcomings that have not allowed it to emerge victorious in the competition. The main disadvantages of the system under consideration are:

- high cost of components, especially compared to the carburetor power system;

- low maintainability, associated both with the design features of the units and with the small number of specialists capable of repairing a single injection unit;

- The speed fluctuates greatly with any deviations in fuel quality;

- inability to start the car with a discharged battery, since the mono-injection system is controlled by an electronic controller;

- Diagnostics, repair and adjustment of mono-injection are very difficult in garage conditions, as they require special equipment.

If the car does not start, then with a carburetor power system, the car owner will check whether the fuel is overfilled and can start the engine. In the case of single injection, only a few know how to adjust the fuel supply, so checking the performance of the system becomes an incomprehensible task for most. The complexity of the electrical circuit has made it impossible to test it with a multimeter; now the fault can only be identified by connecting a diagnostic scanner.