Diesel engine operating temperature standards

Owners of diesel cars often have a question: what should the operating temperature of the engine be? The fact is that the operating temperature on different machines can vary greatly, so it’s worth understanding what this depends on and how to understand how well the temperature of your diesel engine meets the standards. Of course, you can address this issue to a service station, but in this case you shouldn’t choose the first one you come across, since often service employees, seeing an inexperienced diesel operator, in addition to correcting a minor breakdown, can report that boring the cylinder block or repairing all the injectors is of great importance here , for which there will be no real grounds at all.

The importance of normal temperature readings

The viscosity and lubricity of motor oil depend on the degree of heating of the liquid. When the temperature rises excessively, the substance passes through the gap between the parts without forming a separating film, which reduces the rate of wear. As the grease cools, it becomes thick. The oil pump cannot deliver material through thin channels to the contacting parts.

Motor oils are produced in accordance with the SAE standard, which determines the possibility of using the liquid depending on the ambient temperature. For example, grade 0W-30 retains fluidity when cooled to -38... -40 °C. The viscosity of the lubricant with a normally warmed-up power unit should be 8...12 centistokes (cSt). The parameter is calculated taking into account the thermal expansion of engine parts and ensures the preservation of the oil film on the mating surfaces.

When pouring oil, the operating temperature of the engine and the characteristics of the fluid are taken into account. For example, when using a lubricant with increased viscosity, there is an increase in power losses to overcome friction forces, which negatively affects fuel consumption.

In power units of production cars, the oil in the sump warms up to +90…+115 °C; in racing power plants – +130 °C.

Diesel engine operating temperature range

According to experts, normal temperature conditions during operation of a diesel power unit range from 70-90 degrees. The maximum temperature can reach 97 degrees, but this is the limit. As for the example with Toyota Hayes, this temperature indicator is suspiciously low. The fact is that the operation of many components, including the process of mixture formation, depends on the temperature of the diesel engine.

At the optimal temperature during the formation of a combustible mixture, the evaporation time will be reduced, the auto-ignition delay period will be reduced, as a result of which one can happily note an increase in the efficiency of the engine power and, as a result, a decrease in fuel consumption.

Changes in engine oil temperature

Engine parts are designed to expand when heated and return to their original state as the engine cools. The operation of the power unit depends on the temperature of the oil in a running engine. Excessively low or high heating of the oil in a running engine has negative consequences.

The low temperature of the lubricant can be considered + 80 degrees. With this indicator, the efficiency of the power plant decreases and its service life decreases. The parts of the power unit will have a slight expansion, which will lead to the formation of gaps between them and a decrease in compression. When the starter is slightly warmed up, moisture can condense and form acids in the lubricant, which will affect the wear of components and assemblies. Low degrees can cause the lubricant to thicken and freeze. This will affect its passage through the filter, creating a vacuum in the lubrication system and difficulties in the operation of the power plant.

High heat is even more dangerous than low heat. Heating the oil fluid above + 105 degrees leads to its viscosity sharply decreasing and fluidity increasing. Under load, the gap between the parts almost disappears, the parts of the crank mechanism come into contact with each other.

Consequences of low engine temperature

If the engine temperature is low, engine efficiency will decrease. For example, a common problem is tarring of the nozzle nozzle, which results in deterioration in fuel atomization because the injector simply begins to flow. Also, piston burnout may add to this problem, however, this is more likely for power plants with a volumetric mixture formation function and an undivided combustion chamber.

Source

Functions of motor oil

Engine oil plays an important role inside the engine system. It performs the following functions:

Motor oil in the engine.

- Reduces friction between mechanisms and helps maintain the integrity of metal surfaces.

- Prevents gas breakthroughs from the combustion chamber to the outside.

- Cleans the system channels and helps eliminate blockages.

- Prevents the formation of soot and soot inside the workspace.

- Provides protection against corrosive processes.

- Promotes heat removal, stabilizes temperature in friction areas.

Most car owners are confident that the coolant prevents engine overheating, but researchers have proven that it is the engine oil that removes about 70% of the heat from the working area.

CAUSES OF ENGINE OVERHEATING

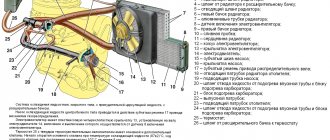

Overheating can be caused by many reasons, all of them are related to a malfunction of the cooling system, or the quality of the coolant, as well as contamination of the cooling system jacket, which impairs the fluid throughput. It is important to use high-quality spare parts, otherwise the reasons below will happen suddenly. Let's look at each of the reasons.

LOW COOLANT LEVEL

The most common problem is a lack of coolant in the system. Coolant, in the form of antifreeze or antifreeze, constantly circulates through the system, removing heat from heated engine parts. If the coolant level is insufficient, the heat will not be removed sufficiently, which means an increase in temperature will be inevitable.

If it is not possible to add coolant, then turn on the heater to reduce the likelihood of overheating. As a last resort, add regular or distilled water, after which the cooling system must be flushed and then filled with fresh antifreeze. At temperatures above 90 degrees, you should immediately stop the car, turn off the ignition, and allow the engine to cool.

ELECTRIC COOLING FAN FAILED

The electric fan forces cool air onto the radiator, which is especially necessary when driving at low speeds when there is insufficient air flow. The fan can be installed either in front or behind the radiator. If the temperature arrow starts to rise, stop the car and check the fan for serviceability. Reasons for fan failure:

- electric motor failed

- connector oxidized

- fan relay burnt out

- The internal combustion engine temperature sensor has failed.

Thermal conditions of a car engine

When a combustible mixture burns in an internal combustion engine (ICE), heat is generated. Critical temperatures at which damage to thermally loaded parts is possible:

| Controlled points | Temperature, °C |

| Piston bottom | 350 |

| At the groove of the upper compression ring | 250 — 260 |

| On the inner piston surface (under the combustion chamber) | 220 |

| Cylinder against the upper piston ring at the end of the compression stroke | 200 |

The temperature of the liquid in the cooling system is set in the range - 80 - 90°C. It is supported structurally: a thermostat, a radiator, and a forced cooling fan that turns on based on a signal from the temperature sensor. The engine oil is heated slightly higher - on average to 90 - 100°C.

CAUSES OF LOW ENGINE TEMPERATURE

Low engine temperature may occur in the following cases:

- use of an inappropriate thermostat (opening temperature too early)

- high performance of cooling fans, or their forced operation from the moment the engine starts

- thermostat malfunction

- non-compliance with the proportion of mixing antifreeze with water.

If you purchase antifreeze concentrate, it must be diluted with distilled water. If in your region the temperature has dropped to a maximum of -30°, then purchase antifreeze marked “-80” and dilute it 1:1 with water. In this case, the resulting liquid will heat and cool in time, and will not lose its lubricating properties, which is extremely necessary for the pump.

Source

Diesel engine temperature

Maintaining the temperature of a diesel engine within strictly specified limits is an important parameter for achieving optimal performance. The design features and intended purpose of the engine will determine what operating temperature of the diesel engine will be normal for a particular engine.

The operating temperature of one internal combustion engine may differ markedly from another. As for the diesel engine, its operating temperature (provided that the unit, cooling system and other components are in full working order) depends on a number of conditions.

Oil functions and lubrication modes

Motor oil performs the following tasks:

- removes heat from the friction zone, helping to reduce operating temperature;

- carries away mechanical particles, preventing abrasive wear;

- neutralizes the aggressive environment, preventing corrosive wear;

- inhibits gas breakthrough by sealing the working chamber.

There are 2 main types of oil interaction: boundary and hydrodynamic.

- In the first mode, lubricant flows to the rubbing surfaces without pressure and wets them, reducing wear. The lubricating product is continuously renewed by spraying or using nozzles. In this way the following are lubricated: connecting rod and piston group (including pistons with rings), toothed chain, rockers, valves and a number of other parts.

- Hydrodynamic lubrication - when lubricating fluid is supplied to the friction area from a pressure oil pump. In this case, an oil wedge is formed, causing the internal part to “float” on an oil film, due to which a gap is formed between the surfaces, eliminating direct mechanical contact. An example is the lubrication of crankshaft and camshaft bearings.

Compression ratio

A diesel engine operates on the principle of self-ignition of the mixture from contact of atomized diesel fuel with air heated by compression. The more the air in the cylinder is compressed (heated), the more intense the flash occurs after fuel injection, while the amount of fuel supplied remains the same.

It is also worth considering that the compression ratio is increased only to certain limits. The fuel-air mixture in the cylinder should not explode upon contact with heated air, but burn evenly. A strong increase in the compression ratio can lead to uncontrolled ignition of the fuel, which causes detonation, local overheating and accelerated wear of the cylinder-piston group.

Basic parameters of diesel units

Before answering the question, what is the operating temperature of a diesel engine, it is worth paying a little attention to its main parameters. These include the type of unit; depending on the number of strokes, there can be four- and two-stroke engines. The number of cylinders with their location and operating order is also of considerable importance. The power of a vehicle is also significantly affected by torque.

Now let’s look directly at the influence of the compression ratio of the gas-fuel mixture, which, in fact, determines the operating temperature in the cylinders of a diesel engine. As already mentioned at the beginning, the engine works by igniting fuel vapors when they interact with hot air. Thus, volumetric expansion occurs, the piston rises and, in turn, pushes the crankshaft.

The greater the compression (the temperature also increases), the more intense the process described above occurs, and, consequently, the value of useful work increases. The amount of fuel remains unchanged.

However, keep in mind that for the engine to operate most efficiently, the air/fuel mixture must burn evenly and not explode. If you make the compression ratio very high, this will lead to an undesirable result - uncontrolled ignition. In addition, such a situation not only contributes to insufficiently efficient operation of the unit, but also leads to overheating and increased wear of the piston group elements.

Permissible operating temperatures of diesel internal combustion engines

The temperature of a diesel engine will directly depend on the type of engine. The process of mixture formation and combustion of the fuel-air working mixture, as well as the normal functioning of other internal combustion engine systems, depends on maintaining the operating temperature of the diesel unit.

After reaching operating temperature, the evaporation time of diesel fuel is reduced to the optimal value, and the auto-ignition delay period is reduced. The fuel-air mixture burns evenly and fully, which leads to increased diesel efficiency, lower fuel consumption and reduced exhaust toxicity.

Viscosity-temperature characteristics

The stability and efficiency of their operation depends on the viscosity characteristics of lubricants. Viscosity, as well as the viscosity index, are one of the most important indicators, since they change during the transition from very low (-40 ° C) to high operating temperature conditions of the power unit.

Overheating of lubricants is very dangerous for the engine. If the composition is heated to +125°C and above, it will lose its viscosity and will not be able to form an oil film. Therefore, it will penetrate into the combustion chamber through the piston rings, burning there along with the fuel. This is how soot deposits form and the lubricant burns out. That is why it is necessary to periodically check the oil level. It happens that a viscosity mismatch leads to lubricant consumption of up to 1 liter per 100–200 kilometers.

It is very important to use working fluids with the viscosity recommended by the manufacturer. This parameter can be determined from the service book issued for each vehicle.

Source

Diesel does not warm up to optimal temperature

When warming up a working diesel engine in idle mode, it is advisable to wait until the coolant heats up to a temperature of about 40-50°C. If there is a strong minus outside, the diesel engine may even begin to warm up only while driving. You need to start driving in a lower gear, sticking to around 2-2.5 thousand rpm. When the temperature rises to 80°C, the load on the motor can be increased.

If a diesel engine does not reach operating temperature while driving, this indicates that its efficiency has decreased. Power decreases, the car accelerates worse, diesel fuel consumption increases, etc. These symptoms may indicate the following problems:

- malfunction of the engine cooling system (thermostat);

- the compression ratio is not normal (low compression);

Diesel engine features

So, before touching on any specific parameters, you should decide what, in general, a diesel engine is. The history of this type of motor begins back in 1824, when a famous French physicist put forward the theory that it was possible to heat a body to the required temperature by changing its volume. In other words, by performing a rapid compression.

However, this principle found practical application several decades later, and in 1897 the world's first diesel engine was released; its developer was the German engineer Rudolf Diesel. Thus, the operating principle of such an engine is the self-ignition of atomized fuel interacting with air heated during the compression process. The scope of application of such a motor is quite extensive, starting with standard cars, trucks, agricultural machinery and ending with tanks and shipbuilding.

Advantages and disadvantages of a diesel engine

Now we should say a few words about all the pros and cons of such structures. Let's start with the positive aspects. Motors of this type operate on almost any fuel, so there are no serious requirements for the quality of the latter; moreover, with an increase in its mass and content of carbon atoms, the calorific value of the engine increases, and, consequently, its efficiency. Its efficiency sometimes exceeds 50%.

Cars with such engines are more “responsive”, and all thanks to the high torque at low speeds . Therefore, such a unit is welcome on sports car models, where you can’t help but rev your heart out. By the way, it was this factor that contributed to the widespread use of this type of engine in large trucks. And the amount of CO in the exhaust gases of diesel engines is significantly lower than that of gasoline engines, which is also an undoubted advantage. In addition, they are much more economical, and even before the cost of fuel was much lower than gasoline, although today their prices are almost equal.

As for the shortcomings, they are of the following nature. Due to the fact that enormous mechanical stress occurs during the work process, diesel engine parts must be more powerful and of higher quality, and, therefore, more expensive. In addition, this also affects the developed power, and not in the best way. The environmental side of the issue is very important today, therefore, in order to reduce exhaust emissions, society is ready to pay for “cleaner” engines and is developing this area in research laboratories.

Another significant disadvantage is the likelihood of fuel solidifying in the cold season, so if you live in a region where fairly low temperatures prevail, then a diesel car is not the best option. It was said above that there are no serious requirements for the quality of fuel, but this applies only to oil impurities, but with mechanical impurities the situation is much more serious. Unit parts are very sensitive to such additives; in addition, they quickly fail, and repairs are quite complex and expensive.

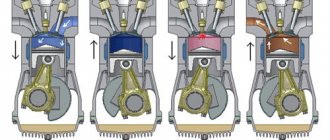

Phases of fuel combustion and the nature of exhaust gases

How is the combustion process of the fuel-air mixture carried out in diesel engines and what is the temperature in the chamber? So, the entire process of engine operation can be divided into four main stages. At the first stage, fuel is injected into the combustion chamber, which occurs under high pressure, which is the beginning of the whole process. Then the well-atomized mixture spontaneously ignites (second phase) and burns. True, the entire volume of fuel does not always mix well enough with air; there are also zones that have an uneven structure; they begin to burn with some delay. At this stage, a shock wave is likely to occur, but it is not dangerous, since it does not lead to detonation. The temperature prevailing in the combustion chamber reaches 1700 K.

During the third phase, droplets are formed from the unprocessed mixture; at elevated temperatures they turn into soot. This process, in turn, leads to a high degree of exhaust gas pollution. During this period, the temperature increases further by as much as 500 K and reaches a value of 2200 K, while the pressure, on the contrary, gradually decreases.

At the last stage, the remaining fuel mixture burns out so that it does not escape as part of the exhaust gases, significantly polluting the atmosphere and roads. This stage is characterized by a lack of oxygen, this is due to the fact that most of it has already been burned in the previous phases. If you calculate the entire amount of energy spent, it will be about 95%, while the remaining 5% is lost due to incomplete combustion of fuel.

By adjusting the compression ratio, or rather, bringing it to the maximum permissible value, you can slightly reduce fuel consumption. In this case, the temperature of the exhaust gases of a diesel engine will be in the range from 600 to 700 °C. But in similar carburetor engines its value can reach as much as 1100 °C. Therefore, it turns out that in the second case much more heat is lost, and there seems to be more exhaust gases.

The role of lubricating oil viscosity

One of the characteristics of motor oil is its dynamic viscosity, measured in centistokes. This parameter affects the longevity of the car engine and is usually indicated in the vehicle manual.

In addition to the technical features of the engine, the choice of lubricant viscosity is also influenced by seasonal operating temperatures. With increasing temperature, the viscosity of the oil decreases, and with decreasing temperature it increases. Therefore, for winter it should be less, for summer - more.

The most used multi-grade oils contain special components - viscosity additives, designed to provide the required viscosity at elevated temperatures. In addition, it is necessary to maintain the operating temperature of the oil within certain limits.

Engine operating temperature in winter - how to start correctly?

Surely, not only owners of vehicles with a diesel engine know that the car should be warmed up for several minutes before driving, this is especially true in the cold season. So, let's look at the features of this process. The pistons are the first to be heated, and only then the cylinder block. Therefore, the temperature expansion of these parts is different, and oil that is not heated to the required temperature has a thick consistency and does not flow in the required quantity. Thus, if you start accelerating the car when the car is not warmed up enough, this will negatively affect the rubber gasket located between the above parts and the engine elements.

However, excessively long warm-up of the engine also poses a danger, because at this time all the parts work, so to speak, to wear out. And, consequently, their service life is reduced. How to correctly carry out this procedure? First, it is necessary to bring the fluid temperature to 50 ° C at idle speed and then start driving, but only in a low gear not exceeding 2500 rpm. After the oil has heated up to the point where the operating temperature is 80 ° C, you can increase the engine speed.

All these methods will help save the engine if it still works in winter, but what to do if it refuses to respond to your actions? It’s hard to advise anything based on the fact of the problem; it’s easier to prevent it. This became possible thanks to a new invention by fuel manufacturers - additives that help the composition not to wax. In addition to the ability to add them yourself, you can purchase ready-made diesel fuel with optimal proportions of these additives. In most regions with low winter temperatures, it appears at gas stations already in the first slight frosts, often called DT-Arctic.

Source

The dangers of oil overheating

Excessive heating of the lubricant is much more dangerous than the previous case. Until the operating temperature of the oil leaves the permissible limits, parts operating in the hydrodynamic lubrication mode (crankshaft connecting rods and main journals) do not have mechanical contact with each other.

After heating the oil above 105°C, its viscosity decreases and it becomes more fluid. In this case, under the influence of load, the oil gap loses its load-bearing capacity, and the interacting parts come into contact.

From this moment, due to friction, the rubbing parts begin to heat up, and the thermal gap between them decreases. Increasing oil temperature leads to its oxidation, which theoretically can be detected using laboratory analysis. When the oil heats up above 125°C, it becomes so fluid that it seeps through the oil scraper rings and penetrates into the working cavity of the cylinder, where it burns out.

Due to increasing consumption, oil has to be topped up, in which case all oil additives are renewed, and the analysis results are unreliable. The engine begins to wear out intensively, but this is often attributed to poor performance of the lubrication system.

And only after the engine breaks down can you discover what reason contributed to the sad outcome. If there was an oil starvation, the oil pump would be damaged, and the pistons could be scored. And in this case, the pump is working, but the crankshaft journals are raised.

Concluding the article, I would like to advise drivers who want to maintain the health of their iron “horse” to avoid long-term driving at high speeds, monitor the temperature of the engine oil, replace it in a timely manner and fill in a proven product with the viscosity recommended by the automaker.