The CVT on the Toyota Corolla, according to reviews from owners, is a reliable unit only if the operating rules are followed. The transmission simplifies the process of driving a car and does not require manual gear shifting. By smoothly adjusting the gear ratio, fuel consumption is reduced regardless of the driving mode.

The Toyota Corolla CVT is a reliable unit.

The concept of a variator

The variator allows you to smoothly change the gear ratio, acceleration and deceleration occur without jerking. The design does not have a pedal-driven clutch; a hydraulic transformer is used to open the engine crankshaft and the primary axis of the box.

The Toyota Corolla uses units manufactured by Aisin, the model depends on the year of manufacture of the car.

Design and principle of operation

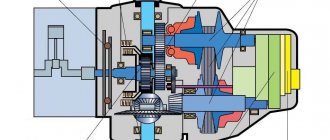

The design of the unit includes 2 conical surfaces located on the drive and driven shafts. Torque is transmitted by a metal plate belt, which is constantly lubricated with special oil. The electronic control unit automatically adjusts the position of the belt on the cones, smoothly changing the gear ratio. Wear products entering the oil are captured by a filter and a magnetic plug in the gearbox housing.

Toyota Corolla has undergone a complete modernization with a new image for 2014

The success of the Corolla has spurred the manufacturer to make changes to its 2014 appearance. The main purpose of these changes was to attract new customers to the Corolla, although we think Toyota should be doubly careful not to alienate existing fans of the vehicle. But what exactly has changed in the 2014 Corolla? For clarity, allow us to present the ten most significant updates to the new 2014 Toyota Corolla in our simple review of this model.

Toyota says all new Corolla models will weigh 1.3 tonnes or less. Although the weight reduction will be minor, this improvement still gives cars like the Chevrolet Cruze and Ford Focus a run for their money. The weight reduction not only improves fuel efficiency, but also makes the Corolla a more nimble vehicle, maintaining its reputation as an easy-to-drive vehicle. The company does not reveal the secrets thanks to which the weight in the car was reduced, but we suspect that this could not have happened without friction stir welding of the car body, which we talked about in our previous articles.

2. THE FOUR SPEED AUTOMATIC TRANSMISSION IS STILL WITH US.

The previous Corolla wasn't particularly noisy inside , but that hasn't stopped Toyota from trying to improve the status quo. The new Corolla will include acoustic glass, better floor insulation with carpeting, a seal between the hood and windshield, sound deadening in the fenders, and a dampening gasket in the dashboard. All these measures should make the car interior especially quiet.

4 . 2014 TOYOTA COROLLA EXTENDED REAR SEAT.

In the style of the most luxurious cars, all versions of the 2014 Toyota Corolla, even those that come with antique four-speed automatic transmissions, will be equipped with LED headlights. LEDs allow Toyota designers to make a model's headlights more creative because they are not as limited in shape as conventional incandescent bulbs. Plus they look really cool. Proof of this can be seen in the examples of the use of LED headlights given in the article: LED optics in the Mercedes-Benz S-Class 2014 model and Headlights of the Audi A8 2015 model.

6. MODERN INTERIOR.

The 1.8-liter engine from the previous Corolla model has migrated to the new generation cars, but there is one small “but”. The new engine features Toyota's Valvematic technology, which the manufacturer claims improves power and efficiency by five percent. The new engine will produce 140 PS of power and 126 Nm of torque, and will be exclusively used in the LE Eco trim, mated to a CVTi-S (continuously variable transmission).

NEW CVT (CVTi-S).

With the new 1.8-liter engine and CVTi-S in LE Eco trim, Toyota expects the 2014 Corolla to cross the elusive 6.0 mpg highway fuel consumption mark. This figure will allow the car to take a leading position in terms of fuel efficiency in its class, especially among compacts equipped with automatic transmissions.

Main types of CVT

CVTs used on cars are divided into types depending on the method of torque transmission:

- steel belt with a wedge-shaped profile or chain;

- rollers (adjustment of the gear ratio is achieved by changing the angle of installation of the disks).

Clinomeric

The classic variator provides for the transmission of torque due to the friction force between the belt and conical surfaces. The design can be equipped with a planetary gear, which prevents the belt from reaching the end edges of the cones. The unit is compact in size and light in weight; manual shifting of fixed gears is possible.

The clinometer variator has compact dimensions.

Toroidal

The design has a driving and driven disks, between which there are rollers with the ability to change the axis angle.

Depending on the position, the gear ratio changes. Toyota cars do not use a toroidal variator.

Advantages and disadvantages

Advantages of the variator noted by owners:

- smooth change in torque;

- reduced fuel consumption due to the optimal ratio of load and crankshaft speed;

- ease of driving.

Disadvantages indicated in reviews:

- the need for regular maintenance with replacement of fluid and filters;

- belt life does not exceed 150 thousand km;

- labor-intensive and expensive repairs;

- in case of breakdown, the car is immobilized;

- The unit is not designed to work with a trailer and quickly breaks down when slipping in snow or mud.

Toyota Corolla CVT repair

Repairing the unit is a rather expensive procedure, since the automatic transmission is a high-tech product with a complex control system. Moreover, unlike other variators, this one is more subject to repair due to its characteristics. To carry out this procedure, it is necessary to dismantle the unit housing, having first disconnected the cooling system pipes and the shaft connecting the box to the engine. After this, you should conduct a preventive inspection of the inside of the unit for various damages. If a malfunction is detected, the failed unit should be replaced.

Toyota models with continuously variable transmission

The Toyota concern began using CVTs in 2000 on Opa cars, which were supplied to the Japanese domestic market. In Europe and North America, cars with CVT appeared only in 2009. The first were Avensis and Verso, equipped with a unified K311 unit with different control units. A year later, the experiment was extended to RAV4 crossovers with front-wheel drive or all-wheel drive. Toyota Corolla began to be equipped with a CVT only in 2013. The type of transmission can be determined by the text on the identification sticker, which contains information about the transmission model.

Since 2000, Toyota models have been produced with a continuously variable transmission.

What kind of variator is on the Toyota Corolla?

Since 2009, a Toyota Corolla with a CVT transmission has appeared on the domestic market, which replaced the single-disc robot. During its production, this unit gained fame as an unpretentious and very reliable device with a minimum of maintenance problems. This car is equipped with a variator from Aisin, which was also installed on other models of this brand.

During production, the box model did not undergo major changes, since, according to the designers, the reliability of all systems was quite sufficient. Also, during use, the owners have accumulated considerable experience in both repair work and identifying various rare faults. Another important indicator of the success of the system is the enormous popularity of these models in both the primary and secondary car markets. Subsequently, Toyota completely abandoned the use of a robotic gearbox in favor of a CVT.

Features of operation and maintenance

During operation, it is necessary to monitor the level and condition of the working fluid. Steel chips in the oil will accelerate wear on the cones and metal belt. Prolonged movement at maximum speed, which leads to overheating of the transmission, is not allowed. The driver needs to smoothly pick up and slow down, avoiding slipping. Before starting to drive, the variator should be warmed up with the car standing and the engine running at idle speed. Do not tow trailers or other vehicles to a CVT-equipped Corolla.

The variator is serviced with fresh fluid refilled after 70-80 thousand km of travel. Some owners try to carry out the procedure 2 times more often, ensuring timely removal of wear products. When servicing, it is necessary to install a new filter (original parts are not supplied for all types of gearboxes), a pan gasket and a drain plug ring.

When draining the crankcase, no more than 80% of the liquid leaves, so you will have to fill and pump out the oil at least 2-3 times in a row.

Frequent malfunctions and repairs

When the working surfaces wear out, the friction coefficient decreases, the car accelerates jerkily, and when the speed is reduced, the engine may stall. In this case, it is necessary to assess the condition of the working fluid. Blackening of the oil and metal inclusions indicate damage to parts. To restore functionality, you will have to disassemble the unit.

Adding fresh fluid can delay repairs for several weeks or months. The burning smell emanating from the oil indicates the need to stop using the variator, which is in disrepair.

The most loaded parts are the rotor bearings. When damaged, a hum occurs, the tonality depends on the speed of movement. Some owners encounter this after 50-60 thousand kilometers. The problem occurs due to metal shavings getting under the rolling elements or due to unstable quality of components at the factory. Fans of sharp acceleration complain that scuff marks form on the cones. In this case, the functionality of the box can only be restored by installing new parts.

Toyota CVTs. Myths and reality

As you know, every car has a gearbox. It helps the engine adapt to different speeds and loads, but here’s the problem: both manual and automatic are essentially a set of pairs of gears with a fixed ratio. To change the ratio, these pairs must be switched and the engine must be disconnected from the drive wheels during the change. In this case, jerks occur and the engine operates in steps - sometimes at high, sometimes at low speeds. But there is a way to connect it to wheels without steps. Such a transmission is called a variator, and its main principle is a stepless change in the gear ratio.

In theory, the variator is designed simply

: two sliding pulleys with a conical belt between them. By pushing and sliding the pulley halves, you can change the diameter at which the belt operates. By changing the diameter, we change the gear ratio. In fact, CVTs are far from new. For more than a hundred years they have been used in all kinds of equipment, for example, in printing presses. However, there they are too bulky and can withstand only small loads. Therefore, the main problems when installing a variator under the hood of a car were reducing the size and increasing the digestible torque. Different companies took different paths, and not all of them ended successfully. The first variators - both for stationary equipment and for cars - were with a rubber belt. And imagine, this worked as long as the engine power measured a couple of dozen horsepower, and the torque did not exceed 50 Nm. But very soon it became clear that rubber was not suitable as the main transmission link in powerful cars. Research and experimentation have led to the conclusion that the only material that can withstand the required loads is steel. And today we will talk about one of the most successful, proven designs over the years - the Toyota RAV4 CVT with a steel belt.

It is this belt, sandwiched between two pairs of cone pulleys, that continuously changes the transmission ratio. That is, one pair of pulleys is turned by the engine, the other is connected to the drive wheels. When the first pair is spread as far apart as possible, the second, on the contrary, is moved close together - this is at the start. And as it accelerates, the second pulleys diverge, the belt falls to a smaller radius, and the first ones move synchronously - the radius increases. Since the cones of the pulleys are smooth, there can be an infinite number of belt positions (and therefore gear ratios) - no steps, at each specific moment of engine operation you can provide the most optimal in terms of economy or the most powerful, if you need to accelerate, gear ratio. What does this give? The fact is that the motor has the most favorable rotation speed - peak power. Revs away from this peak are also possible and are generally used in manual transmissions and conventional automatics, but the efficiency of the power plant outside the peak is lower. And only the variator makes it possible to accelerate exactly at maximum power when the gas pedal is pressed to the floor. At the same time, instead of steps along the steps of a ladder of gears, the situation is more reminiscent of a smooth escalator.

And now

about the most interesting thing in the design of the Aisin , which is exactly what is installed on the Toyota RAV 4

. The fact is that the metal belt, which is the heart of the variator, is designed in an extremely unusual way and works not in tension, but in compression. The silver snake is made of flat plates strung on a steel tape rolled into a ring. On a pulley where the belt is bent, the plates diverge in a Latin “V” shape, but as soon as the belt branch reaches a straight line between the pulleys, the plates form a tight stack that perfectly transmits any force. The CVT belt touches the pulleys only with the side surfaces - the thin ends of the plates - and does not slip. Of course, for this it is necessary to precisely regulate the compression of the pulleys and the distance between them. This is done by the hydraulic unit - the gearbox control system. And its electronics communicate with the engine control system.

However, there is still a moment when the car starts, and here, as in most automatic machines, the torque converter works. It is the first to meet the flow of power from the engine and is able to not only move the car smoothly, but also increase torque. Although its work is fleeting: as soon as the car starts, the lock is activated, and then our old friend - the belt - comes into play. Of course, in reality the CVT is a little more complex, and the apparent simplicity of two pairs of pulleys and a belt is surrounded by numerous engineering solutions. But we will not dive into such depths - the engineering genius has already solved all the problems and we can only enjoy the silent and smooth operation of the mechanism. Most do this, but some believe that if you are an advanced driver, then a CVT is not suitable for you

. Nothing like this! Believe me, continuously variable transmissions are very familiar with the modes of sports driving, forced gear and engine braking. “What programs? - you ask. “They are not here.” Indeed, there are no fixed gears, but they exist virtually, so to speak, programmatically. Hundreds of the best Toyota and Aisin engineers have spent decades perfecting their continuously variable unit. And, before sending CVT cars for export, they thoroughly tested them on the domestic market, collecting a lot of information on the intricacies of settings and teaching them how to significantly save fuel. But for a European client who is accustomed to mechanics, be sure to provide manual shifting on any transmission. Well what can I say? The client is always right, and if he wants to manage everything, then let him manage.

This feature is implemented in the Sport Sequential Shiftmatic CVT. Once you switch the selector to M mode, you will be able to use the lever to change seven ranges of transmission operation, but the electronics will still prevent you from breaking the box. As soon as it turns out that your desires are contrary to the capabilities of the power unit and the engaged downshift can lead to an increase in speed, a double buzzer will sound. Forced limitation is especially useful on long descents, when you need to save on the brakes. The driver can select seven different deceleration rates, but if you're too lazy to operate manually, there's also automatic CVT control when driving on hilly terrain, all for comfort and a smooth ride. By the way, even when accelerating in normal mode, the RAV4 variator skillfully simulates gear changes without irritating the user with a monotonous howl during acceleration. Another system saves fuel at traffic lights and prevents you from rolling back on an uphill slope. If the transmission determines that you have stopped and the selector remains in position D, the engine will reduce the dose of injected fuel during the stop. The speed will drop, which will reduce the load on both the engine and the gearbox. But this will only happen if you stop on a flat surface - on a slope the idle speed will remain unchanged, which will give additional small traction on the wheels and will not allow you to roll back.

The talk of the town is transmission overheating

. Many people are afraid of it, but in reality you need to try very hard to really noticeably heat the oil in the box. Although, of course, if you really want to, the variator can be overheated. To prevent this from happening, the built-in protection will notify the driver in advance with a message on the dashboard.

By the way, about oil. More precisely, a special fluid for CVT. CVTs are really very demanding on its quality. The reason is clear - the belt transmits force to the wheels using friction, which means wear of the steel plates is inevitable. Just like in a motor, and in general in any unit with lubrication, it is the oil that accumulates the smallest wear particles and transfers them to the filter, at the same time cooling the steel parts. According to the regulations, it is necessary to monitor the condition of the oil every 40 thousand km, but if you are a fan of active driving or often use the car for towing and off-roading, then it is better to preventively change the oil in the range of 40–60 thousand. But even without this, your variator will last no less than a regular automatic, and given the lack of clutches in it, even longer. And, believe me, this is not a myth!

But there are many myths, and the first, most common one is “a metal belt is unreliable”

. So, the service life of a variator with a push belt is no lower than that of traditionally designed automatic transmissions, and even more so of robotic transmissions. There are practically no real failures due to belt wear, and the vast majority of drivers operating cars with continuously variable transmissions do not even know what type of gearbox they have.

Another myth - “the variator does not allow off-road driving”

. It's hard to say where it came from. Even theoretically, based on the fact that the variator is capable of maintaining any gear ratio and smoothly changing it in any range, it turns out that it is better suited for off-road use than other transmissions. Quickly changing gearbox operating modes from D to R and back is also not a problem. This technique is called swinging, and it is not difficult to perform it on a car with a CVT. The only thing where the variator can really give up is very long slipping at high speeds. For this purpose, by the way, there is a warning about overheating. But, let’s face it, this is far from the standard operating mode for a crossover.

We have already talked about the specific working fluid of the variator, and the requirement to fill only a specially designed composition, as you understand, seems completely justified. After all, “steel on steel” contact requires a special lubricant, which at a certain moment can lose its properties, turning almost into glue or almost into ordinary oil.

Well, the last prejudice is trying to instill in us the idea that the variator is completely unrepairable

. This is also not true. In fact, if you happen to really burn the belt and pulleys, it's all easy to replace. Moreover, the complexity of the work is no higher than during a standard repair of a conventional machine. So don’t believe any myths or garage stories, but, as they say, trust the professionals.

Text Evgeny Khapov

Is the CVT reliable on Toyota Corolla?

The reliability of the variator directly depends on the management style and the frequency of maintenance. There have been cases where the box has withstood a mileage of more than 200 thousand km without replacing parts. When purchasing a new car, the transmission is covered by a manufacturer's warranty, which is obliged to correct all damage caused by defective parts. When choosing a used Corolla with a CVT, you should diagnose the transmission and evaluate the condition of the unit. On the spare parts market there are units removed from broken cars, so there will be no problems with repairs.

How long does a CVT drive on a Toyota Corolla last?

The service life of the unit and the service life of the Toyota Corolla CVT are also determined by the nature of its use. Despite the enormous reliability potential, if the system is handled incorrectly, the service life can be reduced to 100 thousand kilometers. According to the manufacturer, the declared service life of the box is 200-230 thousand kilometers with appropriate care and timely maintenance. However, many experienced car enthusiasts can easily overcome this milestone. Cases are known for certain when the unit's mileage covered a distance of 300-350 thousand kilometers without major overhauls.

In general, in comparison with other automatic transmissions, this unit is considered very reliable and durable, even if operating requirements are violated.

Owner reviews

Owners of Toyota Corolla with a CVT leave different reviews about the service life and characteristics of the transmission. The opinion is influenced by the mode of operation, total mileage and frequency of maintenance of the box. If the owner likes sharp acceleration and driving at high speed, then the CVT will fail after 20-30 thousand km. Calm drivers can use their car for years without complaining about CVT breakdowns.

Positive

Oleg, 28 years old, Tver

I drive a Corolla with a 1.6-liter engine, released in 2021. The car has covered 82 thousand km, 70% of the mileage was on the highway. Speed up to 140 km/h, I rarely use sport mode. There were no jerks during operation; the control unit firmware was factory installed.

Nikolay, 55 years old, Omsk

I am the owner of a Corolla with a CVT and a 1.8 liter engine. I changed the oil in the gearbox for the first time when the mileage was 110 thousand km, the service was carried out at the dealer at a special stand. The drained liquid was clear and did not contain chips. I drive calmly, the speed on the highway is about 100-110 km/h. I warm up the box for 1-2 minutes in summer and 5-7 minutes in cold weather.

Negative

Mikhail, 31 years old, St. Petersburg

I bought a car with a 1.6-liter engine in 2015. At 50 thousand km, a whistling sound from the variator appeared; when switching modes, the tone of the noise changed. The dealer ran diagnostics and found no faults. I sold the car with 80 thousand km mileage, informing the buyer about the potential problem.

Maintenance of Toyota Corolla CVT

Maintenance of the unit is carried out in accordance with the recommendations of the manufacturer and experienced owners. The CVT operating book contains recommendations for both preventive inspections and transmission fluid replacement intervals. Also, once every 20-30 thousand kilometers, it is necessary to visually inspect the gearbox, crankcase and system housing for the presence of drips and leaks, which may appear as a result of depressurization of oil seals, microcracks as a result of natural wear or for other reasons.

The visual inspection procedure is carried out by lifting the car on a lift and removing the crankcase protection, if any. If leaks or mechanical damage are detected, additional transmission fluid is added and the crankcase housing is dismantled for an internal inspection. Routine internal inspection is also carried out as a result of an oil change when there is a need to open the housing.