Category: KAMAZ

- Description of the boxes used

- Principle of operation

- Start

- Gear shift diagram

- Box KamAZ 15

- Box KamAZ 16 and ZF

- Management Tips

- Hill climb control

- Descent Control

- Driving on an icy road

- Is it possible to drive a KamAZ without urea?

At first glance, driving a KamAZ is similar to driving a car. The principle of operation is the same as on classic transport, however, some features cause complications for the uninitiated user.

You get a complete understanding of how to properly drive and drive a KamAZ by understanding the specifics of gear shifting. The fact is that for every heavy car you need to find an approach to the issue of manipulating the gearbox, and KamAZ is no exception. In order to achieve the required speed limit when transporting cargo, the KamAZ transmission is often operated in a low gear. The acquired skills, knowledge and experience in working with the gearbox are the key to the success of further operation of the vehicle.

KamAZ-6520, dump truck:

Description of the boxes used

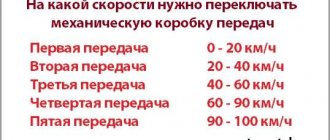

The gear shift pattern directly depends on the type of transmission installed on the KamAZ vehicle. Most of the machines used use a box with five forward speeds and one reverse; this is a model with index 14. The mechanism is relevant if there is no need to tow a trailer, or the cargo being transported weighs less than 10 tons.

KamAZ-14 gearbox:

Equipment used for transporting large loads, or participating in road trains, uses a transmission marked 15. In this case, you need to know how to drive a KamAZ dump truck, since the gearbox includes a gearbox. This is the same 14 transmission with five forward and one reverse gears. The divider, if necessary, includes lower speed ranges, as a result, the car has twice as many gears.

KamAZ-ZF gearbox:

The gearbox used is index 16, with eight mechanical speeds. A four-stage gearbox and a low gear are provided. ZF gearboxes are also installed, which are equipped with nine gears and an auxiliary reduction stage.

Regardless of the transmission model, the gearbox is of a mechanical type, control is carried out using the clutch pedal. The switching takes place in stages, taking into account the lower and higher modes. The lever on the rocker handle is responsible for switching modes. When creating, it was taken into account that KamAZ is a heavy vehicle, which when loaded requires a reduction in force. Conversely, if you drive with an empty body, this will not lead to overheating and fuel consumption.

Principle of operation

KamAZ vehicles are usually equipped with manual transmissions. The mechanism is controlled in the classic way, by pressing the clutch pedal and moving the rocker to the required position. A special feature of the transmission is low (H) and high (B) operating modes. This ability minimizes the load on the power unit. It is typical that for this purpose a divider is used, which acts as a gearbox that increases transmission ratios. On some cars, when changing from a higher gear to a lower gear, they do not use the rocker. For these purposes, a special switch and clutch pedal are used. The gear switches automatically, the upper position of the lever is typical for a loaded vehicle, the lower position is used when moving an empty vehicle. The features of driving a car are indicated in the instructions for the gearbox that comes with the product. You can also read about How to adjust the clutch on a KamAZ.

Oil level control

Filling volumes are indicated on the nameplate located on the side of the gearbox. Before filling the container, the waste is drained and transmission fluid is poured through the hole. Checking the oil level is carried out as follows: the level is considered correct when it reaches the lower edge of the control hole or when material flows out of it.

How to check the oil level

The oil level in the box is checked as follows. Unscrew the crankcase plug. When checking, you must install the crankcase indicator into the hole until it stops. The oil from the crankcase of a ten-speed manual transmission is drained through 3 holes. Of these, 2 holes are located in the lower part of the gearbox housing, and the third is located in the divider. The five-speed gearbox housing is drained through 2 holes.

Change of oil

To change the oil, you need to wash the gearbox housing with engine oil. Clean the magnetic plugs from metal particles and fill in oil to the top line of the indicator. The oil level is measured after 5 minutes. When the car is moving, the gearbox should operate without hesitation, speeds should be switched freely and locked firmly. Loud noise may indicate worn shaft bearings, insufficient oil level, or poor quality lubricant in the crankcase.

Which oil to choose

The ZF 9S1310 TO and ZF 16S151 boxes contain oil that complies with the list of lubricants TE-ML 02. It can be found at all service points of the company. The manufacturer recommends using ZF-Ecofluid M transmission oil.

The oil volume in the ZF 9 box is 9 liters, on KamAZ ZF 16 for standard installation - 11 liters, when replacing - 8 liters.

Start

To know how to properly drive a KamAZ dump truck, you need to understand the gear shift pattern. As in the standard version, manipulations take place using the clutch pedal.

Switching stages:

- 1st gear, high mode (B);

- 2nd gear, high mode (B);

- 3rd gear, high mode (B);

- Transition to the 2nd low (H) stage and switch to 4th gear;

- Transition to the primary stage (B), the gear remains in 4th;

- Shift to a lower gear (H), engage 5th gear;

- Return to the higher gear (B), stay in 5th gear.

KamAZ:

The main feature of starting to move on a KamAZ is a smooth start and acceleration using lower gears. In the case when the dump truck is heavily loaded, or the traffic is in difficult conditions, it is advisable to switch the first 4 gears in low mode (H), then switch to 4th high gear, then lower 5th gear (H) and then to 5th -th increased (B). Manipulations are carried out when the required crankshaft speed is reached. Directly at the start in 1st gear, the shaft speed reaches 7000 min-1, the transition to 2nd gear is made when the speed reaches 3000 min-1. The correctly selected mode saves fuel and minimally wears out the power plant.

Instructions

Now we suggest you find out how to start and in what sequence to correctly engage the gears on a KAMAZ gearbox. There are certain features in this process, and the procedure for changing gears differs from passenger cars.

Start of movement

You need to know how to change gears on a KamAZ. The KamAZ truck should start moving at a reduced speed. Please note that when driving away, the gear shift is carried out with the clutch disengaged. In KAMAZ gearboxes, the switching scheme is carried out in several stages, this is due to the peculiarities of increasing and decreasing speeds.

How to turn on the speeds on KamAZ:

- The truck can drive quickly on different types of roads, but at the first stage, in accordance with the diagram, it is recommended to start driving in gear 1B.

- After this, 2V transmission is switched on.

- At the final stage of starting from a standstill, speed 3B is switched on.

In accordance with this traffic pattern, the vehicle starts at a reduced speed. That is, the shift lever on the box does not need to be touched until fourth gear. To start moving, you need to increase the crankshaft speed to about seven thousand revolutions

Switching speeds

Now we’ll tell you how the gearbox on a KamAZ is switched when the car starts moving. When the car accelerates, the gear shift order on KamAZ is as follows - 4N-4V-5N. To activate the second speed, the crankshaft speed must increase to three thousand revolutions according to the tachometer. Please note that the operation of the crankshaft plays a major role. By changing gears correctly, you can achieve savings in fuel consumption. In this case, the most economical operation of the motor without downtime will be achieved.

Reverse

As for reverse, according to the diagram, to activate it, you need to set the switch to the lower left position. Activating reverse gear is not allowed while driving. To engage reverse, stop the vehicle completely and then perform the maneuver.

Box KamAZ 15

This transmission is installed on KamAZ-55111, KamAZ-43118 and other models. To accelerate the car to the required speed, the following scheme is used: 1B-2B-3B-4N-4B-5N-5B. This scheme allows the box to operate normally, provided that the rules for operating the mechanism are followed:

- Using a special switch lever, change the operating mode of the box from high to low and vice versa;

- Press the clutch pedal;

- We change gears in order using the rocker.

KamAZ switching diagram:

How to start a movement

You need to start driving this car at a reduced speed. Therefore, there is no need to touch the divider lever. A prerequisite is to depress the clutch pedal. The order of switching high and low gears on a KamAZ may vary, depending on environmental conditions and the weight of the truck itself.

The classic scheme looks like this:

- the clutch is depressed and first gear (1B) is engaged;

- then you need to switch to 2B gear;

- the next stage is turning on 3V gear. In this case, the crankshaft rotation speed should already be at least seven thousand revolutions per minute.

The car begins to move and gradually accelerates. Now you can move the divider lever to the upper position. When the tachometer needle shows 3000 rpm, fourth gear 4H is engaged. Next, we lower the speed again and turn on 4V. And at the final stage you need to switch to 5H. If everything was done correctly, KamAZ will already be moving confidently and quickly.

Getting off the road in a KamAZ truck, provided you follow the recommendations described above, is not so difficult. Constant practice will allow you to develop muscle memory, so that the necessary gears will be switched on quickly and without delay.

It is important to understand that fuel consumption also depends on the level of optimization of the crankshaft. Gears on KamAZ switch quickly, without unnecessary delays and exactly at the time when it is required. Failure to comply with basic rules and recommendations leads not only to a significant increase in the amount of fuel used, but also to wear and tear of mechanical parts and transmission components.

Box KamAZ 16 and ZF

This type of transmission is used on KamAZ-65115 vehicles, as well as all-wheel drive KamAZ-43150 KamAZ-4310 and others. The peculiarity of the mechanism is the automatic switching of high and low modes. This means that when shifting from gear 4 to gear 5, the upshift mode is automatically activated. Conversely, shifting from gear 5 to gear 4 automatically activates the reduced mode. The switch is indicated by an indicator on the instrument panel.

Switching diagram ZF 9S109:

Some models of ZF gearboxes, for example, 9S109, with auxiliary gear “C”. The mode is designed for movement and maneuver in difficult conditions (snow, ice, mud).

Specifications

ZF 9S1310 Ecomid

- Number of gears - 9

- Torque – 1300 Nm.

- Gear ratio: 1st – 9.48;

- 2nd – 6.58;

- 3rd – 4.68;

- 4th – 3.48;

- 5th – 2.62;

- 6th – 1.89;

- 7th – 1.35;

- 8th – 1.00;

- 9th – 0.75;

- reverse – 8.97

- New – 380 thousand rubles.

ZF 16S1650 (16S1820) Ecosplit

- Number of gears - 16

- Torque – 1850 Nm.

- Gear ratio: 1st – 16.47;

- 2nd – 13.79;

- 3rd – 11.32;

- 4th – 9.48;

- 5th – 7.79;

- 6th – 6.52;

- 7th – 5.48;

- 8th – 4.58;

- 9th – 3.59;

- 10th – 3.01;

- 11th – 2.47;

- 12th – 2.07;

- 13th – 1.70;

- 14th – 1.42;

- 15th – 1.20;

- 16th – 1.0;

- reverse 1 – 15.42;

- reverse 2 – 12.91;

Hill climb control

Driving up a slope is accompanied by the gearbox switching to a lower mode (H). This makes the transmission work harder and overcome obstacles more easily.

- When lifting heavy equipment, shifting from first to second gear is carried out using the double clutch method;

- To ensure the operation of the power plant, depress the gas pedal to prevent an interruption in the fuel supply;

- The crankshaft speed readings do not fall below 2000 min-1, otherwise the power plant will overheat and stop working.

Descent Control

When driving a KamAZ vehicle on a descent, please note that under no circumstances should you turn off the engine. Drivers use this method to save fuel. However, acting in this way, the amplifier stops working, which blocks the steering. This phenomenon will lead to an emergency situation, the consequences of which are unpredictable.

Problems also arise with brakes, since heavy equipment is equipped with an auxiliary system. Activating the latter eliminates the ability to use the clutch pedal and switch from one mode to another.

Driving on an icy road

A special feature of driving on icy routes is the use of chains on the wheels of the car. The measures will increase the coefficient of road adhesion.

Take into account:

- Keep your distance, leave room for maneuver;

- When braking, use the brake assist system;

- Remember, emergency braking on a KamAZ truck leads to blocking of the trailer wheels.

It is not advisable to use emergency braking, as this will lead to skidding and uncontrolled movement. When skidding, keep your foot on the clutch pedal and turn the steering wheel in the direction of the skid, this will level the car.

Rules for shifting gearboxes in different conditions

Knowing how to start and how to continue moving is not enough for the correct operation of the KAMAZ transmission. To avoid problems with the unit when using the gearbox, you must follow the rules. Errors made during operation can lead to serious malfunctions.

On the rise

How to change gears on a KamAZ when driving uphill

Driving a domestic truck when lifting must be done at increased speed. To switch from first to second speed, the driver needs to depress the clutch twice. Consider the fact that you must simultaneously press the gas pedal and the fuel pedal. These actions are important as they help stabilize the overall performance of the crankshaft. To avoid problems with the operation of the unit, you do not need to reduce the engine speed to less than two thousand when climbing. This will cause the car engine to turn off. Also, such driving increases the operating temperature of the power unit, and this can cause its breakdown.

When driving a car using this principle, you can achieve maximum directional stability. Thanks to the principle of dividing the transmission circuit into two modes, easier engine operation is achieved. Moreover, regardless of whether the car is loaded or not.

On the descent

If you are driving downhill, you do not need to turn off the engine. When the engine is turned off, the steering wheel will lock. And this will lead to an emergency on the road. When driving downhill, do not turn off the auxiliary braking, and also depress the clutch pedal all the way. Newer versions of trucks use improved transmissions, which has allowed engineers to reduce the load on the main gearbox parts. Therefore, when driving in critical conditions and on descents, the car’s engine will not wear out.

KamAZ vehicles use a double-boost braking system. That is, in addition to braking by the power unit, there is an additional engine stopping system. If you are driving downhill with active auxiliary braking, then you cannot disengage the clutch and change gears.

Schemes of the main and transfer cases on KamAZ

Icy areas

Driving a truck on icy areas should be done with the greatest reserve of speed and travel. When braking, use the active brake assist system. If emergency braking occurs, the driver must stop the trailer wheels. If you do not take this point into account, you will end up in a skid. It is recommended to slow down with the power unit only in exceptional cases. Because this leads to accelerated engine wear, but the braking distance is significantly reduced. When braking, do not allow the wheels to slip. To avoid this, you need to turn off the reduced speed in time, this will lead to a drop in crankshaft speed.

Skid

When skidding, follow the main rule - do not squeeze the clutch, otherwise this will worsen the situation. During the production of cars, engineers introduced a scheme due to which the car can drive with the greatest power reserve. Thanks to this, you can achieve course stabilization while driving on any road. If a skid occurs while driving, the steering wheel of the car must be turned in its direction. That is, if the car skids to the left, then the steering wheel also turns to the left.

If the truck begins to slip, then you need to stop moving as quickly as possible and immediately disable the differential axle. You can see the switch to turn it off on the dashboard. When the differential axle is disengaged, a corresponding indicator will appear on the instrument panel. After this, the start of movement is carried out at increased speed, from second gear. When you drive through a hard-to-reach section of the road, do not forget to engage the differential (video shot and published by Vladimir Nikonov).

Is it possible to drive a KamAZ without urea?

Trucks that comply with Euro 4-6 standards use a method to neutralize the impact of exhaust gases on nature. To do this, urea is poured into a special tank, which is subsequently injected into the exhaust system.

In our country, the use of such material borders on difficulties:

- Low quality urea;

- Freezing of the product at a temperature of -11°C;

- Smell of ammonia from the exhaust, burns upon contact with skin;

- Lots of fakes, price.

KamAZ, fluid for the SCR system (urea):

It is not advisable to constantly operate a car without urea, as this will lead to failure of the pump pumping the material. You can disable the neutralization system at the software level, or by contacting an electrician, who will make hydrolysis in the catalyst impossible.